Sendoline Endo Motor User manual

EN

Contents

1Product introduction ............................................................................. 1

2Installation............................................................................................ 5

3Function and operation of product.......................................................12

4Operation instruction ...........................................................................15

5Troubleshooting...................................................................................30

6Cleaning, Disinfection and Sterilization ..............................................31

7Storage, maintenance and transportation.............................................40

8Environmental protection....................................................................41

9After service ........................................................................................41

10 European authorized representative...................................................41

11 Symbol instruction.............................................................................41

12 Statement...........................................................................................41

13 EMC-Declaration of conformity .......................................................42

1

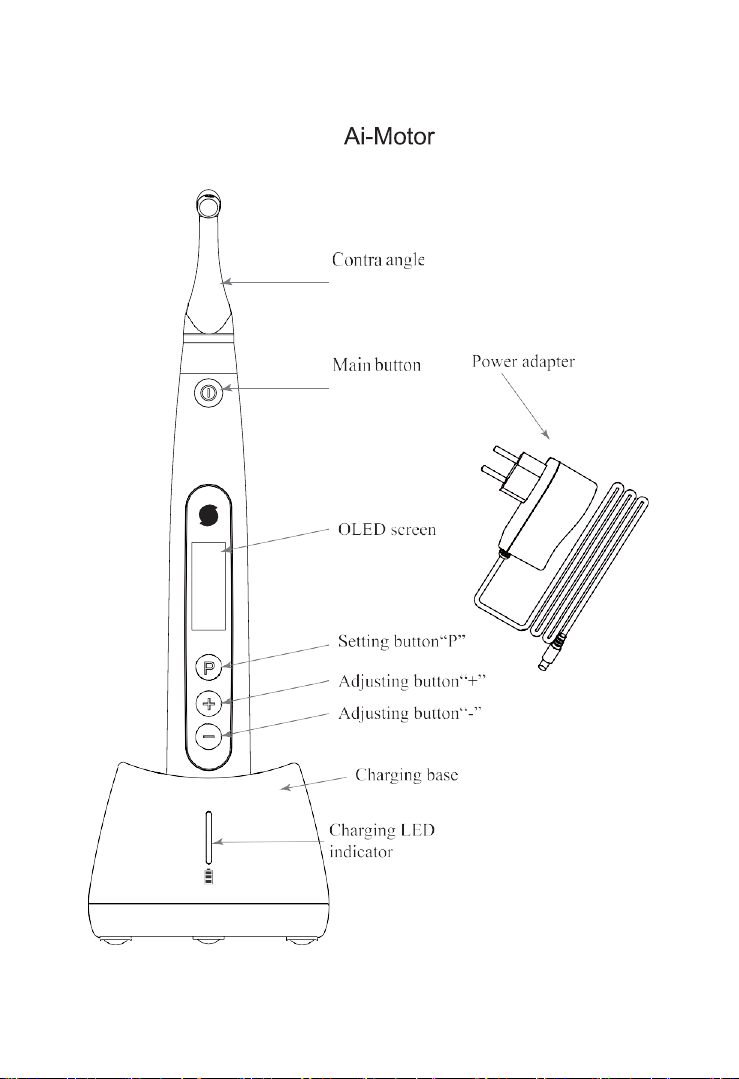

1Product introduction

1.1 Preface

Guilin Woodpecker Medical Instrument Co., Ltd is a professional

manufacturer researching, developing, and producing dental products.

Woodpecker owns a sound quality control system. Guilin Woodpecker

Medical Instrument Co., Ltd has two brands, Woodpecker and DTE.Its

main products include Ultrasonic Scaler, Curing light, Apex locator,

Ultrasurgery, Endo Motor, etc.

