Seintek S2401 User manual

SERVICE MANUAL

for

SCOPE METER

S2480_E040404_R01

Programmable

Handy Scope Series

i

LIMITED WARRANTY & LIMITATION OF LIABILITY

Each Seintek product is warranted to be free from defects in material

and workmanship under normal use and service. The warranty period

is one year and begins on the date of shipment. Parts, product repairs

and services are warranted for 90 days. This warranty extends only to

the original buyer or end-user customer of a Seintek authorized

reseller, and does not apply disposable batteries or to any product

which, in Seintek’s opinion, has been misused, altered, neglected or

damaged by accident or abnormal conditions of operation or handling.

Seintek warrants that software will operate substantially in accordance

with its functional specifications for 90 days and that it has been

properly recorded on non-defective media. Seintek does not warrant

that software will be error free or operate without interruption.

ii

Contents

1. Introduction and Specifications............................................. 1-1

1.1. Main Features ............................................................... 1-1

1.2. Unpacking the Test Tool Kit ........................................... 1-2

1.3. Specification .................................................................. 1-3

1.3.1. General Specifications ......................................... 1-3

1.3.2. Technical Specification......................................... 1-4

2. General Maintenance .............................................................. 2-7

2.1. Introduction.................................................................... 2-7

2.2. Warranty Repairs and Shipping Information ................. 2-7

2.3. Static Safe Handling...................................................... 2-7

2.4. Cleaning ........................................................................ 2-7

2.5. Disassembly Procedures .............................................. 2-8

2.5.1. Remove the Meter Case.................................... 2-10

2.5.2. Remove Rubber button and Battery Pack ......... 2-10

2.5.3. Separate SUB and Main PCB Assembly ............2-11

2.5.4. Remove LCD Cover............................................2-11

2.6. Assembly Procedures ................................................. 2-12

2.6.1. Layout for LCD Assembly .................................. 2-12

2.6.2. Layout for Scope Assembly ............................... 2-13

3. Performance Testing ............................................................... 3-1

3.1. Introduction.................................................................... 3-1

3.2. Required Test Equipment.............................................. 3-1

3.3. Performance Tests ........................................................ 3-1

3.3.1. Scope center Tests .............................................. 3-1

3.3.2. DCV Tests ............................................................ 3-2

3.3.3. ACV Tests ............................................................ 3-2

3.3.4. OHM Tests ........................................................... 3-3

3.3.5. Frequency Tests................................................... 3-3

3.3.6. AC/DC Coupling Tests ......................................... 3-3

3.3.7. External Tests ...................................................... 3-4

3.3.8. CHB Tests ............................................................ 3-4

3.3.9. Duty Tests ............................................................ 3-4

3.3.10. Pulse Width Tests ................................................ 3-4

3.3.11. RS232 Input and Tests......................................... 3-5

iii

4. Calibration................................................................................ 4-6

4.1. Introduction.................................................................... 4-6

4.2. Preparation before Entering Calibration Mode.............. 4-6

4.2.1. Voltage test .......................................................... 4-6

4.2.2. Setting for RS232C.............................................. 4-6

4.3. Entering Calibration Mode............................................. 4-7

4.4. Calibration Scope Center .............................................. 4-7

4.5. Calibration zero point of DMM function......................... 4-8

4.5.1. DC Volts Calibration............................................. 4-8

4.5.2. AC Volts Calibration............................................. 4-8

4.5.3. Ohms Calibration ................................................. 4-9

4.5.4. Frequency Calibration.......................................... 4-9

4.6. Exiting Calibration Mode ............................................... 4-9

5. List of Replaceable Parts........................................................ 5-1

5.1. Introduction.................................................................... 5-1

5.2. How to Obtain Parts ...................................................... 5-1

