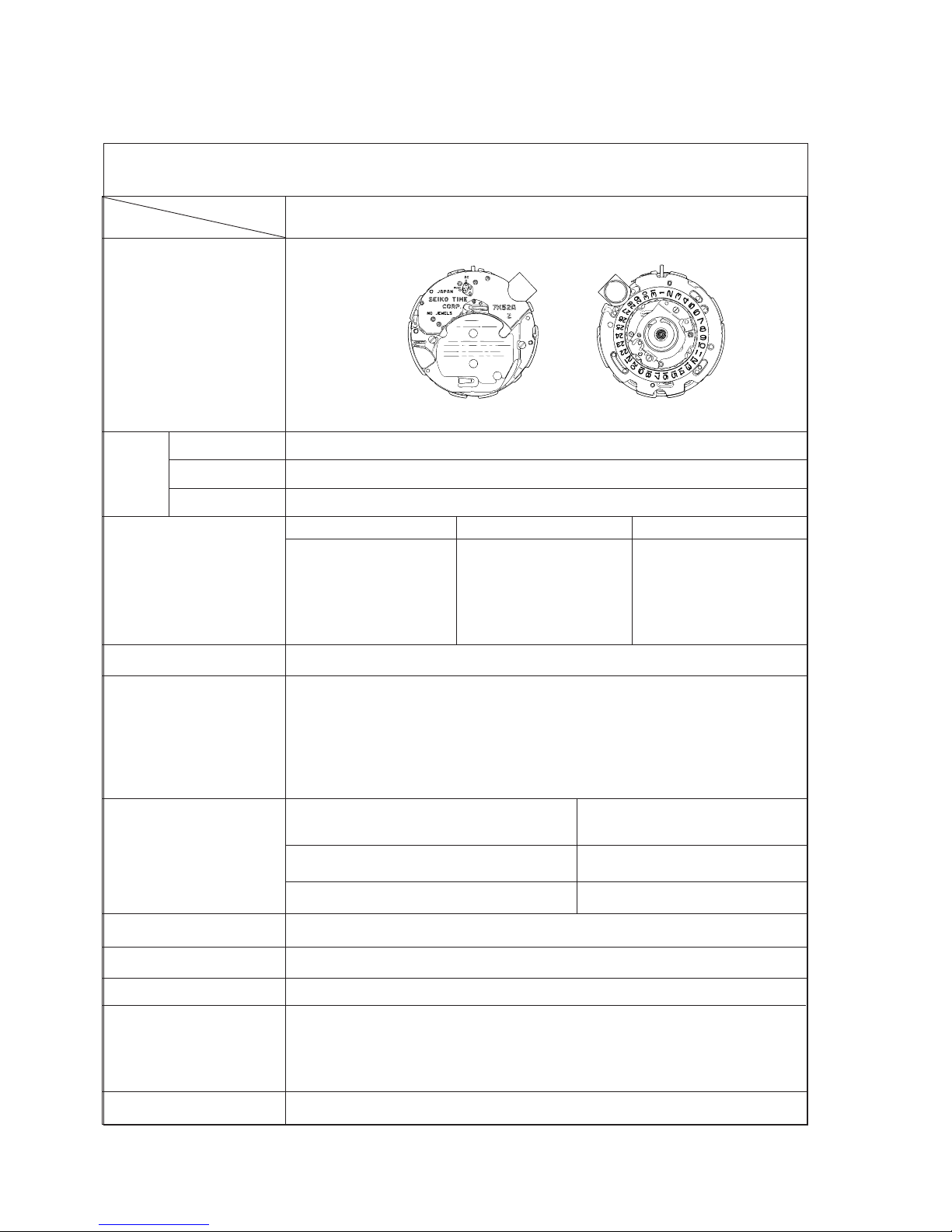

Cal. 7K52A

10

TECHNICAL GUIDE

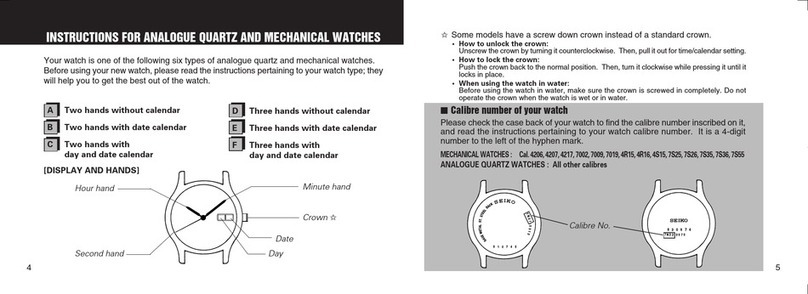

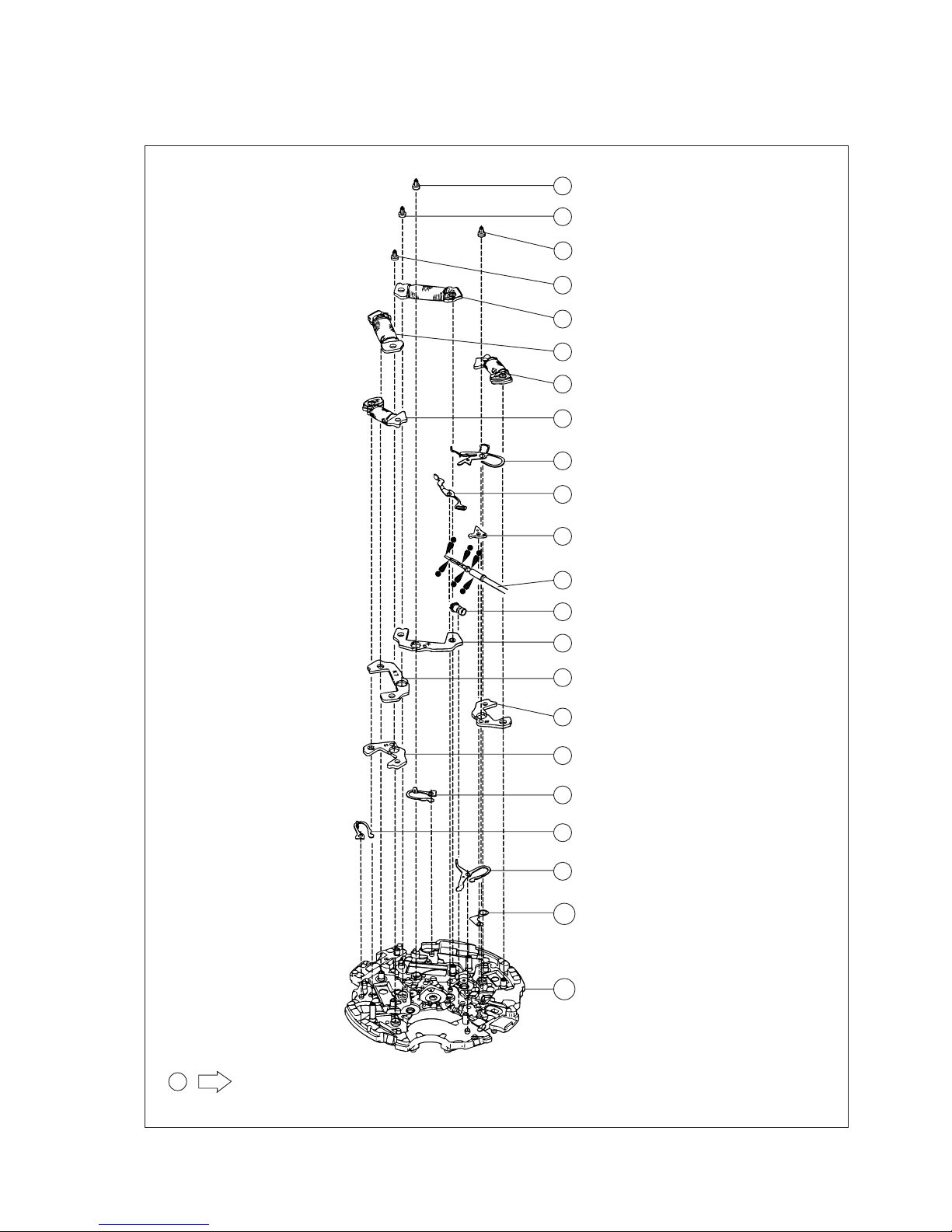

III. REMARKS ON DISASSEMBLING AND REASSEMBLING

The switch lead terminal is

slipped into the gap under the

auto switch terminal.

