Sens DC PowerCab 120 Owner's manual

SENS®DC PowerCab™120

Installation, Operation, & Maintenance Manual

8/24/2017 2 755-00129 R04

Stored Energy Systems Packaged By:

1840 Industrial Circle C&C Power, Inc.

Longmont, Co 80501 395 Mission Street

www.sens-usa.com Carol Stream, IL 60188

Technical Support:

Phone: (303) 678-7500 or (800) 742-2326

Email: service@sens-usa.com

SENS, the SENS logo and PowerCab are trademarks of Stored Energy Systems LLC.

8/24/2017 3 755-00129 R04

TABLE OF CONTENTS

1. Important Information About This Manual................................................................................. 4

1.1 Manual Symbols.................................................................................................................... 4

2. Introduction................................................................................................................................. 5

3. Safety Precautions....................................................................................................................... 6

4. Inspection Upon Receipt of Goods.............................................................................................. 8

4.1 General .................................................................................................................................. 8

4.2 Visible Damage..................................................................................................................... 8

4.3 Concealed Damage................................................................................................................ 8

4.4 Return of Damaged Goods.................................................................................................... 8

5. System Overview ........................................................................................................................ 9

6. System Specifications................................................................................................................ 10

6.1 Batteries............................................................................................................................... 10

6.2 System Grounding............................................................................................................... 10

6.3 AC Input.............................................................................................................................. 10

6.4 DC Output ........................................................................................................................... 10

6.5 Optional AC Output ............................................................................................................ 11

6.6 Optional LVD...................................................................................................................... 11

6.7 General Specifications......................................................................................................... 11

7. Installation................................................................................................................................. 13

7.1 Preparation........................................................................................................................... 13

7.1.1 Equipment Inspection................................................................................................... 13

7.1.2 Necessary Equipment and Tools .................................................................................. 13

7.1.3 Installation Safety Precautions ..................................................................................... 13

7.2 Installation Steps ................................................................................................................. 13

7.2.1 Equipment Location ..................................................................................................... 13

7.2.2 Equipment Mounting.................................................................................................... 14

7.2.3 Equipment Grounding.................................................................................................. 14

7.2.4 AC/DC Connections..................................................................................................... 14

7.2.5 System Operation ......................................................................................................... 15

8. System Maintenance.................................................................................................................. 16

8.1 Battery Replacement ........................................................................................................... 16

9. Reference Materials................................................................................................................... 18

10. Warranty.................................................................................................................................. 23

SENS®DC PowerCab™120

8/24/2017 4 755-00129 R04

1.IMPORTANT INFORMATION ABOUT THIS MANUAL

SAVE THESE INSTRUCTIONS! This manual contains important information that is needed

during the installation and maintenance of the system.

1.1 MANUAL SYMBOLS

Warning / Caution:

Indicates information provided to protect the user against personal injury, safety

hazards and/or possible equipment damage.

Important:

Indicates information provided as an installation or operating instruction or tip as

well as general important installation and system information.

SENS®DC PowerCab™120

8/24/2017 5 755-00129 R04

2. INTRODUCTION

Stored Energy Systems (SENS®) would like to thank you for choosing SENS product for your

power and back-up equipment needs. We know there are a lot of choices in the industry, and we

appreciate the opportunity to supply our customers with the highest quality power products

manufactured in the United States.

All SENS products are built to the highest industry standards and are Hi Pot tested to UL standards

prior to shipment. All standard configurations are C-UL listed.

Sales support for existing or future equipment needs are provided by our technical sales staff. For

all technical, sales, and service related questions please call our office line at 303-678-7500 and

you will be directed to the appropriate individual to answer your questions.

After normal working hoursplease leave a detailed message, withyour phone number, on our voice

mail system and a qualified representative will contact you as quickly as possible.

Stored Energy Systems Packaged By:

1840 Industrial Circle C&C Power, Inc.

Longmont, Co 80501 395 Mission Street

www.sens-usa.com Carol Stream, IL 60188

Technical and Sales Support:

Phone: (303) 678-7500 or (800) 742-2326

Email: service@sens-usa.com

SENS®DC PowerCab™120

8/24/2017 6 755-00129 R04

3. SAFETY PRECAUTIONS

Before installing or maintaining this system, it is extremely important to read this

manual and be surethat all systemdrawings and schematics are reviewed and clearly

understood. If there are any questions concerning this manual or any of the

installation or maintenance procedures and/or requirements please contact a C&C

Power representative before proceeding.

