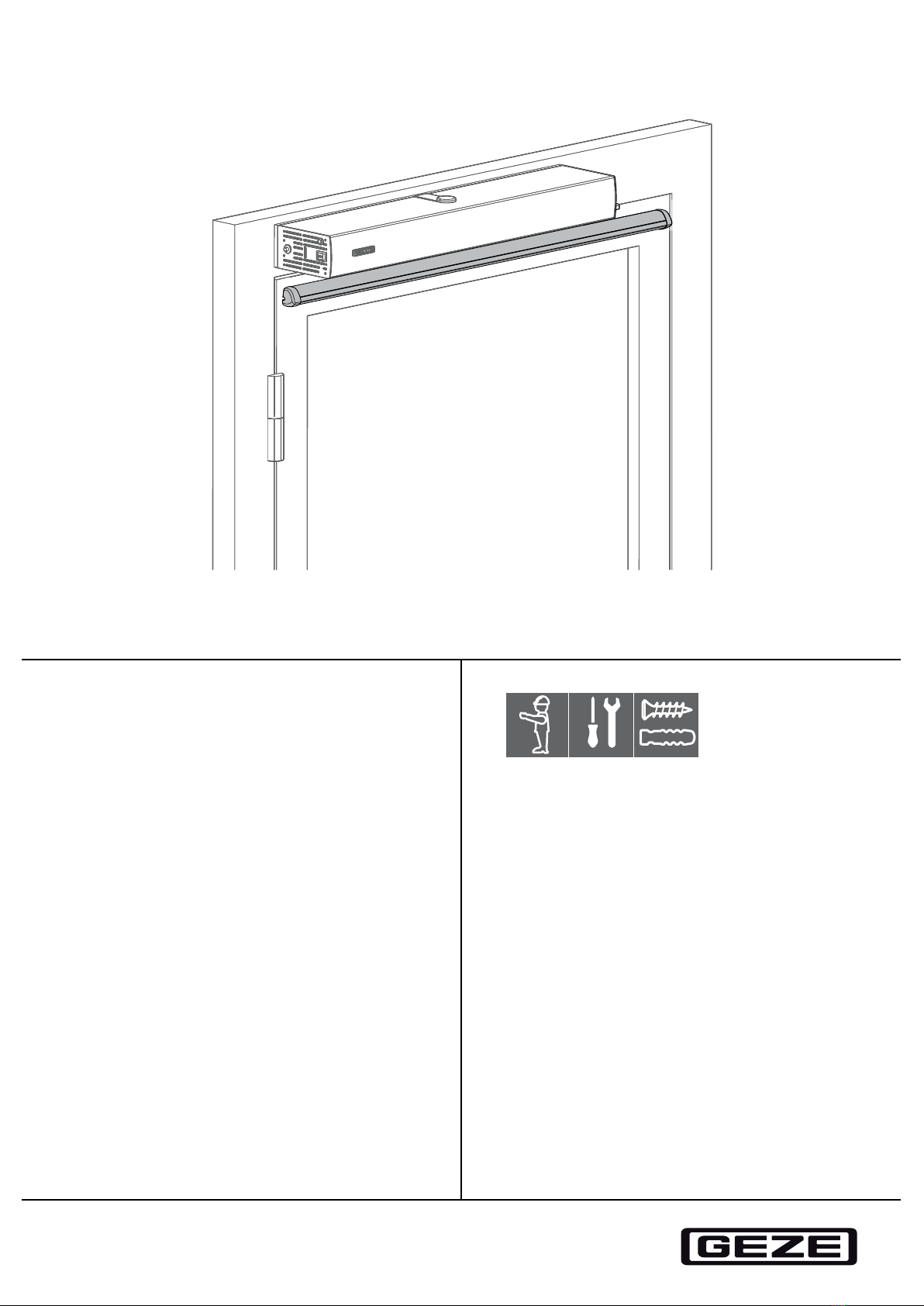

GC 338 Presence sensor

2

Contents

Symbols and illustrations .................................................................................................................................................3

Abbreviations........................................................................................................................................................................3

Product liability.....................................................................................................................................................................3

1 Safety ..........................................................................................................................................................................3

1.1 Intended use.......................................................................................................................................................................................................3

1.2 Safety notices ....................................................................................................................................................................................................3

1.3 Safety conscious working .............................................................................................................................................................................4

1.4 Environmentally conscious working .........................................................................................................................................................4

2 Validity.........................................................................................................................................................................4

3 Description ................................................................................................................................................................4

