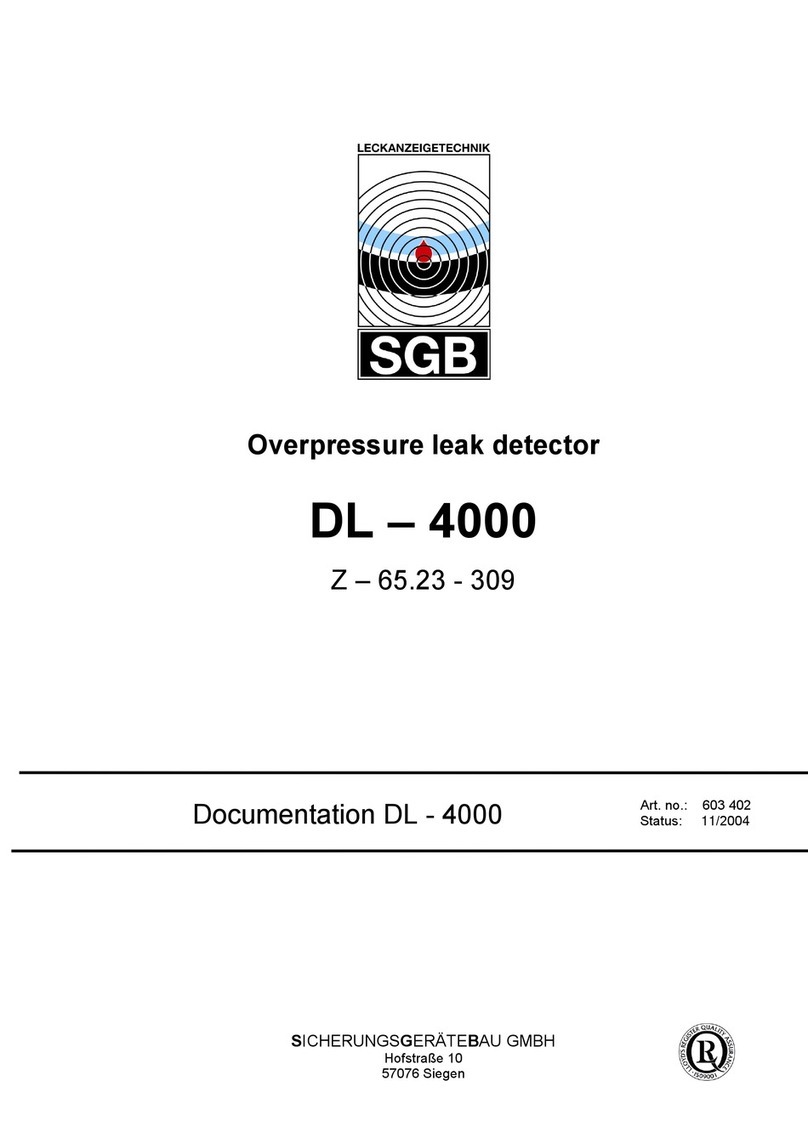

SGB VLX-S 350 M Operator's manual

Documentation

Vacuum leak detector VLX-S 350 M

For 1 up to 6 tanks with a suction line for the leak detector to

the lowest point of the interstitial space

Read the instructions before starting any work

Issued: 08/2020

Art. no.: 602702

VACUUM LEAK DETECTOR VLX-S 350 M 03/08/2020

- 2 -

Table of contents

1.General.................................................................................4

1.1.Information ...................................................................4

1.2.Explanation of symbols ................................................4

1.3.Limitation of liability......................................................4

1.4.Copyright......................................................................4

1.5.Warranty conditions .....................................................5

1.6.Customer service .........................................................5

2.Safety....................................................................................6

2.1.Intended use ................................................................6

2.2.Obligations of the operating company..........................6

2.3.Qualifications ...............................................................7

2.4.Personal protective equipment (PPE)..........................7

2.5.Fundamental hazards ..................................................8

3.Technical data .....................................................................9

3.1.General data ................................................................9

3.2.Electrical data ..............................................................9

3.3.Switching values ..........................................................9

3.4.Field of application .......................................................9

