SENSIRION SDP1108 User manual

www.sensirion.com Sensirion – the sensor company

SDP1108

Low Range Differential Pressure Sensor

with fast response time

−For medical ventilators (ICU and home care)

−High sensitivity below 10 Pa to measure small volume flow (neonatal)

−Fast response time for efficient trigger function

−Unsurpassed performance thanks to CMOSens®technology

−Offset and hysteresis free

−Fully calibrated and temperature compensated

−Not sensitive to the mounting orientation and vibrations

SDP1108 Product Summary

The SDP1108 is a differential pressure sensor for air

based on the successful SDP1000/ SDP2000 sensor

from Sensirion AG. The response time of the SDP1108

has been optimized for medical ventilation applications.

Mounted in a rugged, chemically inert PPS housing the

SDP1108 differential pressure sensors feature a

unique dynamic range, zero offset and unsurpassed

long term stability. This makes it an ideal fit for

demanding yet cost sensitive OEM applications in

medical and HVAC equipment.

The SDP1108 is fully RoHS compliant.

The SDP1108 is supplied with 5.0 V and provides a

0.25…4.0 V output. Although the output of the sensor

is analog, the internal linearization and temperature

compensation is performed digitally. This results in a

superior accuracy, outstanding resolution (up to 0.05

Pa), and lowest temperature dependence.

Its leading performance is based on Sensirion’s

proprietary CMOSens®sensor technology which

combines the sensor element with amplification and

A/D conversion on one single silicon chip. The

differential pressure is measured by a thermal sensing

element. In contrast to other thermal differential

pressure sensors only a very small amount of air is

required. This leads to a reliable operation even under

harsh conditions. In comparison to membrane and

piezo-resistive based sensors the SDP1108 differential

pressure sensors show an extended measurement

range, better offset stability and improved

reproducibility even at lowest pressure ranges. In

addition the SDP1108 is robust against pressure bursts

and shows no sensitivity to the mounting orientation.

Applications

Medical applications:

•Homecare ventilation

•Intensive care ventilation (ICU)

