DT-E 5.8: ALUMINIUM CONSTRUCTION –PERGOLA SYSTEM SB400 (2020)

Edition 2 / June 2020 / EN strona 3 / 42

TABLE OF CONTENTS

1INTRODUCTION............................................................................................................................................................ 4

1.1 SAFETY GUIDELINES FOR THE PRODUCT................................................................................................................. 4

1.2 EXPLANATION OF SYMBOLS AND SIGNS ................................................................................................................. 4

1.3 TERMS AND DEFINITIONS ....................................................................................................................................... 5

1.4 SUBJECT, INTENDED USE AND CONTENTS OF THE DOCUMENTATION................................................................... 5

2PRODUCT TECHNICAL INFORMATION.......................................................................................................................... 7

2.1 TECHNICAL PARAMETERS: ...................................................................................................................................... 7

2.2 PRODUCT SPECIFICATION ....................................................................................................................................... 9

3TRANSPORT AND STORAGE OF THE PRODUCT .......................................................................................................... 10

3.1 COMPLETENESS AND QUALITY CONDITION OF DELIVERY .................................................................................... 10

3.2 GENERAL CONDITIONS FOR TRANSPORT AND STORAGE OF THE PRODUCT ........................................................ 10

3.3 OBLIGATORY DESCRIPTIONS TO BE PLACED ON THE PRODUCT PACKAGING ....................................................... 10

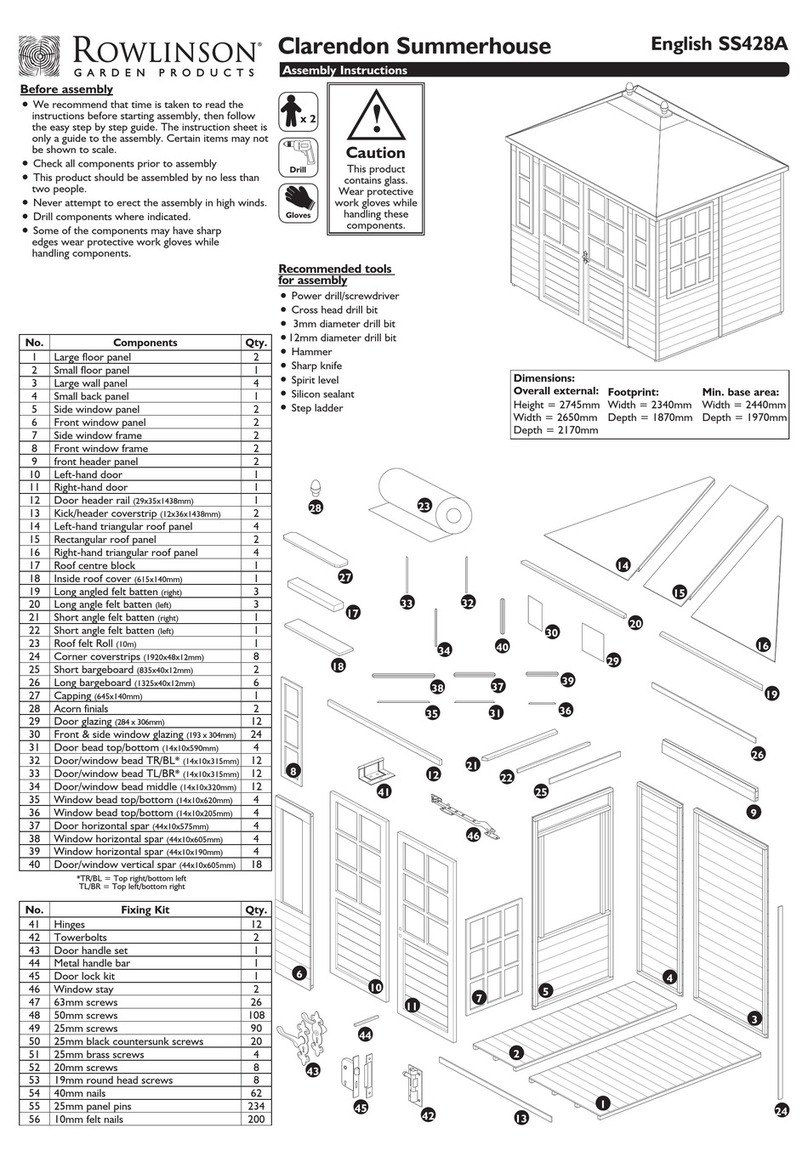

4PRODUCT INSTALLATION........................................................................................................................................... 11

4.1 GENERAL REQUIREMENTS FOR SAFE INSTALLATION ............................................................................................ 11

4.2 REQUIREMENTS FOR SAFE INSTALLATION OF THE PRODUCT AT HEIGHTS........................................................... 11

4.3 PREPARATION FOR INSTALLATION........................................................................................................................ 12

4.4 GENERAL GUIDELINES FOR PRODUCT INSTALLATION........................................................................................... 12

