Sensorex DO6400 Instruction sheet

Page 1 of 8

Your Sensorex Dissolved Oxygen (DO) sensor is a galvanic

electrochemical device; i.e. it does not require power from

your meter or controller to generate its signal (for mV output

models only). The DO sensor will provide a millivolt signal pro-

portional to the concentration of oxygen in the water (model

DO6400, DO6400TC) or 4-20mA current output (models

DO6441 and DO6442). Your Dissolved Oxygen sensor con-

sists of an cathode, anode, and an electrolyte separated from

your process fluid by an oxygen permeable membrane. The

oxygen passing through the membrane reacts at the cathode,

giving up electrons, which produces an electrical current. See

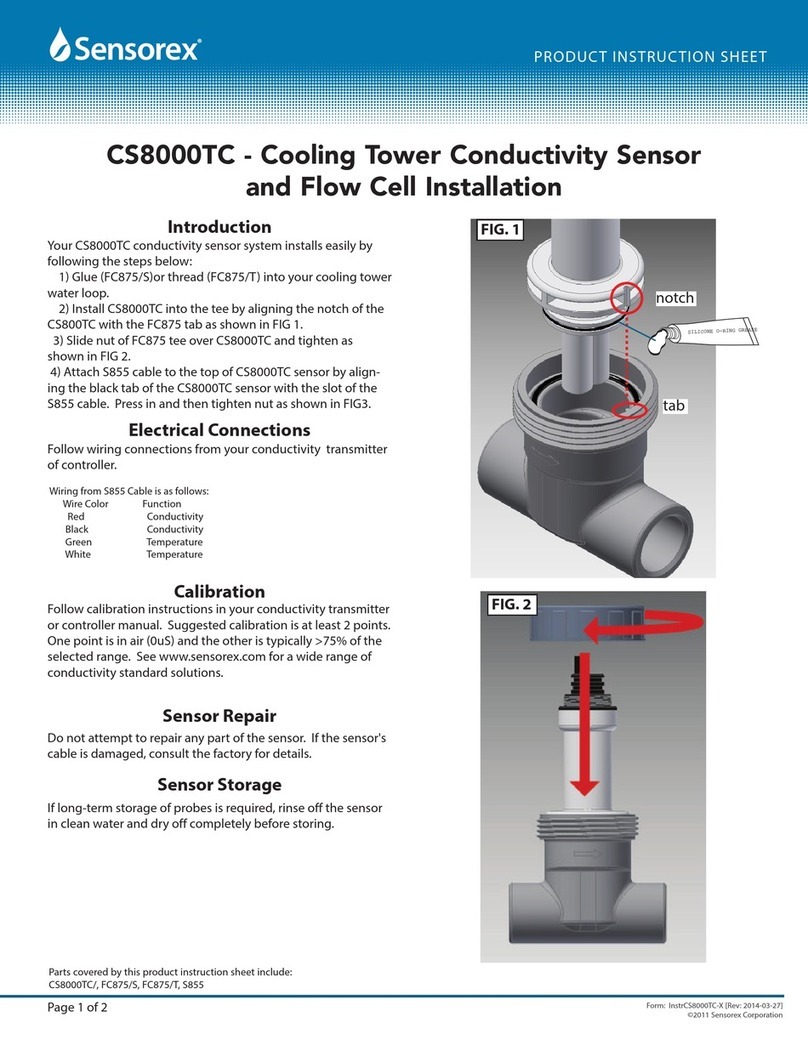

FIG.1 for sensor ID.

Introduction

PRODUCT INSTRUCTION SHEET

Parts covered by this product data sheet include:

