6F2T0 1 7 2

2. Application Notes

2.1 Phase Overcurrent and Residual Overcurrent Protection

GRE110 provides protection for radial distribution networks with phase fault and earth fault

overcurrent elements OC1 to OC4 and EF1 to EF4*. The protection of local and downstream

terminals is coordinated with the current setting, time setting, or both.

*at model 400, 401 and 402, the earth fault current input may be connected either in the residual

circuit of the phase CTs, or alternatively a dedicated earth fault CT may be used. In the case of

connection in the residual circuit of the phase CTs, the settings of the phase CT ratio OCCT and the

earth fault CT ratio EFCT should be equal. On the other hand, where a dedicated earth fault CT is

applied, thenthe settings of OCCT and EFCT should NOT be equal, and in this case the measuring

range of earth fault current is limited to 20A maximum (see section 2.2.5).

** On GRE110-820 and 821 models, current inputs are A phase and C phase only. The B phase

element is currucurate from A phase and C phase current for metering function. But B phase

cullcurated current is not for protection and recording function. So the B phase current is not

operate at the some scheme logic.

2.1.1 Inverse Time Overcurrent Protection

In a system for which the fault current is practically determined by the fault location, without being

substantially affected by changes in the power source impedance, it is advantageous to use inverse

definite minimum time (IDMT) overcurrent protection. This protection provides reasonably fast

tripping, even at a terminal close to the power source where the most severe faults can occur.

Where ZS (the impedance between the relay and the power source) is small compared with that of

the protected section ZL, there is an appreciable difference between the current for a fault at the far

end of the section (ES/(ZS+ZL), ES: source voltage), and the current for a fault at the near end

(ES/ZS). When operating time is inversely proportional to the current, the relay operates faster for

a fault at the end of the section nearer the power source, and the operating time ratio for a fault at

the near end to the far end is ZS/(ZS + ZL).

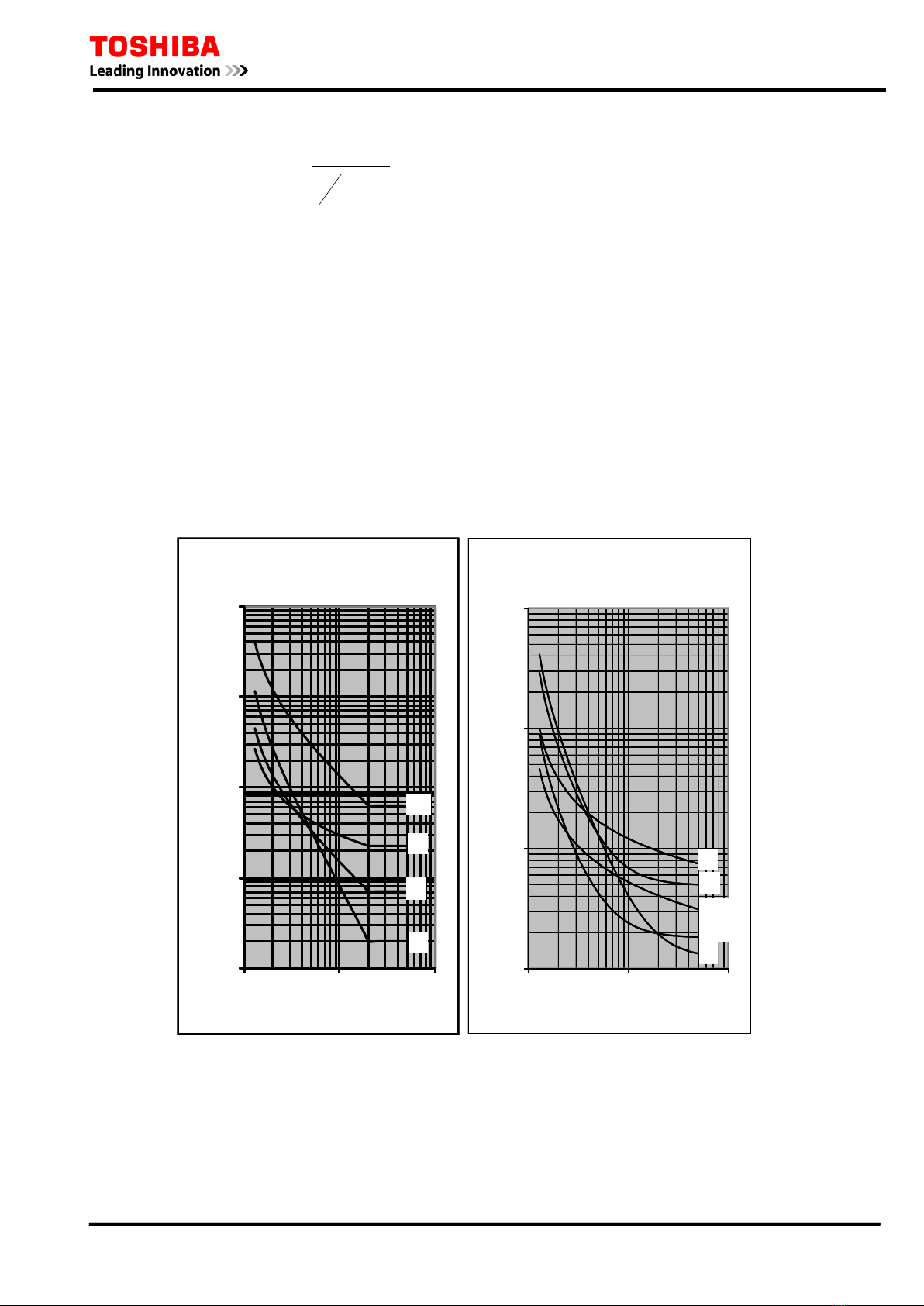

The resultant time-distance characteristics are shown in Figure 2.1.1 for radial networks with

several feeder sections. With the same selective time coordination margin TC as the downstream

section, the operating time can be further reduced by using a more inverse characteristic.

Figure 2.1.1 Time-distance Characteristics of Inverse Time Protection

The OC1 and EF1 elements for stage-1 have IDMT characteristics defined by equation (1) in

accordance with IEC 60255-151:

8