4.5 INSTALLATION TOOLS ........................................................................................................................................... 13

4.6 INSTALLATION....................................................................................................................................................... 14

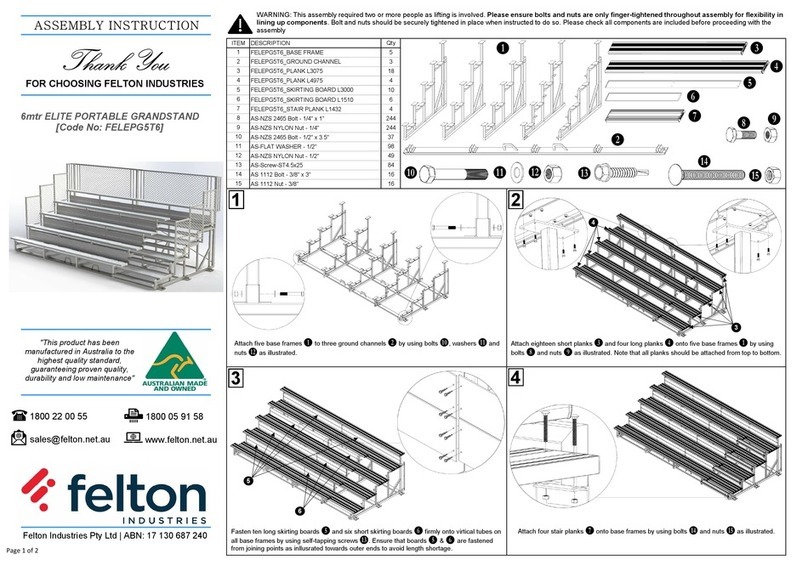

4.6.1 PERGOLA INSTALLATION .................................................................................................................................. 17

4.6.1.1 INSTALLATION OF THE SUPPORT STRUCTURE........................................................................................ 18

4.6.1.2 INSTALLATION OF THE GUTTERS ............................................................................................................ 21

4.6.1.3 INSTALLATION OF THE BLADES............................................................................................................... 23

4.6.1.4 INSTALLATION OF THE DRIVE ................................................................................................................. 25

4.6.2 WALL INSTALLATION ........................................................................................................................................ 27

4.6.2.1 WALL INSTALLATION REAR BEAM .......................................................................................................... 27

4.6.2.2 WALL INSTALLATION LENGTHWISE BEAM.............................................................................................. 28

4.7 ELECTRIC DRIVE..................................................................................................................................................... 30

4.7.1 CONNECTION TO ELECTRICAL INSTALLATION .................................................................................................. 30

4.7.2 START-UP AND ADJUSTMENT .......................................................................................................................... 31

5SYSTEM OPERATION AND PRODUCT SAFETY............................................................................................................. 32

5.1 GENERAL REQUIREMENTS FOR OCCUPATIONAL HEALTH AND SAFETY ................................................................ 32

5.2 SAFETY REQUIREMENTS RELATED TO SPECIAL CONDITIONS AND PLACES OF PRODUCT USE.............................. 32

5.3 OPERATIONAL SAFETY........................................................................................................................................... 33

5.4 CONNECTION TO ELECTRICAL INSTALLATION....................................................................................................... 34

5.5 CONTROL............................................................................................................................................................... 35

5.6 START-UP AND ADJUSTMENT ............................................................................................................................... 35

5.7 MISUSE OF THE SYSTEM........................................................................................................................................ 35

6SYSTEM USE AND MAINTENANCE.............................................................................................................................. 37

6.1 USING THE PRODUCT IN ACCORDANCE WITH ITS INTENDED USE........................................................................ 37

6.2 INSTRUCTION FOR NON-PROFEsSIONALS............................................................................................................. 37

6.3 TECHNICAL INSPECTIONS, MAINTENANCE AND REPAIR ....................................................................................... 37

6.3.1 BASIC OPERATIONS CARRIED OUT DURING PERIODIC INSPECTION................................................................. 38

6.3.2 REMARKS CONCERNING ROUTINE MAINTENANCE.......................................................................................... 38

6.4 MAINTENANCE OPERATIONS................................................................................................................................ 39

7GENERAL WARRANTY CONDITIONS........................................................................................................................... 39

7.1 wARRANTY EXCLUSIONS ....................................................................................................................................... 39

8COMPLAINT / TECHNICAL DEFECTS ........................................................................................................................... 40

8.1 COMPLAINTS......................................................................................................................................................... 40

8.2 TECHNICAL DEFECTS ............................................................................................................................................. 40

9PRODUCT DISASSEMBLY / UTILISATION / DISPOSAL.................................................................................................. 41

10 MARKING AND LABELLING THE PRODUCT WITH THE CE MARK ................................................................................ 42

10.1 PRODUCT COMPLIANCE WITH THE CE STANDARD ............................................................................................... 42

10.2 INFORMATION ACCOMPANYING THE CE MARKING ............................................................................................. 42