•Other

Block Diagram

Differential

pressure

Sensor

CM OSe n s

®

SENSOR CHIP

DI G IT A L

Linearization and

Temperature

com pens at ion

A/ D con v ert er

Memory

D/ A

co nve r ter

V

DD

5.0 V

OUT

0.25 V

to 4 V

GND

Data Sheet – v1.0

www.sensirion.com v1.0 October 2008 2/6

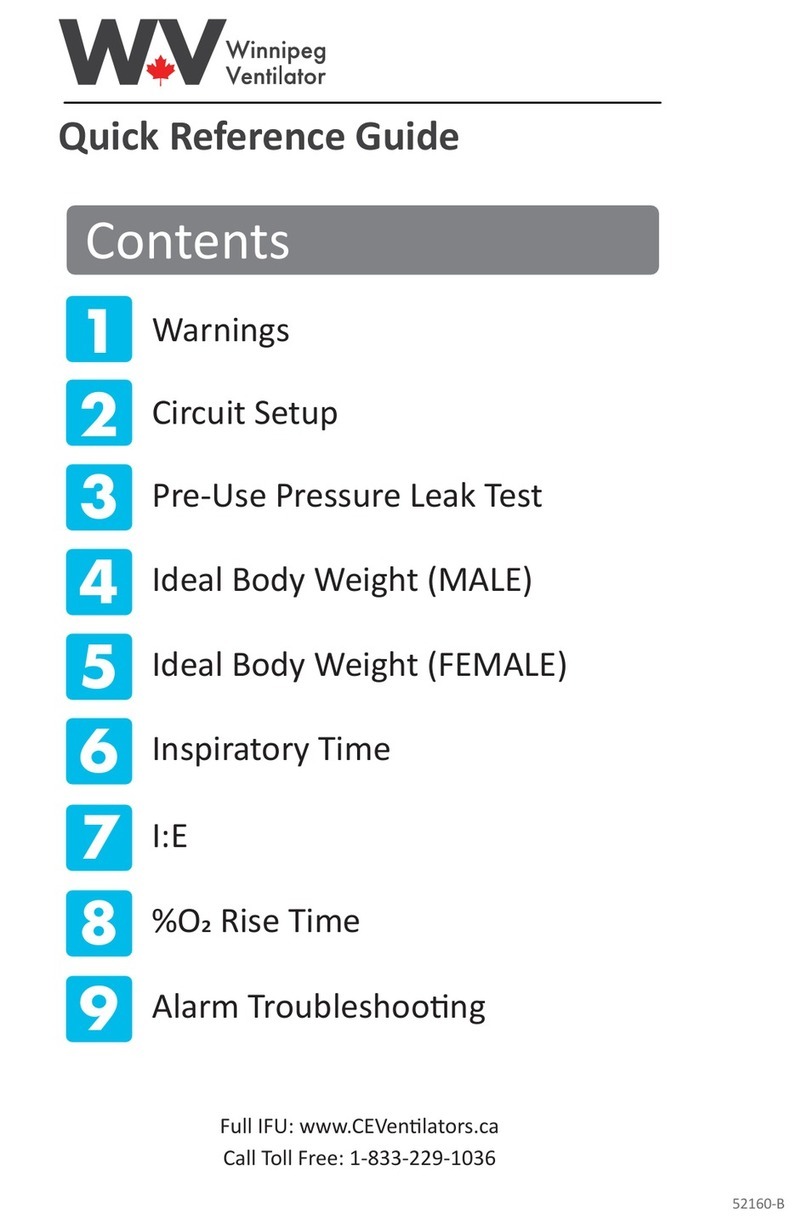

1Sensor Output Characteristics1

The SDP1108-R provides a fully calibrated

voltage output. To enhance resolution and

accuracy at very low differential pressures, the

SDP1108 standard version (SDP1108-R)

comes with a root-square output

characteristics.

For high-quantity OEM applications, other

ranges and output characteristics can be

realized. E.g. linear output and a bidirectional

measurement range is possible. Please contact

Sensirion for further information.

Pa

V.

V.Voltage_Output

]Pa[eal_PressurDifferenti 500

753

250 2

⋅

⎟

⎠

⎞

⎜

⎝

⎛−

=Use this formula to convert the sensor output

into physical value.

(1)Calibration conditions apply unless otherwise noted: 23°C and pabsolute = 966 mbar, dry air, VDD = 5.000 V

