Selden TYPE RB Mk 4 User manual

Contents: Page: Contents: Page:

Product Description 2 Fitting and Hoisting the Sail 8

Checks and Adjustments Before Stepping 4 Before Sailing 9

Line Routing 6 Maintenance 10

Operation 7

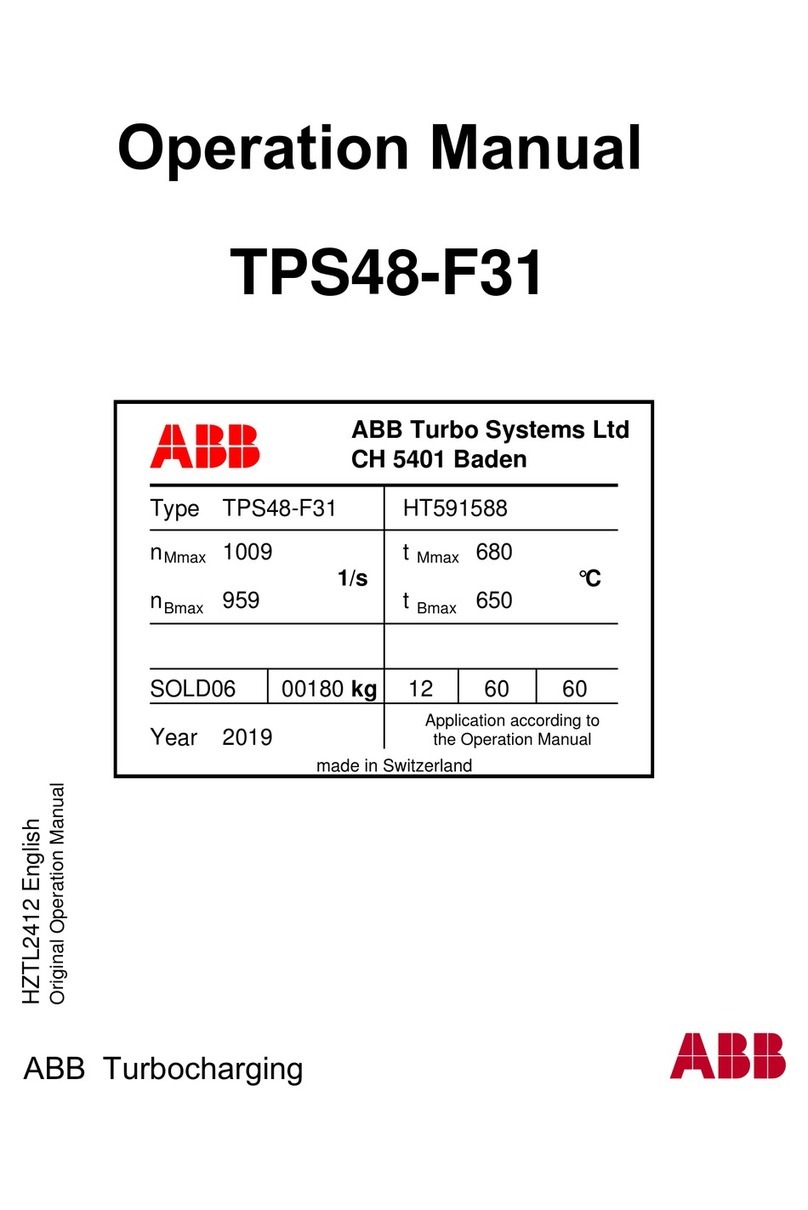

Manual for Furling mast

TYPE RB Mk 4

595-065-E

2017-03-06

2

Product description

• Seldénfurlingmastisamainsailreengandfurlingsystem.

• Theuniquedesignofthehalyardswivelbearingdistributestheloadoverthewholeballracetogive

smootherfurlingandthelowestpossiblefriction,evenunderhighloads.

• ThenewMk4compactgearmechanismoffersimprovedgearefciency,allowsasmallermastcutout

andispreparedforeasyretrotofelectricfurlingdriveunit.

• ThisInstructionManualhasbeencompiledtogiveyouinformationonthein-mastreengsystem.

Studyitandfollowtheinstructionscarefully,andweguaranteeyoupleasurableusefromyour

Seldénfurlingmast.

Followtherelevantrigginginstructionsinourbooklet”HINTSANDADVICE”fortuningtherig.