When installing this power system, follow all applicable federal, state and local

regulations as well as industry guidelines to insure proper system installation.

Only qualified electricians or DC power technicians should attempt to install or

service this equipment.

System installation and maintenance should always be performed with heavily

insulated tools. It is also recommended to wear rubber gloves, boots, and use

insulating mats to stand on when working on this equipment.

Always wear eye protection when installing or maintaining batteries and/or power

equipment.

Do not attempt to unpack or move the battery cabinet without assistance. Use

appropriate handling equipment rated to bear the weight and bulk of the battery

cabinet, such as freight elevators, pallet jacks and forklifts. (Fully extend forks under

load. Spread forks to maximum possible width under load. Lift cabinet from bottom

only. Wear safety shoes.)

Do not smoke or present open flames near any battery system.

For the safety of others, never leave an open cabinet or panel unattended.

To reduce the risk of fire, replace fuses with the same type and rating of fuses

supplied with the system.

SENS®DC PowerCab™120

8/24/2017 7 755-00129 R04

DC Power and Batteries can be very dangerous and have extremely high short circuit

current. Electrical shock, severe burns, fire or death can result from a system short.

To avoid personal injury including electrical shock, severe burns and possible death,

all jewelry including bracelets, rings and watches mustbe removed prior to installing

or servicing this system.

Do not open or mutilate batteries. Opened or severely damaged batteries can release

toxic electrolyte which is harmful to the skin and eyes.

Never lay loose cables, metal parts or tools on top of batteries.

Under certain conditions, batteries can vent potentially explosive gas (hydrogen).

Never enclose batteries or battery cabinets in a sealed room.

SENS®DC PowerCab™120

8/24/2017 8 755-00129 R04

4. INSPECTION UPON RECEIPT OF GOODS

4.1 GENERAL

Special precautions and care have been taken to ensure the system arrives safe and undamaged.

However, upon receipt, you should inspect the entire shipment, including the crate and any boxes

for evidence of damage that may have occurred during transit.

4.2 VISIBLE DAMAGE

It is the responsibility of the person receiving the shipment to inventory and fully inspect all

materials against the bill of lading or weigh bill IMMEDIATELY while the carrier representative

is still present. Insure that all items are accounted for, including number of skids and quantity of

boxes. Also note any visible external damage that may have occurred during transit. Make all

applicable notations on the delivery receipt before signing and file a damage report with the carrier.

4.3 CONCEALED DAMAGE

Within 3 to 30 days of receipt (depending on courier), unpack the system and check for any

concealed damage. Check the materials received against the detailed packing list to verify the

quantity and the condition as complete and satisfactory.

Note any damage to the internal packaging, then request an inspection by the carrier and file a

concealed damage claim. If there is a material shortage, contact a representative at SENS to file a

claim.

Please contact your shipping company for all shipping damage.

C&C Power is not responsible for any shipping damage.

4.4 RETURN OF DAMAGED GOODS

Should equipment be damaged and require return, contact SENS Technical Support. A

representative will provide instructions along with an RMA number to expedite the return.

A RMA number must be obtained before returning equipment to Sens or C&C Power, Inc.

SENS®DC PowerCab™120

8/24/2017 9 755-00129 R04

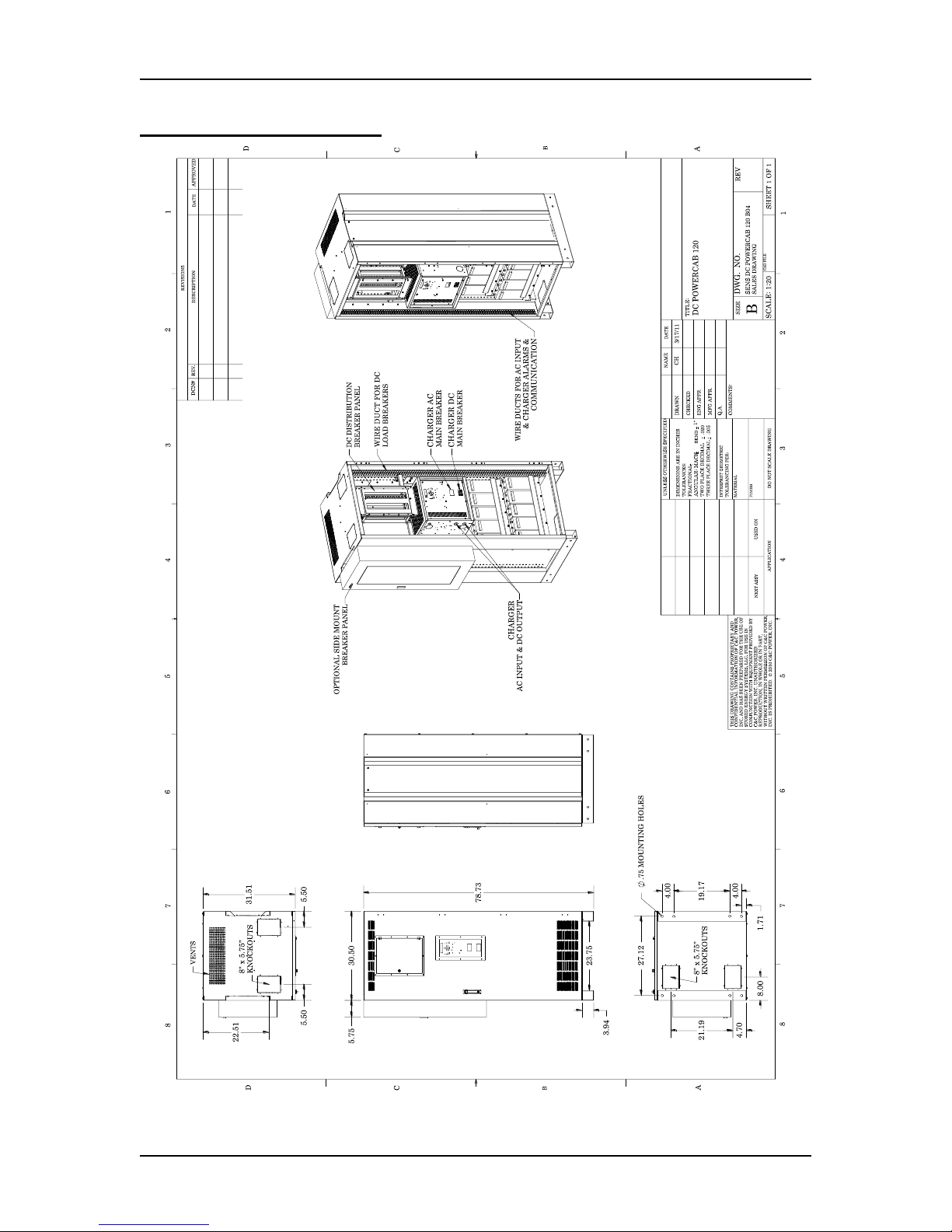

5. SYSTEM OVERVIEW

The DC PowerCab 120 is a non-stop DC power system designed to deliver uninterruptible DC

power to critical loads. PowerCab includes a DC power supply/charger, storage battery string, and

DC distribution to load center.

In addition to the charger, battery, distribution panel and cabinet, PowerCab can be optionally

equipped with:

•Additional DC distribution

•Low voltage disconnect (to prevent battery from over-discharge)

•Top-Lift Bracket

•Multiple DC to AC inverter options

The DC PowerCab system is fully factory assembled and is ready to install upon delivery.

SENS®DC PowerCab™120

8/24/2017 10 755-00129 R04

6.SYSTEM SPECIFICATIONS

6.1 BATTERIES

Type: Valve Regulated Lead Acid (VRLA), sealed, non-spillable

Amp-Hour Options: 100 AH, 150AH, 170AH or 200AH

Voltage: 12 VDC Nominal

6.2 SYSTEM GROUNDING

Cabinet Safety Ground: Each cabinet is supplied with a mechanical ground lug that accepts bare

wire from #2/0 AWG to #14 AWG.

Torque: 375 in-lbs

Wire Size and Type: Ground wire should be sized per NEC and/or all applicable national and

local codes.

6.3 AC INPUT

The AC input to the charger (see Figure 1 for location) can be:

208 VAC 60 Hz, 1ф

230 VAC 50/60 Hz, 1ф

240 VAC 60 Hz, 1ф

115-120/208/230-240 VAC 60 Hz, 1ф

115-120/208/230-240 VAC, 50/60 Hz, 1ф

400 VAC 50/60 Hz, 1ф

480 VAC 60 Hz, 1ф

6.4 DC OUTPUT

DC Output Voltage Options include:

•24-volt nominal (12 cells lead-acid)

•48-volt nominal (24 cells lead-acid)

•120-volt nominal (60 cells lead-acid)

•240-volt nominal (120 cells lead-acid)

Charger Output Current Options include:

•6 Amps (15A charger to panelboard breaker)

•12 Amps (15A charger to panelboard breaker)

•16 Amps (20A charger to panelboard breaker)

•25 Amps (35A charger to panelboard breaker)

•35 Amps (45A charger to panelboard breaker)

•50 Amps (70A charger to panelboard breaker)

Only cabinets with Flame Retardant Batteries are suitable for computer room use.

All system ground wires should be derived from the main building ground source.

SENS®DC PowerCab™120

8/24/2017 11 755-00129 R04

•75 Amps (100A charger to panelboard breaker)

•100 Amps (125A charger to accessory breaker)

•150 Amps (200A charger to accessory breaker)

DC Load Center: Panelboard, 100A, 2-pole battery main breaker, 2-pole charger-feed breaker,

plus 12 each 2-pole load breaker positions.

Wire Size and Type: Per NEC and/or all applicable national and local codes.

6.5 OPTIONAL AC OUTPUT

•600 Watt Inverter, 120VAC, 60Hz

•600 Watt Inverter, 230VAC, 50Hz

•1000 Watt Inverter, 120VAC, 60Hz

•1000 Watt Inverter, 230VAC, 50Hz

•1100 Watt Inverter, 120VAC, 60Hz

•1100 Watt Inverter, 230VAC, 50Hz

•2000 Watt Inverter, 120VAC, 60Hz

•2000 Watt Inverter, 230VAC, 50Hz

•3000 Watt Inverter, 120VAC, 60Hz

•3000 Watt Inverter, 230VAC, 50Hz

AC output option consumes one 2-pole load breaker position.

Wire Size and Type: Per NEC and/or all applicable national and local codes.

6.6 OPTIONAL LVD

When AC power fails,the systems batteries will discharge in order to provide the necessary backup

power to the load. If the DC PowerCab 120 is equipped with the Low Voltage Disconnect (LVD)

feature, the system load will be automatically disconnected at the customer adjustable LVD

disconnect voltage setting. This will prevent the batteries from being discharged to unsafe levels.

A Bender VME420 type Digital Voltage Monitor Relay is used to control the contactor in the LVD

circuit. The LVD circuit, with the Monitor Relay imbedded, wiring connections to the DC load

center and the Charger is shown in Figure 2/Section 9. The activation and factory settings of the

LVD Voltage Relay are shown in Figure 3/Section 9 for a 120 VDC system, Figure 4/Section 9 for

a 48 VDC system and Figure 5/Section 9 for a 24 VDC system.

6.7 GENERAL SPECIFICATIONS

Cabinet Size: 30.5”W x 31.5”D x 78.7”H

Typical Weights:

Empty Cabinet (approximately): 450 lbs

Complete System Weight can be found on the individual cabinet drawing that is mounted to the

inside of the door.

Wire should be sized for a maximum voltage drop of 0.5 volt.

SENS®DC PowerCab™120

8/24/2017 12 755-00129 R04

Operating Temperature: 20°C to 25°C (68°F to 77°F) recommended for optimum battery

performance.

Ventilation: Ventilation holes located in the front, rear, and top of the cabinet. Clearance around

the equipment should be as suggested by NEC and/or all applicable national and local codes. The

battery cabinet does not require rear access or rear clearance.

Under certain conditions, batteries can vent potentially explosive gas (hydrogen).

Never enclose batteries or battery cabinets in a sealed room.