DO6400, DO6400TC, DO6441, DO6442, DO6441TC, DO6442 TC

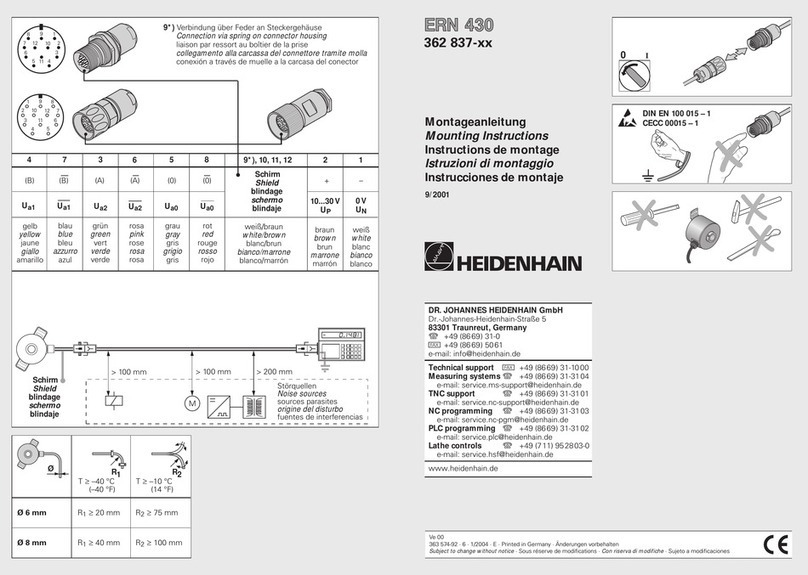

Electrical Connections

Dissolved Oxygen Sensor Care and Use Instructions

Product Instructions

Getting Your DO Sensor Ready to Use

DO6400 and DO6400TC models(mV output):

Red wire of Sensor to DO input + (cathode)

Black wire of Sensor to DO input - (anode)

White and Green wires of Sensor to Temperature input

(see wiring FIG 2.)

DO6441, DO6441TC, DO6442, DO6442TC (4-20mA output):

Red wire of Sensor to DO input + (cathode)

Black wire of Sensor to DO input - (anode)

(see wiring FIG 3.)White and Green wires of Sensor to Temperature input

Your DO sensor is shipped to you dry and is not ready for use. See

steps #1, #7, #8, #9 and #10 of the “Sensor Reconditioning”

section of this sheet for instructions on sensor preparation.

The installed membrane shipped with the probe is usable if it

passes the leak test in step #8. Maintenance items included

with your sensor include: 1 each membrane lock tool, 2 each

PTFE or HDPE membranes, 2 each membrane o-rings and

250mL of electrolyte.

FIG. 1

FIG. 3

Form: InstrDO6400-B [Rev: 2016-02-19]

Part Number Shrink Colors

#1 #2 #3

DO6400 N/A N/A N/A

DO7400 white N/A N/A

DO6441 yellow N/A N/A

DO6442 green yellow N/A

DO7441 yellow white N/A

DO7442 green yellow white

#3

#2

#1

Cable Shrink

4-20mA mV output models

DO6441, DO6441TC, DO6442, DO6442TC (Modbus485 output):

Red wire of Sensor to DO input + (cathode)

Black wire of Sensor to DO input - (anode)

