SENKO Smart Probe 2 User manual

Date: 08-05-2019

Doc Number: ENG-SP2M-0519-001

1

Vue3 User Manual

Your Source for Optical Interconnect Solutions

Design –Test - Manufacture

Date: 08-05-2019

Doc Number: ENG-SP2M-0519-001

2

Contents

1. Read Me First ………………………………………………………………………….4

2. Safety Information ………………………………………………………………….4-5

3. Certification…………………………………………………………………………..5-7

4. Introduction ……………………………………………………………………………7

5. Hardware Overview…………………………………………………………………7-9

5.1. Features ……………………………………………………………………………7-8

5.2. Specification and Accessories …………………………………………………...8-9

6. Basic Operation ………………………………………………………………………9

6.1. Charging ……………………………………………………………………………...9

6.2. Replacing the Battery ……………………………………………………………….9

6.3. Installing Inspection Tips……………………………………………………….10-11

6.4. Optional Interchangeable Inspection Tips…………………………………….....11

6.5. LED Torch…………………………………………………………………………...12

7. Software Download and Initial Set-up …………………………………………..12

7.1. Required Operating System…………………………………………………..…...12

7.2. Getting Started……………………………………………………………………....12

7.3. WiFi Set-up…………………………………………………………………………..12

8. Software Overview …………………………………………………………………14

8.1. Functionality Diagram…………………………………………………………...14-17

9. Customizing the Software ………………………………………………………..18

9.1. Standard Report …………………………………………………………………18-19

9.2. Consolidated Report …………………………………………………………….20-22

9.3. Create a Report Manually………………………………………………………….22

9.4. Automated Report Creation………………………………………………………..22

9.5. Auto Increment ………………………………………………………………………22

9.6. Re-Test Function…………………………………………………………………….23

9.7. Comments………………………………………………………………………...23-24

Date: 08-05-2019

Doc Number: ENG-SP2M-0519-001

3

10.Inspecting Fiber Ends and Analyzing Captures………………………………24

11.Extracting Files………………………………………………………………….25-26

12.Warranty ……………………………………………………………………………..27

13.Maintenance and Support……………………………………………………..27-28

Date: 08-05-2019

Doc Number: ENG-SP2M-0519-001

4

1. Read Me First

Thank you for purchasing the SENKO Smart Probe. Please read this manual before

using the device to ensure safe and proper use.

2. Safety Information

The following general safety precautions must be observed during all phases of

operation, service and repair of the instrument. Failures to comply with these

precautions or with specific warnings elsewhere in this manual violate standards of

design, manufacture and intended use of the instrument. Always read the manual for

safety points before using the instrument. You must follow these to ensure correct and

safe operation of the instrument.

WARNING

Do not install or terminate fibers while a light source is active. Never look directly into

a live fiber and ensure that your ayes are protected at all times.

Battery CAUTION and WARNING:

There areno userserviceable parts inside; under no circumstancesshould you attempt

to access the internal parts. For servicing please contact Senko Advanced

Components or Senko Distribution partner.

Only use battery and accessories specified by the manufacturer.

Do not immerse battery in water.

Do not short circuit.

Do not put on fire.

Dispose of or Recycle Responsibly.

Date: 08-05-2019

Doc Number: ENG-SP2M-0519-001

5

CAUTION:

RISK OF EXPLOSION IF BATTERY IS REPLACED BY AN INCORRECT TYPE.

DISPOSE OF USED BATTERIES ACCORDING TO THE INSTRUCTIONS.

DISPOSAL

All electrical and electronic products including batteries should be disposed of

separately from the municipal waste stream via designated collection facilities

appointed by the government or the local authorities.

3. Certification

FCC

This device complies with part 15 of the FCC Rules. Operation is subject to the

following two conditions: (1) This device may not cause harmful interference, and (2)

this device must accept any interference received, including interference that may

cause undesired operation.

Changes or modifications not expressly approved by the party responsible for

compliance could void the user’s authority to operate the equipment.

NOTE: This equipment has been tested and found to comply with the limits for a Class

B digital device, pursuant to part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference in a residential installation.

This equipment generates, uses and can radiate radio frequency energy and, if not

installed and used in accordance with the instructions, may cause harmful interference

to radio communications. However, there is no guarantee that interference will not

occur in a particular installation. If this probe does cause harmful interference to radio

or television reception, which can be determined by turning the probe off and on, the

user is encouraged to try to correct the interference by one or more of the following

measures:

Reorient or relocate the receiving antenna.

Increase the separation between the probe and receiver.

Consult the manufacturer/distributor dealer or an experienced radio/TV

technician for help.

Date: 08-05-2019

Doc Number: ENG-SP2M-0519-001

6

Industry Canada

This device complies with Industry Canada licence-exempt RSS standard(s).

Operation is subject to the following two conditions: (1) this device may not cause

interference, and (2) this device must accept any interference, including interference

that may cause undesired operation of the device.

Le présent appareil est conforme aux CNR d'Industrie Canada applicables aux

appareils radio exempts de licence. L'exploitation est autorisée aux deux conditions

suivantes : (1) l'appareil ne doit pas produire de brouillage, et (2) l'utilisateur de

l'appareil doit accepter tout brouillage radioélectrique subi, même si le brouillage est

susceptible d'en compromettre le fonctionnement.

CAN ICES-3(B)/NMB-3(B)

Japan

ARIB T66 certified. Registration Number R210-115178.

Japanese translation of this user manual will be supplied.

CE

R&TTE:

This device complies with the tests and standards as stipulated in the R&TTE Directive.

RF: ETSI EN 300 328 V2.1.1 (2016-11)

EMC: EN 62311:2008

Draft ETSI EN 301 489-1 V2.2.0 (2017-03)

Draft ETSI EN 301 489-17 V3.2.0 (2017-03)

LVD: EN 62368-1:2014

U/NZ

RCM registered.