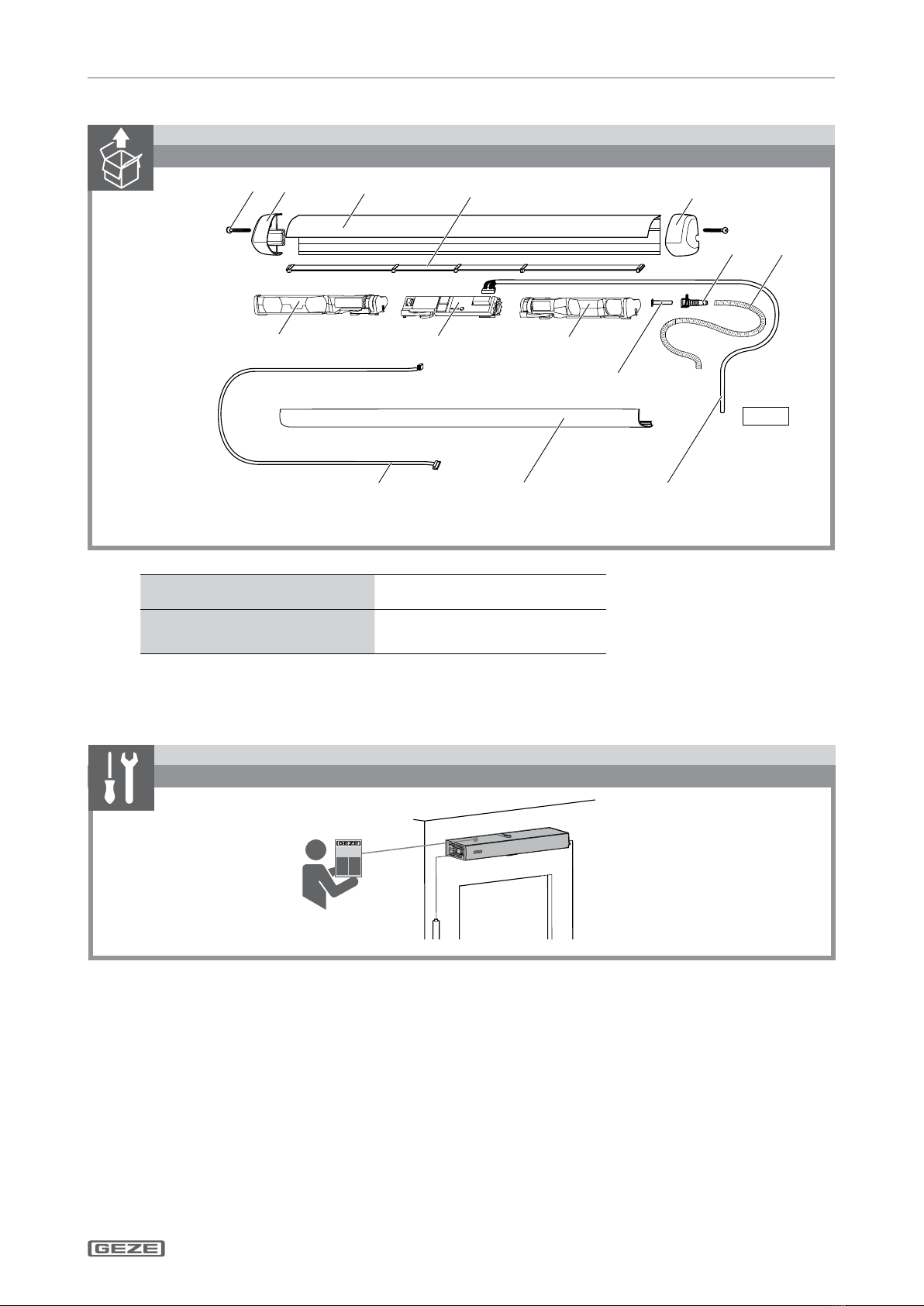

3.1 Supplied by GEZE..............................................................................................................................................................................................5

4 Work to be done before installation.................................................................................................................5

4.1 Installing the drive............................................................................................................................................................................................5

4.2 Preparing the door transmission cable.....................................................................................................................................................6

5 Installation .................................................................................................................................................................7

5.1 Preparation..........................................................................................................................................................................................................7