Batteries should be stored no longer than three months at 25°C (77°F) or lower

before recharging. Exceeding the recommended ambient storage temperature may

cause damage to the batteries.

SENS®DC PowerCab™120

8/24/2017 13 755-00129 R04

7. INSTALLATION

7.1 PREPARATION

7.1.1 EQUIPMENT INSPECTION

Remove the equipment from the packaging material and inspect for any shipping damage that

may have been overlooked upon receipt of goods. Verify that the system includes all necessary

hardware for installation.

7.1.2 NECESSARY EQUIPMENT AND TOOLS

oHeavily insulated assortment of hand tools

oDigital voltmeter

7.1.3 INSTALLATION SAFETY PRECAUTIONS

7.2 INSTALLATION STEPS

7.2.1 EQUIPMENT LOCATION

Prior to installation, verify floor loading requirements (see weights in Section 6.7) and all

applicable codes pertaining to the related equipment. Environmental conditions should also be

reviewed. Battery systems require an area with proper ventilation and cooling. An ambient

temperature between 20°C to 25°C (68°F to 77°F) is recommended for optimum battery life and

performance. Clearance around the equipment should be as suggested by NEC and/or all

applicable national and local codes. The battery cabinet does not require rear access or rear

clearance.

Before proceeding with system installation, be sure to review and understand all of

the SAFETY PRECAUTIONS in this manual!

DC VOLTAGE WARNING!

Hazardous DC voltages are present in the system. This hazard will always be

present in a battery system including when it is offline. Accidental short circuit

of the positive and negative terminal will cause tremendous currents to flow

resulting in electrical shock, severe burns, fire and possible death! Use extreme

caution when installing and maintaining the system!

Before installing or maintaining this system, it is extremely important to read this

manual and be surethat all systemdrawings and schematics are reviewed and clearly

understood. If there are any questions concerning this manual or any of the

installation or maintenance procedures and/or requirements please contact a C&C

Power representative before proceeding.

Under certain conditions, batteries can vent potentially explosive gas (hydrogen).

Never enclose batteries or battery cabinets in a sealed room. Follow international

(IFC 608), state, and local codes for ventilation requirements.

SENS®DC PowerCab™120

8/24/2017 14 755-00129 R04

7.2.2 EQUIPMENT MOUNTING

1. The SENS DC PowerCab 120 cabinet is equipped with pallet jack and/or forklift access

openings in the front and rear of the cabinet. Move the equipment into the desired location

and set into place.

2. With the cabinet in the desired location, mark the location of four mounting holes found at

the bottom of the cabinet legs. Two sets of mount holes are provided so that mount hardware

can be offset in multi cabinet installations.

3. Move the cabinet out of the way and drill holes for the mounting hardware that will be used.

4. Move the cabinet back into place, align the holes, and tighten the hardware.

5. Should any drilling be performed on this equipment, make sure all exposed batteries and

connections are completely covered using insulated type mats.

7.2.3 EQUIPMENT GROUNDING

Terminate a cabinet ground wire from the main building ground source to the supplied #2/0 AWG

- #14AWG mechanical lug located on the bottom panel of the cabinet in the front right-hand corner.

Wire should be sized per NEC and/or all applicable national and local codes.

7.2.4 AC/DC CONNECTIONS

Do not attempt to unpack or move the battery cabinet without assistance. Use

appropriate handling equipment rated to bear the weight and bulk of the battery

cabinet, such as freight elevators, pallet jacks and forklifts. (Fully extend forks under

load. Spread forks to maximum possible width under load. Lift cabinet from bottom

only. Wear safety shoes.)

All system ground wires should be derived from the main building ground source.

For multi cabinet systems, each cabinet needs to have a designated cabinet ground

wire derived from the main building ground source.

Review the attached to the cabinet System Drawings and Schematics for model

specific information on DC output connections to the panelboard.

Wire should be sized for a maximum voltage drop of 0.5 volt.

Verify that the Battery Main Breaker and the Charger Main Breaker on the

panelboard (see System Drawing/Schematic) are in the off/open position before

making any DC connections from the panelboard breakers to their respective loads.

SENS®DC PowerCab™120

8/24/2017 15 755-00129 R04

Open the front doors on the cabinet and check for any noticeable problems or damage that may

have occurred during shipment.

1. Review the attached system drawing/schematic located inside the cabinet doors to find the

location of the jumper that has been left off in the middle of the battery string for added safety

during installation and shipping. This jumper will be installed later.

2. Check and re-torque all internal battery connections, as shipping may have caused these

connections to come loose. Proper torque values are noted on the system schematic/drawing

and can also be found on most battery cases.

3. Refer to the Charger Operation Installation and Operation Manual for instructions for making

AC power connections to the charger. The AC input cables can ingress the cabinet from either

the top panel or the bottom panel by removing the appropriate panel knockout plate. The AC

input cables should be run in the wire ducts located on the left-side of the cabinet from the

cabinet ingress point to the connection point on the charger.

4. Without LVD Option: Verify that the battery string output and the charger DC output are

connected to the breakers on the panelboard specified in the system schematic/drawing.

Assure that thesetwo breakers are in the off/open position before making any DC connections

from the panelboard breakers to their respective loads.

With LVD Option: Referencing Figure 2/ Section 9, verify that the battery string output and

the charger DC output are connected as shown to the LVD circuit and the LVD circuit is

terminated to the proper breaker in the DC Load Center.

5. Review the supplied cabinet schematic/drawing for information on the size and location of

the DC distribution breakers on the panelboard. Route the DC output cables fromthe breakers

through the wire duct located on the right-side of the cabinet to the cabinet egress point on

the top of the cabinet (after removing the knockout plate) and connect to their respective

loads. All cables should be sized per NEC and any other local codes pertaining to this

equipment.

6. Connect the jumper that was left off during shipment and install as shown on the system

schematic. Torque connections properly.

7.2.5 SYSTEM OPERATION

Please refer to the Charger Operation Installation and Operation Manual included with the SENS

DC PowerCab 120 product for startup and operation information for the charger unit.

SENS®DC PowerCab™120

8/24/2017 16 755-00129 R04

8.SYSTEM MAINTENANCE

8.1 BATTERY REPLACEMENT

1. Prepare the new battery for installation. Verify that the battery is the same type and amp-hour

rating as the batteries that are in the system.

2. Using a digital voltmeter, measure the battery voltage to verify that it is 12.4 VDC or above.

3. Use a brass wire brush or abrasive pad to polish the battery terminals.

4. Apply no-ox type terminal grease to the battery terminals to avoid corrosion.

5. Disconnect the loads from the battery string by turning off/opening the Battery Main circuit

breaker on the panelboard.

6. Remove the centerjumper on the battery string to reduce the voltage. If replacing all batteries,

continue reducing the voltage by removing the inter-shelf jumper.

7. Disconnect the cables from the battery to be replaced.

8. Remove the bad battery.

Before proceeding with system maintenance, be sure to review and understand all of

the SAFETY PRECAUTIONS in this manual!

Verify that the Battery Main breaker on the panelboard and Charger AC Main

breaker (on the charger unit) are in the off/open position before servicing the system.

When batteries are replaced they must be properly installed paying special attention

to terminal polarity orientation! If wired incorrectly it will cause a short in the system

and can result in electrical shock, severe burns, fire and possible death! Be sure to

review the system schematics before terminating any battery cables.

Caution: Risk of explosion if batteries are replaced by an incorrect type.

Do not dispose of batteries in a fire. The batteries may explode. Contact your local

hazardous waste or recycling center for battery disposal requirements.

Do not discard batteries in the trash. This product contains sealed lead acid

batteries. Contact your local hazardous waste or recycling center for battery

disposal requirements.

SENS®DC PowerCab™120

8/24/2017 17 755-00129 R04

9. Put the new battery into place. Make sure new battery is installed properly regarding polarity

orientation. Use the supplied wiring schematic/ drawing found inside the battery cabinet door

to verify the cabinet wiring.

10. Reconnect the cables to battery and make sure the connections are properly torqued.

11. Reconnect any removed string jumpers and make sure the connections are properly torqued.

12. Check the battery string voltage at input side of the Battery Main circuit breaker.

13. Start the charger and reconnect the loads to the battery string by turning on/closing the circuit

breakers turned off in step 5.