Certificate Number: RCMP17375 001

EMC Regulations (Battery)

EN 55032:2015

EN 61000-3-2:2014

EN 61000-3-3:2013

EN 55024:2010 + A1:2015

EN 61000-4-2:2009

EN 61000-4-3:2006 + A1:2008 + A2:2010

EN 61000-4-4:2012

EN 61000-4-5:2014

EN 61000-4-6:2014

EN 61000-4-8:2010

EN 61000-4-11:2004

Date: 08-05-2019

Doc Number: ENG-SP2M-0519-001

7

4. Introduction

The Smart Probe 2 Inspection Probe is a portable video microscope with an automated

IEC 61300-3-35 End-Face Inspection App, used to inspect fiber ends. The microscope

can be connected with a WiFi or USB connection to platforms or with a WiFi connection

to mobile smart devices (Android or iOS).

5. Hardware Overview

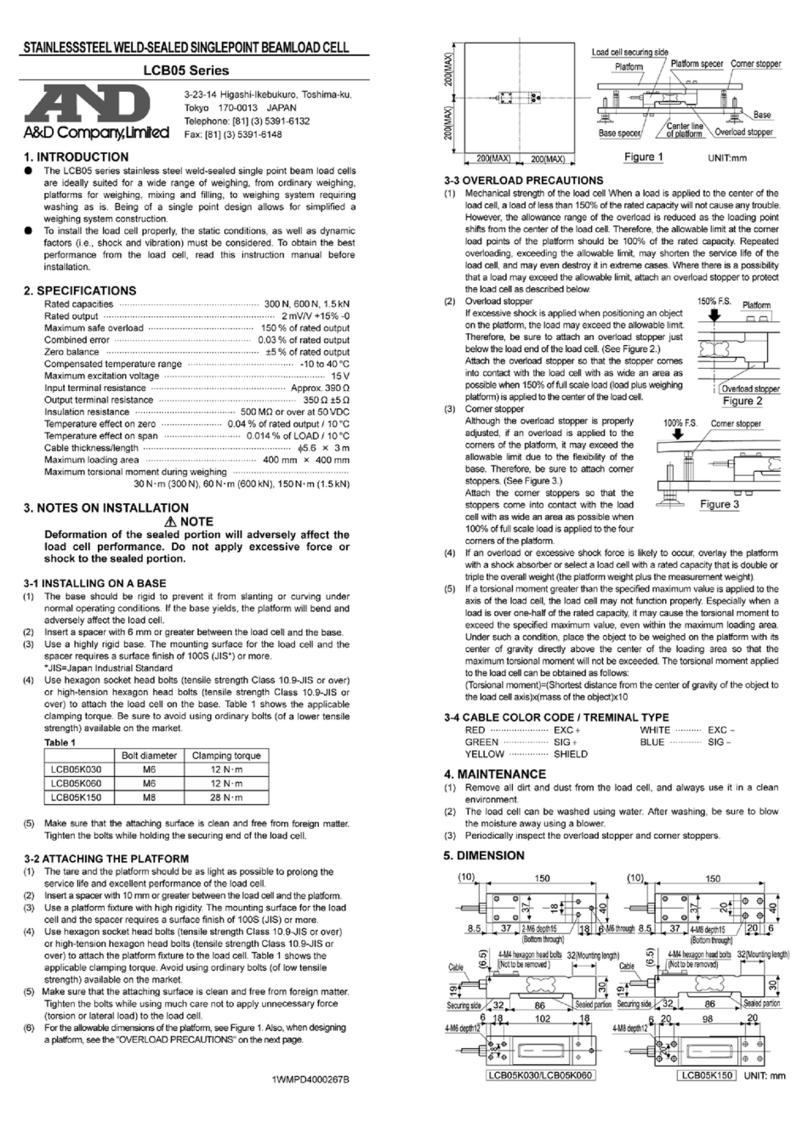

5.1 Features

Captive dust/protective cap.

5h operation from rechargeable battery.

Wide range of inspection tips.

Manual Fcous.

Auto and Manual centering of fiber.

Capture button.

LED.

Date: 08-05-2019

Doc Number: ENG-SP2M-0519-001

8

5.2 Specification and Accessories

Smart Probe 2

Magnification

200x/400x

Field of View

512 x 384 um

Focus method

Manual

Communication Interface

Wifi802.11 / USB 2.0

Power

Built in Lithium battery 2hr charge time

Operating Temp.

-10℃~ 50℃

Storage Temp.

-20℃~ 50℃

Relative humidity

95%

Weight

188g inc battery

Size

195(L) x 40(W) x 25(H) mm

Software Platforms

Android 4.2 & above, iOS 9.3 & above

Date: 08-05-2019

Doc Number: ENG-SP2M-0519-001

9

6. Basic Operation

6.1 Charging

Connect the probe to the supplied USB charger, or to a USB port of a PC using the supplied

USB cable. The Battery Status Indicator (comprises of 3 white LEDs) shows charging

status as below.

Battery Status Indicator Pattern

Meaning

Only Led # 1 Lights up & blinking

Low battery. Instrument will turn off automatically if

not recharged.

All 3 LEDs light up in running

mode

Instrument is being charged. Max charging time

needed is 2.5 hrs.

All 3 LEDs light up continually

Instrument is fully charged.

All 3 LEDs light up & blinking

Battery connection error.