4.Design and function............................................................10

4.1.System design..............................................................10

4.2.Normal mode................................................................16

4.3.Air leak .........................................................................16

4.4.Liquid leak....................................................................16

4.5.Displays and controls...................................................17

5.Installing the system...........................................................18

5.1.Basic instructions .........................................................18

5.2.Signalling unit...............................................................18

5.3.Sensor..........................................................................19

5.4.Requirements for pneumatic connection lines .............19

5.5.Establishing pneumatic connections

(between leak detector and interstitial space)..............19

5.6.Electrical cables ...........................................................20

5.7.Electrical wiring diagram ..............................................20

5.8.Installation examples....................................................22

5.9.Block diagram ..............................................................26

6.Commissioning ...................................................................29

6.1.Interstitial space leak tests...........................................29

6.2.Commissioning of the leak detector.............................29

6.3.Build-up of negative pressure up to operating

pressure .......................................................................30

6.4.Optional data transfer (only available for devices

with one display/control panel).....................................30

Table of contents

03/08/2020 VACUUM LEAK DETECTOR VLX-S 350 M

- 3 -

7.Functional check and maintenance ..................................31

7.1.General ........................................................................31

7.2.Maintenance ................................................................31

7.3.Functional check..........................................................31

7.4.Test scope ...................................................................31

8.Alarm....................................................................................33

8.1.Alarm ...........................................................................33

8.2.How to behave.............................................................33

9.Disassembly and disposal .................................................33

9.1.Disassembly ................................................................33

9.2.Disposal .......................................................................33

10.Spare parts ..........................................................................34

11.Accessories.........................................................................34

12.Appendix..............................................................................35

12.1.Dimensions and drilling pattern (device version

1 up to 4 displays)........................................................ 35

12.2.Dimensions and drilling pattern (device version

5 up to 6 displays)........................................................ 36

12.3.EU Declaration of conformity ....................................... 37

12.4Declaration of performance (DoP) ...............................38

12.5.Manufacturer’s declaration of conformity.....................38

12.6.Certification (TÜV Nord) ..............................................39

Table of contents

VACUUM LEAK DETECTOR VLX-S 350 M 03/08/2020

- 4 -

1. General

1.1. Information

These instructions provide important information on how to handle the

VLX-S 350 M negative pressure leak detector.

The VLX-S 350 M leak detector is only suitable for tanks with a suc-

tion line for the leak detector that runs to the lowest point of the inter-

stitial space.

A requirement for safety during work is the adherence to all stipulated

safety and operating instructions.

Moreover, all the regulations for the prevention of accidents and gen-

eral safety instructions which apply at the location of use of the leak

detector must be adhered to.

1.2. Explanation of symbols

Warnings in these instructions are marked with the adjacent symbol.

The signal word expresses the extent of the hazard.

DANGER:

An immediate hazardous situation which will lead to serious or even

fatal injuries if not avoided.

WARNING:

A possible hazardous situation which may lead to serious or even fa-

tal injuries if not avoided.

CAUTION:

A possible hazardous situation which may lead to minor or light inju-

ries if not avoided.

Information:

Indicates tips, recommendations and information.

1.3. Limitation of liability

All information and instructions in this documentation have been com-

piled while taking into account the applicable standards and regula-

tions, state-of-the-art technology and our many years of experience.

SGB assumes no liability in case of:

Failure to adhere to these instructions

Improper use and the deployment of unqualified staff

Unauthorised modifications

Connection to systems which are not approved by SGB

1.4. Copyright

The content of these instructions, including texts, drawings, images

and other illustrations, are protected by copyright and subject to com-

mercial property rights. All forms of misuse are prosecutable.

General

03/08/2020 VACUUM LEAK DETECTOR VLX-S 350 M

- 5 -

1.5. Warranty conditions

We provide a 24-month warranty for the VLX-S 350 M leak detector

according to our Terms and Conditions, starting from the day of in-

stallation.

The warranty period ends 27 months after the date of sale at the latest.

Before a warranty claim can be made, the functional report/test report

that details the first commissioning by trained staff must first be sub-

mitted.