5.3. How to Contact Seintek................................................. 5-2

5.4. Newer Instruments ........................................................ 5-2

5.5. Parts .............................................................................. 5-2

6. Schematic Diagrams ............................................................... 6-1

6.1. S2401 & S2800 ............................................................. 6-1

6.1.1. Main PCB Assembly ............................................ 6-1

6.1.2. SUB PCB Assembly............................................. 6-1

6.1.3. Analog.................................................................. 6-1

6.1.4. Digital ................................................................... 6-1

6.1.5. Channel A ............................................................ 6-1

6.1.6. Channel B ............................................................ 6-1

6.2. S2405 & S2505 ............................................................. 6-1

6.2.1. Main PCB Assembly ............................................ 6-1

6.2.2. SUB PCB Assembly............................................. 6-1

6.2.3. Analog.................................................................. 6-1

6.2.4. Digital ................................................................... 6-1

6.2.5. Channel A ............................................................ 6-1

6.2.6. Channel B ............................................................ 6-1

7. Troubleshooting ...................................................................... 7-1

7.1. Introduction.................................................................... 7-1

iv

7.2. Troubleshooting guide................................................... 7-1

7.3. Starting with a Dead meter............................................ 7-2

7.4. Can not install the software........................................... 7-2

7.4.1. Check the H/W and S/W requirement:................. 7-2

7.4.2. Error - Could not copy file…. ............................... 7-2

7.5. The back light is not working......................................... 7-3

7.5.1. Desoldering from EL terminal .............................. 7-3

7.5.2. Remove screw for LCD cover.............................. 7-3

7.5.3. Remove LCD cover.............................................. 7-4

7.5.4. Detail for EL terminal ........................................... 7-4

7.5.5. Insert electric wire between PCB and EL ............ 7-4

7.5.6. Layout for LCD Assembly .................................... 7-5

7.5.7. Install LCD cover.................................................. 7-5

7.5.8. Install screw for LCD cover.................................. 7-6

7.5.9. Soldering of EL terminal....................................... 7-6

7.5.10. Reassembly ......................................................... 7-6

1-1

1. Introduction and Specifications

1.1. Main Features

This Programmable Universal Scope Meter offers enhanced features

that similar type test instruments on the market today don't have.

All the functions are designed to be very convenient to use. You can

quickly get used to working with this METER and the great many

functions integrated inside. This instrument features:

1. RS-232C interface for transferring measurement data and

waveform.

2. Dual Channel and Auto Calibration.

3. Automatic setting for horizontal and vertical division.

4. DC to 5MHz(2405, 2505), 1MHz(2401, 2800) oscilloscope band

width.

5. Built-in auto ranging True-RMS digital MultiMeter

6. Auto ranging

7. Data hold and run mode.

8. Back light display and Low battery indication.

9. Display Type: Super-Twist 132 x 128 pixels.

10.Designed to comply with safety standard for UL3111, CSA C22.2

No.1010-1

1-2

1.2. Unpacking the Test Tool Kit

The following items are included in your test tool kit.

Note

When new, the rechargeable Ni-MH battery pack is not fully charged.

■STANDARD

Description S2401 S2405 S2505 S2800

Scope Meter ●●●●

Ni-MH Battery Pack (installed) ●●●●

Rechargeable Adaptor ●●●●

Test Leads & Alligator Clips (2) ●●●●

Users Manual ●●●●

Rubber Holster ●

Carrying case ●

RS-232 S/W & Cable ●

■OPTION

Description S2401 S2405 S2505 S2800

Rubber Holster ●●●

Carrying case ●●●

RS-232 S/W & Cable ●●●

Inductive Pickup ●

Capacitance Pickup ●

Secondary Adaptor ●

Note:

The accessories may be changed to improve the product quality

without notifying the customers.

1-3

1.3. Specification

1.3.1. General Specifications

1) Operational Temperature:

0°C to +50°C (+32°F to +122°F) at a relative humidity 75% or less

2) Storage Temperature:

-20°C to +60°C with a relative humidity of 75% less

3) Temperature Coefficient:

0.1 x (Specified Accuracy) per °C for temperature <18°C to >28°C

4) Max. Voltage between any Input and Ground: DC or AC 600Vrms

5) Basic DC Accuracy: 0.3%

6) Band width: 5MHz(2405, 2505), 1MHz(2401, 2800)

7) Meter AC Band width: 20kHz

8) Power Supply: Ni-MH Battery 4.8V (1.2V x 4 cell)