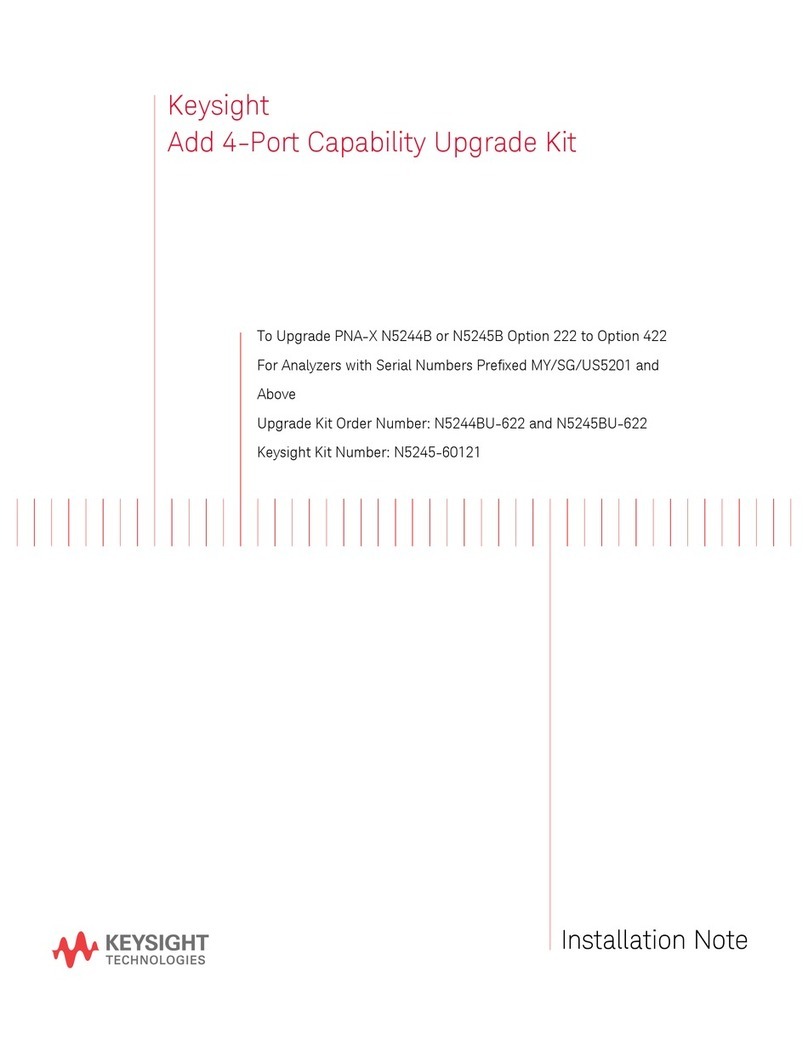

6.2 Replacing the battery

The instrument is powered by a specific built-in Lithium battery which can be replaced

as shown below. Please contact SENKO for replacement battery.

1. Remove 2 screws, using a special screw driver to open battery cover.

2. Pull out battery from the battery compartment.

3. Insert new battery at an angle and plug the contacts of the battery into the

connector in the correct orientation.

4. Place battery cover and screws back on the probe.

5. Charge battery.

Accessories

Tips

1.25m male, 2.5mm male

Wrist strap with protective cap

1 set

USB charger with international adaptors

1 set

USB cable

Type A –Type C

Tip storage case

Up to 5 tips

Carrying case with waist strap

1 set

QA certificate

1 set

Date: 08-05-2019

Doc Number: ENG-SP2M-0519-001

10

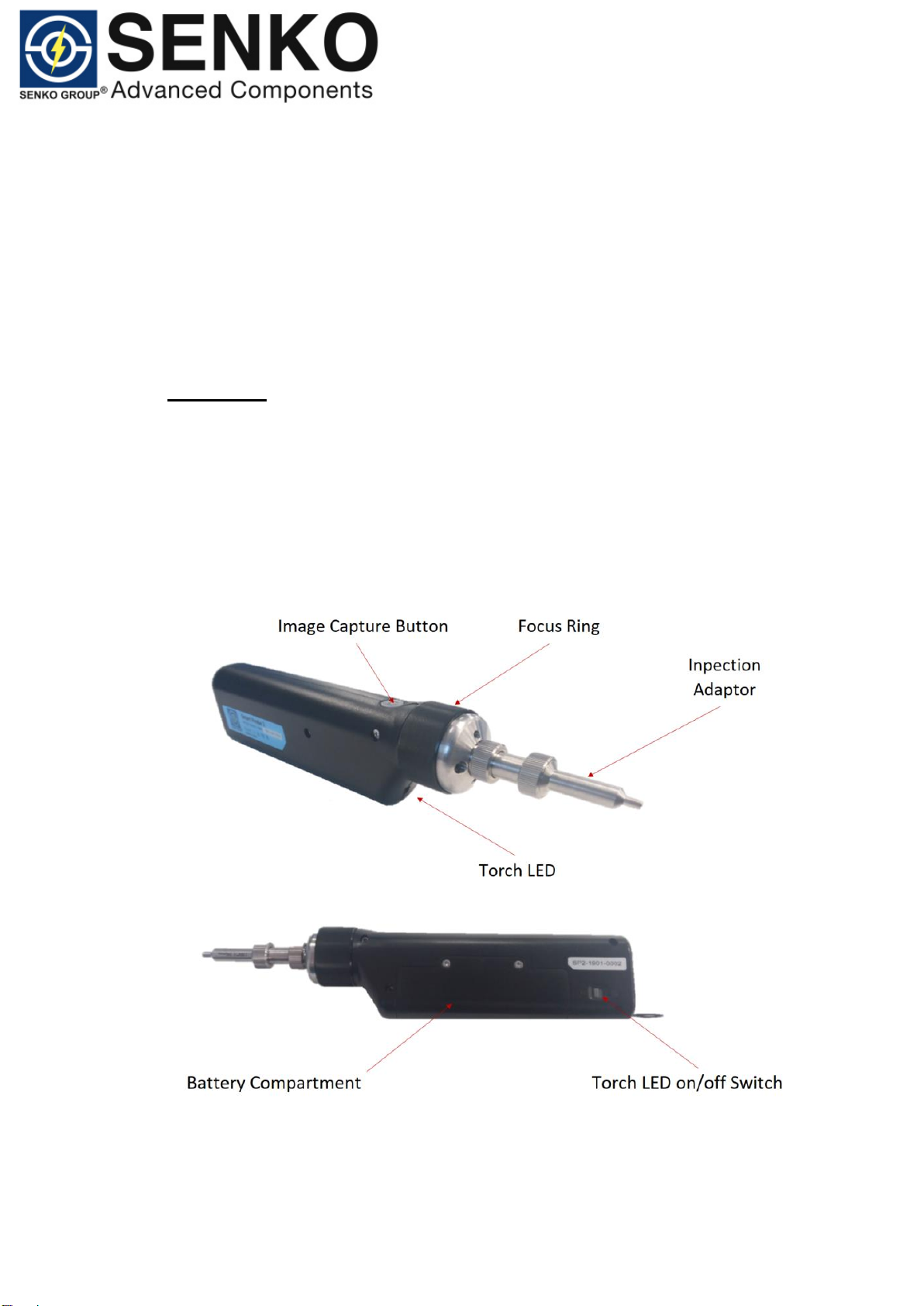

6.3 Installing Inspection Tips

Place inspection tip over focal lens, make sure that the pin is aligned into the grove,

tighten locknut by turning it ANTI-CLOCKWISE as shown below.

