Emerson El-O-Matic E Series Instruction Manual

Other Emerson Controllers manuals

Emerson

Emerson Fisher 1078 User manual

Emerson

Emerson Fisher 1066 User manual

Emerson

Emerson Unidrive M702 User manual

Emerson

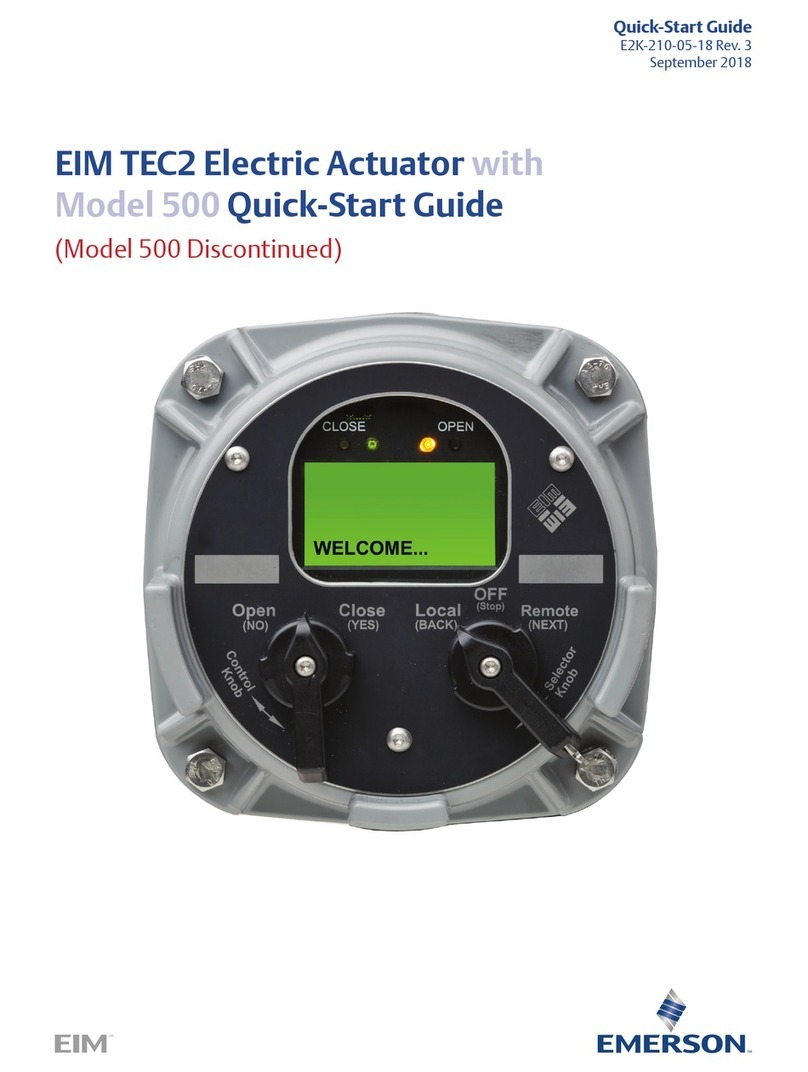

Emerson EIM TEC2 500 User manual

Emerson

Emerson Bettis XTE3000 User manual

Emerson

Emerson Fisher 299H User manual

Emerson

Emerson dixell XW60LT Wiring diagram

Emerson

Emerson FISHER LR128 Series User manual

Emerson

Emerson Bettis EHO User manual

Emerson

Emerson Fisher FIELDVUE DVC6000 HW2 User manual

Emerson

Emerson Powerdrive F300 User manual

Emerson

Emerson Bettis RTS User manual

Emerson

Emerson Fisher L2e Configuration guide

Emerson

Emerson Dixell XR60CHC Wiring diagram

Emerson

Emerson FXMP25 User manual

Emerson

Emerson FISHER MR108 Series User manual

Emerson

Emerson M200-01200024A10101AB100 User manual

Emerson

Emerson NELSON HEAT TRACE CM-2201 User manual

Emerson

Emerson Dixell XT141C Wiring diagram

Emerson

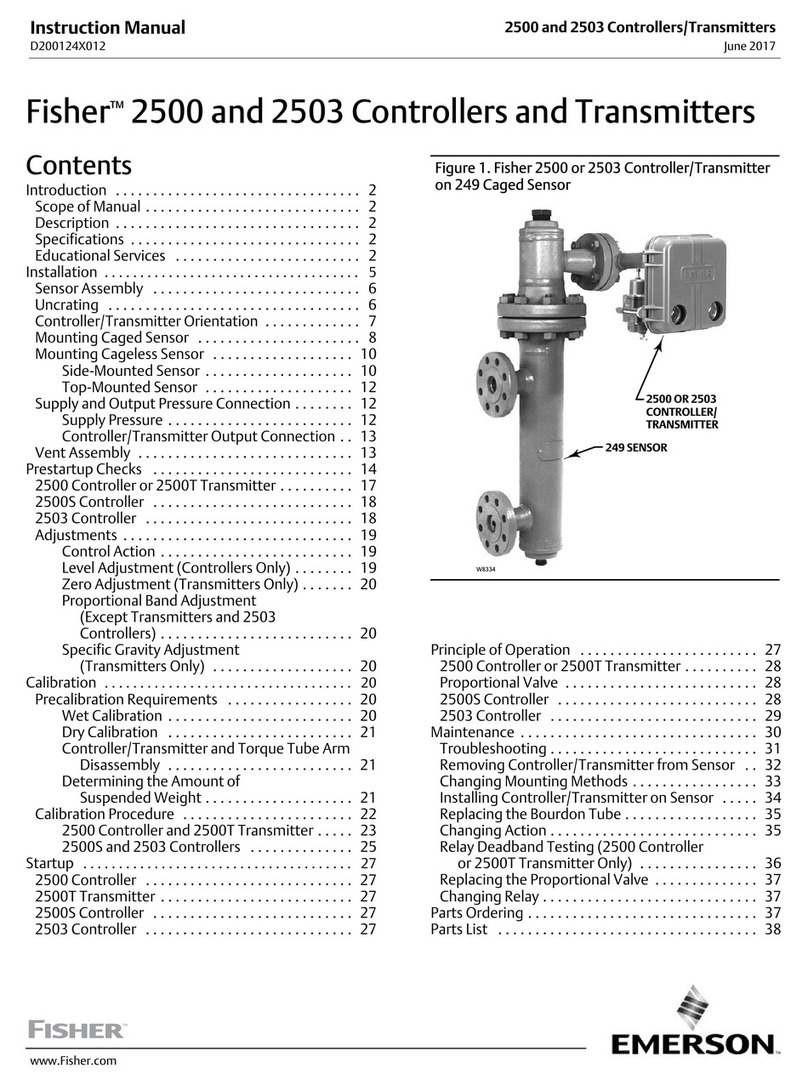

Emerson Fisher 2503 User manual

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions