G36p Oxygen Analyzer

Ve r s i o n 2.11 – Revision January 2021 – Part 01381 3

Content

1INTRODUCTION.................................................................................................. 5

1.1 ABOUT THIS MANUAL .........................................................................................................5

1.2 INQUIRIES AND FEEDBACK..................................................................................................5

1.3 ABOUT THE ANALYZER .......................................................................................................6

2ANALYZER SPECIFICATIONS ............................................................................... 8

3ANALYZER INSTALLATION &CONNECTIONS ......................................................... 9

3.1 CONTROL AT DELIVERY......................................................................................................9

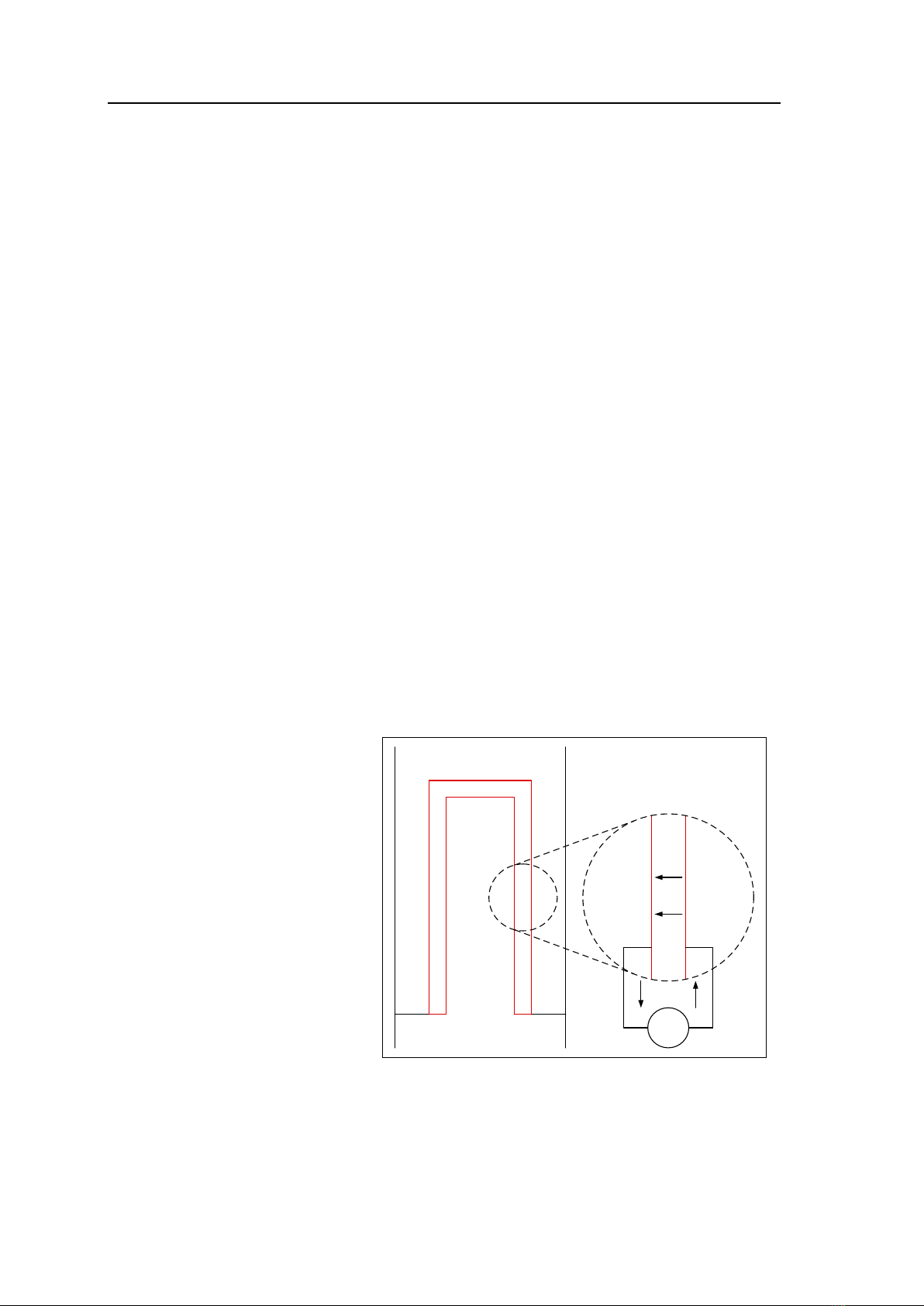

3.2 WHERE TO INSTALL THE ANALYZER.....................................................................................9

3.3 SAFETY ASPECTS............................................................................................................10

3.4 ELECTRICAL CONNECTION ...............................................................................................12

3.4.1 Power Supply ..................................................................................................13

3.4.2 Sensor Connections – SEN.............................................................................13

3.4.3 Relay Outputs – D-OUT ..................................................................................13

3.4.4 Input Connections – A-IN.................................................................................15

3.4.5 Analog Output Connections – A-OUT .............................................................16

3.4.6 SD Card ...........................................................................................................16

3.4.7 Other Connections...........................................................................................17

4MENU STRUCTURE .......................................................................................... 18

4.1 MAIN MENU ....................................................................................................................18

4.2 GRAPH MENU .................................................................................................................19

4.3 INFORMATION MENU ........................................................................................................21

4.4 CALIBRATION MENU.........................................................................................................21

4.5 TOOLS MENU ..................................................................................................................22

4.6 NAVIGATING THE MENU STRUCTURE.................................................................................24

5CONFIGURATION &COMMISSIONING ................................................................. 25

5.1 SETTING OF BASIC DISPLAY PARAMETERS ........................................................................25

5.2 SETTING OF ALARM LIMITS...............................................................................................26

5.3 SETTING OF THE ANALOG INPUT .......................................................................................27

5.4 SETTING OF ANALOG OUTPUTS........................................................................................28

5.4.1 Analog Output 1...............................................................................................28

5.4.2 Analog Output 2...............................................................................................30

5.5 BACK-FLUSHING &AUTO CALIBRATION .............................................................................30

5.6 LOADING DEFAULT SETTINGS &FACTORY SETTINGS .........................................................31

5.7 COMMISSIONING OF THE ANALYZER..................................................................................32

6CALIBRATION.................................................................................................. 34

6.1 CALIBRATION WITH KNOWN OXYGEN GASES.....................................................................34

6.2 ARTIFICIAL CALIBRATION OF OXYGEN SIGNAL ...................................................................36

7ROUTINE MAINTENANCE .................................................................................. 37

7.1 ANALYZER.......................................................................................................................37

7.2 CALIBRATION...................................................................................................................37

7.3 SENSOR .........................................................................................................................37

7.4 GAS CONNECTION...........................................................................................................38