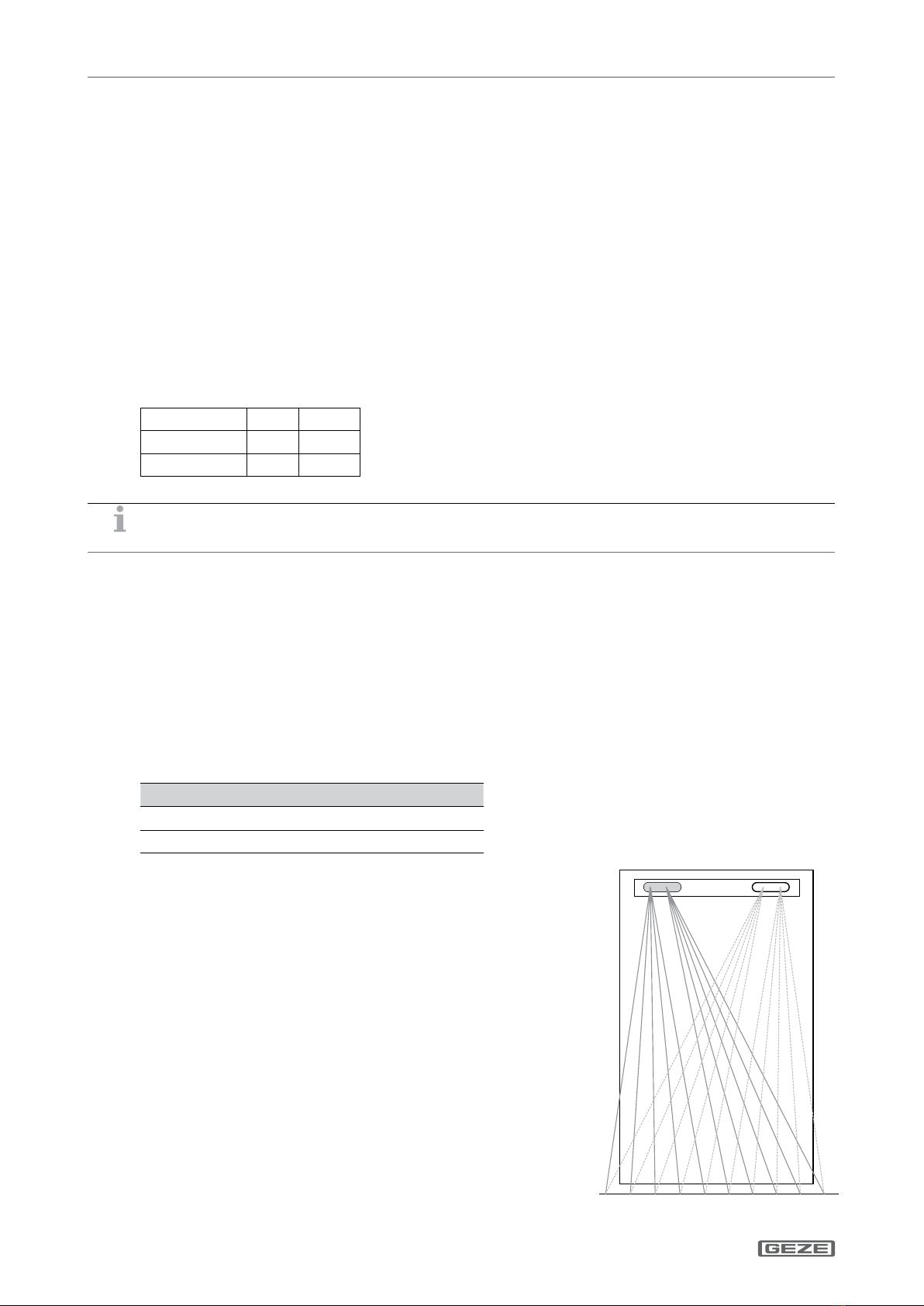

5.2 Position of the modules..................................................................................................................................................................................8

5.3 Installation of the modules ...........................................................................................................................................................................9

5.4 Preparing the transmitter and the receiver for the other side of the door............................................................................... 13

5.5 Special installation situations.................................................................................................................................................................... 13

6 Commissioning ..................................................................................................................................................... 14

6.1 Drive teach-in.................................................................................................................................................................................................. 14

6.2 Sensor teach-in............................................................................................................................................................................................... 14

6.3 Putting the drive and sensor into operation........................................................................................................................................ 17

7 Last assembly steps after commissioning................................................................................................... 18

8 Special installation situations .......................................................................................................................... 19

8.1 Installation on 2-leaf doors......................................................................................................................................................................... 19

8.2 Door leaves which move towards one another.................................................................................................................................. 19

8.3 Strong eects of external light ................................................................................................................................................................. 19

8.4 Installation on doors with door sot..................................................................................................................................................... 19

8.5 Installation on re protection doors / glass doors............................................................................................................................. 20

8.6 Installation on doors with horizontal pull handles or panic bars................................................................................................. 20

8.7 Installation on doors with vertical pull handles. ................................................................................................................................ 21

8.8 Installation on revolving doors................................................................................................................................................................. 21

9 LED status and troubleshooting ..................................................................................................................... 22

9.1 LED status display.......................................................................................................................................................................................... 22

9.2 Troubleshooting............................................................................................................................................................................................. 23

10 Technical data........................................................................................................................................................ 26

11 Accessories / Spare parts................................................................................................................................... 27

Original operating instructions for device version V.03