Senect PS User manual

1

Manual

Sensors

PS

EPS

O2S

pH XR1

ORP XT1

CON

TMP

Version 1.00

From FW Version 1.90 - 27.04.2022

2

Manufacturer:

SENECT GmbH & Co. KG

An 44 –Nr. 11

76829 Landau / Deutschland

Important note:

Please read this manual carefully and store it so that you can use it later. Read the

warning and safety notes attentive.

Further information and latest software releases or documents can be

downloaded from:

www.senect.de

www.produkte.senect.de

© SENECT GmbH & Co. KG

3

4

Index

Index .......................................................................................................................4

Type description ..................................................................................................... 5

General safety instructions.....................................................................................6

Intended use........................................................................................................... 8

Scope of delivery..................................................................................................... 9

Installation ............................................................................................................10

Getting started......................................................................................................12

Sensor –Water level PS & EPS..........................................................................13

Sensor –Pressure EDS ......................................................................................17

Sensor –Oxygen O2S........................................................................................19

Sensor pH XR1 & Redox XT1 .............................................................................23

Sensor - Conductivity CON................................................................................27

Sensor –Temperature TMP & DUO.................................................................. 29

Calibration of sensors ...........................................................................................30

Menu –Sensors in SENECT® OS............................................................................ 37

Technical data....................................................................................................... 42

Information about the correct disposal................................................................53

Guarantee.............................................................................................................53

Notes..................................................................................................................... 54

5

Type description

Art.-No.:

Name:

Type:

2000

Sensor - Water level sensor EPS

EPS-250-MA

2001

Sensor - Water level probe PS

PS-300-MA

2002

Pressure sensor EDS 6 bar

EDS-6000-MA

2003

Pressure sensor EDS 2.5 bar

EDS-2500-MA

2004

Pressure sensor EDS 250 bar

EDS-250B-MA

2100

Sensor - Oxygen O2S

O2S-20-SC

2100-PP

Sensor - Oxygen O2S PP housing

O2S-20-SC-PP

2200

Sensor - pH XR1

PH-410-XR1-SC

2300

Sensor - ORP XT1

ORP-1-XT1-SC

2400

Sensor - Conductivity CON 50 mS/cm

CON-50-SC

2410

Sensor - Conductivity CON 2 mS/cm

CON-2-SC

2420

Sensor - Conductivity CON 10 mS/cm

CON-10-SC

2450

Sensor - Conductivity CON 500 mS/cm

CON-500-SC

2500

Sensor - Temperature TMP PT1000

TMP-50-SC

2501

Sensor - Temperature TMP-DUO

DUO-50-SC

2502

Sensor - Temperature TMP int. transducer

TMP-50-SC-IT

6

General safety instructions

The SENECT pressure sensor EDS is an electronic sensor unit for measuring the pressure in

pipelines, hoses or vessels.

As this is an electronic product, the usual requirements, as with all electrical

appliances, must be met. The device may only be operated with compatible

control units or control units approved by SENECT. The device and all

connected lines must be installed and operated protected from moisture

and wetness. When laying all cables, care must be taken that no safety-

relevant impairments such as tripping hazards occur. For many applications,

fuse protection by a residual current circuit breaker with a tripping current

< 30 mA is mandatory. Find out more about this.

The device must be installed protected from overheating by direct sunlight and must only

be operated at an ambient temperature between 0°C and +40°C. The device must not be

modified, except for extensions or software updates of SENECT®. It is forbidden to open

the device or to penetrate the inside of the housing in any way.

The pressure sensor EDS is not intended to be used by persons (including children) with

limited physical, sensory or mental abilities or for lack of experience and/or knowledge,

unless they are supervised or instructed by a person responsible for their safety on how

to operate the device. Please keep these instructions for use as a reference. Technical and

optical changes as well as printing errors reserved.

7

Symbols and signal words

DANGER!

Warning of life-threatening dangers.

WARNING!

Warning of possible life threatening and / or severe irreversible

injuries.

ATTENTION!

Warning of possible medium or slight injury.

ATTENTION!

Follow the notes to avoid damage of equipment

NOTE!

Further information for the use of the device!

ATTENTION!

Warning of electrical shock.

