SELT V ZIIIP User manual

TECHNICAL AND OPERATIONAL DOCUMENTATION

INSTALLATION MANUAL,

OPERATING MANUAL AND INSTRUCTIONS FOR SAFE USE

(Translated from the original manual)

5. Steel and aluminium components and structural sets

5.7. Veranda V ZIIIP / Pergola V ZIIIP

5.7

DT-E

Translated from the original manual

DT-E 5.7: SYSTEM VERANDA V ZIIIP –SYSTEM PERGOLA V ZIIIP

Edition 3 / March 2021 / EN page 2 / 40

PRODUCT NAME:

VERANDA V ZIIIP

PERGOLA V ZIIIP

MARKING OF PRODUCT MANUFACTURER:

Manufacturer name:

SELT Sp. z o. o.

Manufacturer’s registered office:

45- 449 Opole, ul. Wschodnia 23A

Contact details:

Tel: +48 77 553 21 00 (secretariat)

Fax: +48 77 553 22 00

Website:

www.selt.com

E-mail:

PRODUCT SAFETY MARKING:

The product meets the CE safety requirements.

THIS TECHNICAL AND OPERATIONAL DOCUMENTATION:

Is valid from: 01 March 2021

Is applicable to the above listed product versions.

Translated from the original manual

DT-E 5.7: SYSTEM VERANDA V ZIIIP –SYSTEM PERGOLA V ZIIIP

Edition 3 / March 2021 / EN page 3 / 40

TABLE OF CONTENTS

1INTRODUCTION............................................................................................................................................................ 4

1.1 SAFETY GUIDELINES FOR THE PRODUCT................................................................................................................. 4

1.2 EXPLANATION OF SYMBOLS AND SIGNS ................................................................................................................. 4

1.3 TERMS AND DEFINITIONS ....................................................................................................................................... 5

1.4 SUBJECT, INTENDED USE AND CONTENTS OF THE DOCUMENTATION................................................................... 6

2PRODUCT TECHNICAL INFORMATION.......................................................................................................................... 7

2.1 TECHNICAL PARAMETERS: ...................................................................................................................................... 7

2.2 PRODUCT SPECIFICATION ..................................................................................................................................... 10

3TRANSPORT AND STORAGE OF THE PRODUCT.......................................................................................................... 11

3.1 COMPLETENESS AND QUALITY CONDITION OF THE DELIVERY ............................................................................. 11

3.2 GENERAL CONDITIONS FOR TRANSPORT AND STORAGE OF THE PRODUCT ........................................................ 11

3.3 OBLIGATORY DESCRIPTIONS TO BE PLACED ON THE PRODUCT PACKAGING ....................................................... 11

4PRODUCT INSTALLATION........................................................................................................................................... 12

4.1 GENERAL REQUIREMENTS FOR SAFE INSTALLATION ............................................................................................ 12

4.2 REQUIREMENTS FOR SAFE INSTALLATION OF THE PRODUCT AT HEIGHTS........................................................... 12

4.3 PREPARATION FOR INSTALLATION........................................................................................................................ 13

4.4 GENERAL GUIDELINES FOR PRODUCT INSTALLATION........................................................................................... 13

4.5 INSTALLATION TOOLS ........................................................................................................................................... 13

4.6 INSTALLATION....................................................................................................................................................... 13

4.6.1 BRACKETS –DIMENSIONS ................................................................................................................................ 14

4.6.2 INSTALLATION –VERSION WITH BRACKETS ..................................................................................................... 16

4.6.3 INSTALLATION - WALL VERSION (WITH FRONT POSTS)................................................................................... 23

4.7 ELECTRIC DRIVE..................................................................................................................................................... 30

4.7.1 CONNECTION TO ELECTRICAL INSTALLATION .................................................................................................. 30

4.7.2 START-UP AND ADJUSTMENT .......................................................................................................................... 30

5SYSTEM OPERATION AND PRODUCT SAFETY............................................................................................................. 31

5.1 GENERAL REQUIREMENTS FOR OCCUPATIONAL HEALTH AND SAFETY ................................................................ 31

5.2 SAFETY REQUIREMENTS RELATED TO SPECIAL CONDITIONS AND PLACES OF PRODUCT USE.............................. 31

5.3 OPERATIONAL SAFETY........................................................................................................................................... 31