9) Battery Life Time:

4 Hours without Backlight on,

3 Hours with Backlight on.

10) Battery Change Time: About 3 Hours

11) Battery Change:

Class-2 transformer,

Input: 120V AC 60Hz or 240V AC 60Hz

Output: 9V DC 1A

12) Display Type: Super-Twist 132 x 128 pixels

13) Equipment Dimensions:

90 mm (width) x 195 mm (depth) x 40 mm (height)

14) Equipment Weight: About 460g

1-4

1.3.2. Technical Specification

1) Oscilloscope Function

(1) Horizontal

Sample Rate 25 MS/s (Dual CH mode)

50 MS/s (Single CH mode)

Record Length 512 single shot, 256 in all modes

Sample / Division 25

Modes Single shot, Roll, Normal

Accuracy 0.01%

Sweep Rate 1uS to 5S in 1, 2, 5 sequence

(2) Vertical

Bandwidth 1MHz

Resolution 8 Bit

Channels Dual

Coupling AC, DC

Input impedance 1 MΩ

Accuracy 3%

Max. Input Volts DC or AC 600Vrms

2401, 2800 0.5V to 500V in 1, 2, 5 sequence

Volt / Division 2405, 2505 50mV to 500V in 1, 2, 5 sequence

(3) Triggering

Type CHA, CHB, External

Coupling AC, DC

Slope Rising (↑) or Falling (↓) edge

Internal Trigger Sensitivity 2 / 20 Division

(4) Waveform Memory

2800 8 Shots

Waveform Memory Others 16 Shots

REF Wave From Memory 45 Shots (Only S2800)

1-5

2) Digital MultiMeter Function

DC V

Range Resolution Accuracy Impedance

5V 0.001V

50V 0.01V ±(0.3%+3)

500V 0.1V

1000V 1V ±(0.5%+5)

1 MΩ

AC V

Accuracy

Range Resolution 50~450Hz 0.45k~5kHz 5k~20kHz Impedance

3V 0.001V

30V 0.01V

300V 0.1V

±(2.5%+5)

750V 1V

±(0.75%+5) ±(2%+5)

N/A

1 MΩ

OHM

Range Resolution Accuracy Over Load Protection

5 kΩ0.001 kΩ

50 kΩ0.01 kΩ

500 kΩ0.1 kΩ

±(0.5%+5)

5 MΩ0.001 MΩ±(0.75%+10)

600V DC or

AC rms

Continuity Buzzer

Test Voltage Threshold Over Load Protection

1.7V 100 digits 600V DC or AC rms

1-6

Frequency

Range Resolution Accuracy Overload protection

100 Hz 0.01 Hz

1 kHz 0.0001 kHz

10 kHz 0.001kHz

100 kHz 0.01kHz

1 MHz 0.0001MHz

10 MHz (2405) 0.001MHz

±(0.05%+5) 600V DC

or AC rms

The guaranteed range is below 5 MHz.

RPM (S2401, S2405, S2505)

Range Resolution Accuracy

240 - 60,000 1 RPM ±(0.05%+5)

Pulse Width (S2401, S2405, S2505)

Range

2uS-500mS (Pulse Width > 2uS)

% Duty (S2401, S2405, S2505)

Range

25% - 75%

Only S2800

Function Range Resolution Accuracy

RPM 120 - 12,000 1RPM ± 2RPM

% Duty 1% - 98%

Dwell 3.6° - 352.8°

Pulse Width 2 uS - 450 mS (Pulse Width > 2 uS)

Frequency 2Hz - 1MHz

2-7

2. General Maintenance

2.1. Introduction

This provides handling, cleaning, battery replacement, disassembly,

and assembly instructions.

2.2. Warranty Repairs and Shipping Information

If your meter is still under warranty, see the warranty information at the

front of this manual for instructions on returning the unit.

2.3. Static Safe Handling

Observe the following rules for handling static-sensitive devices:

1. Handle all static-sensitive components at a static-safe work area.

Use grounded static control table mats on all repair benches, and

always wear a grounded wrist strap. Handle boards by their

nonconductive edges only. Store plastic, vinyl, and Styrofoam

objects outside the work area.