SENS®DC PowerCab™120

8/24/2017 18 755-00129 R04

9. REFERENCE MATERIALS

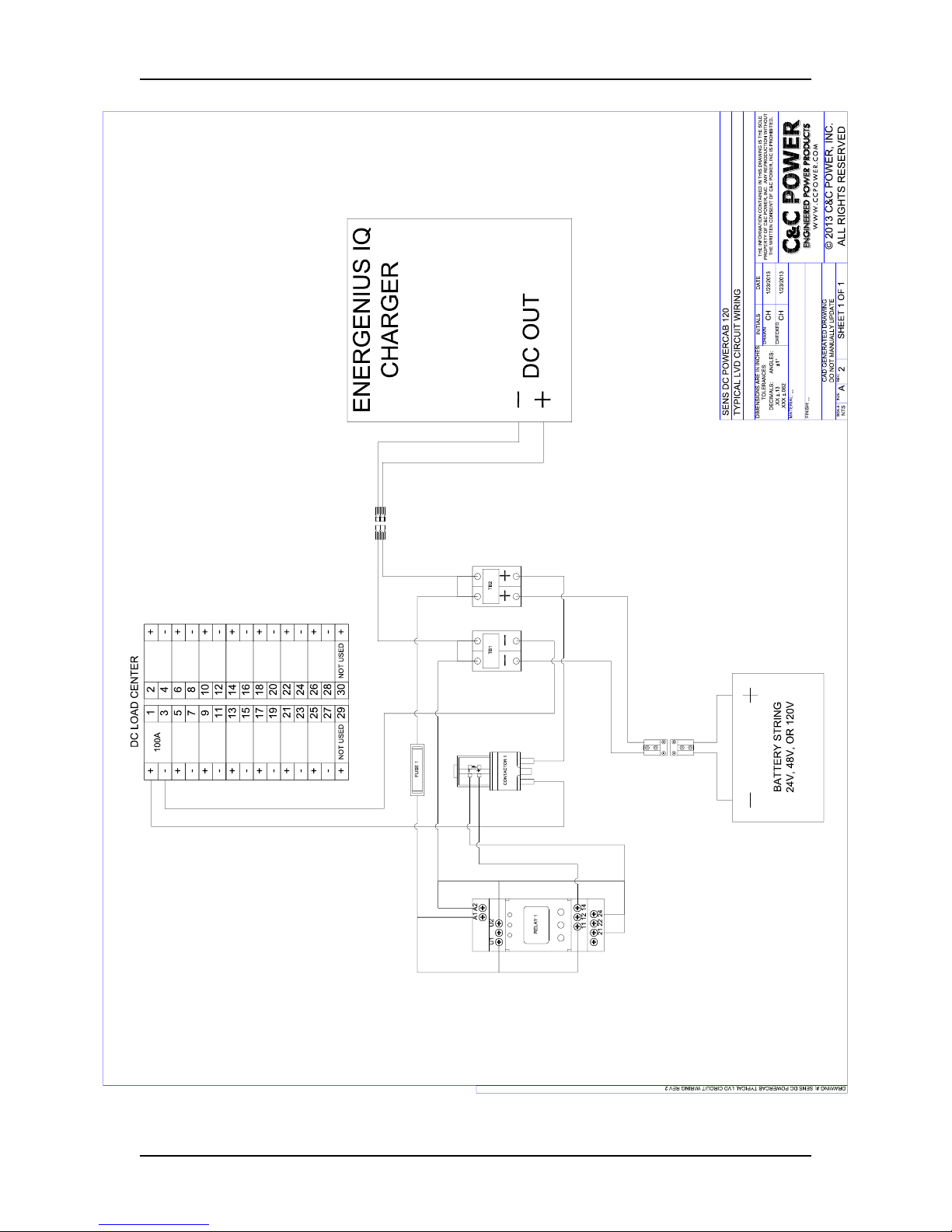

Figure 1

SENS®DC PowerCab™120

8/24/2017 19 755-00129 R04

Figure 2

SENS®DC PowerCab™120

8/24/2017 20 755-00129 R04

SENS DC PowerCab LVD Voltage Relay Settings - 120 VDC Systems

Bender VME420-D-2 (043-00009)

The settings for the LVD Voltage Relay are listed in the table below:

Menu

Sub Menu

Menu Item

Activation

& Setting

Adjustable parameter

AL

(response

- values)

------->

<U

ON

(105V)

Undervoltage

>U

OFF

Overvoltage

U Hys

14%

Hysteresis < U / > U

< Hz

OFF

Underfrequency

> Hz

OFF

Overfrequency

Hz Hys

N/A

Hysteresis, frequency

out

(output

control)

------->

M

OFF

Fault memory

1

N.C.