5.4 MISUSE OF THE SYSTEM........................................................................................................................................ 32

6SYSTEM USE AND MAINTENANCE.............................................................................................................................. 33

6.1 USING THE PRODUCT IN ACCORDANCE WITH ITS INTENDED USE........................................................................ 33

6.2 INSTRUCTION FOR NON-PROFESSIONALS............................................................................................................. 34

6.3 TECHNICAL INSPECTIONS AND REPAIRS................................................................................................................ 34

6.3.1 BASIC ACTIVITIES PERFORMED DURING THE PERIODIC INSPECTION............................................................... 34

6.3.2 NOTES ON CURRENT MAINTENANCE............................................................................................................... 34

6.4 MAINTENANCE...................................................................................................................................................... 35

6.5 GENERAL PRODUCT INFORMATION...................................................................................................................... 36

7GENERAL WARRANTY CONDITIONS........................................................................................................................... 36

7.1 WARRANTY EXCLUSIONS ...................................................................................................................................... 36

8COMPLAINT / TECHNICAL DEFECTS ........................................................................................................................... 38

8.1 COMPLAINTS......................................................................................................................................................... 38

8.2 TECHNICAL DEFECTS ............................................................................................................................................. 38

9PRODUCT DISASSEMBLY / UTILISATION / DISPOSAL.................................................................................................. 38

10 MARKING AND LABELLING THE PRODUCT WITH THE CE MARK ................................................................................ 39

10.1 PRODUCT COMPLIANCE WITH THE CE STANDARD ............................................................................................... 39

10.2 INFORMATION ACCOMPANYING THE CE MARKING ............................................................................................. 39

Translated from the original manual

DT-E 5.7: SYSTEM VERANDA V ZIIIP –SYSTEM PERGOLA V ZIIIP

Edition 3 / March 2021 / EN page 4 / 40

1INTRODUCTION

1.1 SAFETY GUIDELINES FOR THE PRODUCT

The product has been manufactured in accordance with the latest technical knowledge in the field of construction and

manufacturing and meets the safety requirements in accordance with the following standards.

No.

Subject

European Legal Basis

Polish Legal Basis

1

External blinds and awnings.

Performance requirements

including safety

EN 13561:2015

PN-EN 13561:2015

2

Construction Products

Regulation (CPR)

Regulation No 305/2011 of the

European Parliament and of the

Council

Act of April 16, 2001 on building products

(Journal of Laws of 2020, item 215) as

amended

3

Essential requirements for the

machinery

Directive 2006/42/EC of the

European Parliament and of the

Council

Regulation of the Minister of Economy of

October 21, 2008 on the essential

requirements for machines (Journal of

Laws 2008 No. 199, item 1228) as

amended (Dz.U. Journal of Laws

2011.124)

Related documents: Declaration of Performance (external products), Declaration of Conformity and instructions for

installation, use of motors and control.

1.2 EXPLANATION OF SYMBOLS AND SIGNS

The following symbols (pictograms) indicate particularly important threats and safety information.

Pictogram

Pictogram meaning

Information

INFORMATION

Prior to using the product, its operating manual should be read.

Following the operating manual guarantees:

- failure-free use of the product,

- warranty coverage against product defects.

Keep the operating manual for safety of people.

INFORMATION

No harmful or dangerous consequences for people or facilities.

NOTE!

A situation likely to cause product damage or other damage.

No threat for people.

WARNING!

Threat of danger.

DANGER!

This symbol marks all safety information which, if not observed, could

endanger the life or health of persons. Health or life hazard. Risk: danger of

serious injury or death. Unsafe operation that may cause injury or damage to

the product.

WARNING!

Threat to human life or health due to electric shock.

ENVIRONMENT

Marking of electronic or electric equipment, which should be collected in the

designated points.

Translated from the original manual

DT-E 5.7: SYSTEM VERANDA V ZIIIP –SYSTEM PERGOLA V ZIIIP

Edition 3 / March 2021 / EN page 5 / 40

1.3 TERMS AND DEFINITIONS

For the purposes of this documentation the following terms and definitions shall apply:

Product: PERGOLA V ZIIIP

Product made of fabric/material, placed outside; above, in front of or within an opening in a building, or anywhere within

the outer surface of a building; extending in a horizontal and/or inclined and/or vertical plane, pulled in by rolling up the

fabric fixed to the front beam that is mounted with the side guiding beams (side guides). The possible movement of the

fabric - up - down (rolling up - unfolding) is carried out with the use of an electric drive. The product may have front

supports for guiding beams or mounting brackets. The structure of the product is offered in a standard colour from the RAL

palette after confirmation of their availability by the manufacturer. The product serves the function of a sun shading

system.