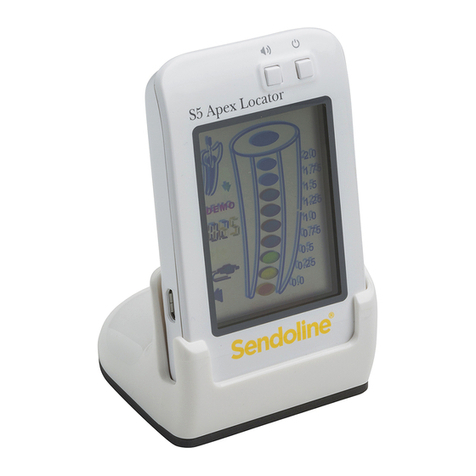

1.2 Product description

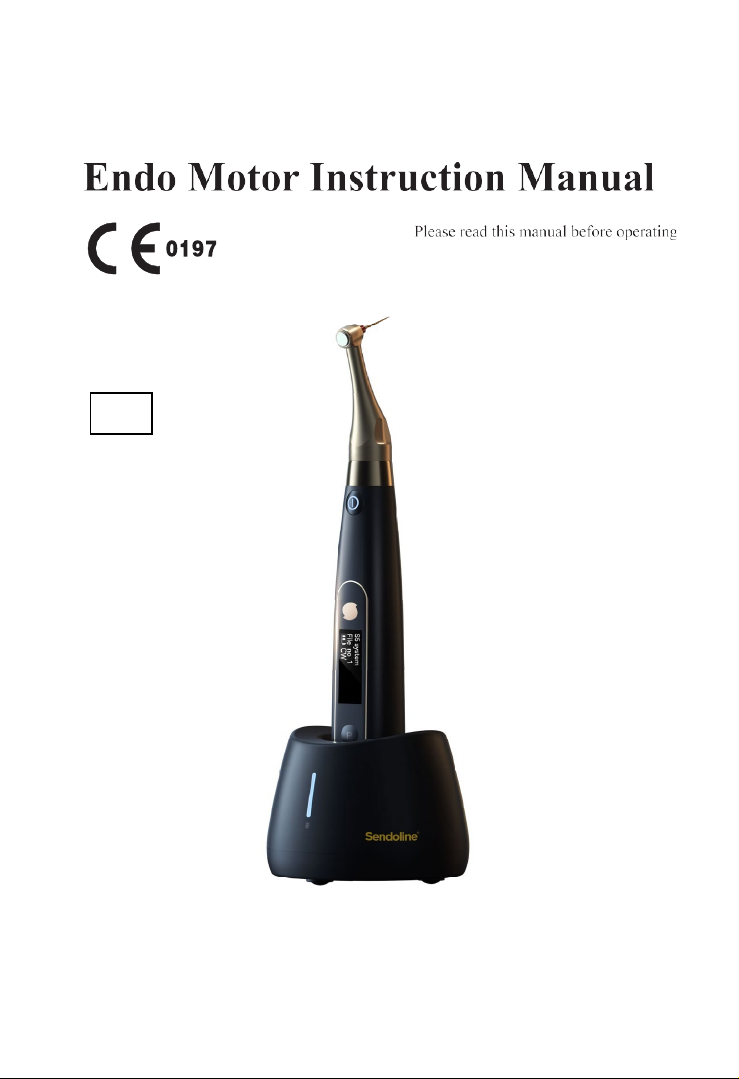

Endo Motor (mode :Ai-Motor) is mainly used in Endodontic

treatment. It is a cordless endo motor with root canal measurement

capability. It can be used as an endo motor for preparation and

enlargement of root canals, or device for measuring canal length. It can

be used to enlarge the canals while monitoring the position of the file tip

inside the canal.

Features:

a) Efficient brushless motor, low noise, long service life.

b) Cordless portable endo motor with combined length determination.

c) 360 degrees rotation of contra angle.

d) Adopt real-time feedback technology and dynamic torque control,

effectively preventing file separation.

1.3 Model and specification

Ai-Motor

1.4 Performance and composition

The device is composed of charging base, motor handpiece, contra

angle, measuring wire, lip hook, file clip, power adapter, protectivesilicon

cover, etc.

2

3

1.5 Indications for Use

Endo Motor, Ai-Motor is cordless endodontic treatment motorized

handpiece with root canal measurement capability. It can be used for

preparation and enlargement of root canals, or measuring the canal length.

And it can be used to enlarge the canals while monitoring the position

of the file tip inside the canal.

1.6 Scope of application

The device must be operated in hospital and clinic by the qualified

dentists.

1.7 Caution

Federal law restricts this device to sale by or on the order of a

dentists.

1.8 Contraindication

a) The doctor with a pacemaker is disabled.

b) Do not use on patients with cardiac pacemakers.

c) Hemophilia patients are banned.

d) Use with caution in patients with heart disease, pregnant women

and young children.

1.9 Warnings

1.9.1 Please carefully read this Instruction Manual before first

operation.

1.9.2 This device should be operated by professional and qualified

dentist in qualified hospital or clinic.

1.9.3 Do not directly or indirectly place this device near heat source.

Operate and store this device in reliable environment.

1.9.4 This device requires special precautions regarding

electromagnetic compatibility (EMC) and must be in strict accordance

with the EMC information for installation and use. Do not use this

equipment especially in the vicinity of fluorescent lamps, radio

transmitting devices, remote control devices, handheld and mobile high-

frequency communication devices.

1.9.5 Please use the original contra angle. Otherwise it will not be used

or cause adverse consequences.

1.9.6 Please do not make any changes to the device. Any changes may

violate safety regulations, causing harm to the patient.

4

1.9.7 Please use original power adapter. Other power adapter will

result in damage to lithium battery and control circuit.

1.9.8 The motor handpiece cannot be autoclaved. Use disinfectant of

neutral pH value or ethyl alcohol to wipe its surface.

1.9.9 Before the contra angle stopping rotating, do not press the push

cover of contra angle. Otherwise the contra angle will be broken.

1.9.10 Before the motor handpiece stopping rotating, do not remove

the contra angle. Otherwise the contra angle and the gear inside motor

handpiece will be broken.

1.9.11 Please confirm whether the file is well installed and locked

before starting the motor handpiece.

1.9.12 Please set torque and speed as per the recommended

specifications of file manufacturer.

1.9.13 Error in replacing lithium batteries can lead to unacceptable

risks, so use the original lithium battery and replace the lithium battery

according to the correct steps in the instructions.

1.9.14 Please remove the battery if the motor handpiece is not likely

to be used for some time.

1.9.15 Charging the wireless handpiece will generate heat, and the

surface temperature of charging base and motor handpiece will rise. It is

recommended that the time of contacting motor handpiece and charging

base during wireless charging should not exceed 10 seconds (only for Ai-

Motor).

1.10 Device safety classification

1.10.1 Type of operation mode: Continuous operating device

1.10.2 Type of protection against electric shock: Class II equipment

with internal power supply

1.10.3 Degree of protection against electric shock: B type applied

part

1.10.4 Degree of protection against harmful ingress of water:

Ordinary equipment (IPX0)

1.10.5 Degree of safety application in the presence of a flammable

anesthetic mixture with air, oxygen, or nitrous oxide: Equipment cannot

be used in the presence of a flammable anesthetic mixture with air,

oxygen, or nitrous oxide.

1.10.6 Applied part: contra angle, lip hook, file clip, touch probe.

1.10.7 The contact duration of applied part: 1 to 10 minutes.

1.10.8 The temperature of the surface of applied part may reach

46.6℃.

5

1.11 Primary technical specifications

1.11.1 Battery

Lithium battery in motor handpiece: 3.7V /2000mAh

1.11.2 Power adapter (Model: ADS-6AM-06N 05050/UE08WCP-

050100SPA)

Input: ~100V-240V 50Hz/60Hz 0.4A Max

Output: 5.0V 1A

1.11.3 Torque rang: 0.4Ncm-5.0Ncm(4mNm ~ 50mNm)

1.11.4 Speed rang: 100rpm~1800rpm

1.11.5Wireless charging (only for Ai-Motor)

Frequency range: 112-205KHz

Maximum RF output power of the product: 9.46dBuA/m@3m

1.12 Environment parameters

1.12.1 Environment temperature: +5℃ ~ +40℃

1.12.2 Relative humidity: 30% ~ 75%

1.12.3 Atmospheric pressure: 70kPa ~ 106kPa

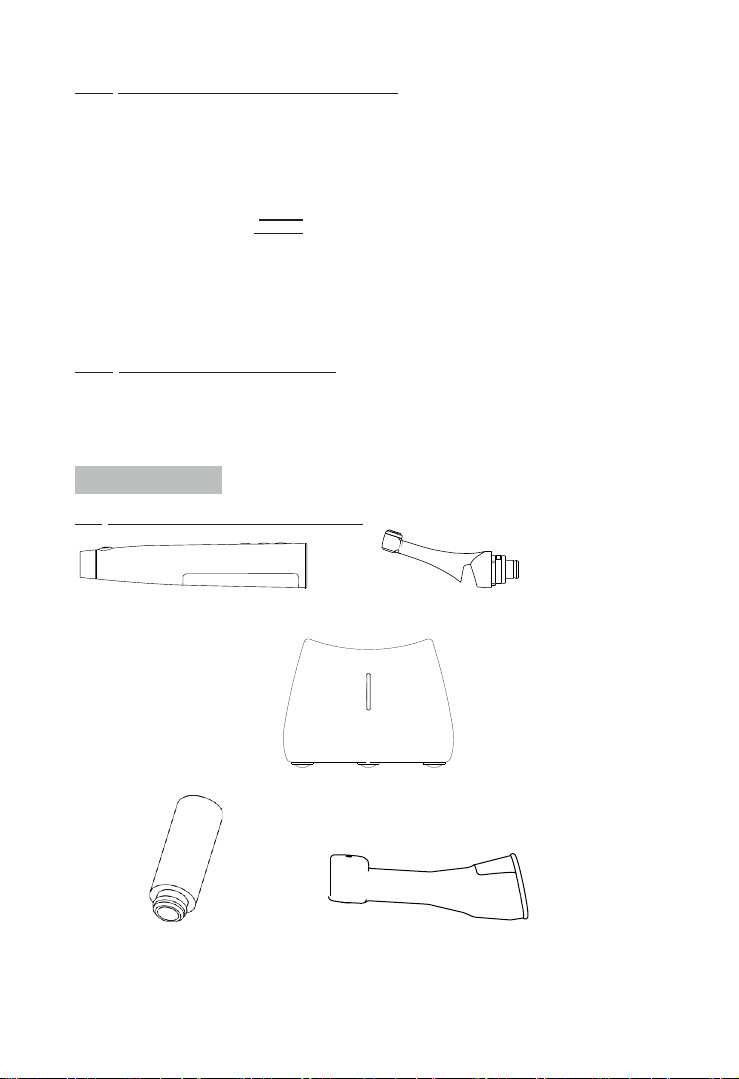

2Installation

2.1 Basic accessories of product

Motor handpiece Contra angle

Ai-Motor Charging base

Nozzle Protective silicon cover

6

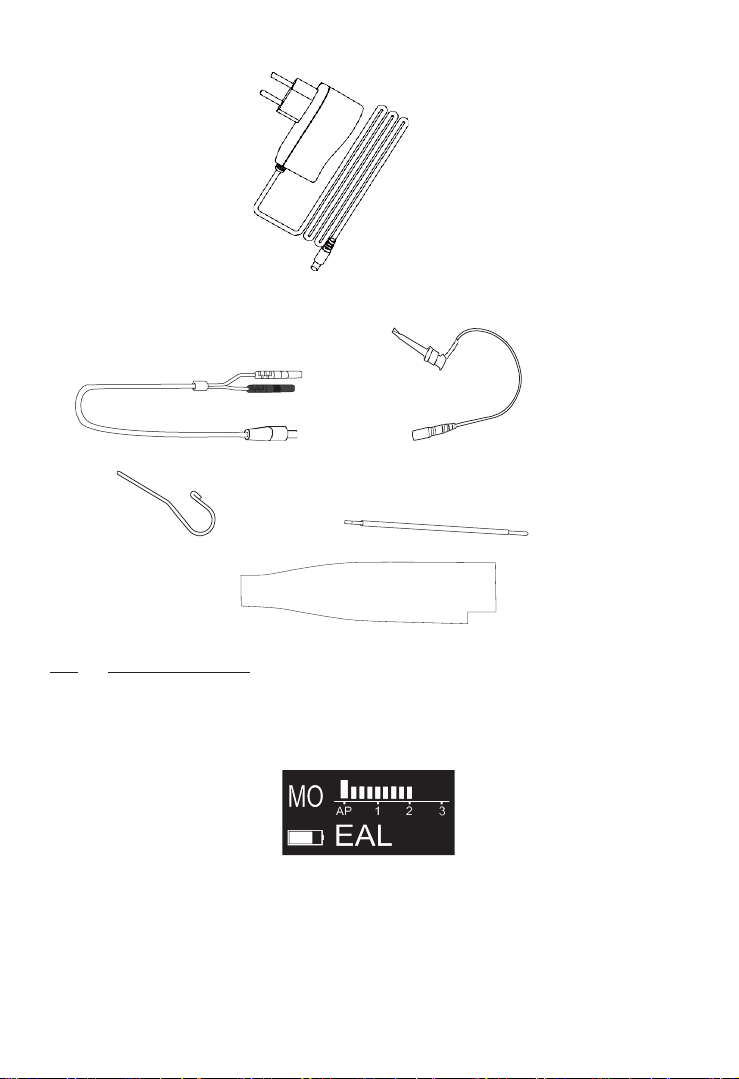

Power adapter

Measuring wire File clip

Lip hook Touch probe

Disposable insulation sleeves

2.2 Display Screens

2.2.1 Display Screens for 6 Operation Modes and Standby

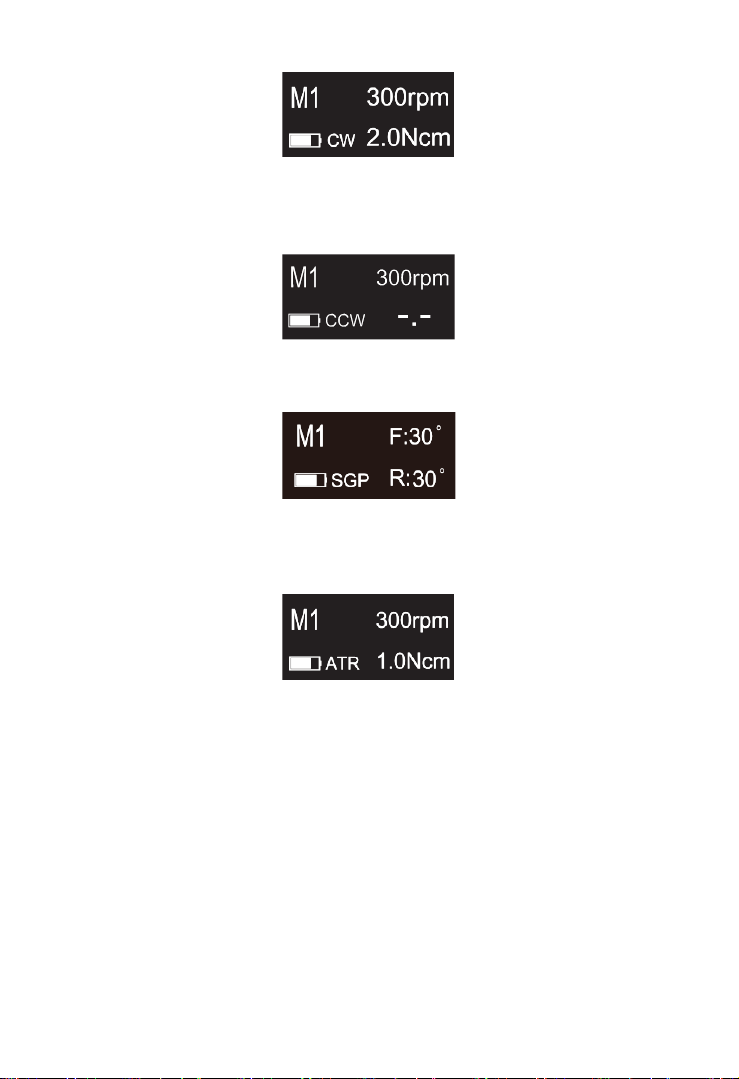

2.2.1.1 EAL Mode

This mode is for canal measurement. The motor handpiece does not

run in this mode.

2.2.1.2 CW Mode

The motor handpiece rotates forward 360º, clockwise direction.

7

2.2.1.3 CCW Mode

The motor handpiece rotates counterclockwise direction only. This

mode is used to inject calcium hydroxide and other medicant. When this

mode is being used, a double-beep sounds continuously.

2.2.1.4 SGP Mode

Safety Glide Path Mode

F: Forward angle, R: Reverse angle

The rotation angle is adjustable, but the forward angle must be equal

to the reverse angle.

2.2.1.5 ATR Mode

ATR: Adaptive Torque Reverse function.

During continuous rotation movement, when torque resistance of the

instrument is higher than the pre-set torque limit the instrument will rotate

counter clockwise

2.2.2 Torque Display

This appears when the motor is running. Meter shows the torque load

on the file.

8

2.2.3 Canal Measurement Display

This appears when a file is inside the canal and the lip hook is

contacting the patient mouth. Bars in meter show the location of the file

tip. In the EAL Mode, If the length is less than 1.0, the display will be

enlarged.

The meter numbers 1.0, 2.0, 3.0 and digital numbers 00-16 do not

represent the actual length from the apical foramen. It simply indicates the

file progression towards the apex. The digital numbers -1 and -2 indicate

that the file has passed the apex foramen. The digital number “00”indicate

that the file has reached the apex foramen. Subtract 0.5-1mm from the

measured file length as the working length. These numbers are used to

estimate the canal’s working length.

2.3 Instructions for contra angle

2.3.1 The contra angle adopts precision gear transmission, and the

transmission ratio is 6:1.

2.3.2 Before the first use and after treatments, please clean and

disinfect contra angle with disinfectant of neutral PH value. After

disinfection, lubricate it with specific cleaning oil. Finally, sterilizeit

under high temperature and high pressure (134℃, 2.0bar~2.3bar

(0.20MPa~0.23MPa)).

2.3.3 The contra angle can only be used cooperatively with thisdevice.

Otherwise the contra angle will be damaged.