The serial number of the leak detector must also be specified.

The warranty is rendered null and void in the event of:

- faulty or improper installation

- improper operation

- changes/repairs without the manufacturer’s consent.

Our warranty does not include parts, which may be perished prema-

ture due to their consistence or category of usage (e.g. pumps,

valves, gaskets, etc.). Furthermore, we are not liable for defects or

corrosion damages caused by humid or inappropriate installation en-

vironments.

1.6. Customer service

Our customer service department is available to provide you with fur-

ther information.

A list of contact persons can be found online at sgb.de or on the type

plate on the indicator unit.

General

VACUUM LEAK DETECTOR VLX-S 350 M 03/08/2020

- 6 -

2. Safety

2.1. Intended use

Only use the VLX-S 350 M leak detector for interstitial spaces which

are resistant to negative pressure up to at least 800 millibars, as

part of double-walled tanks with a maximum constructed height of 3

metres or double floors of flat bottom tank constructions.

Depending on its design, the VLX-S 350 M leak detector is suita-

ble for the monitoring of between one and six tank interstitial

spaces.

The tank has a suction line to the lowest point of the interstitial

space for evacuation / emptying the interstitial space.

The signalling unit is mounted outside the Ex-zone (potentially ex-

plosive zone)

Internally (pneumatic side), the sensor for the VLX-S 350 meets

the requirements of category 1, thus connection to suitable intersti-

tial spaces (Zone 0, 1, 2 or outside the Ex-zone)

Classification of potential vapour-air mixtures emanating from

stored goods into explosion groups II A up to II B and temperature

classes T 1 up to T4.

Earthing/equipotential bonding as per applicable regulations

(e.g. EN 1127).

Leak tightness of the interstitial spaces as per this documentation

The total volume of every individual interstitial space does not ex-

ceed 8000 litres.

Ambient temperature range for sensor: -20°C to +60°C

Ambient temperature range for signalling unit: 0°C to +40°C

Empty pipe for electrical connection cables in dome shafts and

control shafts must be sealed and gas-tight

Power connection cannot be shut off

Claims of any kind made as a result of improper use are not valid.

2.2. Obligations of the operating company

The VLX-S 350 M leak detector is for commercial use. The operating

company is thus subject to the legal obligations of occupational health

and safety regulations.

Alongside the safety instructions in this documentation, all the appli-

cable regulations for safety, accident prevention and environmental

protection must be adhered to. In particular:

Compilation of a risk assessment report and implementation of its

results in an operation manual

Regular checks to make sure that the operation manual is in line

with the current regulations

Content of the operation manual includes responses to possible

alarms

Scheduling of an annual functional test

Safety

WARNING:

Danger due to

improper use

03/08/2020 VACUUM LEAK DETECTOR VLX-S 350 M

- 7 -

2.3. Qualifications

Staff must be sufficiently qualified so that they are able to recognise

and prevent possible hazards independently.

Operating companies putting this leak detector into operation should

have attended the appropriate training course provided by SGB or an

authorized representative.

National regulations must be observed.

For Germany:

Certified company qualification for assembly/installation, commission-

ing and maintenance of leak detector systems

2.4. Personal protective equipment (PPE)

Personal protective equipment must be worn during work.

Wear the safety clothing and equipment required for the respec-

tive work

Adhere to and follow the signs relating to PPE

Keep a long in the “Safety Book”

Wear a high-visibility vest

Wear safety shoes

Wear a safety helmet

Wear safety gloves (where necessary)

Wear safety goggles (where necessary)

2.4.1 Personal protective equipment on systems that could present the risk of potentially explo-

sive atmospheres

The information described here relates above all to the safety of work

on systems that could present the risk of potentially explosive atmos-

pheres.