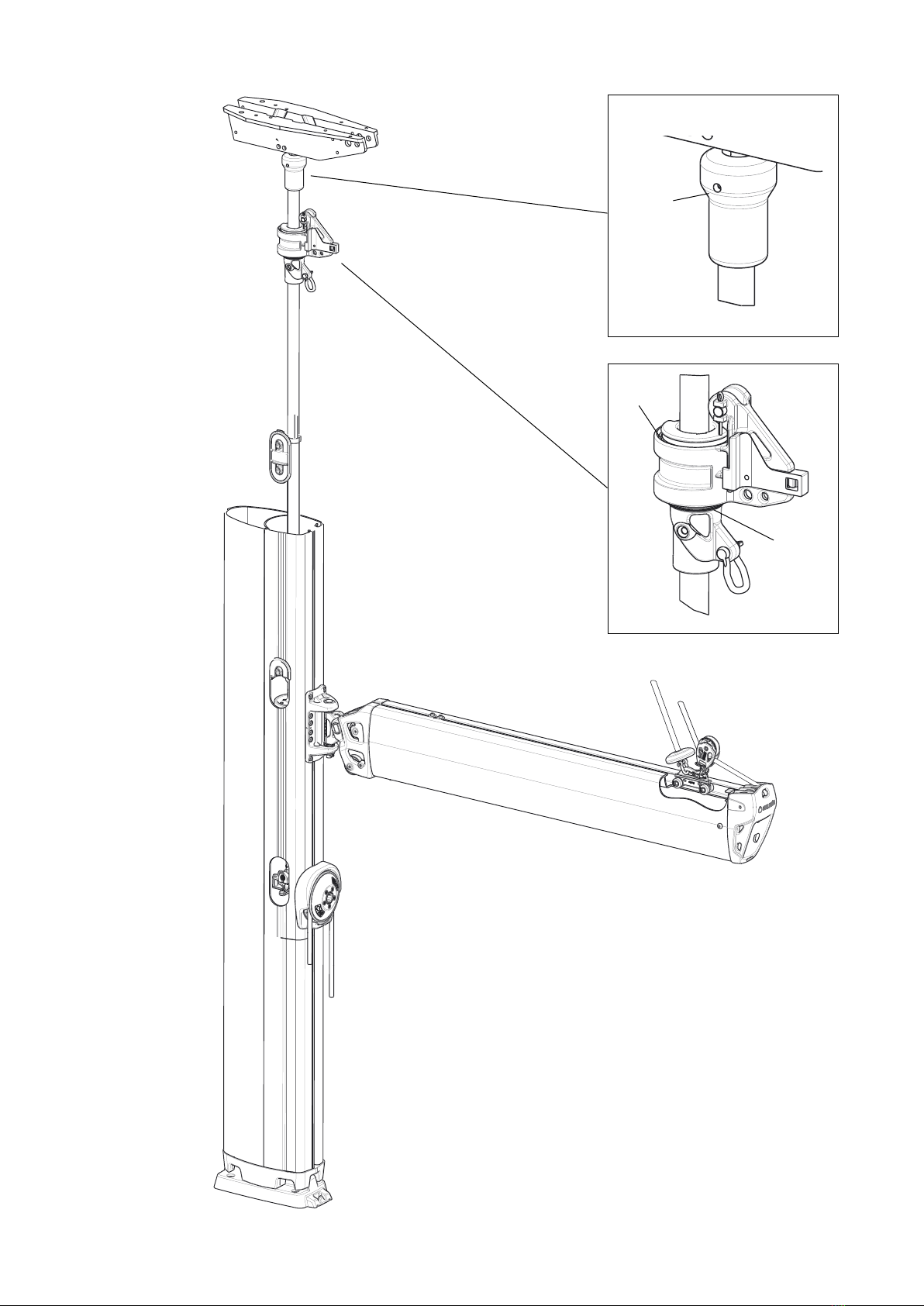

Sail compartment with luff extrusion

Fig. 2:1

3

Top swivel

Halyard swivel

Sail feeder

Outhaul car

Access to sail feeder and

halyard swivel

Access to tack hook and

tensioning screw

Fig 3:1

Tack hook

Rachet lever

Line driver

Tensioning screw

Winch handle socket

4

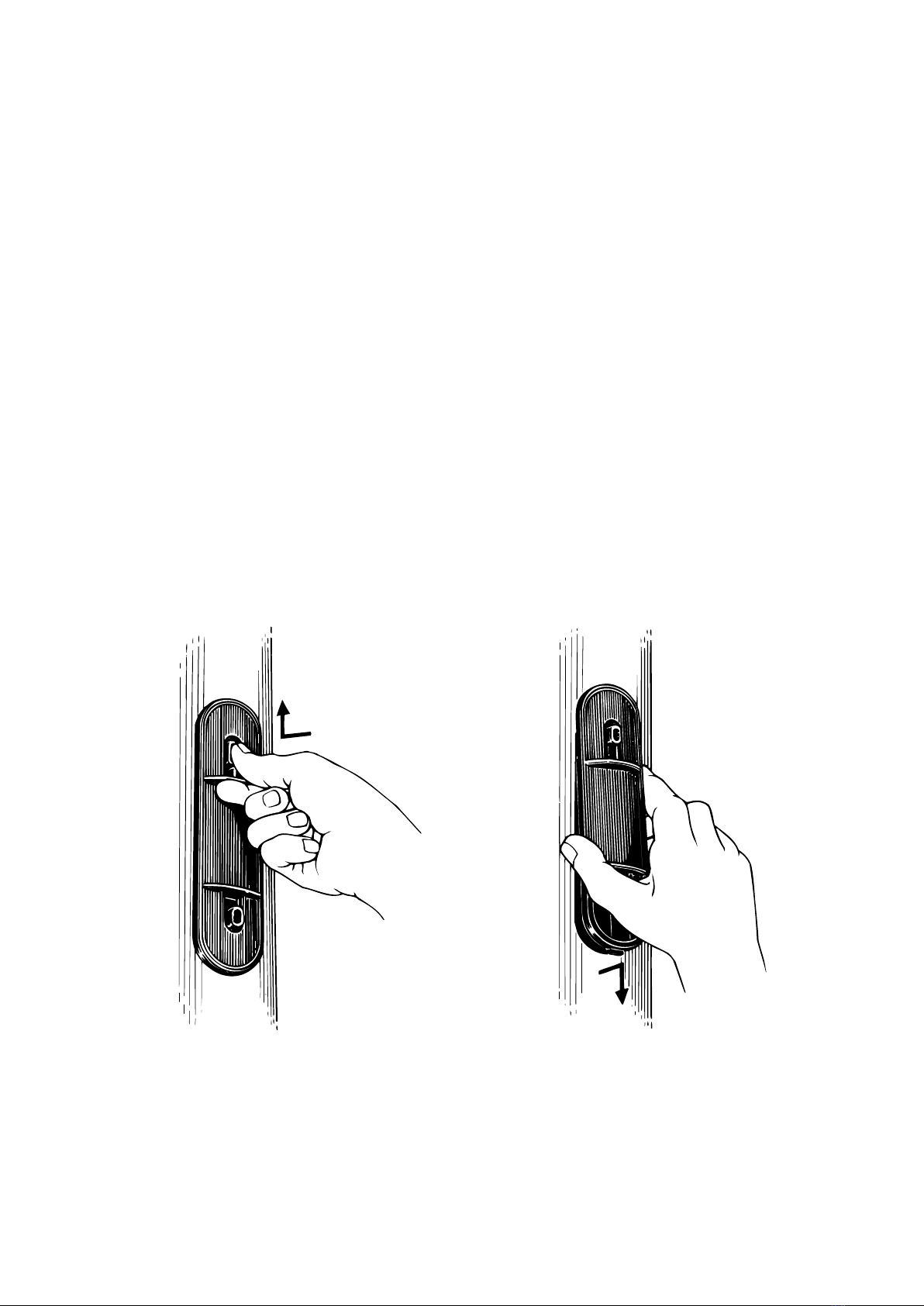

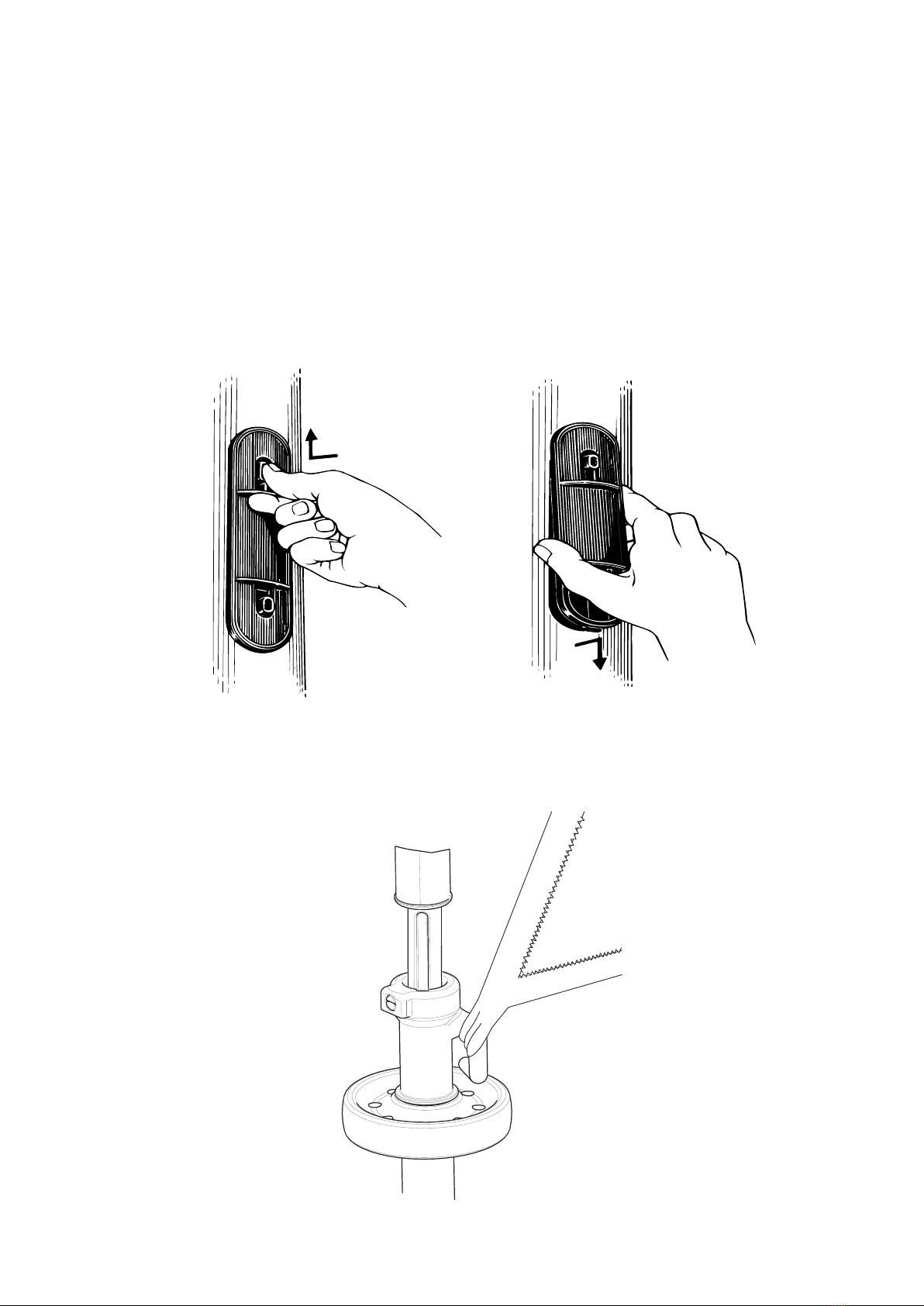

1. Remove the access covers.

Depress one button and push. Lift the opposite end and remove.

Fig. 4:1 Fig. 4:2

Luff extrusion adjustment

Checking luff extrusion tension prior to stepping the mast

Theluffextrusioniscorrectlytensionedbeforeleavingthefactory,buttensioncanbere-checkedbeforestepping

themastinthefollowingmanner.

Laythemasthorizontallyonit´ssideandkeepitstraight.Theluffextrusionshouldnowbejustclearoffthemast

wallatitsmidpoint.Ifadjustmentisnecessaryseepoints1-5below.

Ifadjustmenthastobemadeafterthemasthasbeenstepped,thentheluffextrusionshouldbesotensionedthatit

doesnotbeatagainstthemastwallwhenyougraspitthroughtheupperaccessholeandshakeit.

Theluffextrusioncanbetensionedalsowiththesailttedifthewindsareverylight;Rolloutthesail,lowerit

slightlyandremovethetackfromthetackhook.Hoistthesailsoitdoesnotinterferewithtensionscrew.

Partoftheextrusionwillberestingontheaftfaceofthesailcompartmentwhensailing.

DONOTOVER-TENSION!Aluffextrusionthatisover-tensionedwillrequireincreasedfurlingeffort.