(see wiring FIG 3.)White and Green wires of Sensor to Temperature input

FIG. 2

Page 2 of 8

PRODUCT INSTRUCTION SHEET

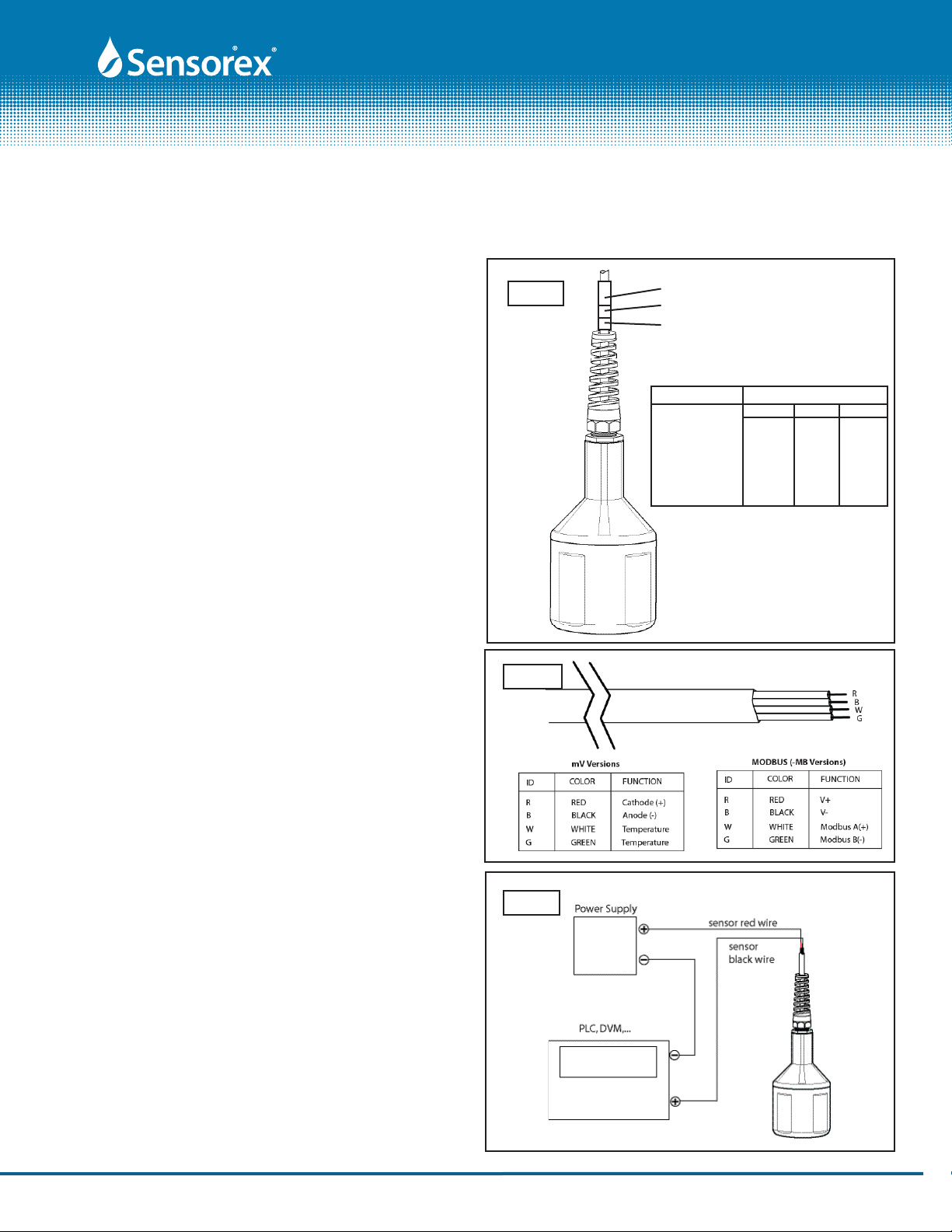

membrane lock

spacer

membrane

FIG. 4

FIG. 5

FIG. 6 FIG. 7

o-ring

Form: InstrDO6400-B [Rev: 2016-02-19]

large

o-ring to

seal body.

Seats in

groove in

bottom

cap.

Mounting Your DO Sensor

Submersion mounting of the sensor is recommended. To

prevent air bubbles from becoming trapped on the membrane

and producing falsely high DO readings, it is recommended

that the sensor be mounted at a slight angle (SEE FIG. 4).

Sensor Re-Conditioning

1. Unscrew the lower body from the upper body (FIG. 5).

2. Safely dispose of the electrolyte (Sodium Chloride solution

(salt water). Make sure o-ring does not fall out of cap.

3. Using the Membrane Tool, unscrew the Membrane Lock in

the lower body as shown in FIG. 6

4. Remove and dispose of the membrane and its o-ring as

show in FIG 7.

See page 3 for more sensor reconditioning.

Page 3 of 8

PRODUCT INSTRUCTION SHEET

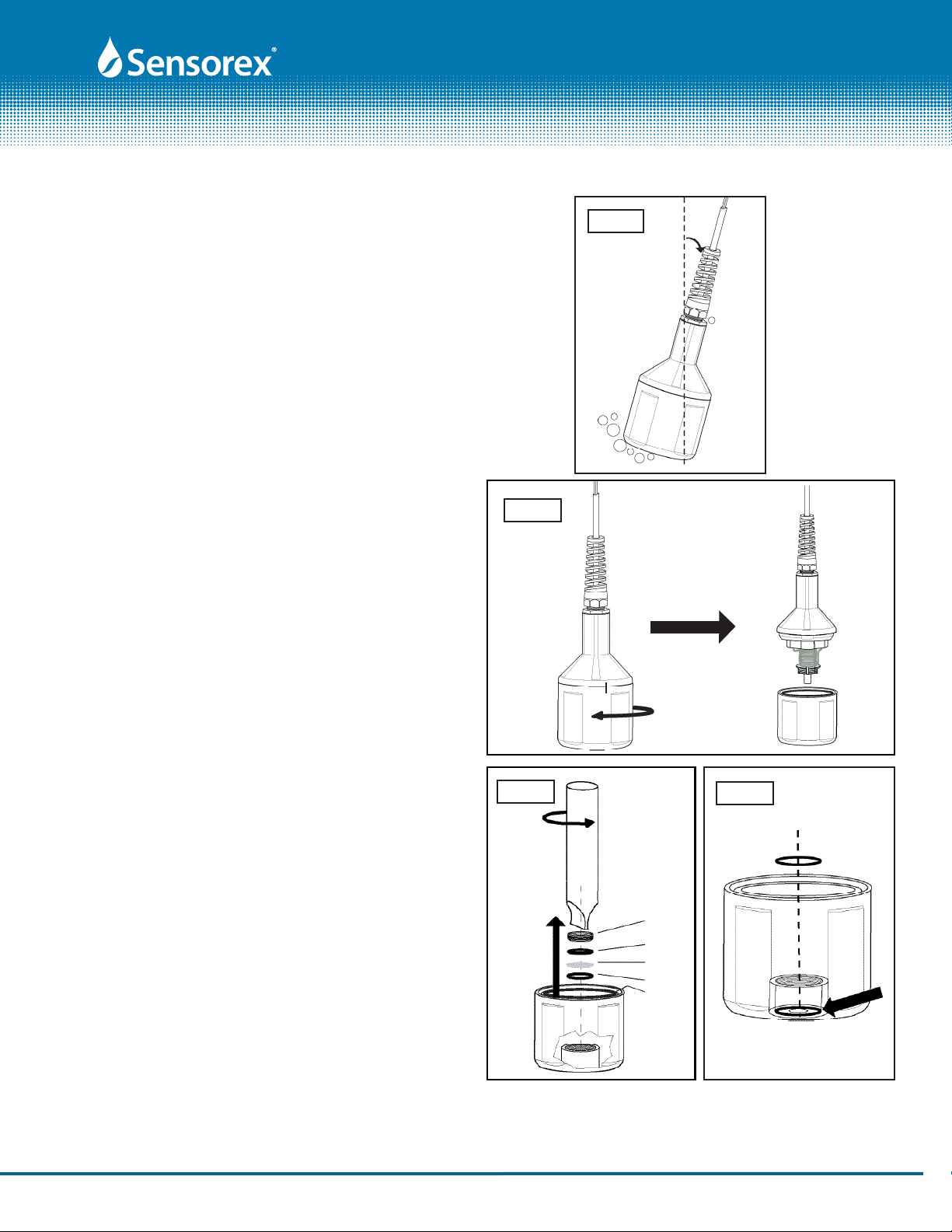

membrane

lock

spacer

membrane

o-ring

FIG. 8 FIG. 9

FIG. 10

Form: InstrDO6400-B [Rev: 2016-02-19]

ALIGN TOP AND BOTTOM

CAP TO MARKS.

DO NOT OVER

TIGHTEN!

FIG. 11

Small gap

when aligned

correctly

Sensor Re-Conditioning(cont.)

5.To clean, take the top part of the sensor and immerse in

distilled white vinegar (3% acetic acid) for about 30 minutes.

If you don't have vinegar, you can use a SOFT toothbrush,

dish washing powder, and clean water, clean the cathode,

anode, and plastic between them. Rinse all components

thoroughly with clean water after cleaning (SEE FIG. 8).

6. First, install a new o-ring into the lower body membrane

cavity (the o-ring must go all the way to the bottom as

shown in FIG 7), then a new membrane (remove paper back-

ing from membrane before installing), then the spacer. Using

the Membrane tool, install the Membrane Lock on top of

the spacer as shown in FIG. 9. Make sure cap is upright (not

sideways) when screwing in lock.

7. Inspect the membrane for wrinkles--replace if it is wrinkled.

8. Pour some clean water into the lower body and look for

leakage around the membrane (SEE FIG. 10)--replace it if

there is leakage. If there is no leakage, dispose of the water.

9. Fill the bottom cap to the top with fresh electrolyte.

10. Keep the sensor upright so that the cable is pointed

upwards(not sideways). Screw the bottom cap onto the

upper body until the alignment marks on the top of the

sensor and the bottom cap are aligned. There will be a very

small gap at the joint between the sensor's cap and upper

body. See FIG. 11.

NOTES: Sensor bottom cap must be used only on the sensor it is received on.

Do not mix bottom caps. This could cause leaking or measuring errors.

Do not overtighten the bottom cap past the alignment marks as shown in

FIG. 11

Replace large o-ring when reconditioning the sensor. The o-ring should

be lubricated before installation. See large o-ring position in FIG. 6. The

o-ring is pre-lubricated. Be sure not to get o-ring lubricant on the sensor's

membrane.

Allow the sensor to stabilize. A few minutes is adequate for a

new probe or new membrane. If recalibrating a probe with an

old membrane, several minutes may be required for stabiliza-

tion.

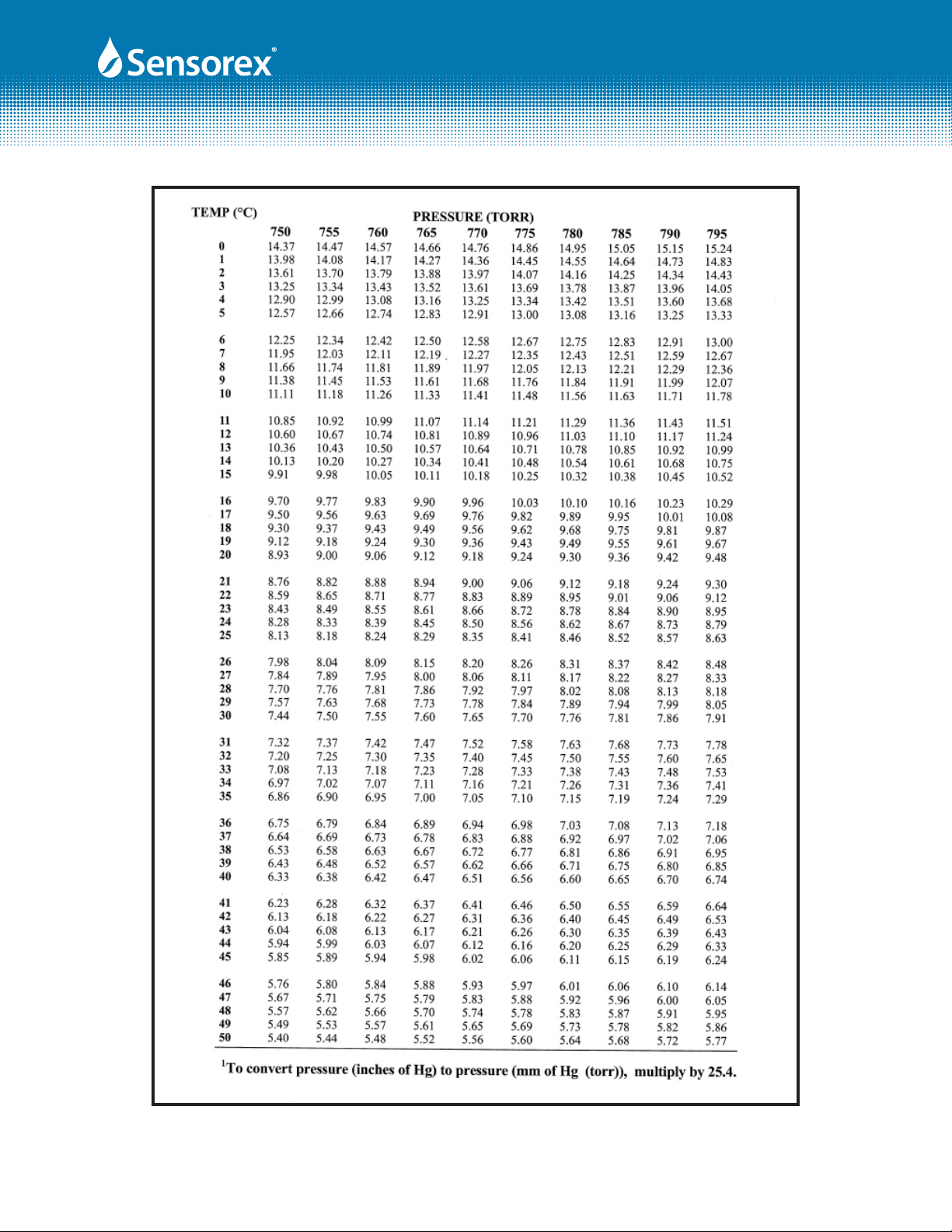

Determine the atmospheric temperature and the barometric

pressure and salinity. Using the charts on pages 5-7 of this

instruction manual, determine the saturation value for this

temperature, pressure and salinity. This 100% saturation value

is equal to the millivolt output reading of the sensor (for series

DO6400 and DO7400), or equal to the milliamp output of the

sensor (for series DO6441, DO6442, DO7441, DO7442).

When the output is stable, indicating that temperature equal-

izing has taken place, measure the level of saturation. For

example, using the DO6400/T electrode, a reading of 36.0 mV

could be a typical saturated output reading. For the DO6442/T

probe, a saturated reading in air could provide a calibration

reading of 12.0 mA.

Most customers will find that this single point reading is

satisfactory. The assumption is that the millivolt probes series

DO6400 and DO7400 will read 0.0 mV when there is 0.00

ppm O2. For series DO6441, DO6442, DO7441, DO7442, the

assumption is the milliamp output of the sensor will be 4.25