WARNING:

Risk to personnel

and the environ-

ment due to insuffi-

cient qualifications

Safety

VACUUM LEAK DETECTOR VLX-S 350 M 03/08/2020

- 8 -

If work is performed in areas where one must assume that atmos-

pheres could potentially be explosive, then the following equipment is

essential:

Suitable clothing (risk of electrostatic charges)

Suitable tools (as per EN 1127)

Suitable gas warning device, calibrated for the respective vapour-

air mixtures (work should only be performed at a concentration

50% below the lowest explosion limit)1

Measuring device to establish the oxygen content of the air

(Ex/O–meter)

2.5. Fundamental hazards

DANGER

from electrical current

When working on the electrics of the VLX-S 350 M, it must first be

shut off and electrically isolated.

Adhere to the valid regulations relating to electrical installation,

explosion protection (e.g. EN 60 079-17) and the regulations for

the prevention of accidents.

DANGER

from potentially explosive vapour-air mixtures.

Potentially explosive vapour-air mixtures may be produced in tank in-

terstitial spaces. In certain circumstances, potentially explosive va-

pours may escape when the connections to the interstitial space are

opened.

There may be potentially explosive vapour-air mixtures in the connec-

tion lines if vapours penetrate the inner walls due to permeation or in

case of a leak.

The leak detector system must be free of gas before carrying out

work on it.

If there is a possibility of potentially explosive vapour-air mixtures, use

pumps with explosion protection to evacuate the interstitial space.

Adhere to the explosion protection regulations, e.g. BetrSichV (Di-

rective 1999/92/EC and the derived laws of the respective member

states) and/or others.

DANGER

from working in shafts.

Leak detectors are mounted outside the manholes. The pneumatic

connections to the interstitial spaces are usually installed in dome

shafts or other shafts. Thus, the shaft is to enter for mounting.

Before entering shafts, the relevant safety measures must be taken,

and shafts must be free of gas and have sufficient oxygen.

1

Other percentage values may be stipulated by factory-specific or country-specific regulations.

Safety

03/08/2020 VACUUM LEAK DETECTOR VLX-S 350 M

- 9 -

3. Technical data

3.1. General data

Dimensions and drilling pattern see Chap. 12.1, 12.2

Storage temperature range -30°C to +60°C

Sensor application temperature range -20°C to +60°C

Accuracy of sensor 2% FK ≜20 mbar

Signalling unit application temperature range 0°C to +40°C

Protection class of leak detector device IP 30

Weight Version with 1 display 1.2 kg

Version with 4 displays 2.1 kg

Version with 6 displays 5.6 kg

3.2. Electrical data

Voltage supply: 100 to 240 V AC

optional 24 V DC

Terminals 5, 6, external signal: 24 V DC, 2 A

(only for devices with 1 display)

Terminals 11 to 13 (floating): DC ≤25 W or AC ≤50 VA

Terminals 17 to 19 (floating): DC ≤25 W or AC ≤50 VA

Terminals 21, 22, pressure sensor

Fuse protection: max. 10 A

Overvoltage category 2

3.3. Switching values

For VLX-S 350 M

(relative negative pressure)

Alarm ON > 350 mbar

Alarm OFF < 400 mbar

Recommended negative pressure for operation: 700 mbar

3.4. Field of application

Monitoring of suitable double-walled tanks for storage of mineral oil

products which are usually used at service stations

(Tanks suitable for leak monitoring are sufficiently leak-tight, have a

suction line for the leak detector running to the lowest point of the in-

terstitial space and are sufficiently resistant to negative pressure)

Technical data

VACUUM LEAK DETECTOR VLX-S 350 M 03/08/2020

- 10 -

4. Design and function

4.1. System design

The VLX-S 350 M leak detector comprises a signalling unit and an

installation kit for the tank. The signalling unit features either 1, or 2 –

4 or 5 – 6 display/control panels for the monitoring of 1 – 6 tanks.

A display/control panel for an individual tank comprises a display for

the digital pressure display, an acknowledge button for the acoustic

alarm signal, a green operating light and a red alarm lamp.

The installation kit comprises a pressure sensor with explosion pro-

tection and a shut-off valve for the suction connection.

