2

Contents

1 Preliminary note���������������������������������������������������������������������������������������������������4

1�1 Symbols used ������������������������������������������������������������������������������������������������4

1�2 Warnings used�����������������������������������������������������������������������������������������������5

2 Safety instructions �����������������������������������������������������������������������������������������������5

2�1 General requirements on the safety-related functions�����������������������������������6

3 Functions and features ����������������������������������������������������������������������������������������7

3�1 General function description��������������������������������������������������������������������������7

3�2 Safe state of the output relays�����������������������������������������������������������������������8

3�3 Switching function "Overspeed"���������������������������������������������������������������������8

3�4 Hysteresis������������������������������������������������������������������������������������������������������8

3�5 Initialisation����������������������������������������������������������������������������������������������������9

3�6 Fault output (Y7)��������������������������������������������������������������������������������������������9

3�7 Overspeed output (Y8) ����������������������������������������������������������������������������������9

3�8 Feedback circuit for external device monitoring (Y1-Y2)�������������������������������9

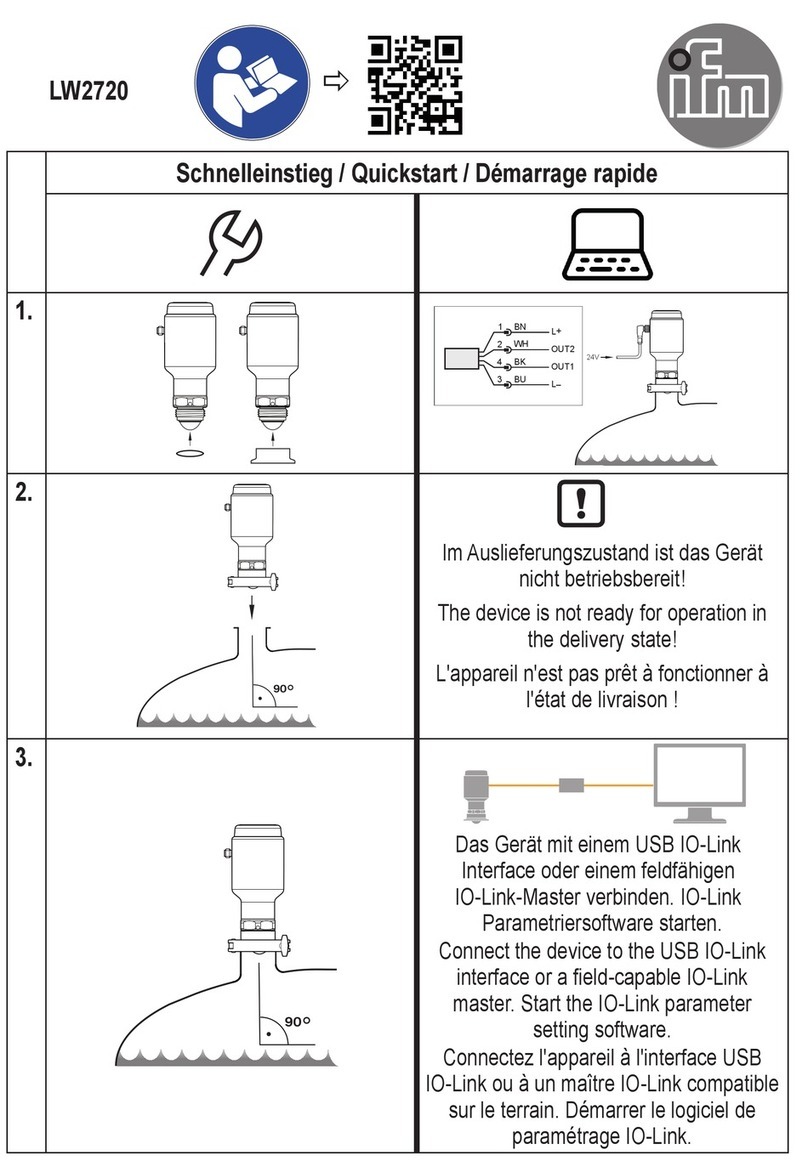

4 Installation����������������������������������������������������������������������������������������������������������10

4�1 Mechanical installation of the device �����������������������������������������������������������10

4�2 Remove the device��������������������������������������������������������������������������������������10

5 Electrical connection������������������������������������������������������������������������������������������ 11

5�1 Terminals ����������������������������������������������������������������������������������������������������� 11

5�2 Automatic/manual mode selection���������������������������������������������������������������13

5�2�1 Automatic mode����������������������������������������������������������������������������������13

5�2�2 Manual mode��������������������������������������������������������������������������������������14

5�3 Enable input�������������������������������������������������������������������������������������������������16

6 Indicators and operating elements���������������������������������������������������������������������17

6�1 LEDs������������������������������������������������������������������������������������������������������������17

6�2 Switches ������������������������������������������������������������������������������������������������������18

7 Set-up ����������������������������������������������������������������������������������������������������������������19

7�1 Configuration position (factory setting) ��������������������������������������������������������19

7�2 Setting the switch point��������������������������������������������������������������������������������20

7�3 Examples of switch point settings����������������������������������������������������������������21

7�4 Checklist after installation and set-up����������������������������������������������������������21

8 Technical data����������������������������������������������������������������������������������������������������22

8�1 DD110S �������������������������������������������������������������������������������������������������������22

8�2 DD111S��������������������������������������������������������������������������������������������������������24