mA. The output of all of these sensors are linear. For custom-

ers routinely measuring 3 or more ppm, the assumptions will

provide excellent results. Using these 2 points, a line may be

drawn between these 2 points. All subsequent readings will

fall on this line, or for higher values, beyond the extended line

to higher levels of O2 saturation at higher pressures.

Calibration

First, ensure that the sensor is properly connected to the

instrumentation circuitry. A visual display must be available to

read the sensor output. For sensors that have been installed

in service, gently wipe the membrane using a soft cloth to

remove accumulated biological debris. The Probe may be

calibrated in air, or in air-saturated water. Please calibrate out

of direct sunlight, which may effect accurate calibration. The

simplest method is to calibrate in air. Simply hold sensor in air

and take reading (wait for reading to equilibrate). If calibrat-

ing in air saturated water, ensure that the water is saturated,

by agitating the water sample. Place the probe just below the

surface of the water level.

PRODUCT INSTRUCTION SHEET

Should you expect readings below 2 ppm, you should

perform a 2 point calibration. Prepare a solution of satu-

rated sodium sulfite (Na2SO3) in water. 17g Sodium sulfite

in 125mL DI water is more than enough. Sodium sulfite may

not reach a true zero output on your display but it should

read less than 2 mV for series DO6400 and DO7400, and

less than 5mA for series DO6441, DO6442, DO7441, DO7442

after 5 minutes.

Calibration should be performed periodically to ensure the

best accuracy. The application will determine the interval of

calibration. The user is responsible to understand how often

calibration will be performed for that application.

Page 4 of 8 Form: InstrDO6400-B [Rev: 2016-02-19]

Calculating DO in % Saturatio or ppm/

mg/L

Calculating Dissolved oxygen (DO):

% DO for mV sensors only (note that % DO us independent

of temperature):

1) Take Air reading in mV or mA and record value

2) Measure unknown sample of water mV or mA

3) Unknown/Air x 100% = % DO

a. Example: mV Sensor in air = 40mV, unknown sample

water = 20mV

20/40 x 100% = 50% Saturation

% DO for mA sensors only (note that % DO us independent of

temperature):

ppm or mg/L (temperature, salinity and pressure

dependent)