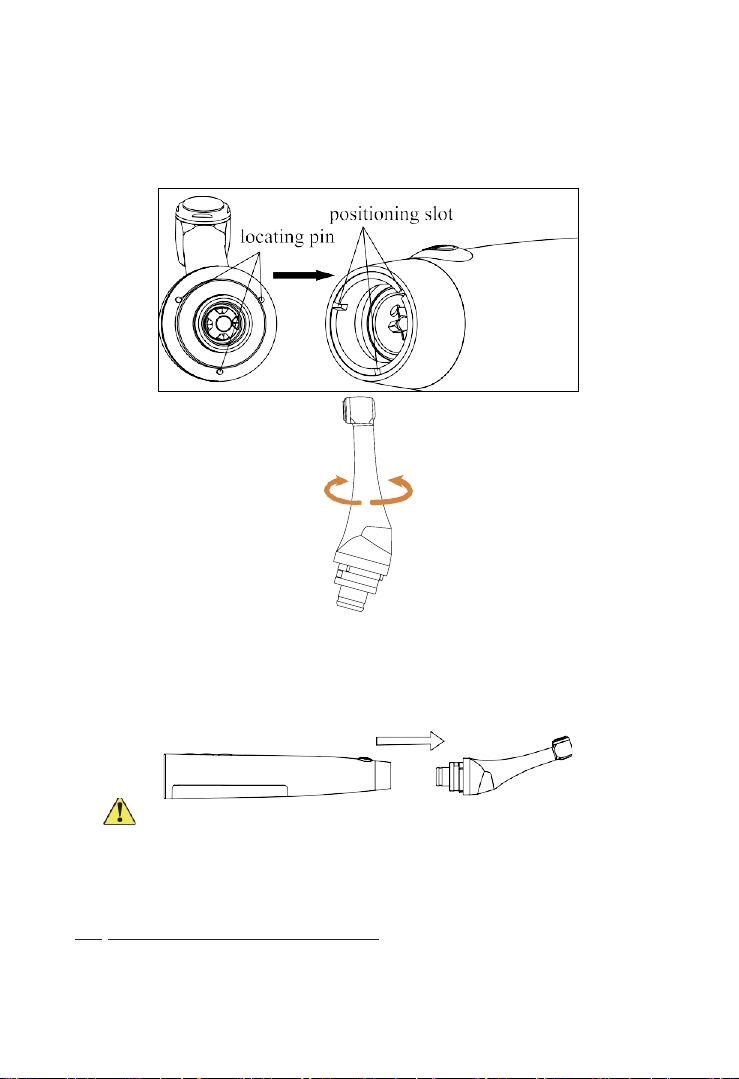

2.4 Installation and removal of contra angle.

2.4.1 Installation

9

Align any locating pin of the contra-angle with the positioning slot

on the motor handpiece and push the contra-angle horizontally. The three

locating pins on the contra-angle are inserted into those three positioning

holes on the motor handpiece. A “click” sound indicates that the

installation is in place. The contra-angle can be rotated 360° freely.

The contra-angle is free to rotate, adapting to the root canal of different

positions, and it is convenient to watch the screen when operating.

2.4.2 Removal

Pull out the contra angle horizontally when the motor handpiece does

not run.

Warnings:

a) Before plugging in or pulling out contra angle, please first stop the

motor handpiece.

b) After installation, please check and confirm that the contra angle

has been well installed.

2.5 Installation and removal of file

2.5.1 Installation of file

10

Before starting the device, plug the file into the hole of contra angle

head.

Hold down the push button on the contra angle and insert the file. Turn

the file back and forth until it is lined up with interior latch groove and

slips into place. Release the button to lock the file into the contra angle.

Warnings:

After plugging the file into contra angle, let go the hand on push

cover to assure that the file cannot be taken out.

Be careful when inserting files to avoid injury to fingers.

Inserting and removing files without holding the push button may

damage the chuck of contra angle.

Please use files with shanks meet the ISO standard. (ISO standard:

Ø2.334 – 2.350 mm)

2.5.2 Removal of file

Pressing the push cover, and then directly pull out the file.

Warnings:

Before plugging and pulling out the file, the motor handpiece must be

stopped.

Be careful when removing files to avoid injury to fingers.

Removing files without holding the push button will damage the

11

chuck of contra angle.

2.6 Canal measurement functional connection

This is not required if the canal measurement function will not be used.

Connect the measuring wire to the motor handpiece. Line up the

measuring wire plug with the notch on the back of the motor and push it

all the way in.

Connect the file clip plug into the socket (black) on the measuring

wire. Connect the lip hook to the socket (white) on the measuring wire.

Warnings:

Connect the lip hook to the socket (white) on the measuring wire.

Otherwise, the function of root canal preparation and root canal length

measurement cannot be used together.

2.7 Installation and removal of disposable insulation sleeves

12

2.7.1 Installation

Before each use of the handpiece and after the handpiece is cleaned

and disinfected,put on a disposable insulating sleeve. Take the insulating

sleeve out of the insulating sleeve box, then insert the insulating sleeve

into the motor handpiece from the thin end of the handpiece and install the

insulating sleeve until there is no obvious wrinkle.

After installing the disposable insulating sleeve, wrap the barrier film

around the handpiece surface. After that, clean and disinfect the surface of

the handpiece. Refer to Chapter 6.3 for cleaning and disinfection

procedures.

2.7.2 Removing

After each use, remove the barrier film and slowly pull the isolation

sleeve from the thin end of the handpiece.

Warming: Insulating sleeves are not reusable

3Function and operation of product

3.1 Button definition and settings

a. Turn power on

Press Main button to turn on motor handpiece.

b. Turn power off

Hold down the setting button “P”, then press Main button to turn off

motor handpiece.

c. Customized program change

Press Adjusting button “+”/“-” during standby sate.

d. Parameter setting

Press Setting button “P” till target parameters, press Adjusting button

“+”/“-” to change, then press Main button or wait 5 seconds to confirm.

e. Preset program selection

Long press Setting button “P” to entry preset program during standby

state, press Adjusting button “+”/“-” to select file system , press Setting

button “P” to entry select file number, press Adjusting button “+”/“-” to

select file number, then press Main button to confirm.