2. Store and transport all static-sensitive components and assemblies

in static shielding bags or containers.

Static shielding bags and containers protect components and

assemblies from direct static discharge and external static fields.

Store components in their original packages until they are ready for

use.

2.4. Cleaning

Warning

To avoid electrical shock or damage to the meter, never allow

water inside the case. To avoid damaging the meter’s housing,

never apply solvents to the meter.

If the meter requires cleaning, wipe it down with a cloth that is lightly

dampened with water or a mild detergent. Do not use aromatic

hydrocarbons, chlorinated solvents, or methanol-based fluids when

wiping the meter.

2-8

2.5. Disassembly Procedures

The following paragraphs describe disassembly of the Meter in

sequence (from the fully assembled meter to the Sub-assembly.) Start

and end your disassembly at the appropriate heading levels.

64

9

10

BATTERY

8

7

5

PC Cover

S2 EL

PCB

LCD

BATTERY

2

3

S1

S3

1

10

S4

Disassembly

2-9

No Description Q’ty

1 Top Case 1Pcs

2 Rubber Button 1Pcs

3 LCD Cover 1Pcs

4 LCD 1Pcs

5 EL 1Pcs

6 SUB PCB Assembly 1 Set

7 Main PCB Assembly 1 Set

8 Battery Pack 1Pcs

9 Bottom Case 1Pcs

10 Stand Top & Bottom 1Pcs

S1 Screw for Top and Bottom case 3Pcs

S2 Screw for Sub and Main PCB 4Pcs and 4Pcs

S3 Screw for LCD Cover 5Pcs

S4 Screw for Stand 1Pcs

2-10

2.5.1. Remove the Meter Case

S1

3 PCS

Use the following procedure

to remove the meter case.

①Power OFF

Make sure the meter is

turned off and unplugged

from the power Adaptor.

②Remove Screw:

Remove the three screw

from the bottom of the

case. (3 Pcs)

③Remove the PCB Ass’y:

Now remove the PCB

Assembly by releasing the

four snap retainers

securing it to the case.

2.5.2. Remove Rubber button and Battery Pack

Rotate the PCB Assembly

180 degrees.

①Remove Rubber Button:

②Remove Battery Pack:

Remove the battery plug

from the connector

2-11

2.5.3. Separate SUB and Main PCB Assembly

①Remove Screw:

Remove the four screw

from the Sub PCB

assembly. (4 Pcs)

②Separate PCB:

The SUB PCB Assembly

can now be lifted away

from the Main PCB

Assembly.

2.5.4. Remove LCD Cover

①Remove screw:

Remove the five screw for

LCD cover. (5 Pcs)

②Rotate the Sub PCB:

Rotate the SUB PCB

Assembly 180 degrees.

③Remove LCD Cover:

The LCD Cover can now

be lifted away from the

SUB PCB Assembly.

2-12

2.6. Assembly Procedures

Generally, assembly procedures follow a reverse sequence of

disassembly procedures. As some differences do apply, assembly is

described separately in the following paragraphs. Begin assembly at

the appropriate level, as defined by the heading. References are

made to items in below Figure for assembly details of standard meter

parts.

2.6.1. Layout for LCD Assembly

PCB

EL

LCD

PC Cover

①LCD Cover:

②LCD:

③EL:

④SUB PCB

We recommend that do not remove LCD from SUB PCB.

2-13

2.6.2. Layout for Scope Assembly

64

9

10

BATTERY

8

7

5

PC Cover

S2 EL

PCB

LCD

BATTERY

2

3

S1

S3

1

10

S4

Assembly

3-1

3. Performance Testing

3.1. Introduction

This chapter of the Service Manual provides performance tests that

can be used at any time to verify the meter operation within published

specifications. A complete calibration procedure is also included. The

performance test and, if necessary, the calibration procedure can be

performed periodically and after service or repair.