Fabric:

A part of the product made of fabric or other material that is set in motion by means of a control mechanism, ensuring that

the product fulfills its function. It acts as a sun shield.

Front supports:

A part of the product that serves as a support for the beams guiding the fabric (side guides).

Mounting brackets:

A part of the product that serves as a support for the side beams guiding the fabric, ensuring that the product fulfills its

function.

Guiding beams (side guides):

A part of the product connected to the cassette, acting as a fabric guide and including a fabric tensioning mechanism and

constituting a suspension for the beams supporting the fabric.

Cassette:

Oval-shaped part of the product, fixed to the ground or wall with brackets, or supported only on guiding beams (in the

version with mounting brackets).

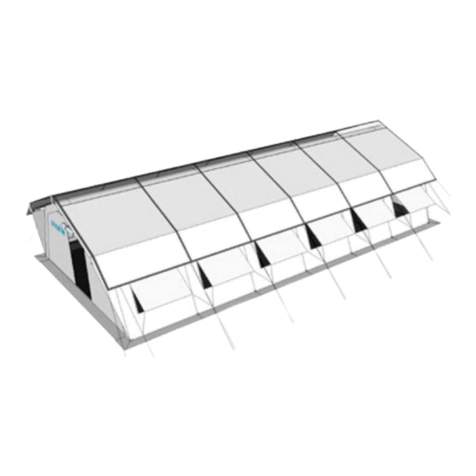

PRODUCT VERSIONS:

Veranda V ZIIIP single-module with mounting brackets –a sun protection system consisting of a cassette and two side

guides connected to it together with the fabric, supported on a load-bearing surface by means of mounting brackets

supporting the side guides and cassette mounting brackets, constituting one separate product.

Veranda V ZIIIP multi-module with mounting brackets –a sun protection system consisting of a structure of two or more

single-module veranda awnings joined together, supported on a load-bearing surface by means of common mounting

brackets supporting the side guides and independent cassette mounting brackets, consitutitng one joint product.

Pergola V ZIIIP single-module with front supports (TA - terrace awning) –a sun protection system consisting of a wall-

mounted structure including cassette and two side guides connected to it together with the fabric, supported on the load-

bearing surface only by the cassette mounting brackets and two front supports, constituting one separate product.

Pergola V ZIIIP multi-module with front supports (TA - terrace awning) –a sun protection system consisting of a wall-

mounted structure consisting of two or more single-module Pergolas V connected to each other, supported on the load-

bearing ground only by the cassette mounting brackets and common front supports.

Translated from the original manual

DT-E 5.7: SYSTEM VERANDA V ZIIIP –SYSTEM PERGOLA V ZIIIP

Edition 3 / March 2021 / EN page 6 / 40

1.4 SUBJECT, INTENDED USE AND CONTENTS OF THE DOCUMENTATION

This documentation covers the products manufactured by SELT Sp. z o.o.

This documentation applies to all types of PERGOLA V ZIIIP.

User’s manual and instructions for safe use, with motor manual, should be handed over to the end

user

IMPORTANT INSTRUCTION RELATED TO SAFETY

WARNING - IT IS VERY IMPORTANT TO PROCEED ACCORDING TO THIS MANUAL

TO ENSURE PEOPLE SAFETY.

KEEP THIS MANUAL

The documentation is valid together with the product-specific information available on the website

www.selt.com

This documentation contains:

important guidelines for installation, use and maintenance of the product,

important recommendations for storage and transport,

guidelines, which observance would ensure long-lasting and failure-free operation of the product.

SELT Sp. z o.o. shall not be responsible for damages resulting from non-observance of the recommendations included in

this documentation.

For further improvement of the product, SELT Sp. z o.o. reserves the right to introduce changes, which, while maintaining

significant technical parameters, will be considered as appropriate for increasing the quality of product operation and

safety of use.

Copyrights for this documentation remains with SELT Sp. z o.o. with its registered office in Opole. This documentation may

not be used in any way, either in whole or in part, without the permission of SELT Sp. z o. o.

Translated from the original manual

DT-E 5.7: SYSTEM VERANDA V ZIIIP –SYSTEM PERGOLA V ZIIIP

Edition 3 / March 2021 / EN page 7 / 40

2PRODUCT TECHNICAL INFORMATION

Technical specifications of the product are available after logging in on website www.selt.com

2.1 TECHNICAL PARAMETERS:

Veranda V ZIIIP - single-module veranda version with guide rail brackets

Translated from the original manual

DT-E 5.7: SYSTEM VERANDA V ZIIIP –SYSTEM PERGOLA V ZIIIP

Edition 3 / March 2021 / EN page 8 / 40

Pergola V ZIIIP –terrace awning version single-module with front posts

Translated from the original manual

DT-E 5.7: SYSTEM VERANDA V ZIIIP –SYSTEM PERGOLA V ZIIIP

Edition 3 / March 2021 / EN page 9 / 40

Pergola V ZIIIP

Module dimensions:

Width of single

module

Projection

Maximum

height of the

front posts

Tilt angle

adjustment

range –pergola

version

Tilt angle

adjustment range

- veranda version

Supporting structure

up to 5000

mm

up to 6000 mm

2450 mm

from 10° to 45°

from 0° to 45°

Axial spacing of mounting:

Cassette:

Guide rail

brackets:

Front

supports for

the guide

Support beams

Height of

mounting

brackets

Single

Modular

Maximum:

1600 mm

2870 mm

5700 mm

1900 mm

250

mm

200

mm

Scope of use / exploitation

Scope of use / exploitation

+5 to +40°C (opening / closing of the fabric)

- 30 to +50°C (supporting structure)

Air humidity

90% no steam condensation (opening / closing of the fabric)

to the full extent (supporting structure)

Fabric:

Serge 100 / Serge 600 –in accordance with the current price list

Fabric tensioning system:

Pneumatic: gas springs ST500 600N, jump 500mm, length 1075mm

Electric drive - motor with the following parameters

- supply voltage

230V/50Hz

- power

270 W

- power consumption

1,2 A

- protection level

IP 44

- torque

40 Nm

- rotation speed

17 rpm

- operating temperature

up -10 to +40°C

Technical data of electric motors

Drives (types of drives):

-remotely controlled electromechanical drive

Connection to the electrical system

Power cord fixed with a Hirschmann plug (not for Somfy IO)

Support beams:

Fabric supporting tubes from 1 to 2 pieces, depending on the size

Installation:

Application

External

Site installation

-Single or multi-module

-on mounting brackets to the load-bearing surface or on the cassette and front

supports

-To the ground or to the wall (structural element) and the ground

Translated from the original manual

DT-E 5.7: SYSTEM VERANDA V ZIIIP –SYSTEM PERGOLA V ZIIIP

Edition 3 / March 2021 / EN page 10 / 40

Detailed data for parameters of the individual motors are available on the websites of motor manufacturers and on the

website:

https://www.selt.com/automatyka-en

2.2 PRODUCT SPECIFICATION

Products manufactured by SELT Sp. z o. o. have appropriate technical and operational parameters.

List of product types:

Installed outside the building, started by electromechanical drive connected with the control system,

Single and multi-module versions connected in width direction,

wall-mounted version (with front supports) or self-supporting version (with mounting brackets).

They have the following features:

Electric movable roof.

Possibility of modular assembly.

They do not protect against rain and snow.

The system is not rainproof and should be rolled up when it rains.

It is forbidden to unroll the fabric during rain, snow or sub-zero temperatures.

They protect against excessive penetration of sunlight in their outline, protect surfaces against heating, thus

contributing to the improvement of thermal comfort in terms of their outline.

Includes a special fabric tensioning system provided by a belt and gas spring assembly.

Possibility of using mounting brackets and cassette mounting brackets or front supports and cassette mounting

brackets.

It is possible to set the inclination angle of the cover in the range of 10° to 45° (assembly with the use of front

supports) or from 0° to 45° - version (assembly on mounting brackets).

They do not emit toxic substances during operation.

Noise emission by a product with an electromechanical drive (associated with the working movement of moving

parts, produced by an electric motor during operation) is not considered a significant hazard and is a matter of

comfort.

Motors have cover protection degree not worse than IP 44.

The construction of the product and the drive allows for safe stopping of the movable roof cover in any position

within the working area and remaining there in a state of rest.

The movement of the movable roof (rolling up and unfolding) can be activated by a manual switch or remotely

controlled.

Covers of moving parts have been designed and made in a way that ensures safety for the operators, assuming

that they are properly operated.

Note:

Deflection/sagging of the fabric does not cause incorrect operation of the system and is not a defect of

the product.

Translated from the original manual

DT-E 5.7: SYSTEM VERANDA V ZIIIP –SYSTEM PERGOLA V ZIIIP

Edition 3 / March 2021 / EN page 11 / 40

3TRANSPORT AND STORAGE OF THE PRODUCT

3.1 COMPLETENESS AND QUALITY CONDITION OF THE DELIVERY

SELT Sp. z o. o. makes every effort to ensure compliance of the goods with the order. However, checking the completeness

of the product is the responsibility of the Buyer and should take place at the time of its receipt. Discrepancies should be

immediately reported to the driver/warehouseman/assembly team and marked on the WZ document under pain of loss of

claims in this respect. Checking the quality in terms of obvious defects is the responsibility of the Buyer and should take

place at the time of receipt of the goods. Apparent defects are mechanical damage, scratches, cracks, etc. Quantitative

discrepancies and possible replacement of parts with obvious defects SELT Sp. z o. o. undertakes to complete or replace it in

the shortest possible time.

3.2 GENERAL CONDITIONS FOR TRANSPORT AND STORAGE OF THE PRODUCT

List:

the product is factory packed in cardboard packaging protecting against damage during storage, during transport

and during relocation to the final installation location,

products for transport/storage should be set in accordance with the arrows indicated on the product packaging,

do not stack the products in more than two (2) layers because the packing material can be crushed, what in turn

may lead to permanent damage to the product,

products places on means of transport should be protected against relocation and damage during the transport

(e.g. with distance pieces, protecting belts etc.),

during transport the product should be protected against rain or snow,

storage locations should be dry, well-ventilated and protected against harmful impact of the weather

(sun, rain, etc.)

moving the product to the place of its assembly should be carried out in accordance with the applicable

Health and Safety regulations applicable to the place of assembly.

3.3 OBLIGATORY DESCRIPTIONS TO BE PLACED ON THE PRODUCT PACKAGING

Prior to installation and use of the product please read carefully the operation and maintenance

manual available at the following website https://www.selt.com/dte-en

Translated from the original manual

DT-E 5.7: SYSTEM VERANDA V ZIIIP –SYSTEM PERGOLA V ZIIIP

Edition 3 / March 2021 / EN page 12 / 40

4PRODUCT INSTALLATION

This chapter contains general requirements concerning the product installation.

Correct assembly is a necessary condition for smooth operation of the product.

SELT Sp. o.o. recommends using only professional assembly crews, which guarantee the Purchaser that the conducted

installation will be correct.

4.1 GENERAL REQUIREMENTS FOR SAFE INSTALLATION

it is necessary to observe general rules of good building practice,

it is necessary to comply with applicable Occupational Health and Safety regulations concerning in particular

those applying to the safety of operation of electrical equipment and work on heights,

the product must be fixed mechanically (foams, adhesives or similar materials are not allowed as fastening

materials),

the base to which the product brackets and/or front supports will be attached should be a load-bearing structure

(concrete, brick, etc.),

in the case of metal structures joined together in accordance with the applicable rules for joining metals, the

assembly is made to materials with the appropriate wall thickness,

before commencing installation, remove all unnecessary electrical wires from the installation area.

Information table

The manufacturer allows the installation of the product in the following types of substrate (wall bearing layer):

- reinforced or unreinforced concrete, class at least C20/25, non-cracked,

- concrete specified above having a layer of insulation with a thickness of up to 25 cm,

- wall at least 24 cm, of Mz solid bricks, NF format, with a strength of at least 20 MPa and a density of >1.8 kg/dm3

based on M2.5 - M9 mortar,

- wall at least 24 cm, of silicate blocks with a strength of at least 10 MPa and a density of >2 kg/dm3 based on M2.5 -

M9 mortar,

- wall at least 17.5 cm, of silicate perforated blocks with a strength of at least 20 MPa and a density of >1.8 kg/dm3

based on M2.5 - M9 mortar,

- wooden (wall/ceiling) beams, class of at least C24, without cracks, with a thickness of at least 100 mm,

- wooden rafters, class of at least C24, without cracks, with a thickness of at least 70 mm,

- walls made of silicate blocks (full or hollow) with a layer of insulation –to be consulted with an authorised designer,

- solid brick walls with a layer of insulation - to be consulted with an authorised designer,

- wall made of cavity ceramic hollow bricks without insulation or with a layer of insulation - to be consulted with an

authorised designe,

- autoclaved aerated concrete blocks - this substrate is not recommended.

The above list of substrates is only indicative. Each substrate suitability depends on the specific location and size of the

product, and must be selected by an authorized constructor.

4.2 REQUIREMENTS FOR SAFE INSTALLATION OF THE PRODUCT AT HEIGHTS

Product installation, due to a necessity of execution of works on heights, is classified to the particularly

hazardous works because it causes high risk of occurrence of threats for human health and safety - in

particular in case of fall from heights.

It is the Buyer's responsibility to ensure that a health and safety plan is developed during installation.

Translated from the original manual

DT-E 5.7: SYSTEM VERANDA V ZIIIP –SYSTEM PERGOLA V ZIIIP

Edition 3 / March 2021 / EN page 13 / 40

4.3 PREPARATION FOR INSTALLATION

unpack the product and check if there are all components necessary for assembling,

prior to installation you should check whether the substrate has sufficient load capacity allowing safe assembly

and operation.

Note: Purchase and selection of the screws, pins and bolts connecting the system with the facility

structure should be done by installer or investor.

4.4 GENERAL GUIDELINES FOR PRODUCT INSTALLATION

System/brackets are attached to the structure using appropriately selected assembly products (they are not

included with the product),

The product should be protected against dirt (e.g. mortar, mounting foam, silicone) as it may damage it,

If it is necessary to use polyurethane foam, silicone or other agents, it is absolutely necessary to follow the

manufacturer's instructions on the packaging.

Incorrect assembly can lead to dangerous situations for the user.

4.5 INSTALLATION TOOLS

List:

Phillips screwdriver

set of Allen keys

socket wrench

drill

tape measure

spirit level

two ladders

At least 3 people are required for assembly.

4.6 INSTALLATION

Instructions for assembly, operation and safe use are available after logging in on the website www.selt.com

Note: Before proceeding with the assembly, it is necessary to verify the visual condition of the packaging of the

elements delivered for assembly, the visual condition of the elements and their completeness. The carrier is

responsible for damage caused in transit.

For the installation of Pergola V ZIIIP, we distinguish four installations for different types of the product:

veranda awning with mounting brackets for guides and cassettes,

veranda awning in the wall version, with front posts,

modular assembly using a common guide bracket,

modular assembly using a common modular post.

NOTE: For threaded connections during assembly, use an anaerobic locking agent such as LOCTITE® 243 or

another with the same properties.

Translated from the original manual

DT-E 5.7: SYSTEM VERANDA V ZIIIP –SYSTEM PERGOLA V ZIIIP

Edition 3 / March 2021 / EN page 14 / 40

4.6.1 BRACKETS –DIMENSIONS

1. Vertical cassette bracket

2. Horizontal cassette bracket

3. Guide rail bracket (Type A)

4. Transverse guide rail bracket (Type D)

Translated from the original manual

DT-E 5.7: SYSTEM VERANDA V ZIIIP –SYSTEM PERGOLA V ZIIIP

Edition 3 / March 2021 / EN page 15 / 40

5. Rotatable guide rail bracket (Type B)

Note: The bracket can be used for max. 19,5 m2 of

cover area.

6. Modular guide rail bracket (Type C)

7. Modular transverse guide rail bracket (Type G)

Translated from the original manual

DT-E 5.7: SYSTEM VERANDA V ZIIIP –SYSTEM PERGOLA V ZIIIP

Edition 3 / March 2021 / EN page 16 / 40

4.6.2 INSTALLATION –VERSION WITH BRACKETS

Perform steps 1 to 4 for mounting using cassette brackets.

1. Measure and drill the mounting holes for the

cassette mounting (1). Dimension "A" should be

selected according to the used mounting brackets.

The spacing and number of brackets is closely

related to the width of the system.

NOTE: The brackets must not overlap the

drainage holes in the cassette!