5

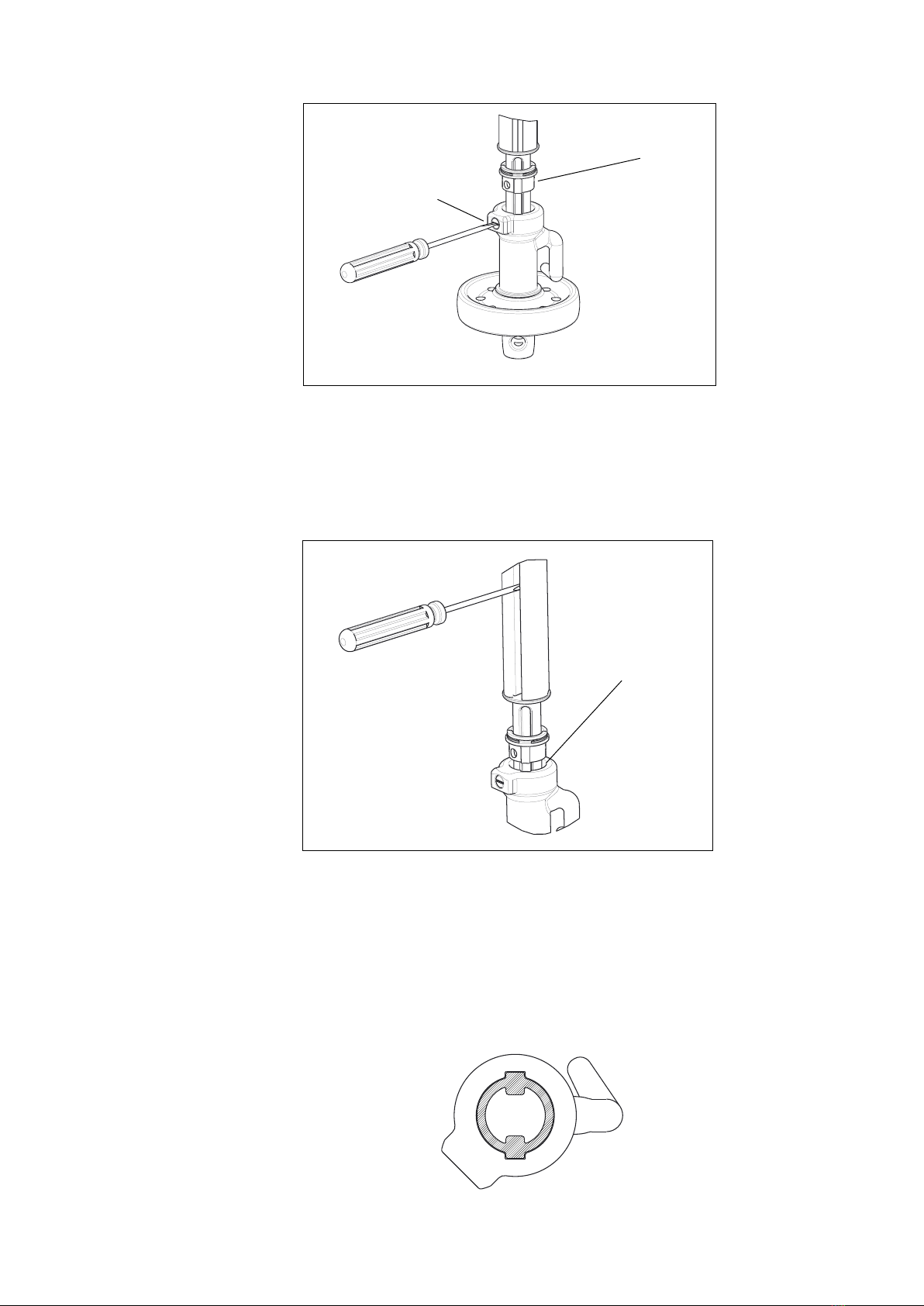

Releasethelockingscrew!3turnsandliftthelockingring".Lockingringcanbetemporarilysecuredby

apieceoftape.

Lubricatethetensionscrewwithriggingscrewoil(art.nr312-502).Putascrewdriverinthesailgrooveofthe

luffproletopreventitfromrotating.Apieceoftapeonthetipofthescrewdriverpreventsdamagetotheluff

prole.Turnthereengwinchusingthewinchhandleuntiltheluffproleiscorrectlytensioned.

4dropsofoil

2. Release locking ring

3. Adjust luff tension

!

"

3. Engage locking ring in position and tighten locking screw

5. Refit access covers.

6

Alternative clew outhaul arrangement.

Fig. 7:1 Fig. 7:2

Layout 1

Figs.6:suggestedarrangement.

Line routing

Reengandunreengisaccomplishedwithanendlessreenglineandanouthauloperatedeitherfromthecockpit

oratthemast.Inthelattercasetheouthaulisalsotakentotheboomormastnearthegooseneck.(SeeFig.7.1).

Endless reefing line

Ifin-mastfurlingmastistobeoperatedfromthecockpitanendlessreengline(loop)incombinationwithaself-

tailingwinchisrecommended.Reenglineshouldbeø10mmpolyesterrope.Theendlessloopmusthaveextra

lengthtoallowittobeeasilyremovedfromthewinch.Thetail-endoftheloopmustalsobebelayedonastopper.

Onmostinstallations,thereenglineneedstobefedthroughblocksandstoppersbeforemakinganendlesssplice

accordingtoSeldéninstruction595-673.Iftheblocksandstoppersarepossibletodismantle,asplicedendlessline

canbeusedaccordingtosparepartslistatpage15.

Outhaul line

Aself-tailingwinchandastopperisalsorecommendedfortheouthaulline.

FreeRatchet

Lead Blocks

Lead Blocks

Turning Blocks

Kicking Strap

Rope-Stoppers

Topping Lift

Endless Reeng

Line

Fig 6:2

Outhaul

7

Operation

Furlingandunfurlingisaccomplishedeitherfromthecockpitwithanendlessreenglineandanouthaullineorat

themastusingawinchhandleatthemastlinedriver.Inthelattercasetheouthaulistakentotheboomormastnear

thegooseneck.(SeeFig.7.1).

Unfurling

Whenunfurlingfromthecockpitthelinedrivermustbesetto”free”.(SeeFig.7:2).

1. Freebothsidesoftheendlessloopfromthewinchandstopper.Itwillthenslideonthelinedriver.

2. Pulloutthesailwiththeouthaulline.

Furling

1. Theleechshouldbekeptfairlytightwhenreengorfurling.Adjusttheboomangle(vangortoppinglift)

toachievethis,andthesailwillformatightrollaroundtheluffextrusion.

2.Locatethestarboardpartoftheendlessfurlinglineonthewinchandpullbyhand,orifnecessaryusea

winchhandle.

3. Keepslighttensionontheouthaulwhiledoingthis.Thisappliesespeciallywhenthewindisabaftthebeam

orinlightair.

Reefing

1. Carefullyslackenofftheouthaulline.

2. Locatethestarboardpartoftheendlessfurlinglineonthewinchandpullbyhand,orifnecessaryuseawinch.

3. Theleechshouldbekeptfairlytight.Keepslighttensionontheouthaulduringthemaneuver.

Whenworkingatthemast:

Activatethelockonthelinedrive(-IN’)beforereengthesail.Useawinchhandletofurlthesail.When

thedesiredamountofsailisrolledin,usetheouthaultostretchthefootofthesail.Don´t leave the winch

handle in the linedriver!