13

f. Handpiece functions setting

With the motor handpiece turned off, hold down the Setting button “P”

and press Main button to entry handpiece functions setting, press Setting

button “P” till target setting, press Adjusting button “+”/“-” to adjust, then

press Main button to confirm.

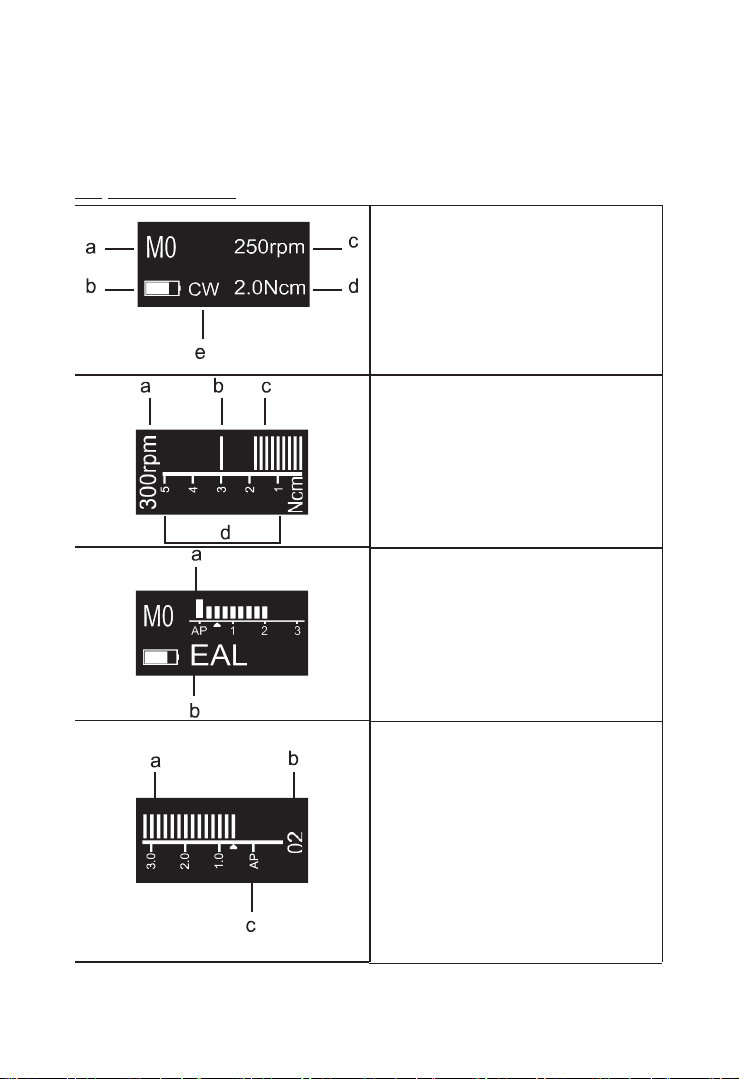

3.2 Screen display

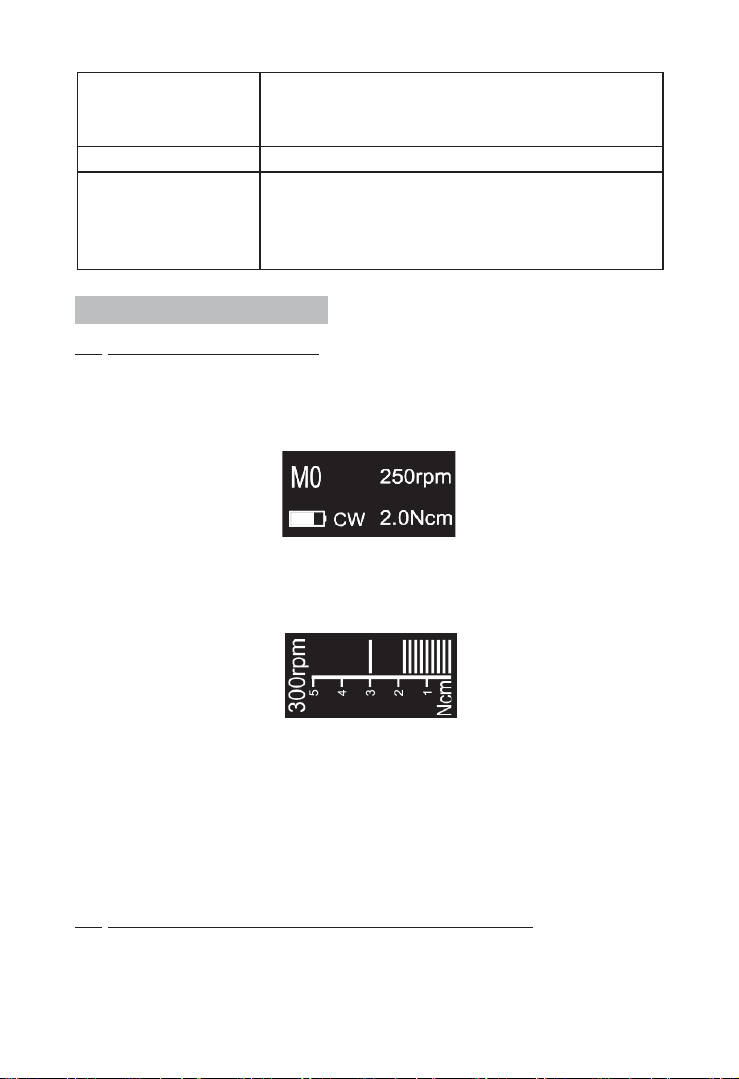

Standby interface

a. Customized program sequence

number 0-9, totally 10 programs.

