Operating Instructions

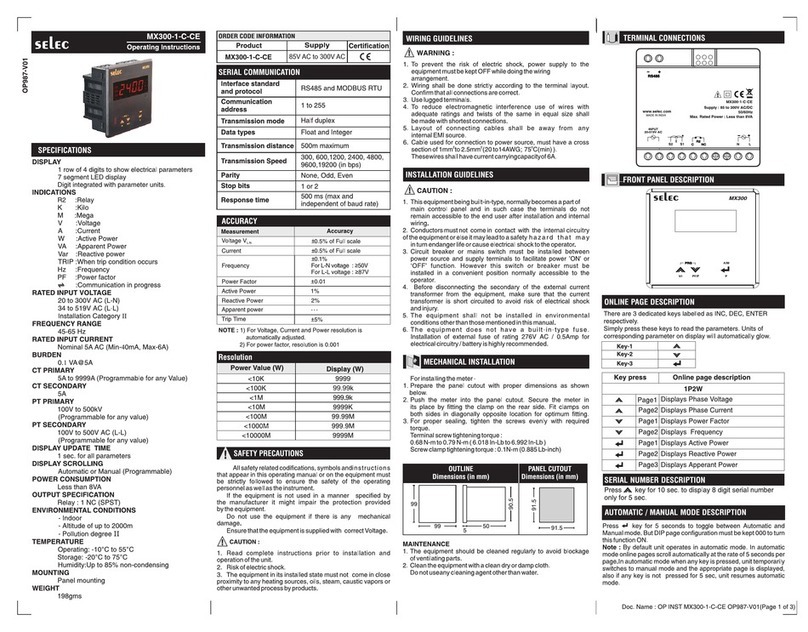

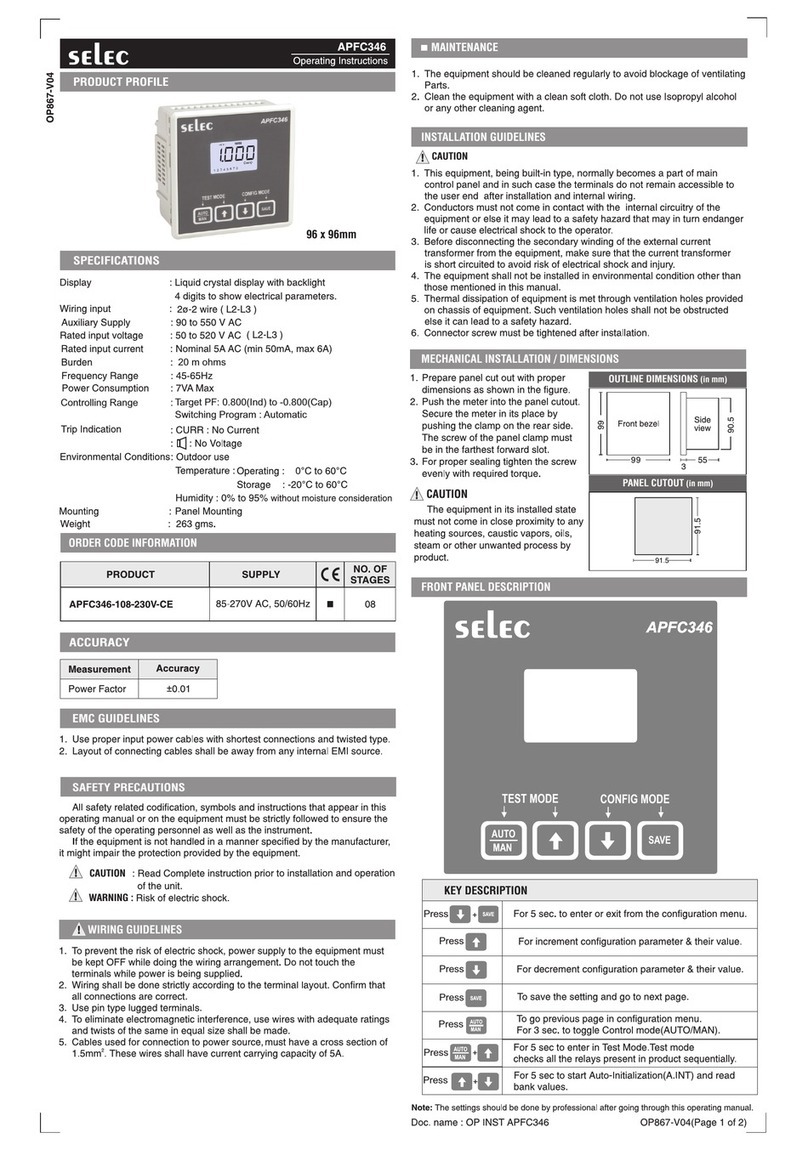

SPECIFICATIONS

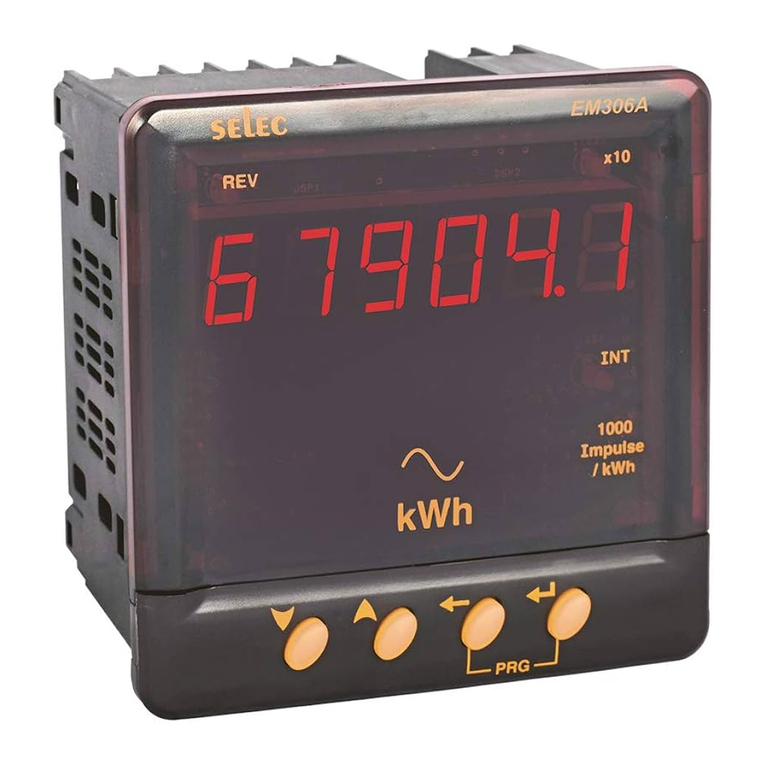

DISPLAY

i

1 row of 6 digits to show electr cal parameters

7 segment LED display 71*24mm

e e

Digit integrated with param t r units

D

IN ICATIONS

en

EXP - CT Rev rse Detectio

k - Kilo

M- Mega

WIRING INPUT

- wr

3 Ø 4 ire, 3 Ø - 3 wire, 2 Ø - 3 wi e and

r

1 Ø - 2 wi e system

T

RATED INPU VOLTAGE

C

11 to 300V AC (L-N) ; 19 to 519V A (L-L) ;

C

Installation ategory III

E RFREQU NCY ANGE

45-65 Hz

A N

RTED INPUT CURRE T

5

Nominal A AC (Min-50mA, Max-6A)

BURDEN

h

0.5 VA@5A per p ase

Y

CT PRIMAR

r

1A / 5A to 10,000A (Programmable fo any Value)

,

Note : 1A to 10 000A if CT secondary is 1 else

CT primary is 5A to 10,000A

CT SECONDARY

1A or 5A (Programmable)

PT PRIMARY

l100V to 500kV (Programmab e for any value)

SPT ECONDARY

l

100 to 500V AC (L-L) (Programmab e for any value)

POWER CONSUMPTION

Less than 8VA

O

ENVIRONMENTAL CONDITI NS

d- In oor use

l

- A titude of up to 2000 meters

e- Pollution d gree II

t

Tempera ure :

:Humidity Up to 85% non-condensing

II

T

INS ALLATION CATEGORY : III

MOUNTING :Panel mounting

WEIGHT : 210gms

OUTPUT

Pulse output :Voltage range external 24V DC max

Current capacity: 100mA

+

w

Pulse idth :100ms 5ms

INT :1000 pulses / kWh

C

Operating : -10° to 55°C

Storage : -20°C to 75°C

PROTECTION CLASS :

EM306

r

MAINTENANCE

1. The equipment should be cleaned regularly to avoid

blockage of ventilating parts.