Whenoperatingfromthecockpit:

Whenreefedtodesiredsailarea,lockbothpartsoftheendlesslinesinstoppersandtightentolockthereeng

winch.Finally,tensiontheouthaul.

When leaving the boat.

Alwayslockthelinedriverwiththeratchetleverwhenleavingtheboat!

WARNING! Never leave the winch handle in the linedriver!

It will rotate very rapidly when the sail is unfurled.

8

Fitting and hoisting sail

CheckthattheTackandHeadofthesailaremadeinaccordancewithSeldéninstruction595-542“Sailmakersguide”.

Anincorrectdesigncancausewrinklesinthesailandmakesmoothfurlingdifcult.

1. Removethecovers.Pressonebuttonandpush.Lifttheoppositeendandremove.Pressonebuttonandpush.

Lifttheoppositeendandremove.

2. Attachtheheadofthesailtothehalyardswivel.

Remove the covers.

Depress one button and push. Lift the opposite end and remove.

Fig. 8:1 Fig. 8:2

Fig. 8:3

9

Sail dimensions

Foruptodatesaildesigninformation,pleaseseethesailmakersguide,595-542-E.

Port

Fig. 9:1

Starboard

Before sailing

1. CheckthatthesailiscorrectlyfurledontheSTARBOARDSIDEoftheluffextrusion.(SeeFig.9:1).

2. Furlandunfurlthesailacoupleoftimestoensurethatthesystemworksasitshould,andtofamiliarize

yourselfwithitsoperation,andalsotocheckthatthesailiscorrectsize.

3. Theareaaftofthemastmustbefreefromhalyardsetc.orthesecanbecaughtbythesailduringthe

furlingprocedure.

Note. For correct furling, pull on starboard part of the endless

furling line for the line driver to turn clockwise.

4. AttachtheclewtotheOuthaulCar.

5. Hoistthemainsailwhilstsimultaneouslyensuringthatitisfeedingcorrectlyintotheluffextrusion.

6. Jointhesailtothetackhook.(Seeg.8:3).

7. Tightenthehalyard.

8. Furlthesailuntilonly200-300mmoftheclewisexposed.Thelinedrivershouldbeturnedclockwise.

(SeeFig.9:1).

10

Maintenance of the in-mast furling mast

Periodic Maintenance

Maintenanceshouldbeundertakenatleastonceayear.Morefrequentcleaningforremovalofsaltandsand

isdonebyrinsingwithfreshwateronly.AllbearingsshouldbegreasedwithGREASE(PartNo.312-501),

atubeofwhichisdeliveredwiththemast.ReadthefollowinginstructionsandseeFig.13:l.

Whengreasingbearingsandgears,donotover-grease.Athincoatingofevenlyappliedgreaseissufcient.

TOP SWIVEL:

Thebearinghasalubricationholemarked”GREASE”wherethegreaseshouldbeinjected.Accessthroughthe

sailslot.

HALYARD SWIVEL:

Lubricatetheswivelbyinjectinggreaseintothegaps& inthering.Thisisbestdonethroughtheupperaccess

hole.

IN-MAST FURLING MAST GEAR.

1. Removetheaccesscoversandun-tensiontheluff-seepages4&5.

2. Removeratchetcoverassembly .

3. Greasethebevelgears andball-bearing .

Complete Service

Itisagoodideaaftersomeyearsusetoremovethegearforthoroughcleaningandre-greasing.Thein-mastfurling

mastisbuiltsothatservicingwillbeeasyevenafterprotracteduse.Topswivel,halyardswivelandfurlinggearcan

becleanedinkerosene,bloweddrywithcompressedairandre-greased.

Removal of the gear

1. Relievetensionontheluffextrusionbyslackeningthetensioningscrewasdescribedonpage4-5.

2. Removethe2insexscrewsholdingthefurlinggearandtheratchetcover.

3. Releasethetwoscrewsattheballfurlinggearjoinconnectiontoreleasethefurlinggearandtakeoutthegear

viatheratchetcoverhole.

Removal of the top swivel and halyard swivel.

Thiscanonlybedonewiththemastdown.

1. Relievetensionontheluffextrusionbyslackeningthetensioning

screwasdescribedonpage4-5.

2.Releasetheheadboxbyundoingthenutsontop.Liftoffthe

headboxwhileyoufollowwithreleasingthetensioningscrewuntil

itseparatesfully.Theboxcanthenbeliftedoff.DetachtheTop

Swivelfromtheheadbox.

3. TheluffsectionandtheHalyardSwivelcannowbepulledoutof

themast.