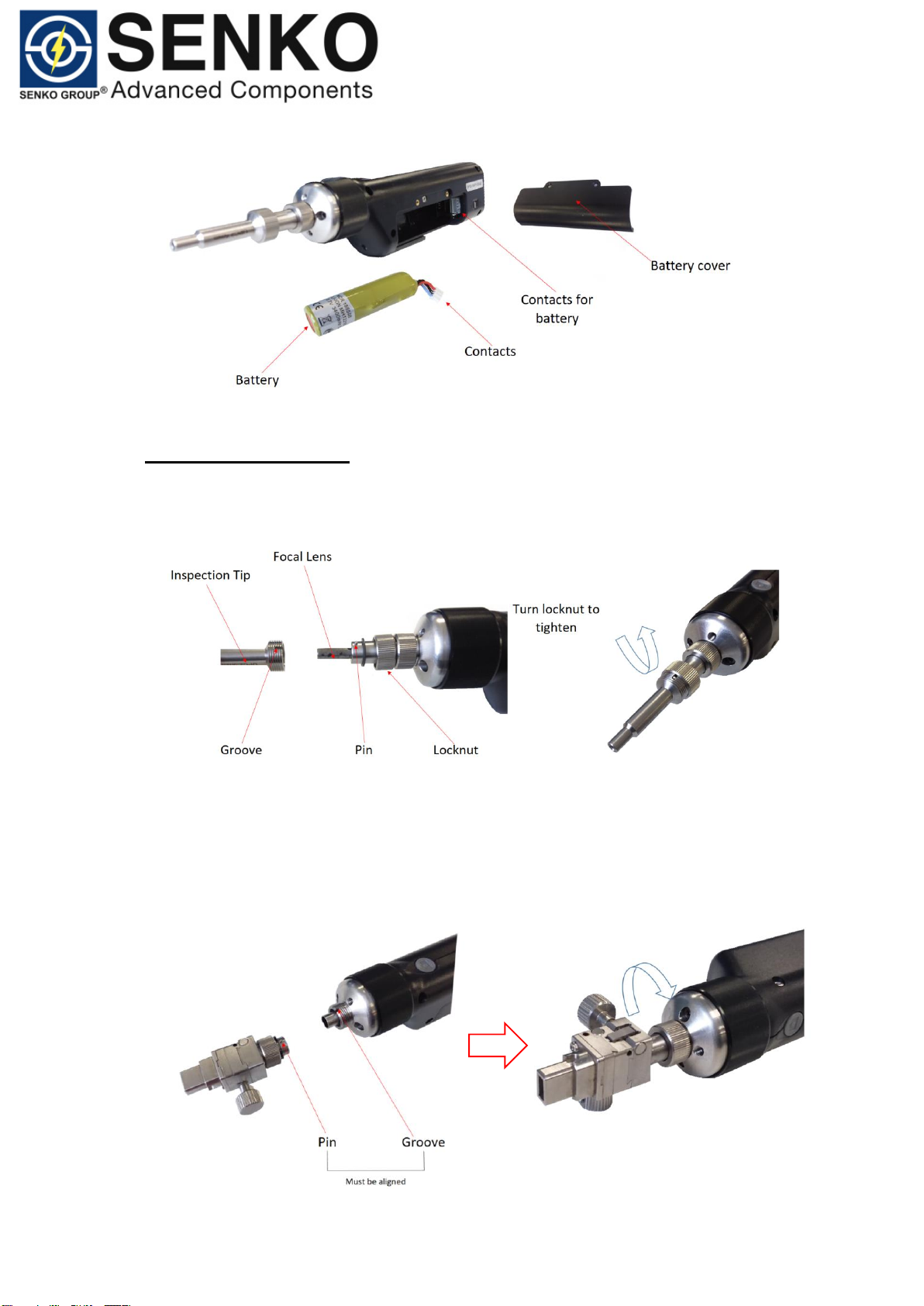

MPO Inspection Tips

Remove focal lens holder. Place MPO inspection tip on the probe, make sure that pin

on the inspection tip is aligned into the groove. Tighten locknut by turning it

CLOCKWISE as shown below.

Date: 08-05-2019

Doc Number: ENG-SP2M-0519-001

11

Please note: MPO inspection tip come with both PC and an APC tips which are

interchangeable by loosening/tightening 2 screws as shown above.

6.4 Optional Interchangeable Inspection Tips

Description

Part Number

1.25mm PC Male Universal Tip

SCK-SPT2-PC125-M

2.5mm PC Male Universal Tip

SCK-SPT2-PC250-M

1.25mm APC Male Universal Tip

SCK-SPT2-APC125-M

2.5mm APC Male Universal Tip

SCK-SPT2-APC250-M

SC APC In Adapter Tip

SCK-SPT2-SC-APC-F

SC UPC In Adapter Tip

SCK-SPT2-SC-UPC-F

FC APC In Adapter Tip

SCK-SPT2-FC-APC-F

FC UPC In Adapter Tip

SCK-SPT2-FC-UPC-F

LC UPC In Adapter Tip

SCK-SPT2-LC-UPC-F

MU UPC In Adapter Tip

SCK-SPT2-MU-UPC-F

ST UPC In Adapter Tip

SCK-SPT2-ST-PC-F

MPO APC Female Tip,12/24

SCK-SPT2-MPO-APC-F

MPO PC Female Tip, 12/24

SCK-SPT2-MPO-PC-F

E2000 UPC Female Tip

SCK-SPT2-E2000-UPC-F

E2000 UPC Male Tip

SCK-SPT2-E2000-UPC-M

E2000 APC Female Tip

SCK-SPT2-E2000-APC-F

E2000 APC Male Tip

SCK-SPT2-E2000-APC-M

Date: 08-05-2019

Doc Number: ENG-SP2M-0519-001

12

6.5 Torch LED

The built-in Torch LED can be turned on to assist works in dark or low light conditions.