8

Intended use

The SENECT® sensor is designed to measure the respective parameter in water. The

measuring range, resolution and accuracy can be found in the following table.

All SENECT® sensors are designed for the use in industrial aquaculture applications.

Type:

Measured value / Remark

Measuring range

Resolution

EPS-250-MA

Water level in tanks, sensor screwed in

0 –250 mbar /

0 –250 cm

0,1 mbar

0,1 cm

PS-300-MA

Water level, sensor submerged

0 –300 mbar /

0 –300 cm

0,1 mbar /

0,1 cm

EDS-6000-MA

Pressure of gaseous media (air,

oxygen) or liquid media (water) in

pipelines or containers

0 –6000 mbar

1 mbar

EDS-2500-MA

0 –2500 mbar

1 mbar

EDS-250B-MA

0 –250 bar

1 bar

O2S-20-SC

O2S-20-SS

Concentration of dissolved oxygen,

Water temperature

0 –400 % a.s.

0 –40°C

0,1 % a.s.

0,1 °C

PH-410-XR1-SC

pH-value in water

pH 4 –pH 10

0,01 pH

ORP-1-XT1-SC

Oxidation-reduction potential (ORP or

redox potential)

-2000 –

+2000 mV

1 mV

CON-50-SC

Electrical conductivity in water,

temperature.

An integrated temperature sensor

provides temperature compensation

so that the displayed values refer to

the temperature-corrected

conductivity at 25°C.

0 –50 mS/cm

0 –40 °C

0,01 mS/cm

0,1°C

CON-2-SC

0 –2 mS/cm

0 –40 °C

1 µS/cm

0,1°C

CON-10-SC

0 –10 mS/cm

0 –40 °C

0,01 mS/cm

0,1°C

CON-500-SC

0 –500 mS/cm

0 –40 °C

0,1 mS/cm

0,1°C

TMP-50-SC

TMP-50-SC-IT

Temperature in water

0 –50 °C

0,1 °C

DUO-50-SC

Temperature in water

Temperature in air

0 –50 °C

-10°C –50 °C

0,1 °C

0,1 °C

9

Scope of delivery

Sensor type

Delivered Items

Conductivity Sensor CON

1 x Conductivity Sensor CON

1 x Manual

Pressure Sensor EDS

1 x Pressure Sensor EDS incl. connection cable

1 x Manual

Water level Sensor EPS

1 x Water level Sensor EPS

1 x Manual

Oxygen Sensor O2S

1 x Oxygen Sensor O2S

1 x Manual

ORP Sensor XT1

1 x ORP Sensor XT1 electronic interface

1 x ORP Sensor XT1 electrode

1 x ORP Calibration-Solution (+475 mV)

1 x Calibration-BNC-plug (0 mV)

1 x Manual

pH Sensor XR1

1 x pH Sensor XR1 electronic interface

1 x pH Sensor XR1 electrode

1 x pH Calibration-set (pH 4 and pH 10)

1 x Manual

Water level probe PS

1 x Water level probe PS

1 x Manual

Temperature Sensor TMP

1 x Temperature Sensor TMP (incl. electronic interface)

1 x Manual

Temperature Sensor DUO

1 x Double Temperature Sensor DUO (incl. electronic

interface)

1 x Manual

Please check directly after delivery, that the package is not destroyed or

damaged or was opened before. Please check also, that all parts as listed

above are included. If anything is missing or broken, please contact us as

soon as possible within 14 days. Unfortunately, we cannot accept later

information of damage, which happened during the transport.

10

Installation

Choose a place for the electronic interface (electronic unit protected by

black silicone casing) which is clean, dry and protected from direct sunlight.

Ensure that all cables are placed safely and all regulations are fulfilled.

Mount the sensor so that the sensor head is permanently submerged. This can be

achieved, for example, by attaching it using suction cups or, if the water level fluctuates

greatly, by attaching it to a float. Alternatively, the sensors can also be installed in the pipe

system (e.g. within a measuring chamber).