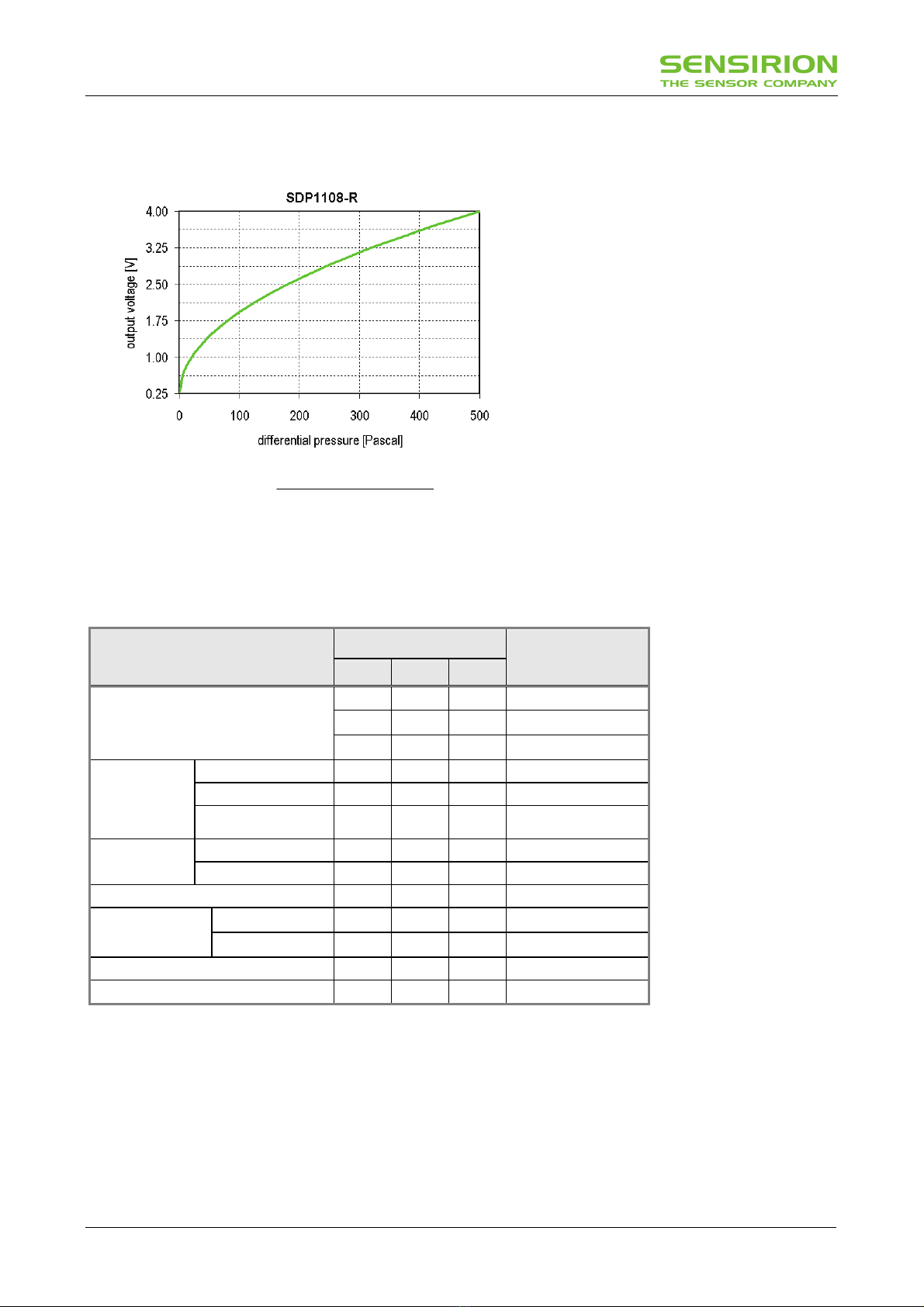

2Specifications

Table 1: SDP1108-R Sensor specifications(1)

SDP1108-R

Parameter

Min Typ Max

Unit

0.25 - 4 Volts

0 - 500 Pa

Measurement range

0 - 2 Inch water

100 to 500 Pa - 1.0 2.0 % Measured Value(4)

0 to 100 Pa - 0.2 0.4 % Full Span(5)

Accuracy(3)

zero(2) -

15

0.01

40

0.06

mV

Pa

100 to 500 Pa - 0.3 1.0 % Measured Value

Repeatability 0 to 100 Pa - 0.05 0.2 % Full Span(5)

Null drift per year(6) - 0 0.1 Pa / year

0 to 500 Pa - 0.03 0.05 % Measured Value / °C (4)

Additional error over

temperature (7)

(T ≠23°C) zero - 1 2 mV/°C

Response time(8) 6.6 8.0 10.1 Ms

Cut off frequency of internal filter 17 20 24 Hz

(1) Calibration conditions apply unless otherwise noted: 23°C and pabsolute = 966 mbar, dry air, VDD = 5.000 V

(2) Variance between the zero point (offset) of different sensors measured under the same conditions (e.g. same supply voltage, temperature, …)

(3) Include deviations due to linearity, hysteresis, and repeatability

(4) % measured value = (SDP1108 output [Pa] - output of reference instrument [Pa]) / output of reference instrument [Pa].

(5) Full span = 3750mV or 500 Pa

(6) Drift over time due to aging, pressure cycles… Test results can be provided.

(7) The additional error due to temperature variation is temporary. Once the sensor is back to the calibration temperature, the shift disappears

(no hysteresis).

(8) Tau= 0 to 63%, filter response time = 8ms. For faster response time, contact Sensirion.

www.sensirion.com v1.0 October 2008 3/6

Table 2: Additional sensor specifications.

Parameter

Media Air, N2– for other gases contact Sensirion AG.

Operating Conditions:

- Temperature

- Humidity

-10 °C … +60 °C / 14°F … 140 °F

non-condensing

Ambient storage conditions1 -40 °C … +80 °C / -40°F … 176 °F

Position sensitivity below resolution

Admissible overpressure (short term) 1 bar (14.5 PSI)

Burst Pressure Capability 2 bar (29 PSI)

Weight 14 g

Protection Class IP 20

Wetted materials Glass (silicon nitride, silicon oxide), Silicon, PPS (Polyphenylene Sulfide),

PEEK (Polyetheretherketone), FR4, Silicone as static sealing, Epoxy, Gold

EN 61000-4-2 Air discharge (ESD) ±2 kV

EN 61000-4-3 High frequency

electromagnetic radiation (HF) 3 V/m

Electromagnetic compatibility

EN 61000-4-4 Fast transients (burst) ±4 kV

Lead free ROHS compliant.

(1)For maximum 2 weeks

2.1 Temperature Compensation

The SDP1108 differential pressure sensor features a

sophisticated built-in temperature compensation circuit.

The temperature is measured on the CMOSens® chip by

means of a PTAT bandgap reference temperature

sensor. Its data is fed into a compensation circuit which

is also integrated on the CMOSens®sensor chip. No

external temperature compensation is therefore required.