Fig. 1

2. Install the cassette mounting brackets (1) with an

anchoring product matched to the substrate.

X –cassette mounting spacing (max. 1600 mm)

Fig. 2

3. Install the complete cassette (2) on the cassette

mounting brackets (1) in the direction of the

arrow.

Fig. 3

Translated from the original manual

DT-E 5.7: SYSTEM VERANDA V ZIIIP –SYSTEM PERGOLA V ZIIIP

Edition 3 / March 2021 / EN page 17 / 40

4. Tighten the supplied screws (3) M6 DIN 7984 to

the mounting plate (4).

Do this for all cassette brackets.

Fig. 4

5. Remove the (5) M5 ISO-10642 and (6) M6 ISO-

4762 screws. Perform the steps for both sides of

the cassette.

Fig. 5

6. Open the revision (8), then remove the upper

side of the cassette (9). After removing the

element (9) lower the revision (8) on the

stiffening of the cassette (7).

Fig. 6

7. Slide the guide rail (10) onto the two brackets

(11) located at the end and the beginning of the

guide. Slide the guide onto the U-shaped fork of

the cassette (see Fig. 6) and onto the rollers of

the front beam (12).

Repeat the steps for the other guides.

Fig. 7

Note: for modular assembly, use modular rail brackets (12) - as shown in the picture:

Translated from the original manual

DT-E 5.7: SYSTEM VERANDA V ZIIIP –SYSTEM PERGOLA V ZIIIP

Edition 3 / March 2021 / EN page 18 / 40

Fig. 8

8. Set both guides (10) parallel to each other. Measure the distances at the start and end of the guide rail (B1 and B2) along

with measuring the diagonals (A1, A2). The condition for correct installation is the dimensional compliance between

diagonals A1=A2 and dimensions B1=B2. In case of discrepancies, go back to point 7 and re-establish the guide brackets.

9. Mark the holes of the brackets (11). Dismantle the

guide with the brackets and determine the center

line "C" for mounting the brackets (11) - for both

guides.

Fig. 9

10. Drill the holes and install the guide brackets in the

designated places. Repeat the operation for the

second guide.

NOTE: the number of brackets is closely related

to the projection of the system - the drawing

shows the approximate spacing and quantity.

Fig. 10

Translated from the original manual

DT-E 5.7: SYSTEM VERANDA V ZIIIP –SYSTEM PERGOLA V ZIIIP

Edition 3 / March 2021 / EN page 19 / 40

11. NOTE: When using a rotatable bracket (type

B), the bracket should be set in such a way

that the side of the bracket with the

securing screw is on the outside of the

system as shown in the picture on the right.

Fig. 11

12. Slide the guide (10) onto the brackets (11),

then onto the C-shaped fork of the cassette

(see Fig. 6) and onto the rollers of the front

beam (12). Slide the ZIIIP fabric zipper into the

guiding profile (13) in the guide (10).

Repeat the steps for both guides.

Fig. 12

Translated from the original manual

DT-E 5.7: SYSTEM VERANDA V ZIIIP –SYSTEM PERGOLA V ZIIIP

Edition 3 / March 2021 / EN page 20 / 40

Fig. 13

13. Set both guides (10) parallel to each other. Measure the distances at the start and end of the guide rail (B1 and B2) along

with measuring the diagonals (A1, A2). The condition for correct installation is the dimensional compliance between

diagonals A1=A2 and dimensions B1=B2. In case of discrepancies, go back to step 7 and re-position the guide brackets.

Fig.14

14. Tighten the jaws of the guide rail brackets (11) with the screws (14) M8 ISO-4762. Additionally, tighten the guides to the

side of the cassette (17) with screws (16) M5x10 ISO-10642. Repeat the steps in the same way for the remaining guides.

Table of contents

Other SELT Tent manuals

Popular Tent manuals by other brands

Let's Go Aero

Let's Go Aero Tentris TreeHaus TRE-07 owner's manual

Cabela's

Cabela's ULTIMATE ALAKNAK 51-9278 GEAR GUIDE

NRS Relief

NRS Relief HuggyPRO 72 m2 Assembly manual

Elk Mountain Tents

Elk Mountain Tents YUKON BELL TENT instructions

Idena

Idena 7570010 Assembly instructions

skandika outdoor

skandika outdoor COPENHAGEN 8 Setup Instruction