3.2. Required Test Equipment

The following equipment, or a suitable equivalent, is required for

performance testing and calibration:

Description Minimum requirements Examples

Multifunction Calibrator Refer to 4808 specification 4808

Multifunction Calibrator Refer to 9100 specification 9100

Arbitrary function generator Refer to HC9302

specification HC930

Function generator Refer to G5100 specification G5100

Power supply Refer to P6100 specification P6100

Resistance calibrator

Tool for a short circuit test

To test current and voltage

Personal Computer IBM computer

3.3. Performance Tests

The following performance tests are provided to ensure that the meter

is in proper operating condition.

3.3.1. Scope center Tests

1. Turn off the equipment and turn on the equipment.

2. Move to DCV (Press FUNC, F1 and then select DCV; then press

F3, F4, F4).

3. Press DIV button; then press the F1, Æ, F2, Æ, F3 and Æbutton

to change of A/Div,. B/Div and H/Div to AUTO mode.

This manual suits for next models

3

Table of contents

Other Seintek Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Novus

Novus N1540-485 instruction manual

Topcon

Topcon RD-80SA instruction manual

Airport Lighting

Airport Lighting L-880 owner's manual

Endress+Hauser

Endress+Hauser MODBUS RS485 operating instructions

Teledyne Lecroy

Teledyne Lecroy MDA800A Getting started guide

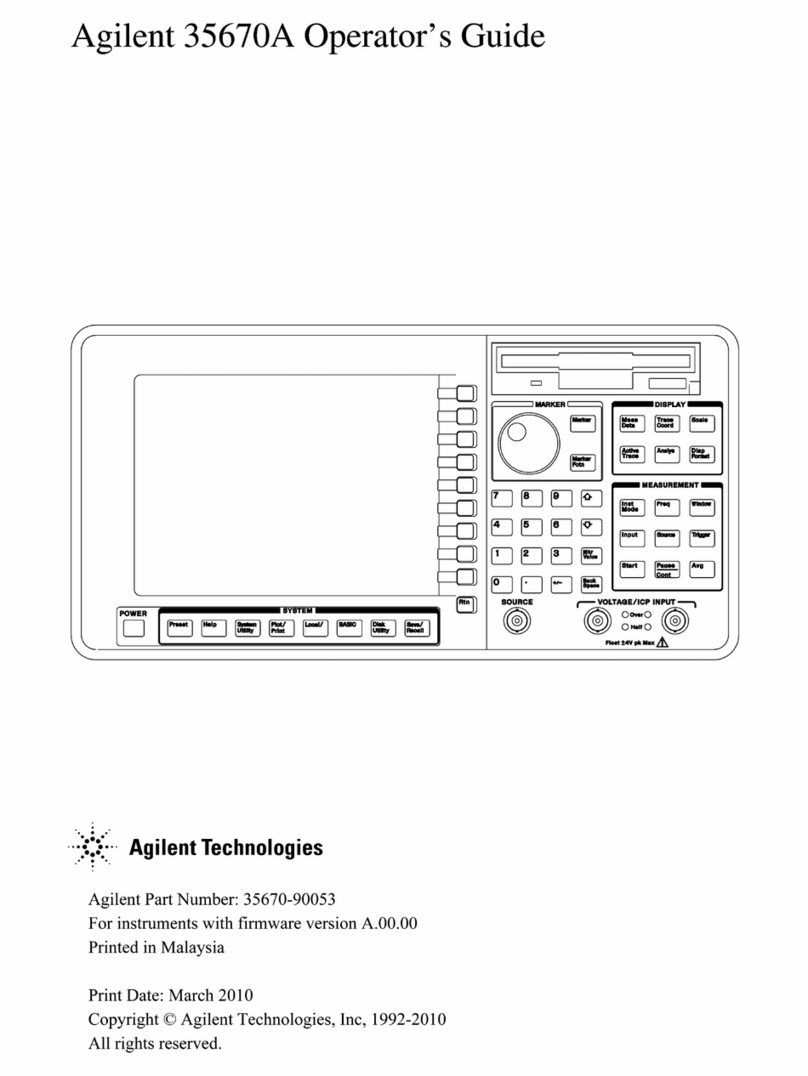

Agilent Technologies

Agilent Technologies 35670A Operator's guide