2.2 Altitude Correction

The SDP1108 differential pressure transducer achieves

its unsurpassed performance by using a dynamic

measurement principle: An applied differential pressure

forces a small air flow through the SDP1108, which

measures this air flow.

The sensor signal is dependant on the ambient air

density. The temperature effect on density is

compensated by internal intelligence (see Paragraph

2.3). Effects on density due to a change of ambient

pressure, typically a change of altitude above sea level,

can be compensated using a correction factor according

to the following equation:

Dpeff = Dpsensor *Pcal / Pamb

where Dpeff is the effective differential pressure, Dpsensor

the differential pressure indicated by the SDP1108, Pcal

the absolute pressure during calibration (966 mbar)

and Pamb the actual ambient absolute pressure.

This leads to the following correction factors:

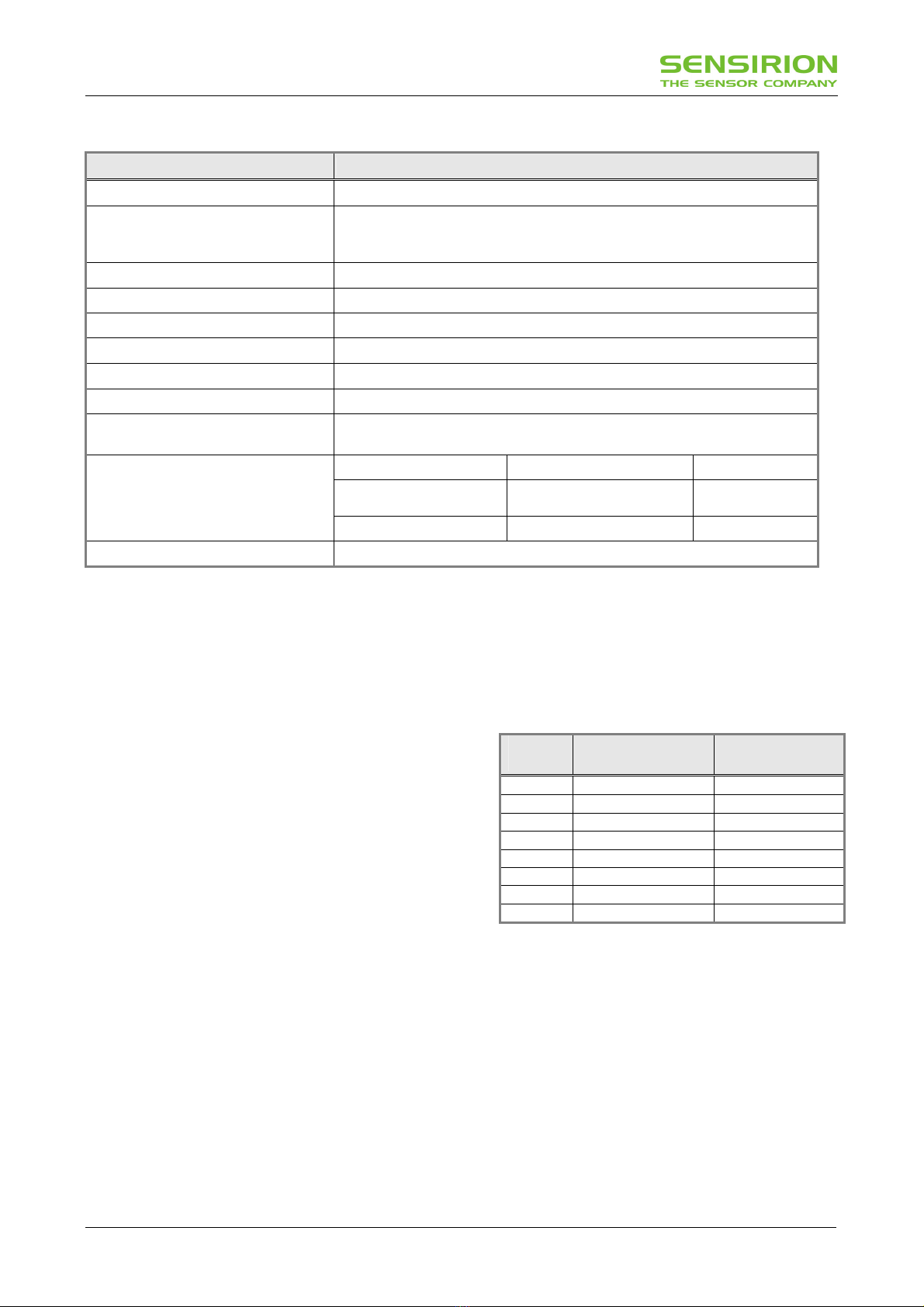

Table 3: Altitude correction factors.

Altitude

[meter]

Ambient Pressure

(Pamb) [mbar]

Correction Factor

Pcal / Pamb

0 1013 0.95

250 984 0.98

425 966 1.00

500 958 1.01

750 925 1.04

1500 842 1.15

2250 766 1.26

3000 697 1.38

Example:

The SDP1108 is used at 750 m above sea level. The

output of the SDP1108 shows 0.5 V, which

corresponds to Dpsensor = 33.3 Pa. Taking into account

the correction factor Pcal / Pamb = 1.04 the effective

differential pressure Dpeff is 33.3 Pa * 1.04 = 34.6 Pa.

Note:

In many medical and HVAC applications such as filter

monitoring, fan/ventilator control or air flow

measurement the described effect is actually

welcome since at the end the mass flow and not

volume flow is the effective value to control.

www.sensirion.com v1.0 October 2008 4/6

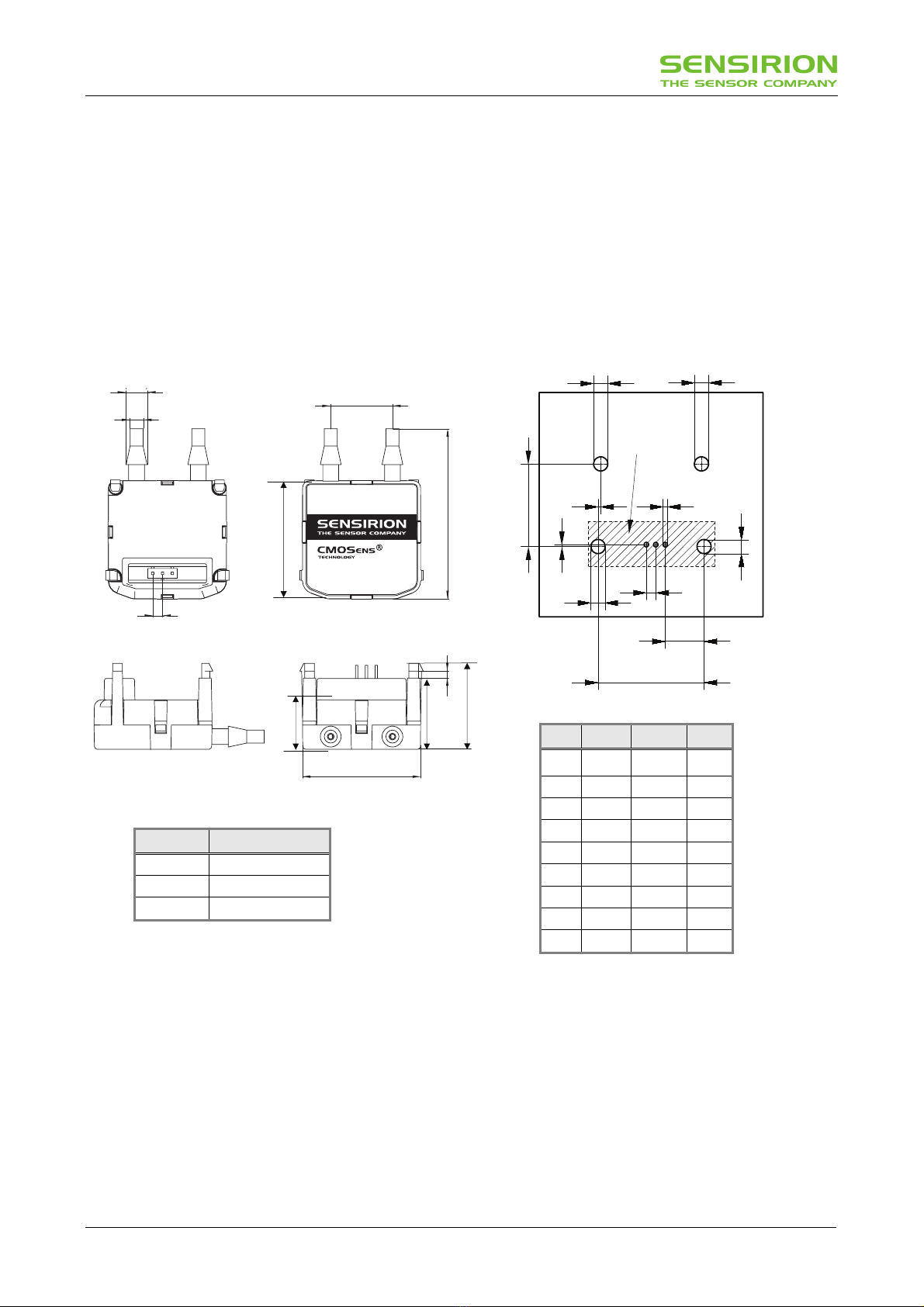

3Physical Dimensions and Mounting Information

3.1 Housing

The SDP1108 differential pressure transducer is mounted

in chemically inert PPS housing. The rugged package

has been designed to withstand continuous

overpressures of at least 1 bar (14.5 PSI). Burst pressure

is > 2 bar (29 PSI)

The physical dimensions and mounting information is

given in Figure 1 and 2.

3.4

(0.134)

5.4

(0.213)

2.54

(0.100)

16.0

(0.630)

44.0

(1.732)

SDP100000206-10033-250-001

Hi Lo

1.8

(0.071)

30.0

(1.181)

Pin#

1 2 3

A

G C

F

D

E

H

I

No Components

inside this Area

B

B

A

Figure 1: Pin out and physical dimensions in mm (inch). The

drawing is not to scale.

Figure 2: SDP1108 PCB footprint. The drawing is

not to scale.

3.2 Soldering Instructions

The SDP1108 differential pressure sensor can be wave

soldered. Direct reflow soldering is not recommended

since it may affect the accuracy.

If reflow soldering is required Sensirion recommends to

use an SMD connector (e.g. type Samtec SSM-103-L-

SV) and to mount the SDP1108 after soldering.

22.1

(0.870)

Dim.

[mm] [inch] [mil]

A 3.00 0.118 118

B 3.30 0.130 130

C 1.20 0.047 47

D 10.20 0.402 402

E 28.20 1.110 1110

F 2.54 0.100 100

G 0.60 0.024 24

H 0.50 0.020 20

I 22.70 0.894 894

Pin# Function

1 VDD

(

5

Vdc

)

2 Ground

3 OUT (0.25…4 Vdc)

18.3

(0.720)

30.5

(1.200)

5.2

(

0.205

)

13.1

(0.516)

www.sensirion.com v1.0 October 2008 5/6

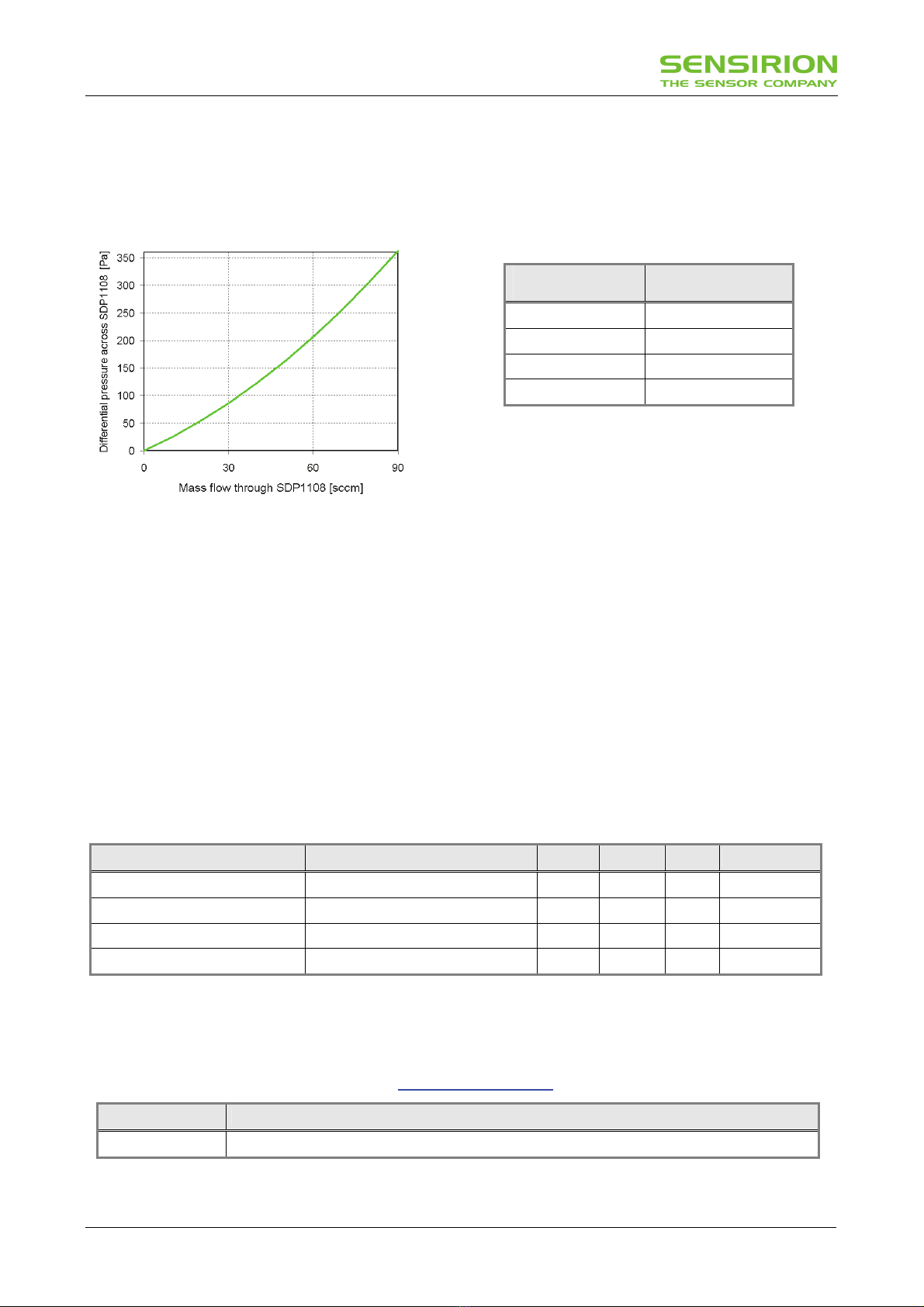

3.3 Connecting Hose

Sensirion recommends a hose with an inner diameter

of 1/8 to 3/20 inch (3.18 to 3.8mm). Due to the dynamic

measurement principle, a small air flow is required

(Figure 3) which leads to a dependence on the length

of the hose (Figure 4). Tubes up to 1 m show less than

1 % error of the measured value (Figure 4).

Figure 3: Typical air flow through the SDP1108.

Please note: 1 scc/min = 1 cm3/min at 0°C and

1013 mbar pressure (1 sccm = 0.001 norm liter).

Figure 4: Influence of the length of the connecting hose on the

accuracy (using 3/16 inch inner diameter). Example:

a 50 Pa difference pressure is shown as 49.8 Pa

when using 0.5 m tube with 3/16 inch diameter.

4Electrical Specifications

4.1 Power Supply

The SDP1108 differential pressure sensors require a

stable voltage supply of 5.0 V. Influence of the supply

voltage variation on the offset and the sensitivity are

given in Table 5.

4.2 Voltage Output

The SDP1108 features a voltage output from 0.25 V to

4.0 V. An output voltage below 0.25 V indicates a

negative differential pressure (not calibrated).

The resistive load at the output pin should be larger

than 20 kOhm. The capacitive load at the output pin

must not be larger than 200 pF. If the design shows a

larger capacity at the output pin an additional resistor is

required in series at the output (e.g. 620 Ohm).

Table 4: SDP1108 electrical characteristics.

Parameter Conditions Min. Typ. Max. Units

Power Supply Voltage VDD 4.75 5.0 5.25 VDC

Operating Current 5 V, no load, zero flow 5.1 6 mA

Output capacitive load Cload 20 200 pF

Recommended load Rload 20 100

∞kΩ

5Ordering Information

When ordering please refer to the following part names and article numbers. For the latest product information and

local distributor check out Sensirion’s website on http://www.sensirion.com

Part Name Article Number

SDP1108-R 1-100339-01

Length of the

connecting hose

Deviation of

Measured Value

0.5 m (20 inch) - 0.4 %

1.0 m (40 inch) - 0.8 %

2.0 m (80 inch) - 1.6 %

4.0 m (160 inch) - 3.2 %

www.sensirion.com v1.0 October 2008 6/6

Important Notices

Warning, personal injury

Do not use this product as safety or emergency stop devices or in any

other application where failure of the product could result in personal

injury (including death). Do not use this product for applications other

than its intended and authorized use. Before installing, handling,

using or servicing this product, please consult the data sheet and

application notes. Failure to comply with these instructions could

result in death or serious injury.

If the Buyer shall purchase or use SENSIRION products for any unintended

or unauthorized application, Buyer shall defend, indemnify and hold

harmless SENSIRION and its officers, employees, subsidiaries, affiliates

and distributors against all claims, costs, damages and expenses, and

reasonable attorney fees arising out of, directly or indirectly, any claim of

personal injury or death associated with such unintended or unauthorized

use, even if SENSIRION shall be allegedly negligent with respect to the

design or the manufacture of the product.