b. Battery consumption

c. Set speed

d. Set torque

e. Operation mode

Working interface

a. Set speed

b. Set torque

c. Real time torque

d. Torque display scale

Canal measurement mode interface

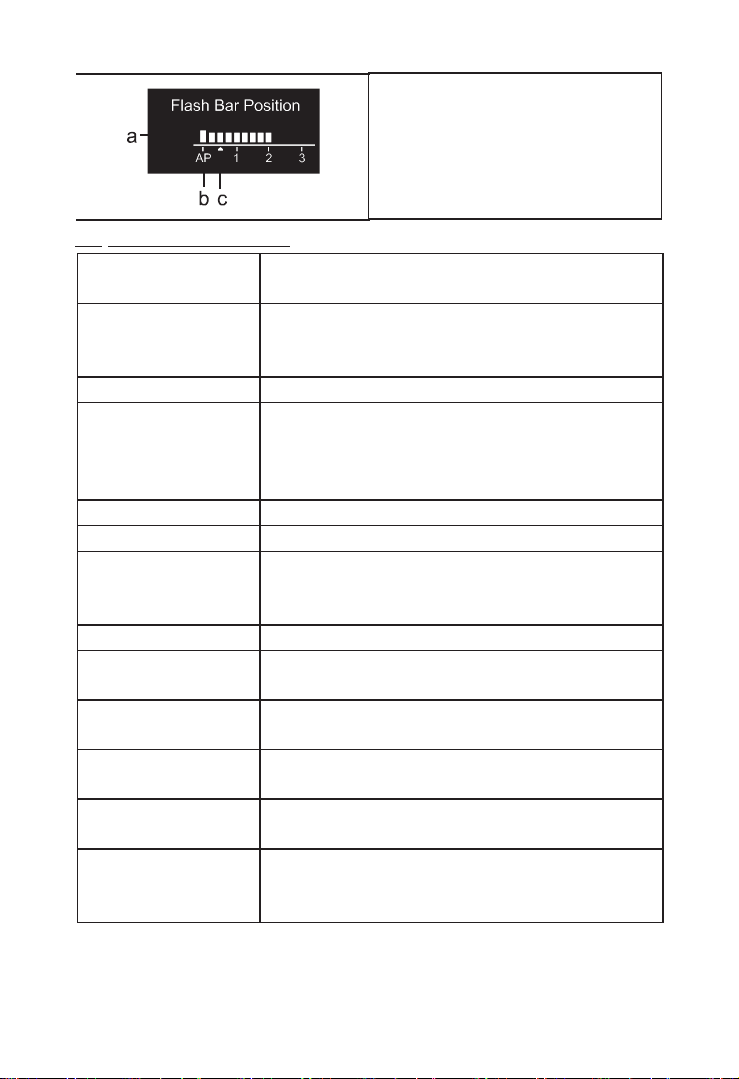

a. Apical reference point flash bar

b. EAL: Electronic apex locator

Canal measurement state interface

a. Canal length indicator bar

b. Indication number

Digital numbers 00-16 do not

represent the actual length from the

apical foramen. It simply indicates

the file progression towards the

apex. Number “00” indicate that the

file has reached the apical foramen.

c. Apical foramen.

14

3.3 Terms and definition

CW

Clockwise rotation, forward ration

Be applied to rotary file

CCW

Counter clockwise rotation, reverse rotation

Be applied to special file, inject calcium

hydroxide and other solutions

SGP

Safety Glide Path Mode

ATR

Adaptive torque reverse

When the torque reverse value is reduced to

normal – the motor will use a clockwise

continuous rotation movement.

Forward Angle

Angle of clockwise rotation of the file.

Reverse Angle

Angle of counter clockwise rotation of the file.

EAL

Electronic apex locator

In the mode, the device will work like a stand-

alone apex

AP

Apical foramen.

Apical Action

The file action when file tip reaches the flash bar

point.

Flash Bar Position

Shows the point inside the canal where specified

apical action is triggered.

Auto Start

The file rotation starts automatically when the file

is inserted in the canal.

Auto Stop

The file rotation stops automatically when the file

is taken out of the canal.

Apical Slow Down

The file slows down automatically as it

approaches the apex.

Activating in CW and CCW operation mode.

Apical reference point setting

interface

a. Apical reference point flash bar

b. Apical foramen

c. Digital “02” meter reading, very

near physiological apical foramen.

15

Operation Mode

5 operation modes for canal shaping and

measurement.

Such as CW, CCW, SGP, ATR and EAL.

Speed

File rotation speed.

Torque

(Torque Limit /

Trigger Torque)

For CW and CCW modes, the torque value

(Torque Limit) that triggers reverse rotation. For

ATR mode, the torque value (Trigger Torque)

that triggers ATR action.

4Operation instruction

4.1 Power on and power off

4.1.1 Starting and stopping of motor handpiece

a) Under the power off state of motor handpiece, press Main button,

and then the motor handpiece will enter Standby interface. The interface

displays are as follow:

Standby interface

b) Under Standby interface, press Main button, and then the motor

handpiece will enter Working interface. The interface displays are as

follow:

Working interface

c) Press the Main button again, and then the motor handpiece backs

to Standby interface.

d) Hold down the setting button “P”, then press Main button to turn

off motor handpiece. In Standby Interface, the motor handpiece would

automatically shut down after 3 minutes without any button-pressing

operation. The motor handpiece will also automatically shut down while

it is put into the charging base.