1) Take Air reading in mV or mA and record value

2) Take readings for: temperature, salinity, pressure

(pressure only if calibration and measurement are at different

elevations) and record values

3) If fresh water then salinity = 0, use chart on page 6,

column “0”, otherwise find salinity column and use that value

a. Example 1: Air = 20mA, Unknown water = 12mA,

temperature = 25°C, salinity = 0

i. 0.5 x 8.24ppm = 12mA (12mA is 50% of 4-20mA scale

(you cannot use 12/20mA) = 4.12ppm)

b. Example 2: Air = 40mV, Unknown water = 20mV,

temperature = 25°C, salinity = 0

i. 20/40 x 8.24ppm = 4.12ppm

c. Example 2: Air = 40mV, Unknown water = 20mV,

temperature = 25°C, salinity = 30ppt

i. 20/40 x 6.95ppm = 3.48ppm

Page 5 of 8

PRODUCT INSTRUCTION SHEET

Outline and Dimensions

DO6400 and DO6441, 6442

DO6400TC

Sensor Storage

If long-term storage of probes is required, empty electrolyte

out of probe, rinse with clean water and remove and discard

the membrane and the membrane o-ring. Store dry and empty.

Sensor Repair

Do not attempt to repair any part of the sensor. If the sensor's

cable is damaged, consult the factory for details.

SPECIFICATIONS

Sensor Materials

Top and Bottom Cap: PPO

Sensor Body: POM

Anode: Zinc wire

Cathode: Silver

Output at 100% Saturation (mV models)

PTFE Membrane: 36+/-8 mV

HDPE Membrane: 48+/-8 mV

Output at 100% Saturaion (mA models)

DO6441: 18-22mA

DO6442: 11-14mA

Output at 0% Saturation (mV models)

PTFE & HDPE Membrane: <1mV

Output at 0% Saturation (mA models) <4.6mA

Temperature Range

Max: 50 deg C

Min: 0 deg C

Response Time

PTFE Membrane: 5 minutes from 100% to 0%

Oxygen (<1mV or 4.5mA)

Water Flow Rate: Min 2 inch/second across membrane.

Wetted Materials

Body: PPO

Membrane: PTFE or HDPE

Cable: 4-conductor, 24AWG, Copper/PVC,

polyurethane outer jacket.

Wiring

DO6400, DO6441*, DO6442* Red = + , Black = -

DO6400/TC Red = + , Black = -, White & Green = Temp,

Green = Temp

Power Requirement: DO6441, DO6441TC, DO6442, DO6442TC

24 V DC, min 150mA

Note: * 4-20mA output versions

Form: InstrDO6400-B [Rev: 2016-02-19]

TEMPERATURE SALINITY- in parts per thousand (ppt)