ESD Precautions

The inherent design of this component causes it to be sensitive to

electrostatic discharge (ESD). To prevent ESD-induced damage and/or

degradation, take customary and statutory ESD precautions when handling

this product.

See application note “ESD, Latchup and EMC” for more information.

Warranty

SENSIRION warrants solely to the original purchaser of this product for a

period of 12 months (one year) from the date of delivery that this product

shall be of the quality, material and workmanship defined in SENSIRION’s

published specifications of the product. Within such period, if proven to be

defective, SENSIRION shall repair and/or replace this product, in

SENSIRION’s discretion, free of charge to the Buyer, provided that:

• notice in writing describing the defects shall be given to SENSIRION

within fourteen (14) days after their appearance;

• such defects shall be found, to SENSIRION’s reasonable satisfaction,

to have arisen from SENSIRION’s faulty design, material, or

workmanship;

• the defective product shall be returned to SENSIRION’s factory at the

Buyer’s expense; and

• the warranty period for any repaired or replaced product shall be limited

to the unexpired portion of the original period.

This warranty does not apply to any equipment which has not been

installed and used within the specifications recommended by SENSIRION

for the intended and proper use of the equipment. EXCEPT FOR THE

WARRANTIES EXPRESSLY SET FORTH HEREIN, SENSIRION MAKES

NO WARRANTIES, EITHER EXPRESS OR IMPLIED, WITH RESPECT TO

THE PRODUCT. ANY AND ALL WARRANTIES, INCLUDING WITHOUT

LIMITATION, WARRANTIES OF MERCHANTABILITY OR FITNESS FOR

A PARTICULAR PURPOSE, ARE EXPRESSLY EXCLUDED AND

DECLINED.

SENSIRION is only liable for defects of this product arising under the

conditions of operation provided for in the data sheet and proper use of the

goods. SENSIRION explicitly disclaims all warranties, express or implied,

for any period during which the goods are operated or stored not in

accordance with the technical specifications.

SENSIRION does not assume any liability arising out of any application or

use of any product or circuit and specifically disclaims any and all liability,

including without limitation consequential or incidental damages. All

operating parameters, including without limitation recommended

parameters, must be validated for each customer’s applications by

customer’s technical experts. Recommended parameters can and do vary

in different applications.

SENSIRION reserves the right, without further notice, (i) to change the

product specifications and/or the information in this document and (ii) to

improve reliability, functions and design of this product.

Bare Die Disclaimer

All die are tested and calibrated and are guaranteed to comply with all data

sheet limits. Only random sample tests are performed on individual die.

SENSIRION has no control of third party procedures in the handling,

packing or assembly of the die. Accordingly, SENSIRION assumes no

liability for device functionality or performance of the die or systems after

third party handling, packing or assembly of the die. It is the responsibility of

the customer to test and qualify their application in which the die is used.

Copyright©2001-2008, SENSIRION.

CMOSens®is a trademark of Sensirion

All rights reserved

Revision history

Date Revision Changes

October V1.0 Initial release

Headquarters and Sales Office

SENSIRION AG Phone: + 41 (0)44 306 40 00

Laubisruetistr. 50 Fax: + 41 (0)44 306 40 30

Switzerland http://www.sensirion.com/

SENSIRION Korea Co. Ltd. Phone: +82-31-440-9925~27

#1414, Anyang Construction Tower B/D, Fax: +82-31-440-9927

Gyeonggi-Province, South Korea http://www.sensirion.co.kr

SENSIRION Inc Phone: 805-409 4900

Westlake Pl. Ctr. I, suite 240 Fax: 805-435 0467

2801 Townsgate Road michael.karst@sensirion.com

Westlake Village, CA 91361 http://www.sensirion.com/

USA

SENSIRION Japan phone: +81 3-3444-4940

Sensirion Japan Co. Ltd. fax: +81 3-3444-4939

Shinagawa Station Bldg. 7F info@sensirion.co.jp

4-23-5 Takanawa http://www.sensirion.co.jp

Minato-ku, Tokyo, Japan

Find your local representative at: http://www.sensirion.com/reps

Table of contents

Other SENSIRION Medical Equipment manuals

Popular Medical Equipment manuals by other brands

Getinge

Getinge Arjohuntleigh Nimbus 3 Professional Instructions for use

Mettler Electronics

Mettler Electronics Sonicator 730 Maintenance manual

Pressalit Care

Pressalit Care R1100 Mounting instruction

Denas MS

Denas MS DENAS-T operating manual

bort medical

bort medical ActiveColor quick guide

AccuVein

AccuVein AV400 user manual