<Improper contact>

<Proper contact>

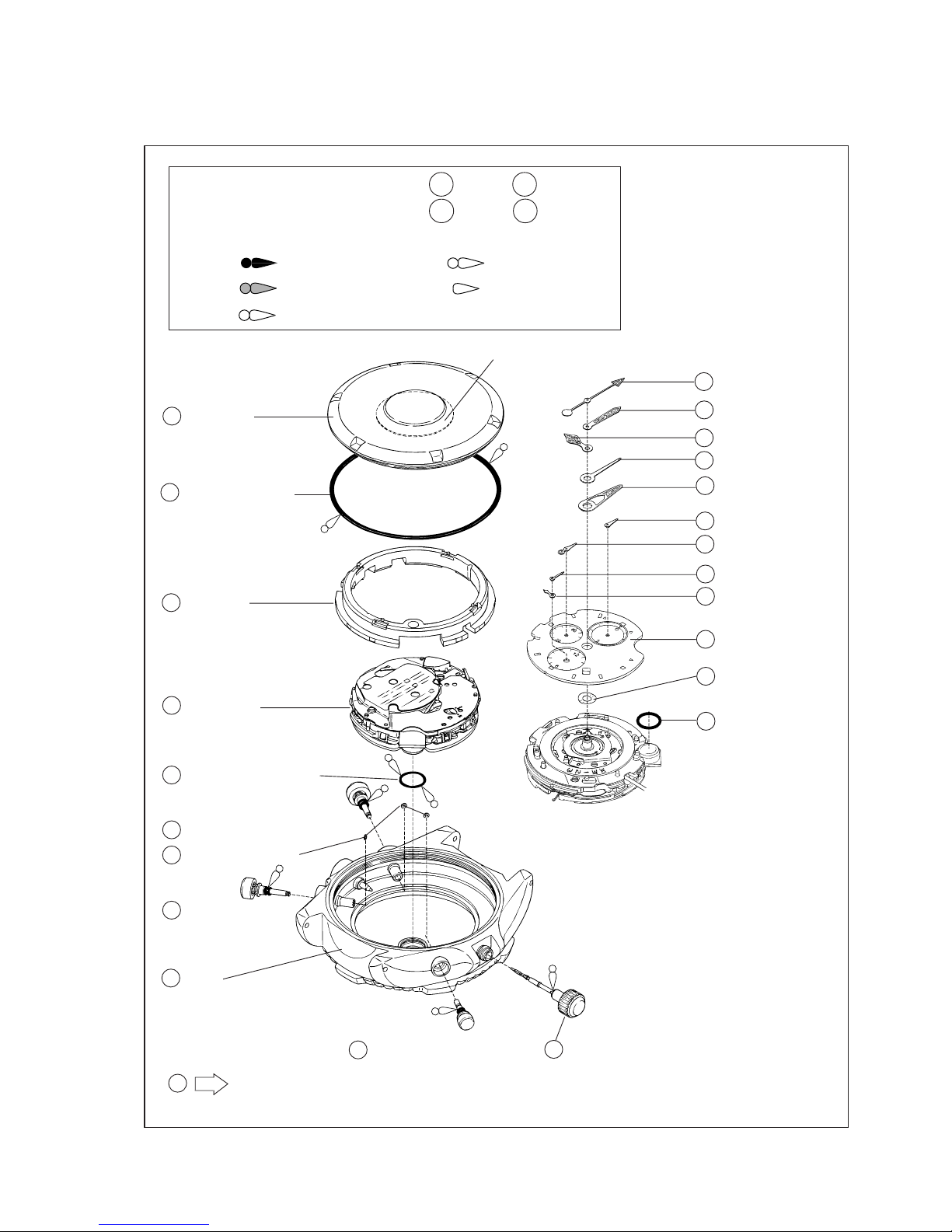

5 Movement

When installing the movement into the case, check that the switch lead terminal (A) securely makes contact

with the auto switch terminal of the case.

Note :

Be sure to observe the following to prevent any difference of indication between the depth and

maximum depth hands.

• After pressing the button at the 2 o’clock side in step "4" above, be careful not to give the watch any

vibration or impact until you finish installing the maximum depth hand.

• Push in the hands straight from above, taking care not to turn them.

*After installing the hands, recall the log data to check that :

• there is no difference of indication between the depth and the maximum depth hands.

• when the depth hand returns to indicate the average depth, the maximum depth hand stays where it

was advanced by the depth hand.