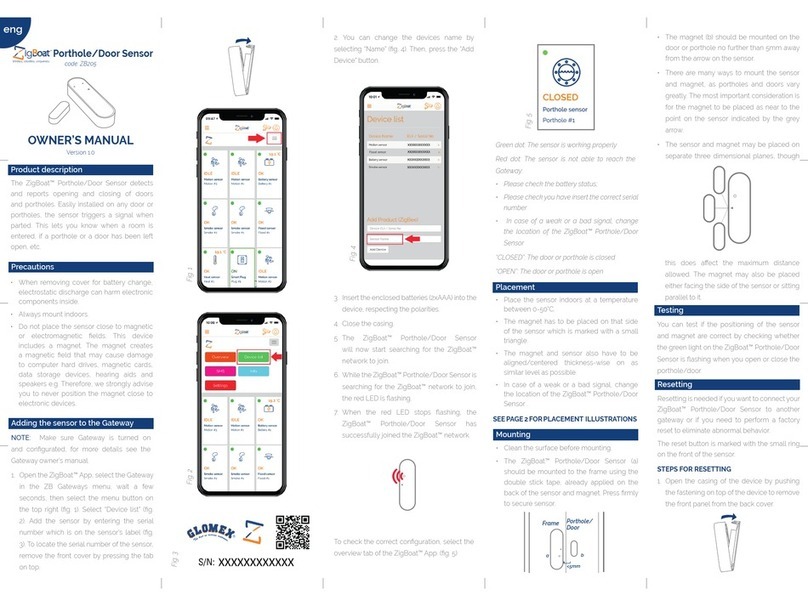

Figure 1: Example of the installation of the oxygen sensor

Figure 2: Example of mounting an electrode in a flow chamber or float

11

Figure 3: Mounting sensor CON in a pipeline

To increase the service life, the sensor can be mounted so that the upper

part of the sensor and the cable are not submerged. This can be achieved

either by mounting using brackets or suction cups, or by mounting on a float

if the water level fluctuates greatly.

Important Note: Sensor EPS

The Water level sensor EPS must not be submerged. Use the submersible water level

probe PS for this purpose.

12

Getting started

Short version

1. Attach the probe to the measuring point.

2. Mount the electronic interface at a protected location.

3. Connect the sensor cable with a control unit (plug „SENSOR“).

4. The control unit recognizes the sensor and starts the measurements.

The menu may differ depending on the software version used.

Updates to these operating instructions can be found at

www.senect.de.

13

Sensor –Water level PS & EPS

EPS:

Mount the water level sensor screwed in (either with seal and lock nut or with sealing tape

and matching thread in the container wall) in a container or in a filter chamber (when used

to control drum or belt filters).

PS:

Attach the water level probe submerged at the desired location in the filter (if the water

level probe is to be used to control a drum or belt filter) or in the pond / basin. The probe

must be firmly anchored in a location with low currents to avoid interference.

It is important to ensure that the connector is kept permanently dry, as this

is where the pressure equalization with the atmosphere takes place. Please

note that there is a capillary in the cable for pressure equalization and

therefore a minimum bend radius of 15 cm is required.

Connect the connection cable to your control unit at one of the sensor slots marked in

blue. The SENECT control units automatically detect the water level sensor and start

operation.

1. Assign the type of sensor in the menu under Sensors / Plug X / Sensor Type (EPS-

250-MA or PS-300-MA).

2. To assign a function to the water level sensor, select the place of use under

Sensors / Plug X / Position. This is linked to a respective function:

-Pre-chamber: The water level sensor is used to control filters in pumped

version and is installed in the filter pre-chamber.

-Filter: The water level sensor is installed behind the drum or belt in filters

and is used to control the filter in gravity mode.

-Refill sensor: The water level sensor is used to refill water in the pond or

basin.

-Other: The water level sensor is not assigned to any of these functions

and can be assigned a function via the Outputs menu.

3. To set the measured value to 0cm (reference the sensor), select Sensors / Plug /

Sensor referencing.

14

Water level probe –Controlling particle filters

The optimal location for the PS level probe for filter control is where the

level of pollution of the filter mesh is "measured" and where it is also

possible to check the function of the circulation pump. In gravity systems

this is usually behind the filter or in the filter chamber, while in pumped

systems it is in front of the drum filter or in the pre-chamber of the filter.