11

Fig. 13:1

1212

Spare parts

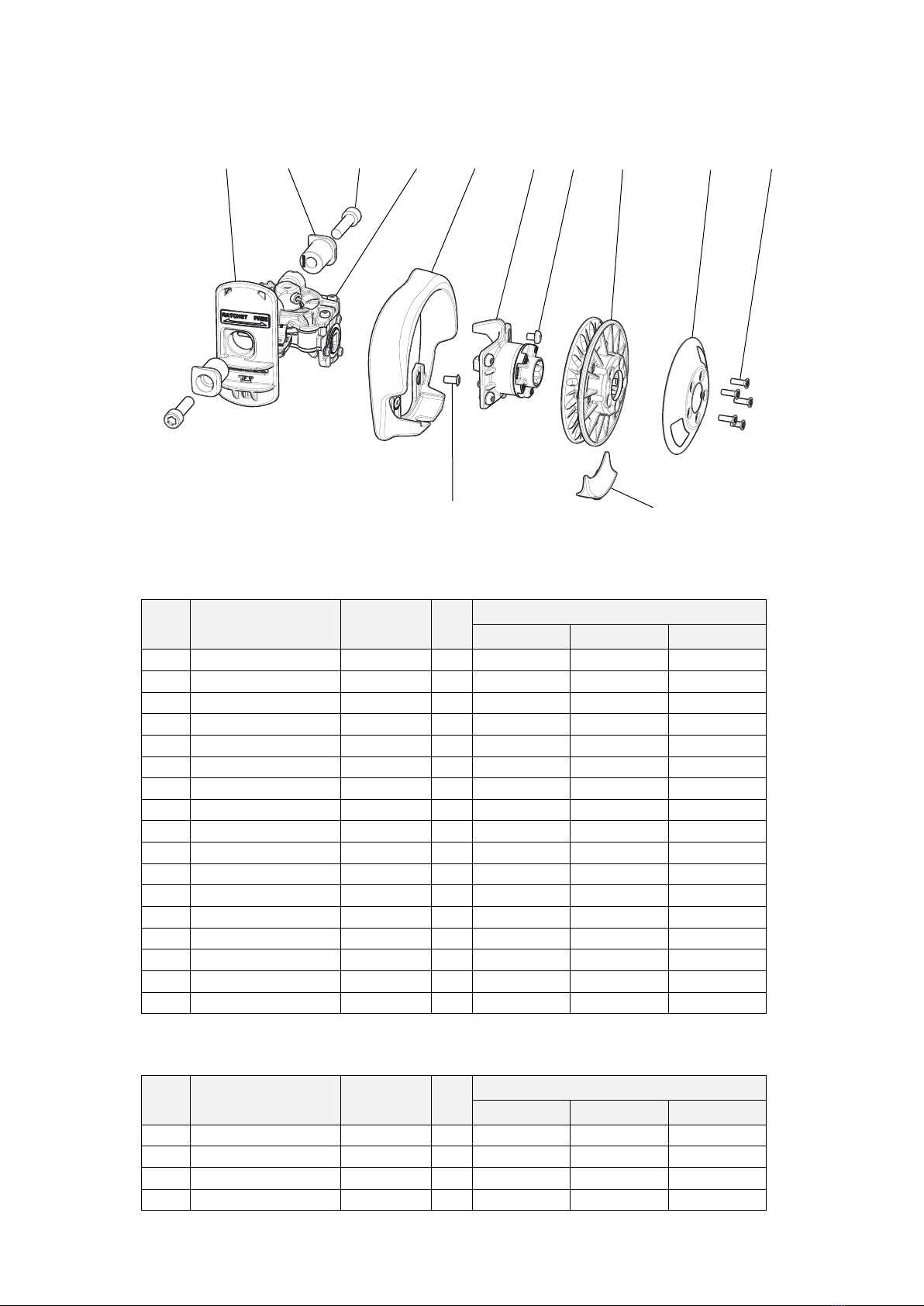

Furling gear

Item Description Dimension Qty Mast extrusion

F228 F246 F265

1 Gear house assembly - 1 540-090-01 540-090-01 540-090-01

2 Ratchet cover assembly - 1 540-392-01 540-392-01 540-392-01

3 Flange bush Ø23/10.5-28 2 540-388 - -

3 Flange bush Ø23/10.5-32 2 - 540-389 -

3 Flange bush Ø23/10.5-36 2 - - 540-390

4 Screw MC6S 10x30 2 153-059 - -

4 Screw MC6S 10x35 2 - 153-061 -

4 Screw MC6S 10x35 2 - - 153-061

5 Line driver cover 142x148 1 540-089 540-089 540-089

6 Pop rivet Ø6.4x12.7 4 167-004 167-004 167-004

7 Bearing house assy - 1 540-087-01 540-087-01 -

7 Bearing house assy - 1 - - 540-087-02

8 Screw MRT 6x8 4 155-624 155-624 155-624

9 Linedriver assembly Ø120x33 1 540-085-01 540-085-01 540-085-01

10 Stripper 58x20 1 540-034 540-034 540-034

11 Cover ø112x29 1 540-194 540-194 540-194

12 Screw MFT5x12 5 162-048 162-048 162-048

ab c hgd e

f

i

j

k l

Sail feeder tube assembly

Item Description Dimension Qty Mast extrusion

F228 F246 F265

13 Sail feeder tube 30/29-524 1 540-381 540-381 540-381

14 Joint sleeve L=192 1 540-167 540-167 540-167

15 Pop rivet 4.8x9.9 4 167-007 167-007 167-007

16 Sail feeder 32x12 1 540-344 540-344 540-344

1313

Tack assembly

Item Description Dimension Qty Mast extrusion

F228 F246 F265

17 Tack hook body 37x117 1 540-100 540-100 540-100

18 Tensioning screw M22x165 1 540-099 540-099 540-099

19 Torque connector 30x17 2 540-098 540-098 540-098

20 Retaining ring - 1 301-063 301-063 301-063

21 Screw MC6S 5x6 1 155-072 155-072 155-072

22 Wheel ø90/31-20 1 319-622 319-622 319-622

23 Split pin 3.7x40 1 301-062 301-062 301-062

24 Pop rivet 4.8x9.9 4 167-007 167-007 167-007

Shaft assembly

Item Description Dimension Qty Mast extrusion

F228 F246 F265

25 Shaft Ø25x356 1 540-399 540-399 540-399

26 Gimbal joint Ø34/32-49 2 540-097 540-097 540-097

27 Clevis pin Ø10x40 2 165-211 165-211 165-211

28 Split pin 2.9x16 2 301-049 301-049 301-049

29 Clevis pin Ø10x40 1 165-211 165-211 165-211

30 Split pin 2.9x16 1 301-049 301-049 301-049

Luff extrusion

Item Description Dimension Qty Mast extrusion

F228 F246 F265

31 Luff extrusion w. cover L=7500 1 540-111-01 540-111-01 540-111-01

32 Joining sleeve L=180 1 540-148 540-148 540-148

33 Pop rivet 4.8x9.9 8 167-007 167-007 167-007

13

14

15

16

17

18

19

20

21

27

26

25

24

23

22

28

32

31

30

29

33