2. Clean the equipment with a clean dry or damp cloth.

Do not use any cleaning agent other than water.

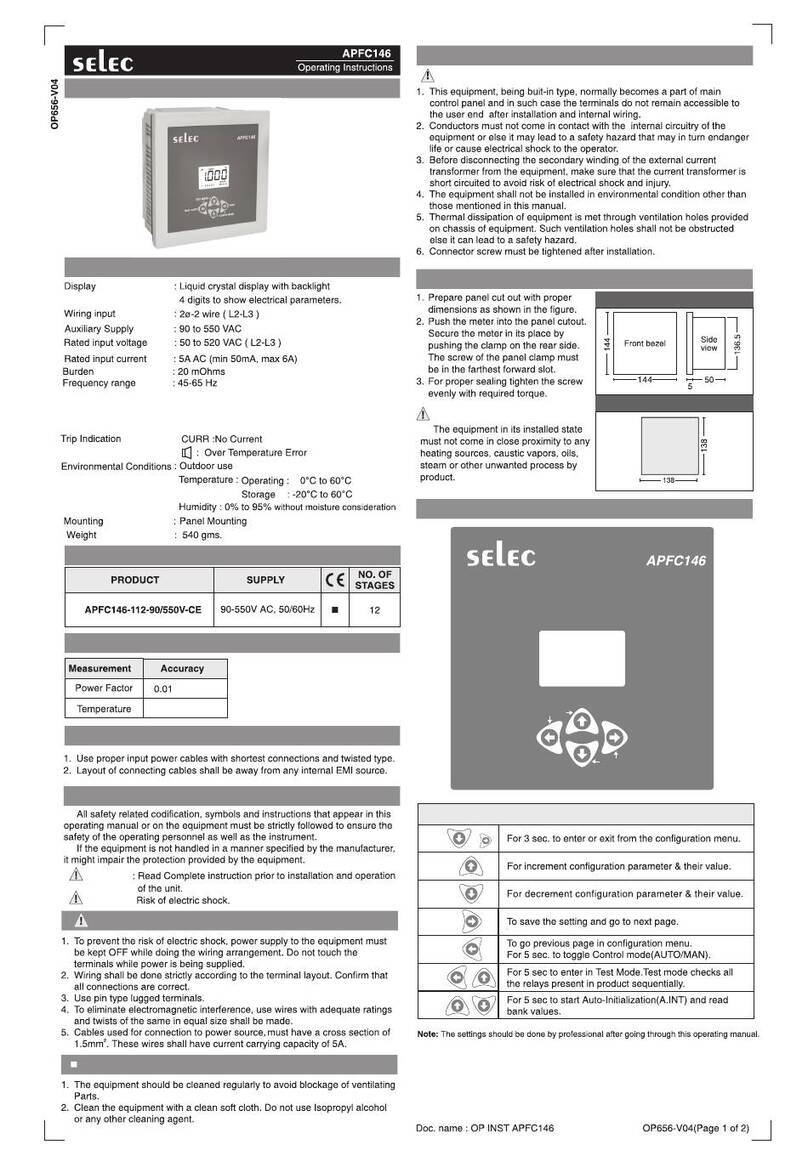

OUTLINE

Dimensions (in mm)

PANEL CUTOUT

Dimensions (in mm)

90.5

99

99

550 91.5

91.5

FRONT PANEL DESCRIPTION

ONLINE PAGE DESCRIPTION

WIRING GUIDELINES

WARNING :

Active energy

Measurement Accuracy

Class 1

ACCURACY

RESOLUTION

PT Ratio x CT Ratio kWh

<15

<150

<1500

<15000

<150000

0.01K 0.01

0.1K 0.1

1K 1

0.01M 10

0.1M 100

1M 1000150000

Pulse output

kWh/pulse

TERMINAL CONNECTIONS

N

S2S1S2S1S2S1 V1

N

L

O

A

D

I1V2 V3

L1

L2

L3

I2I3

PULSE

OUTPUT

CONNECTIONS DIAGRAM

LN

+

SERIAL NUMBER DESCRIPTION

Press key for 10 sec. to display serial number.