To turn light on, flip Torch LED on/off Switch to .

7.0 Software Download and Initial Set Up

7.1 Required Operating System

Android Lollipop 4.2 & above.

iOS 9.3 & above.

7.2 Getting Started

Download Vue3 App from the Google Play (Android), App Store (iOS).

Download Adobe Acrobat Reader.

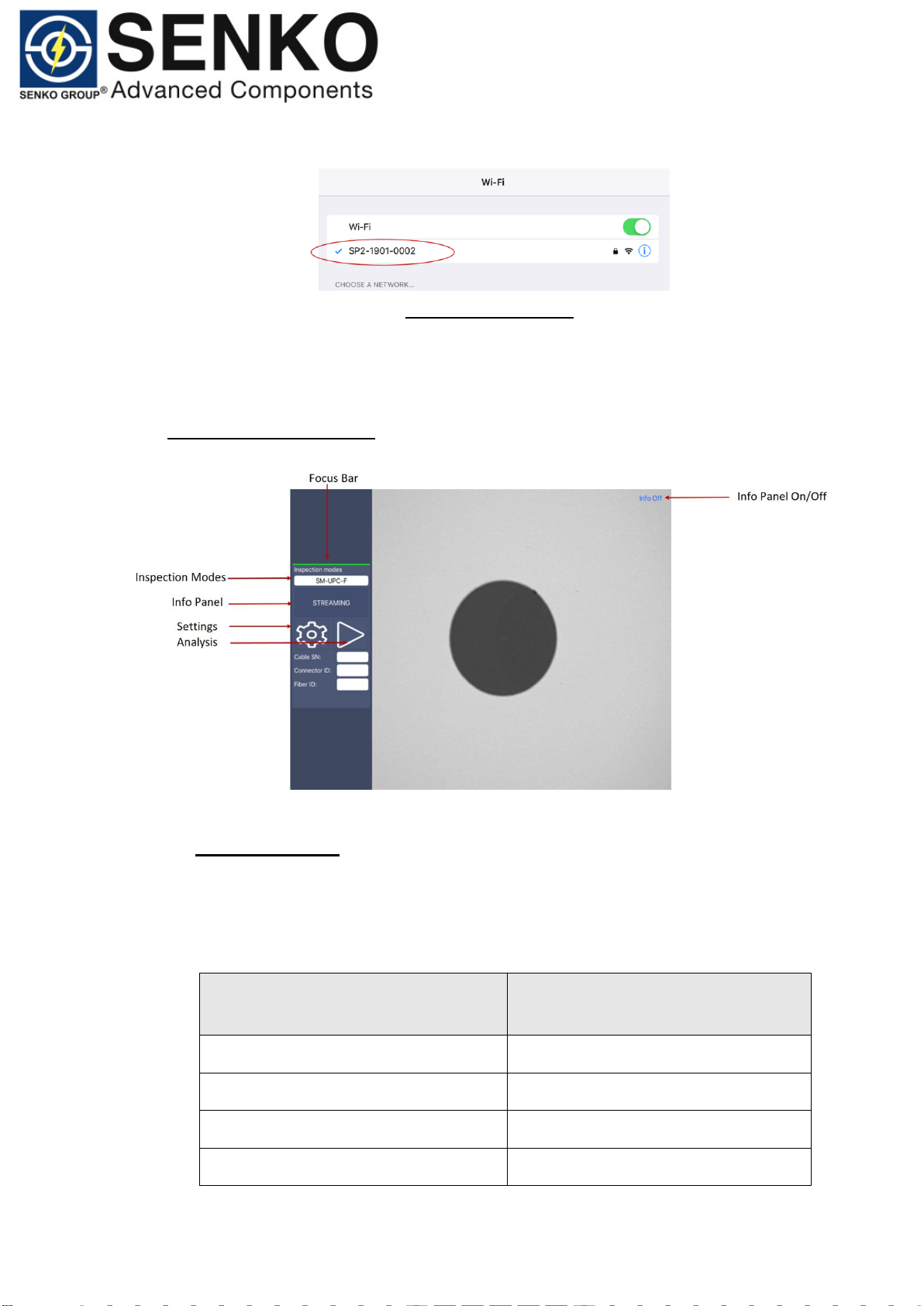

7.3 WiFi Set-up

All SENKO probes are identified by their serial numbers (prefixed SSID “SP2-XXXX-

XXXX”)

Example: “SP2-1901-0002”

oSP2= Smart Probe 2.

o1901= Manufacturing ‘Year’ and ‘Month’.

o0002= Identification Number.

Date: 08-05-2019

Doc Number: ENG-SP2M-0519-001

13

To connect the wireless probe:

1. Turn on the probe by pressing down the Main On/Off Switch. The blue LED

near the switch will light up.

2. Flip WiFi/USB Switch to . Wait until the green LED has lights up

continually.

3. Start the Vue3 application and open WiFi Setting (see below).

Date: 08-05-2019

Doc Number: ENG-SP2M-0519-001

14

4. Select the wireless probe you want to work with. Once connected go back

to the Vue3 app.