Figure 4: The locations of the water level probe when a drum filter is to be controlled. Please note,

that in the gravity mode, the PS is in the filter chamber, while in pumped mode, the PS is installed in

the pre-chamber.

15

The cleaning of drum or belt filters can be triggered depending on the contamination by

measuring the water level. A distinction must be made here as to whether a rise or fall in

water level should trigger cleaning. In gravity mode (see Figure 4 ), the probe is mounted

in the filter chamber and a drop in the water level triggers cleaning.

In pumped mode, the probe is installed in the pre-chamber and a rising water level triggers

the cleaning.

Therefore, select one of both variants for your filter control.

Differential operation: Use two water level probes to control the filter operation via the

water level difference between the pre-chamber and filter chamber, assign the water level

probes to the position where the probes are located. If the pre-chamber and filter

chamber are selected, cleaning triggering takes place automatically according to the water

level difference.

After selecting the position(s), trigger a filter cleaning with the CLEAN FILTER key and then

set the water level to "0 cm" with the "Reference sensor" menu item. Now the relative

water level is set to "0 cm" (the absolute water level always refers to the actual installation

depth of the probe).

Now you can adjust further filter settings.

Figure 5: Difference between relative and absolute water level. The relative water level is used for

control purposes (e.g. control filter, refill water) while the absolute water level is used for alarming.

reference zero level

absolute water level

(used for alarming,

e.g. +48 cm)

relative water level

(used for filter

operation, e.g. -5 cm)

16

Water level probe –Refilling water level

Select "Refill sensor" as the position and place the probe in your pond or basin. Set the

water level to "0 cm" with "Reference sensor". With the position "Refill sensor" the sensor

value is additionally displayed in the app as "Pond" in the filter sensor values field.

You can move the "0 cm" line in the menu under "Change zero-point". Positive values (e.g.

+5 mm) move this line upwards while negative values (e.g. -2 mm) move this line

downwards.

Now you can set the other water refill settings. For the FILTER|CONTROL unit you will find

them in the water refill menu while for the other controllers you must use the "Sensor

control" function.

Water level probe –Other position

If you want to use the water level only for monitoring or to do a sensor contro select as

the position "Other". You can then set the alarm thresholds. Please note that these

thresholds refer to the absolute water level. You can change to the referenced water level

in the alarm threshold menu.

17

Sensor –Pressure EDS

The sensor is screwed into a suitable thread using the pressure sensor-side G1/4" threaded

nipple.

Seal the thread with sealing tape or a suitable and approved sealing

compound (e.g. Loxeal 58-11, BAM-approved Teflon tape). Make sure never

to touch the sensor membrane (not even for cleaning purposes) and that

the cable connection side must be kept permanently dry, as this is where

the pressure equalization to the atmosphere takes place.

Connect the supplied connection cable to the sensor and your control unit at one of the

sensor slots marked in blue. The SENECT control units automatically detect the sensor and

start operation.

1. Select the correct sensor type under Sensors / Plug X / Sensor type (EDS-2500-

MA).

2. Enter the measuring range of your sensor in mbar (e.g. 2500 mbar) in the

submenu Sensors / Plug X: EDS / Measuring range.

The sensor is now ready for use and you can make further settings. For further

information, please refer to the manual of your SENECT controller.

18

Application example

The pressure sensor EDS can be used to monitor the line pressure of the ventilation line

(oxygen or compressed air). If there is a fault in this supply line (tank empty, generator

defective, leakage), the EDS can trigger an alarm if the pressure falls below the set lower

threshold value.

Apply the following settings:

-Sensor / Plug X: EDS / Alarm / Lower Threshold: e.g. 1500 mbar

-Sensor / Plug X: EDS / Alarm / Upper Threshold: e.g. 2000 mbar

-Sensor / Plug X: EDS / Alarm / Hysteresis: e.g. 10 mbar

These settings trigger an alarm when the pressure drops below 1500 mbar or exceeds

2000 mbar.

19

Sensor –Oxygen O2S

Remove the blue protective cap of the sensor and attach the sensor. The probe itself must

be suspended in the water so that the membrane is permanently submerged.

To increase the service life, the sensor can be mounted so that the upper

part of the sensor and the cable are not submerged. This can be achieved

either by mounting using brackets or suction cups, or by mounting on a float

if the water level fluctuates greatly.