Switch lead terminal (A) Auto switch terminal

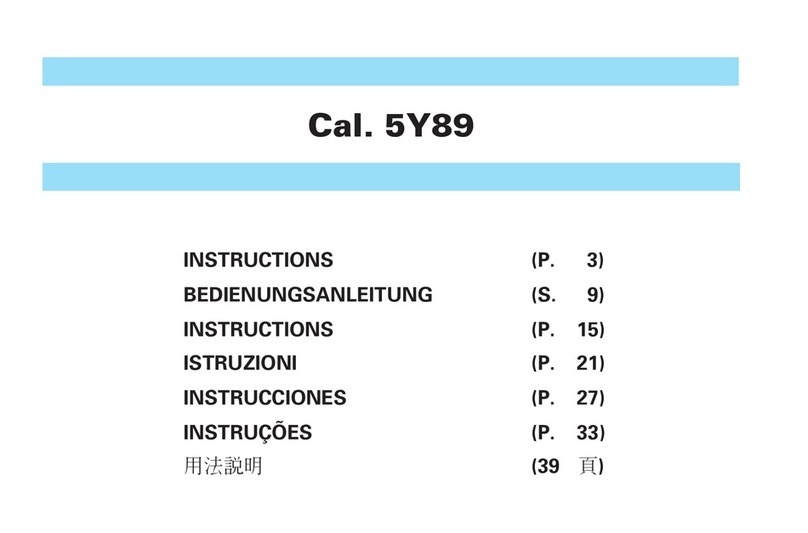

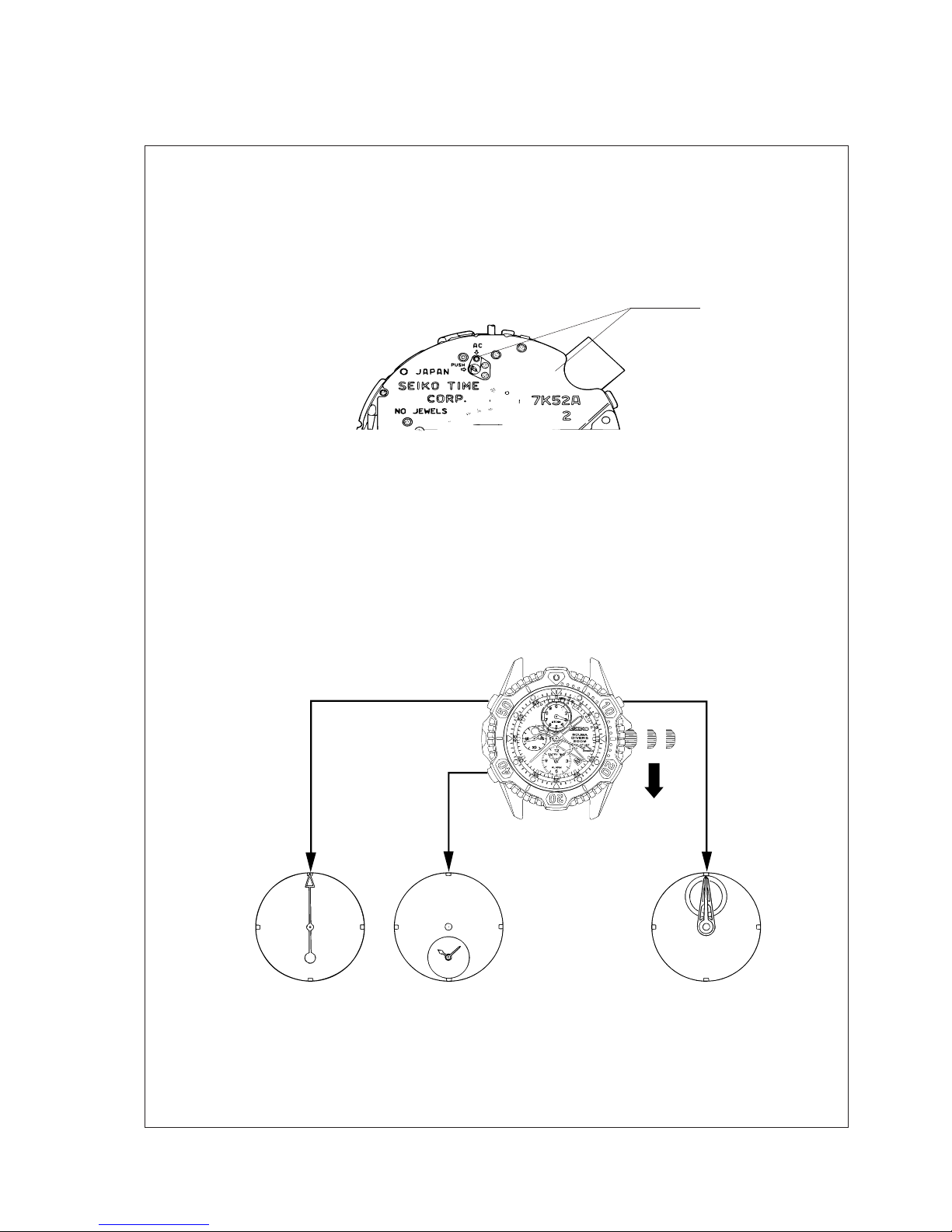

15 Maximum depth hand

17 1/10 m depth hand

16 Depth hand

10

1/10 m depth hand

Depth hand

Maximum depth

hand

• Remarks on installing

• When installing the hands for diving measurement, check

that they accurately point to the diving measurement

scales on the dial.

• The depth hand moves correspondingly with the 1/10 m

depth hand, and the maximum depth hand is advanced by

the depth hand. To install them, therefore, be sure to

follow the procedure below.

1) Reset the circuit.

2) Pull out the crown to the second click and wait for more

than 40 seconds until all the wheels on the train wheel

bridge stop moving.

3) Reset the 1/10 m depth and depth hands to “0” posi-

tion as shown in the illustration at upper right.

4) After pressing the button at the 2 o’clock side more

than 15 times, put the maximum depth hand exactly

onto the depth hand as shown in the illustration at right.