Wi-Fi Password

(12345678)

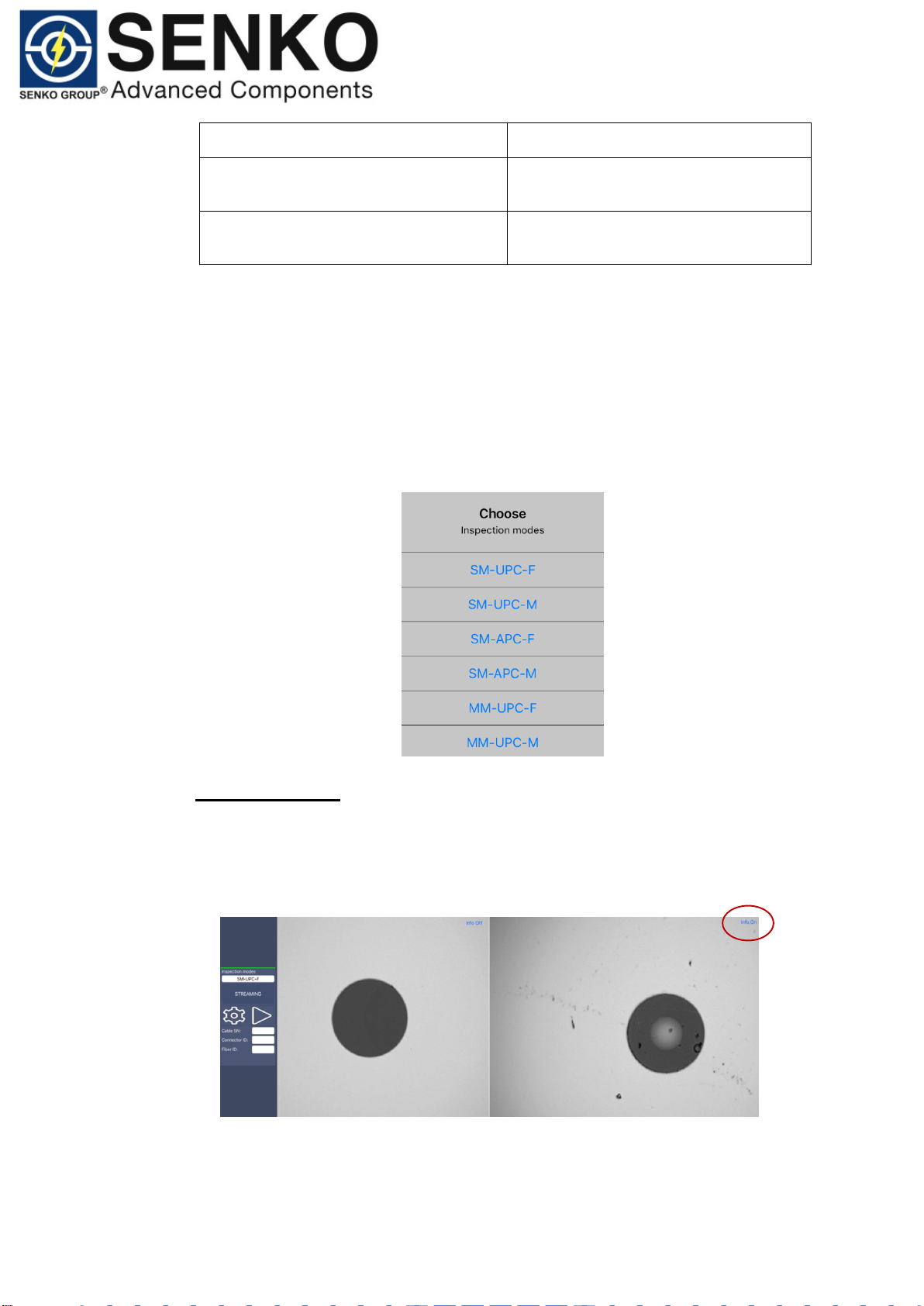

8.0 Software Overview

8.1 Functionality Diagram

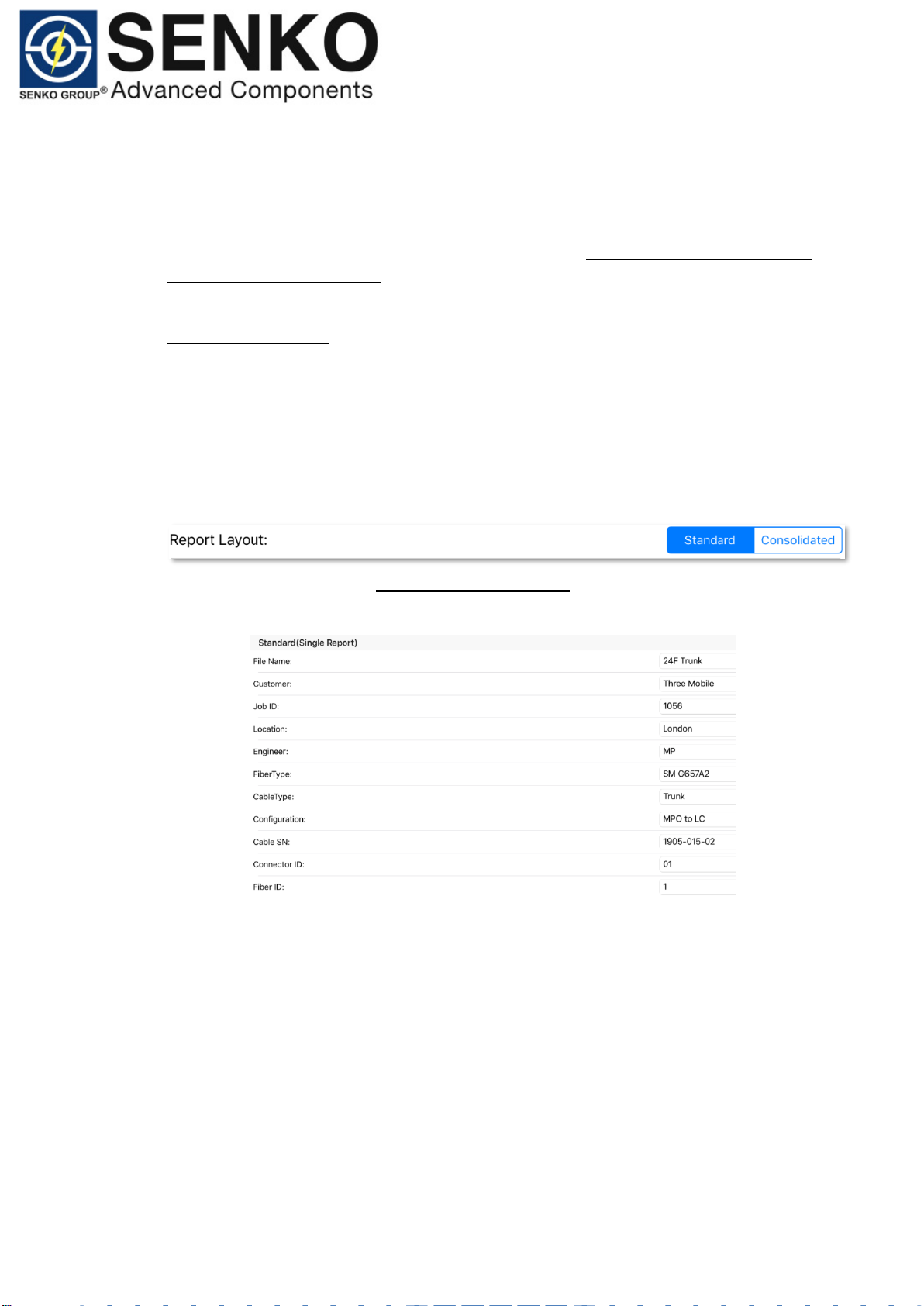

Inspection Modes:

There are 6 inspection modes covering various connector types. Select correct

inspection mode corresponding to connector type (see below).

Inspection Mode

Connector Types

SM-APC-M

(Patchcord)

SC, FC, ST, LC, MU, DIN, CS, E-2000

SM-APC-F

(In-adapter)

SC, FC, ST, MU, DIN, E-2000

SM-UPC-M

(Patchcord)

SC, FC, ST, LC, MU, DIN, CS, E-2000

SM-UPC-F

(In-adapter)

SC, FC, ST, LC, MU, DIN, E-2000, CS

Date: 08-05-2019

Doc Number: ENG-SP2M-0519-001

15

MM-UPC-M

(Patchcord)

SC, FC, ST, LC, MU, DIN, CS, E-2000

MM-UPC-F

(In-adapter)

SC, FC, ST, LC, MU, DIN, CS, E-2000

Please note: all 6 inspection modes have specially optimized algorithm settings, tuned to

accommodate various inspection tips. It’s important to select correct inspection mode for

analysis.

To select inspection mode:

1. From the main screen, tap Inspection Mode button.

2. Popup Menu will appear in the middle of the screen. Select correct

inspection mode.

Info Panel On/Off:

To hide info panel:

1. Tap on/off button in the top right corner of the screen.

Date: 08-05-2019

Doc Number: ENG-SP2M-0519-001

16

Process Button:

To trigger PASS/FAIL analysis:

1. From the Main Screen, tap process button.

Please note: PASS/FAIL analysis can also be triggered by pressing the ‘capture button’

on the top of the probe.

Focus Indicator:

The focus indicator is displayed in the upper left part of the main window. The focus

bar shows whether the current view is optimized for a capture. A green indicator

shows image that can be captured and analyzed. Analysis will be impossible with

a red indicator.

Date: 08-05-2019

Doc Number: ENG-SP2M-0519-001

17

Info Panel:

To access ‘Inspection Results Summary’:

1. From the Main Screen, tap PASS/FAIL button.

Settings Menu:

Test Set-up:

In this section you can create test configurations as per inspection

requirements.

PDF Reports:

In this section you can access all standard & consolidated PDF reports.

Images:

In this section you can access all end-face screen shots.

User Guide:

In this section you can access ‘User Guide’ and support.

Date: 08-05-2019

Doc Number: ENG-SP2M-0519-001

18

9.0 Customizing the Software:

Vue3 can be customized in various ways to suite your inspection requirements. You

can set the application to generate an inspection report automatically or manually.

either a single page report or consolidated report (consolidating multiple reports

merged into a single report). During testing you can also add ‘comments’ to your

reports and review them later on.