Please consider when selecting the mounting location that in surface waters like fish ponds

the solar radiation can lead to a thermal stratification of the water body, associated with

strong gradients in dissolved oxygen

Protect your sensor from fish biting on the sensor membrane! SENECT offers

protection cages.

The oxygen sensor O2S-20-SC-PP already has a protection cap.

Connect the blue marked plug of the sensor with a sensor input port (also blue marked) of

your control unit. The SENECT control units recognize the sensor itself and start

automatically the measurements. Take into account that the measurement interval is set

to 30 s to elongate the lifetime of the sensing cap.

The oxygen sensor O2S is factory calibrated and need to be recalibrated –under for

aquaculture typical environmental conditions –earliest 6 months.

20

Recalibration intervals

Recalibration of the sensor is regularly recommended every 6 months. To determine if a

calibration is necessary, hold the sensor in air (preferably with 100% humidity) for a few

minutes. If the sensor shows about 100% oxygen saturation (usually this value is just below

100% due to insufficient humidity), no calibration of the upper calibration point is

necessary. Repeat this procedure for the lower calibration point, keeping the sensor in 0%

O2 solution. If the sensor indicates approx. 0%, no recalibration is necessary for this point

either.

Membrane wear

Since the fluorescent membrane fades due to the measurement, we recommend replacing

the sensor cap (Art. No.: 2101, Type: O2S-ATK), which contains the photoreactive

membrane, at intervals of three years. To do this, simply unscrew the cap and replace it.

The sensor must always be recalibrated after replacing the cap!

Cleaning

If algae or microorganisms grow up, the sensor membrane must be cleaned regularly. It is

best to remove soiling or growth carefully with a cotton swab and water. If the membrane

is more heavily soiled, you can also use diluted acetic acid.

Avoid contact with organic solvents such as toluene, acetone or

chloroform at all costs. These solvents can cause damage to the

membrane! Steam sterilization can also damage the sensor.

Disinfection

The sensor can be disinfected with peracetic acid (max. 5 mg / l), methanol, ethanol,

isopropanol or 3% H2O2 solution. Rinse the sensor afterwards with tap water.