deg C deg F 0 5 10 15 20 25 30 35 40

0 32 14.6 14.11 13.64 13.18 12.74 12.31 11.9 11.5 11.11

1 33.8 14.2 13.73 13.27 12.83 12.4 11.98 11.58 11.2 10.83

2 35.6 13.81 13.36 12.91 12.49 12.07 11.67 11.29 10.91 10.55

3 37.4 13.45 13 12.58 12.16 11.76 11.38 11 10.64 10.29

4 39.2 13.09 12.67 12.25 11.85 11.47 11.09 10.73 10.38 10.04

5 41 12.76 12.34 11.94 11.56 11.18 10.82 10.47 10.13 9.8

6 42.8 12.44 12.04 11.65 11.27 10.91 10.56 10.22 9.89 9.57

7 44.6 12.13 11.74 11.37 11 10.65 10.31 9.98 9.66 9.35

8 46.4 11.83 11.46 11.09 10.74 10.4 10.07 9.75 9.44 9.14

9 48.2 11.55 11.19 10.83 10.49 10.16 9.84 9.53 9.23 8.94

10 50 11.28 10.92 10.58 10.25 9.93 9.62 9.32 9.03 8.75

11 51.8 11.02 10.67 10.34 10.02 9.71 9.41 9.12 8.83 8.56

12 53.6 10.77 10.43 10.11 9.8 9.5 9.21 8.92 8.55 8.3

13 55.4 10.53 10.2 9.89 9.59 9.3 9.01 8.74 8.47 8.21

14 57.2 10.29 9.98 9.68 9.38 9.1 8.82 8.55 8.3 8.04

15 59 10.07 9.77 9.47 9.19 8.91 8.64 8.38 8.13 7.88

16 60.8 9.86 9.56 9.28 9 8.73 8.47 8.21 7.97 7.73

17 62.6 9.65 9.36 9.09 8.82 8.55 8.3 8.05 7.81 7.58

18 64.4 9.45 9.17 8.9 8.64 8.39 8.14 7.9 7.66 7.44

19 66.2 9.26 8.99 8.73 8.47 8.22 7.98 7.75 7.52 7.3

20 68 9.08 8.81 8.56 8.31 8.07 7.83 7.6 7.38 7.17

21 69.8 8.9 8.64 8.39 8.15 7.91 7.69 7.46 7.25 7.04

22 71.6 8.73 8.48 8.23 8 7.77 7.54 7.33 7.12 6.91

23 73.4 8.56 8.32 8.08 7.85 7.63 7.41 7.2 6.99 6.79

24 75.2 8.4 8.16 7.93 7.71 7.49 7.28 7.07 6.87 6.68

25 77 8.24 8.01 7.79 7.57 7.36 7.15 6.95 6.75 6.56

26 78.8 8.09 7.87 7.65 7.44 7.23 7.03 6.83 6.64 6.46

27 80.6 7.95 7.73 7.51 7.31 7.1 6.91 6.72 6.53 6.35

28 82.4 7.81 7.59 7.38 7.18 6.98 6.79 6.61 6.42 6.25

29 84.2 7.67 7.46 7.26 7.06 6.87 6.68 6.5 6.32 6.15

30 86 7.54 7.33 7.14 6.94 6.75 6.57 6.39 6.22 6.05

31 87.8 7.41 7.21 7.02 6.83 6.65 6.47 6.29 6.12 5.96

32 89.6 7.29 7.09 6.9 6.72 6.54 6.36 6.19 6.03 5.87

33 91.4 7.17 6.98 6.79 6.61 6.44 6.26 6.1 5.94 5.78

34 93.2 7.05 6.86 6.68 6.51 6.33 6.17 6.01 5.85 5.69

35 95 6.93 6.75 6.58 6.4 6.24 6.07 5.92 5.76 5.61

36 96.8 6.82 6.65 6.47 6.31 6.14 5.98 5.83 5.68 5.53

37 98.6 6.72 6.54 6.37 6.21 6.05 5.89 5.74 5.59 5.45

38 100.4 6.61 6.44 6.28 6.12 5.96 5.81 5.66 5.51 5.37

39 102.2 6.51 6.34 6.18 6.03 5.87 5.72 5.58 5.44 5.3

40 104 6.41 6.25 6.09 5.94 5.79 5.64 5.5 5.36 5.22

PRODUCT INSTRUCTION SHEET

Page 6 of 8 Form: InstrDO6400-B [Rev: 2016-02-19]

PRODUCT INSTRUCTION SHEET

Page 7 of 8 Form: InstrDO6400-B [Rev: 2016-02-19]

PRODUCT INSTRUCTION SHEET

Page 8 of 8 Form: InstrDO6400-B [Rev: 2016-02-19]

This manual suits for next models

8

Table of contents

Other Sensorex Accessories manuals

Popular Accessories manuals by other brands

turck

turck BC3-M12-AP6X 15M quick start guide

Sealey

Sealey LED110S instructions

Klimasan

Klimasan S 56 SC operating manual

PCB Piezotronics

PCB Piezotronics 208A33 Installation and operating manual

PRIMAVERA

PRIMAVERA Simply Silent Important information

Outdoor Revolution

Outdoor Revolution Compactalite Pro Integra 325 instructions

Silvercrest

Silvercrest B69PF manual

Graphtech

Graphtech Ghost user guide

Chef's Choice

Chef's Choice Pronto Diamond Hone 463 manual

S+S Regeltechnik

S+S Regeltechnik Premasreg 7165 Operating Instructions, Mounting & Installation

Carefree

Carefree FREESTYLE EVOLUTION installation manual

SkyBound

SkyBound TRAMPOLINE MAT installation manual