4.2 Selecting customized program sequence number

The motor handpiece has 10 memory programs(M0-M9) and 5 preset

programs, press Adjusting button “+”/“-” to change customized program

16

sequence number during standby state.

M0-M9 is a memory program for canal shaping and measurement,

every memory program has its own parameters such as Operation mode,

speed and torque, all these parameters can be changed.

17

4.3 Parameter setting

Before starting of motor handpiece, please

check the operation mode is correct.

It has 5 operation modes for canal shaping

and measurement: CW, CCW, SGP, ATR and

EAL(See chapter 3.3 Terms and definition to get

the explanations of these modes.)

Press Setting button “P” once during standby

state, press Adjusting button “+”/“-” to select

correct Operation mode.

CCW mode is used to inject calcium hydroxide

and other medicant. When this mode is being

used, a double-beep sounds continuously,

used for indicating counter clockwise rotation

happening.

Repeatedly press Setting button “P” to check all the next level

parameters of this operation mode are expected, press Adjusting button

“+”/“-” to select if not.

The speed setting can be adjusted from 100 rpm

to 1800 rpm.

Press Adjusting button “+”/“-” to increase or

decrease speed. Long press to fast increase or

fast decrease speed.

In ATR mode, speed of 100~500rpm are

available.

In SGP mode, speed of 100~500rpm are

available.

18

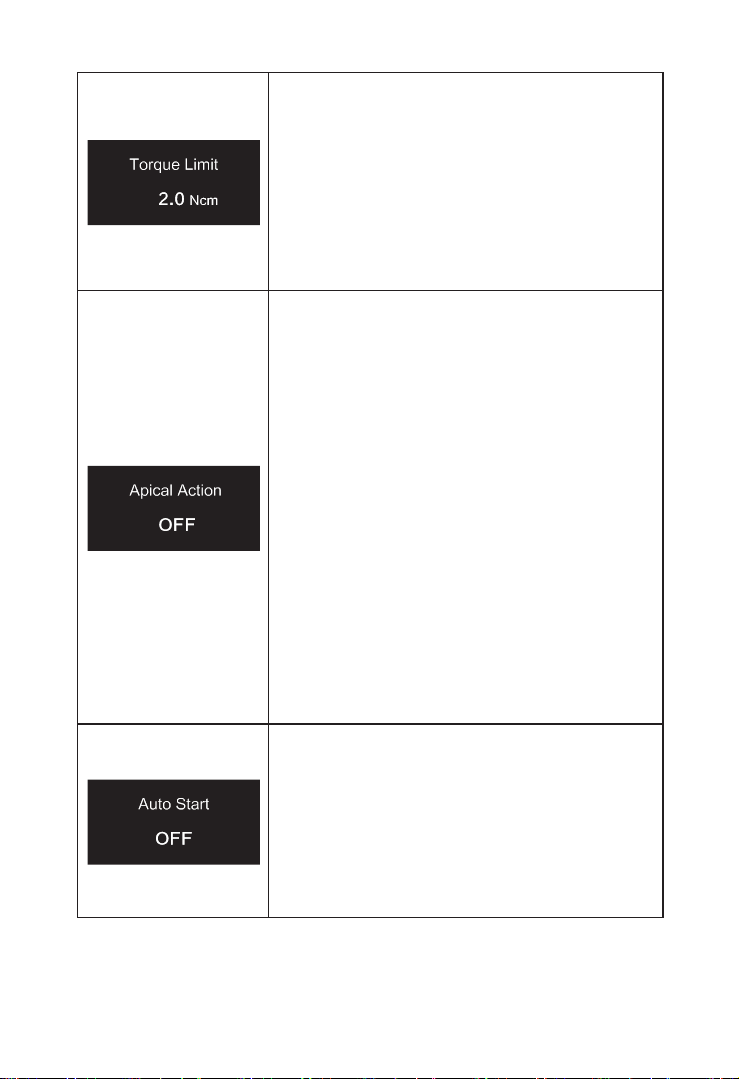

The torque setting can be adjusted from 0.4Ncm

to 5.0Ncm.

Press Adjusting button “+”/“-” to increase or

decrease torque. Long press to fast increase or

fast decrease torque.

In ATR mode, the Trigger Torque of 0.4Ncm~

4.0Ncm are available.

In SGP mode, the torque of 2.0Ncm~5.0Ncm

are available.

Actions that happen automatically when the file

tip reaches the point inside the canal determined

by the Flash Bar setting.

Benefit from integration of length determination,

when the file reaches the reference point, the

motor will response according to setting, it can

be Reverse, Stop and OFF.

Press Adjusting button “+”/“-” to change.

OFF: Disable Apical Action function, file

rotating as usual even if reach the reference

point.

Stop: automatically rotation stop when reach

the reference point, upward a little bit and will

rotate again.

Reverse: automatically reverses rotation when

reach or pass the reference point, upward a

little bit, the rotation direction will change back

again.

Rotation starts automatically when the file is

inserted into the canal and the canal length

indicator bar lights up more than 2 bars.

Press Adjusting button “+”/“-” to change.

OFF: Motor does not start when file is inserted

into the canal. The Main button is used to start

and stop the motor handpiece.

ON: Motor starts automatically.

This manual suits for next models

1

Table of contents

Other Sendoline Dental Equipment manuals

Popular Dental Equipment manuals by other brands

Durr Dental

Durr Dental VS 300 S Installation and operating instructions

TPC

TPC PC2630 user manual

B.A. International

B.A. International BA-Optima BA121T Instructions for use

Woodpecker

Woodpecker UDS-K LED instruction manual

EMS

EMS AirFlow Master Operation instructions

Mikrona

Mikrona MIGMA 200-E PLANNING / MOUNTING GUIDELINES