14

a

b

c

g

d

e

f

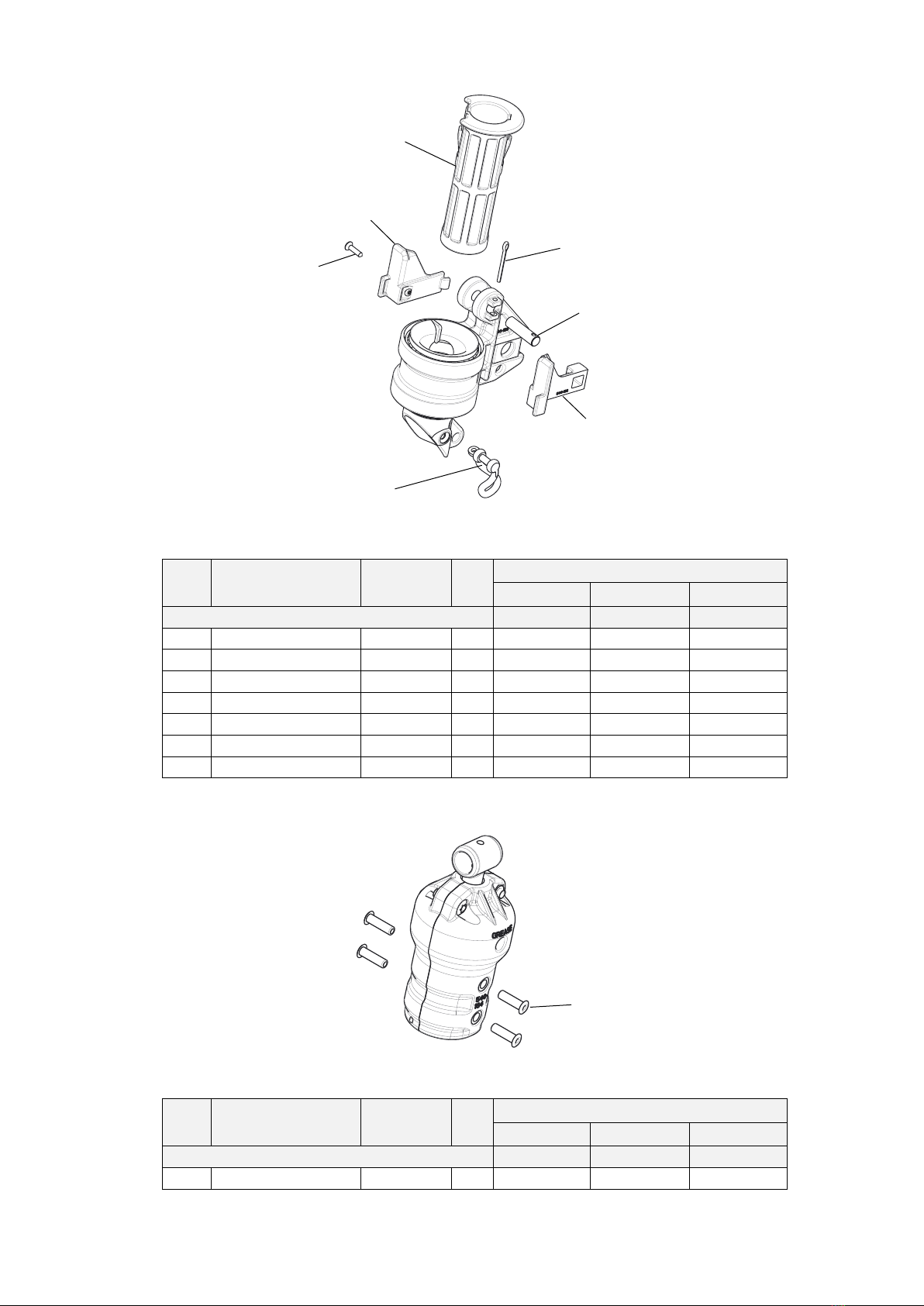

Halyard swivel

Item Description Dimension Qty Mast extrusion

F228 F246 F265

Complete halyard swivel -> 540-158-01 540-158-01 540-158-01

1 Sliding sleeve 64x140 1 540-159 540-159 540-159

2 Sliding insert-stb 52x52 1 540-165 540-165 540-165

3 Sliding insert-port 52x52 1 540-166 540-166 540-166

4 Screw 3.5x9.5 1 171-047 171-047 171-047

5 Schackle M7/13/25 1 307-023 307-023 307-023

6 Pin ø10x37 1 166-222 166-222 166-222

7 Split pin 2.9x32 1 301-525 301-525 301-525

Top swivel

Item Description Dimension Qty Mast extrusion

F228 F246 F265

Complete top swivel (pop rivets not included)-> 540-164-01 540-164-01 540-164-01

1 Pop rivet 4.8x16.5 4 167-006 167-006 167-006

a

15

Additional items

Item Description Dimension Qty Mast extrusion

F228 F246 F265

1 Grease 100g 1 312-501 312-501 312-501

2 Access hole cover 57x126 1 540-026 540-026 540-026

3 Manual/Spare parts

list-Swedish

A4 1 595-065-S 595-065-S 595-065-S

3 Manual/Spare parts

list-English

A4 1 595-065-E 595-065-E 595-065-E

3 Manual/Spare parts

list-German

A4 A4 595-065-T 595-065-T 595-065-T

4 Endless line Ø10 2x5000 1 611-011-05 - -

4 Endless line Ø10 2x7000 1 - 611-011-06 -

4 Endless line Ø10 2x9000 1 - - 611-011-07

12

34

595-065-E Printed in Sweden

Seldén Mast AB, Sweden

Tel +46 (0)31 69 69 00

Fax +46 (0)31 29 71 37

Seldén Mast Limited, UK

Tel +44 (0) 1329 504000

Fax +44 (0) 1329 504049

e-mail [email protected]

Seldén Mast Inc., USA

Tel +1 843-760-6278

Fax +1 843-760-1220

e-mail [email protected]

Seldén Mast A/S, DK

Tel +45 39 18 44 00

Fax +45 39 27 17 00

Seldén Mid Europe B.V., NL

Tel +31 (0) 111-698 120

Fax +31 (0) 111-698 130

e-mail [email protected]

Seldén Mast SAS, FR

Tel +33 (0) 251 362 110

Fax +33 (0) 251 362 185

e-mail [email protected]

www.seldenmast.com

Dealer:

DINGHIESKEELBOATSYACHTS

TheSeldénGroupistheworld’sleadingmanufacturer

ofmastsandriggingsystemsincarbonandaluminium

fordinghies,keelboatsandyachts.TheGroupconsistsof

SeldénMastABinSweden,SeldénMastA/SinDenmark,

SeldénMastLtdintheUK,SeldénMidEuropeB.V.inthe

Netherlands,SeldénMastIncintheUSAandSeldénMast

inFrance.OurwellknownbrandsareSeldénandFurlex.

TheworldwidesuccessofFurlexhasenabledustobuild

anetworkofover750authoriseddealerscoveringthe

world’smarinemarkets.Sowhereveryousail,youcanbe

sureoffastaccesstoourservice,sparepartsandknow-

how.