CONFIGURATION

Note : Setting should be done by professional after going

through this user manual and having understood the

application situation.

• Use key to shift the cursor for next digit and to edit.

Use key to increment the configuration value.

Use key to decrement the configuration.

• Use key for save parameter value & go to the next page

For the configuration setting mode :

• Use key for 3 sec to enter and exit from

configuration menu.

Display will show only kWh page.

ORDER CODE INFORMATION

Product Supply

Certification

Doc. Name: OP INST EM306 OP1029-V01(Page 1 of 3)

EM306

85 TO 276 V AC, 50/60 Hz -

-

OP1029-V01

1. To prevent the risk of electric shock, power supply to the

equipment must be kept OFF while doing the wiring

arrangement.

2. Wiring shall be done strictly according to the terminal

layout. Confirm that all connections are correct.

3. Use lugged terminals.

4. To reduce electromagnetic interference use of wires with

adequate ratings and twists of the same in equal size shall

be made with shortest connections.

5. Layout of connecting cables shall be away from any

internal EMI source.

6. Cable used for connection to power source, must have a

2 2 0

cross section of 0.5mm to 2.5mm ( 20 to 14AWG ; 75 C

(minimum)). These wires shall have current carrying

capacity of 6A.

SAFETY PRECAUTIONS

All safety related codifications, symbols and

instructions that appear in this operating manual or on

the equipment must be strictly followed to ensure the

safety of the operating personnel as well as the

instrument.

If the equipment is not used in a manner specified by the

manufacturer it might impair the protection provided by the

equipment.

Do not use the equipment if there is any mechanical

damage.

Ensure that the equipment is supplied with correct

voltage.

1. Read complete instructions prior to installation and

operation of the unit.

2. Risk of electric shock.

3. The equipment in its installed state must not come in

close proximity to any heating sources, oils, steam,

caustic vapors or other unwanted process by products.

CAUTION :

1. This equipment, being built-in-type, normally becomes a

part of main control panel and in such case the terminals do

not remain accessible to the end user after installation

and internal wiring.

2. Conductors must not come in contact with the internal

circuitry of the equipment or else it may lead to a safety

hazard that may in turn endanger life or cause electrical

shock to the operator.

3. Circuit breaker or mains switch must be installed

between power source and supply terminals to facilitate

power 'ON' or ‘OFF’ function. However this switch or

breaker must be installed in a convenient position

normally accessible to the operator.

4.

5. The equipment shall not be installed in environmental

conditions other than those mentioned in this manual.

. The equipment does not have a built-in-type fuse.

Installation of external fuse of rating 275V AC / Amp for

electrical circuitry is highly recommended.

Before disconnecting the secondary of the external

current transformer from the equipment, make sure that

the current transformer is short circuited to avoid risk of

electrical shock and injury.

6

0.5

/ battery

INSTALLATION GUIDELINES

CAUTION :

For installing the meter

1. Prepare the panel cutout with proper dimensions as

shown below.

2. Push the meter into the panel cutout. Secure the meter

in its place by fitting the clamp on the rear side. Fit

clamps on both sides in diagonally opposite location for

optimum fitting.

3. For proper sealing, tighten the screws evenly with

required torque.

Terminal screw tightening torque :

0.68 N-m to 0.79 N-m ( 6.018 In-Lb to 6.992 In-Lb )

Screw clamp tightening torque : 0.1N-m (0.885 Lb-inch)

MECHANICAL INSTALLATION

7. Copper cable should be used.

(Stranded or Single core cable).

8. Before attempting work on device, ensure absence of

voltages using appropriate voltage detection device.

9. Recommended CT: Measuring type.

LISTED

R

All manuals and user guides at all-guidesbox.com