Operating mode K1

2

N.C.

Operating mode K2

LEd

OFF

LED’s Signal relay in alarm state

r1 (K1:

(assignment

alarm

category)

1 Err

OFF

Device error at K1

r1 < U

ON

Undervoltage K1

r1 > U

OFF

Overvoltage K1

r1 < Hz

OFF

Underfrequency K1

r1 > Hz

OFF

Overfrequency K1

1 S.AL

OFF

Start with alarm during (t+t) on1

r2 (K2:

(assignment

alarm

category)

2 Err

OFF

Device error K2

r2 < U

ON

Undervoltage K2

r2 > U

OFF

Overvoltage K2

r2 < Hz

OFF

Underfrequency K2

r2 > Hz

OFF

Overfrequency K2

2 S.AL

OFF

Start with alarm during (t+t) on2

t

(timing

check)

------->

t on 1

0

Response delay K1

t on 2

0

Response delay K2

T

0

Starting delay

t off

0

Delay on release K1/K2

Set

(device

control)

------->

OFF

Parameter setting via password

FAC

-

Re-establish factory settings

PrE

-

Manual preset

SYS

-

Function blocked

InF

--------------->

-

Display hard/ software version

HiS

------->

Clr

-

History memory for the first alarm value, erasable

Figure 3

Table of contents

Popular UPS manuals by other brands

Elen

Elen B1 Series user manual

Vertiv

Vertiv Liebert GXT5-5000MVRT4UXLN Installer/user guide

GE

GE Uninterruptible Power Supply user manual

Pacific Power Source

Pacific Power Source 3060-UMS Operation manual

Eaton

Eaton Powerware 9395 installation instructions

Cineparts

Cineparts SRWpower LE User instructions

Tech Novitas

Tech Novitas venus flexi series user manual

OPTI-UPS

OPTI-UPS Line Interactive UPS Series PS1000B-RM Specifications

Para systems

Para systems ETR500 user manual

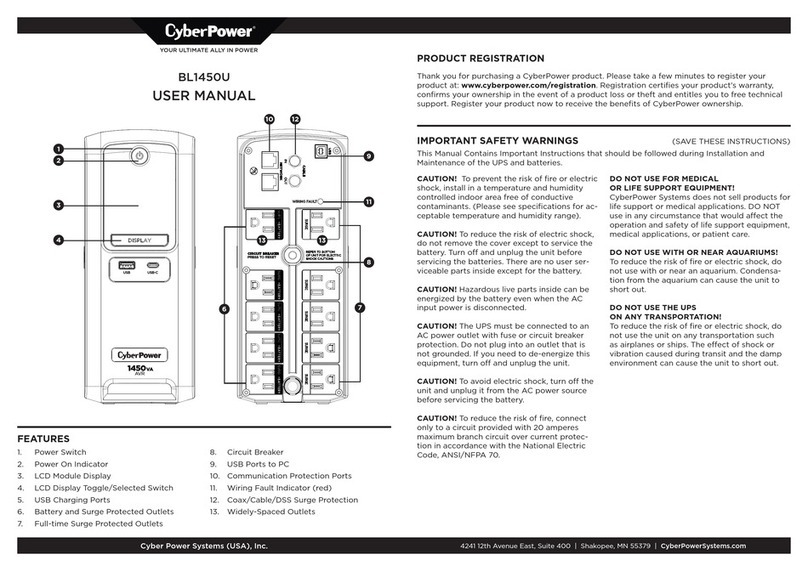

CyberPower

CyberPower BL1450U user manual

socomec

socomec Green Power 2.0 10 Installation and operating manual

Lowell

Lowell UPS9-1000 User & installation manual