Table of contents

Popular Industrial Equipment manuals by other brands

schmersal

schmersal AZM201B-ST2-T-1P2PW Instructions for operation

Electrolab

Electrolab 2110EX-A user manual

SCE

SCE ENVIRO-THERM SCE-HE08W120V user manual

Magnum Industrial

Magnum Industrial MI-31662 operating manual

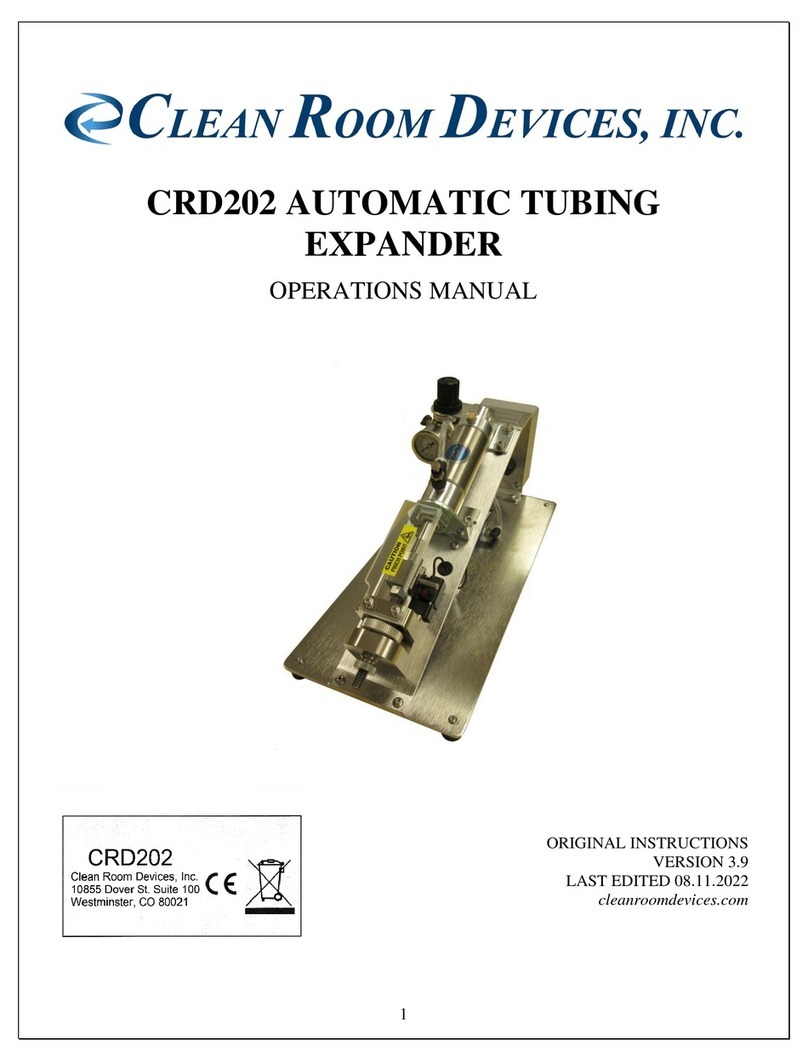

CLEAN ROOM DEVICES

CLEAN ROOM DEVICES CRD202 Operation manual

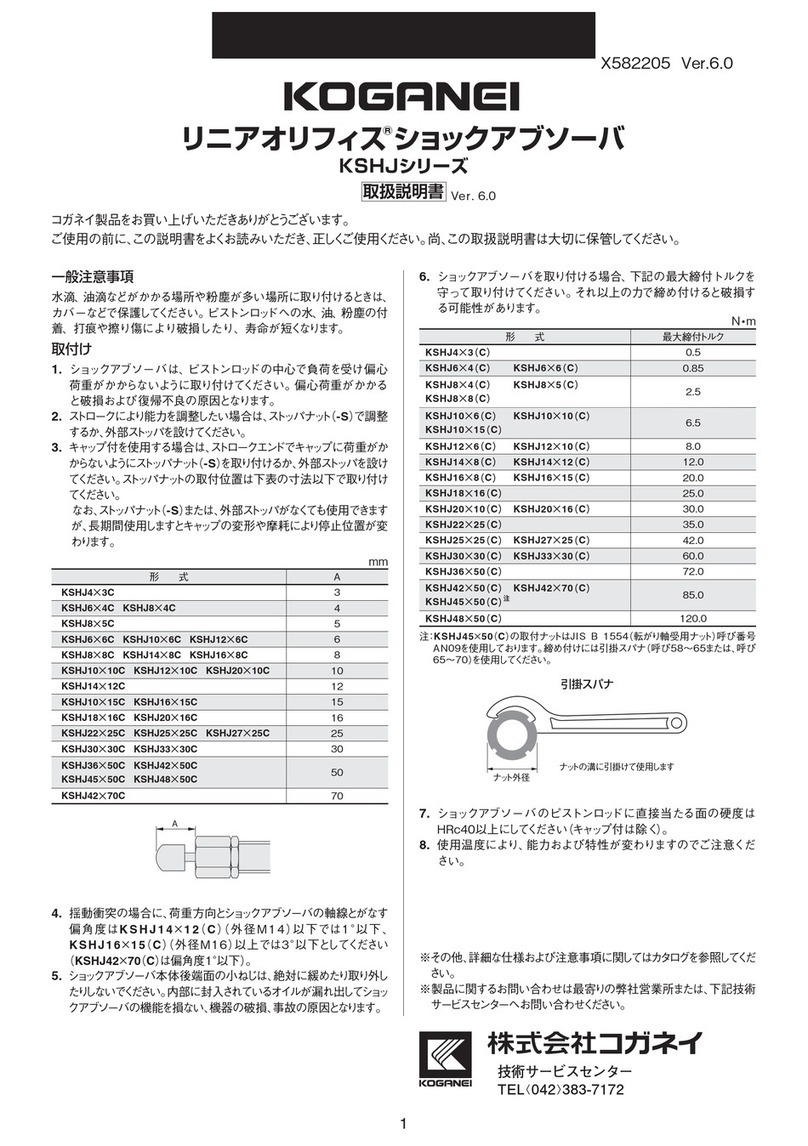

Koganei

Koganei KSHJ Series instruction manual