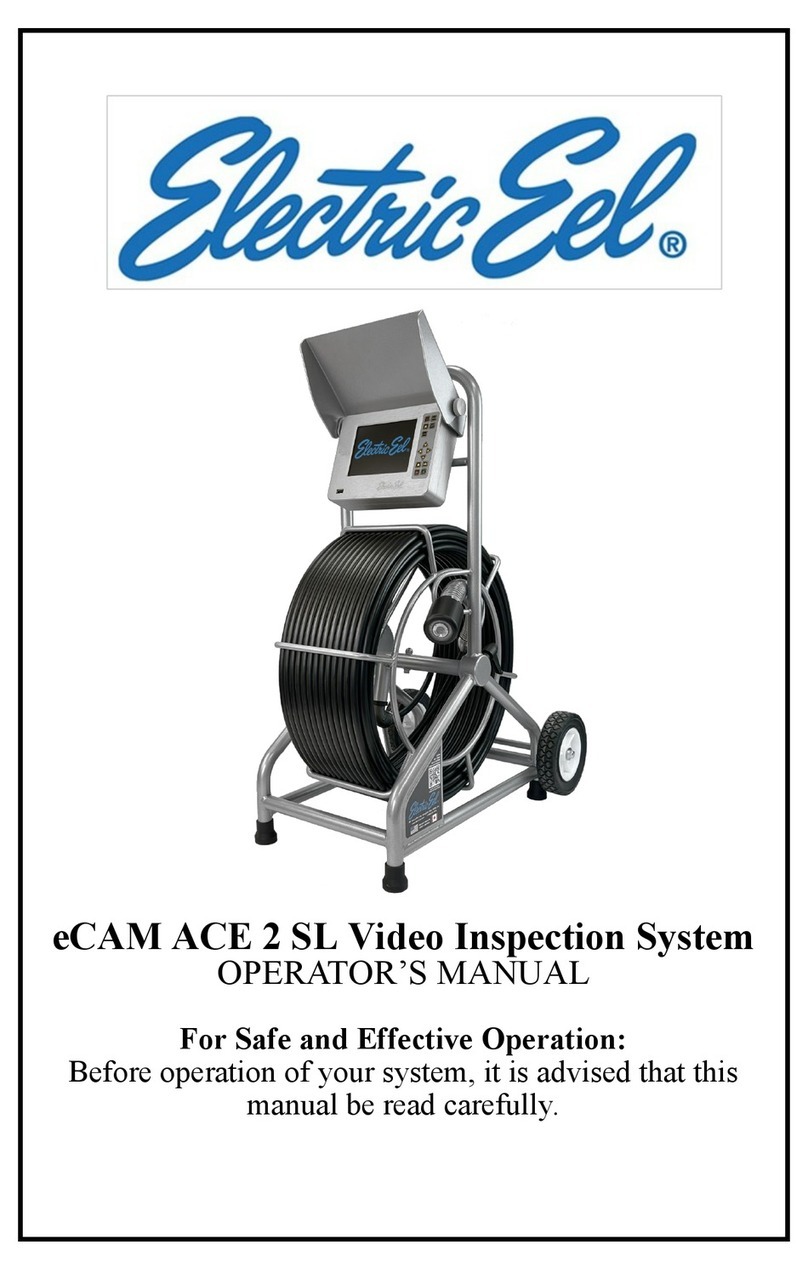

9.1 Standard Report

A standard report is a single page PDF report. The report contains a summary of end-

face inspection.

To activate standard report:

1. From the Main Menu, tap ‘Settings’ button.

2. Select Standard in ‘Report Layout’.

3. Under heading ‘Standard Single Report’ within the Test Set-up Menu.

Start filling information which you want to include in your test report.

Please note:

(a) As a minimum requirement, ‘Cable SN, Connector ID & Fiber ID’ information

MUST to be provided. The application won’t proceed with inspection if one of the

information is incomplete.

(b) File name: this will become a ‘title’ of the PDF report, followed by date and time

(see below).

Date: 08-05-2019

Doc Number: ENG-SP2M-0519-001

19

Standard Report Template: (Example)

The standard report structure:

1. General & Fiber information.

This section of the report provides a summary of the test ‘Set-up’

configuration.

2. Captured & Analyzed Image.

The application provides two screen shots of the inspected end-face in the

standard report. First image is a screen shot of the end-face without

software analysis. Second image highlights debris on the fiber surface. On

3. Test Summary Table.

Contains inspection result summary as per IEC 61300-3-35 standard.

4. Comments.

This section contains ‘comments’ entered during testing.

Date: 08-05-2019

Doc Number: ENG-SP2M-0519-001

20

9.2 Consolidated Reporting

This feature allows combining multiple reports into a single PDF file. This feature is

useful when inspecting cable assemblies with a high number of ports e.g (144F trunks).

To activate consolidated report:

1. From the Main Menu, tap ‘Settings’ button.

2. Select Consolidated in the ‘Report Layout’.

3. Under heading ‘Consolidated Report’ within the Test Set-up Menu. Start

filling information which you want to include in your consolidated report.

Please note:

(a) As a minimum requirement, ‘Cable SN, Connector ID, Fiber ID & Total Fibers’

information MUST to be provided. The application won’t proceed with inspection if

information is incomplete.

(b) Total Fibers: this number determines how many fibers will be inspected. If you

want to inspect 144 fibers, enter ‘144’. The application will generate a consolidated

report for 144 individual fibers.

(c) File name: this will become a ‘title’ of the PDF report, followed by date and time.

Table of contents

Popular Analytical Instrument manuals by other brands

Electric Eel

Electric Eel eCAM ACE 2 SL Operator's manual

Pacific Laser Systems

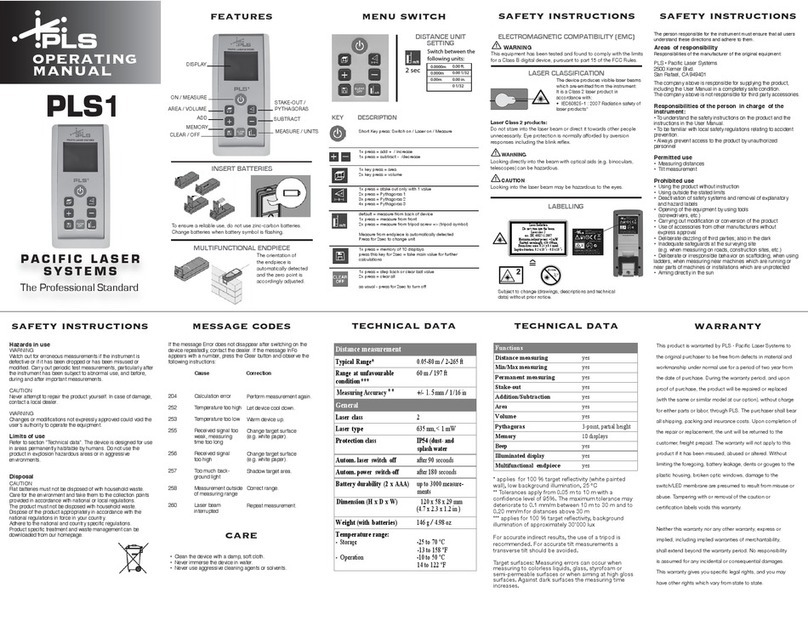

Pacific Laser Systems PLS1 operating manual

Ryobi

Ryobi LDM-32 Owner's operating manual

Agilent Technologies

Agilent Technologies 89410A Installation and Verification

Gibertini

Gibertini densimat instruction manual

Tektronix

Tektronix 570 instruction manual

Bosch

Bosch UniversalInspect Original instructions

Green

Green G36P manual

Rothenberger

Rothenberger ROCAM Plus Instructions for use

CHALCO ELEVEN LIMITED

CHALCO ELEVEN LIMITED CC-M420-PH operating manual

Buhler

Buhler BA 1000 Installation and operation instruction

Wolfgang

Wolfgang LDM01 Operation and Function Manual