This manual suits for next models

23

Table of contents

Other Senect Accessories manuals

Popular Accessories manuals by other brands

Reimo

Reimo TAVIRA AIR 390 installation instructions

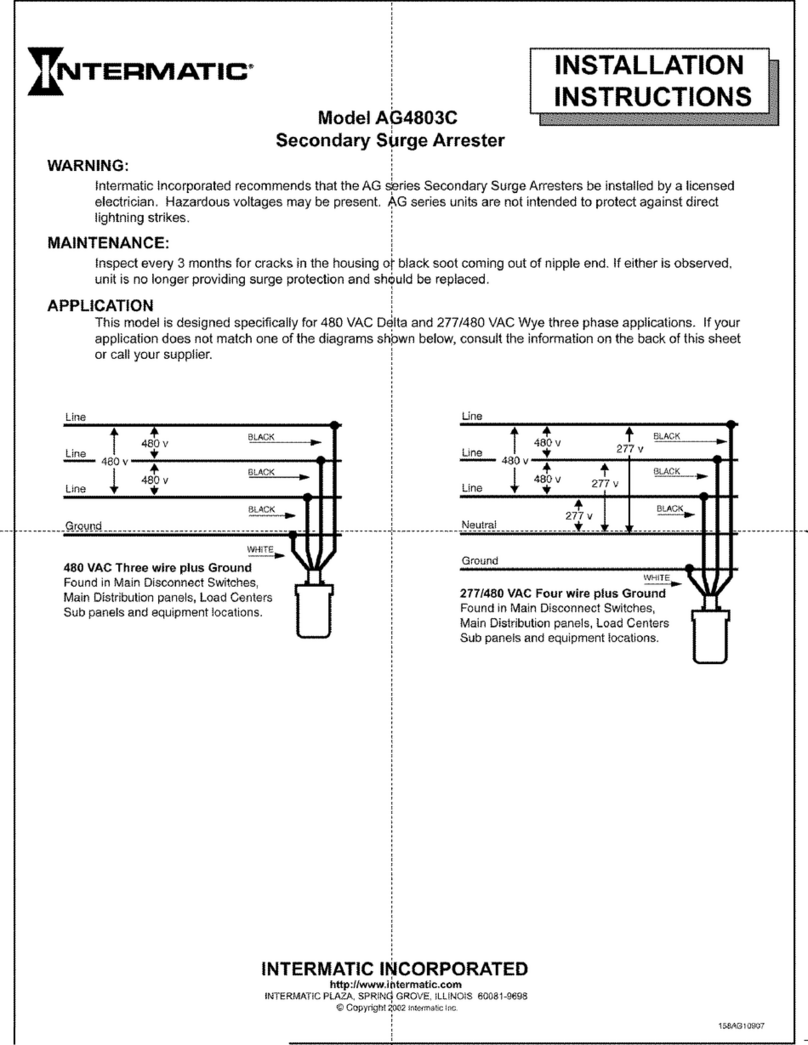

Intermatic

Intermatic AG4803C installation instructions

SunSynk

SunSynk POCKET POWER STATION 2 user manual

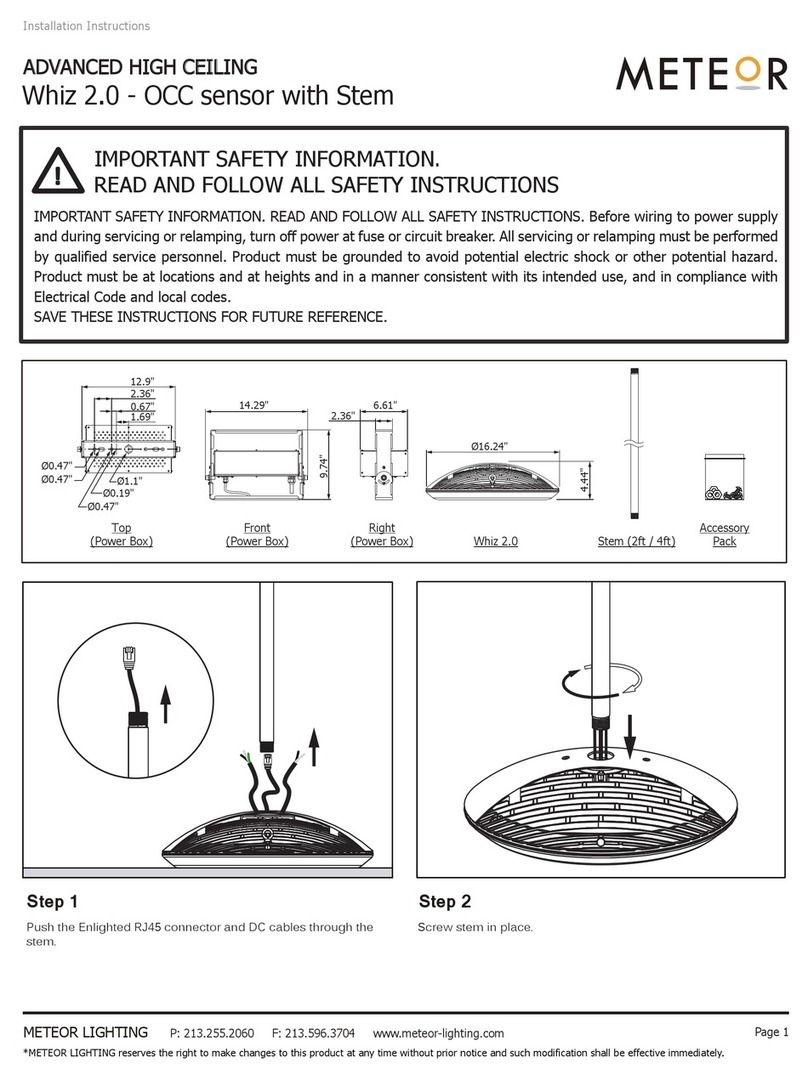

Meteor

Meteor Whiz 2.0 installation instructions

Omron

Omron ZW-8000 Series user manual

Oliver Kessler

Oliver Kessler SOLITAIRE PUNKAH Installation & owner's manual