Signalling unit with 1 display/control panel:

01 “Alarm” signal lamp, red

09 “Operation” signal lamp, green

71 “Mute” button

103 Display with digital pressure reading

Design and function

103

09

71

01

03/08/2020 VACUUM LEAK DETECTOR VLX-S 350 M

- 11 -

Signalling unit of this device version with 4 display/control panels

01 “Alarm” signal lamp, red

09 “Operation” signal lamp, green

71 “Mute” button

103 Display with digital pressure reading

Signalling unit of this device version with 6 displays/control panels

01 “Alarm” signal lamp, red

09 “Operation” signal lamp, green

71 “Mute” button

103 Display with digital pressure reading

103

09

71

01

Design and function

09

71

103

01

VACUUM LEAK DETECTOR VLX-S 350 M 03/08/2020

- 12 -

Interior view of this device version with one display/control panel and a DTM

that is only available for this variant, as used for the LOD (Leak Online Diag-

nosis Service), with:

01 “Alarm” signal lamp, red

09 “Operation” signal lamp, green

31 Terminal strip

69 Buzzer

71 “Mute” button

75 Display circuit board

76 Main circuit board

149 Data transfer module (DTM)

75

01

09

76

71

69

149

31

Design and function

03/08/2020 VACUUM LEAK DETECTOR VLX-S 350 M

- 13 -

Interior view of this device version with four display/control panels, featuring:

31 Terminal strip

69 Buzzer

75 Display circuit board

76 Main circuit board (yellow: 1, red: 2, blue: 3, green: 4)

139 Membrane keypad (yellow: 1, red: 2, blue: 3, green: 4)

Design and function

139

76

69

75

31

VACUUM LEAK DETECTOR VLX-S 350 M 03/08/2020

- 14 -

Interior view of this device version with six display/control panels, featuring:

31 Terminal strip

69 Buzzer

75 Display circuit board

76 Main circuit board (yellow: 1, red: 2, blue: 3, green: 4)

139 Membrane keypad (yellow: 1, red: 2, blue: 3, green: 4)

Design and function

139

75

76

31

03/08/2020 VACUUM LEAK DETECTOR VLX-S 350 M

- 15 -

Installation kit:

Installation kit with:

02 Shut-off valve

68 Suction connection (with protective cap)

100 Measurement connection to interstitial space

101 Suction connection to interstitial space

102 Pressure sensor (designed as explosion-proof)

Design and function

68

102

02

101

100

VACUUM LEAK DETECTOR VLX-S 350 M 03/08/2020

- 16 -

4.2. Normal mode

Normal mode status is established during commissioning for each

tank interstitial space by generating negative operating pressure us-

ing an external installation pump.

The negative pressure in the interstitial space is measured by the

sensor and displayed on the digital display of the signalling unit (for

devices with several displays, several interstitial spaces can be con-

nected and their negative pressure levels showed on the correspond-

ing displays.)

Any leaks will result in a drop in negative pressure.

Very high demands are placed on the leak tightness of the interstitial

space(s) and the connecting line in order to ensure fault-free opera-

tion.

If the operating lamp goes out, it means there is an interruption in the

voltage supply and the alarm relay is de-activated.

4.3. Air leak

If there is a leak in the outer wall (above the ground water) or in the

inner wall above the liquid level, air is sucked into the interstitial

space due to the prevailing negative pressure. The negative pressure

drops. In cases where the negative pressure drops to the set alarm

level, an alarm is triggered.

4.4. Liquid leak

In the event of a liquid leak, liquid enters the interstitial space and col-

lects at the lowest point of the interstitial space.

The ingress of liquid causes the negative pressure to drop. If leaking

liquid continues to enter the interstitial space (due to the negative

pressure therein), there is a further drop in negative pressure. If the

ingress of liquid into the interstitial space is large enough to cause the

negative pressure limit to be undershot, an alarm is triggered immedi-

ately.

Note:

after a leak has occurred, there is a risk that liquid will be sucked in

when evacuating the interstitial space again.

Before re-commissioning the leak detector, any liquid that has seeped

in must be fully channelled off via the suction line.

Design and function

03/08/2020 VACUUM LEAK DETECTOR VLX-S 350 M

- 17 -

4.5. Displays and controls

4.5.1 Display

4.5.2 “Switch off acoustic alarm” function

Press the “mute” button once. The acoustic signal is switched off and

the red LED flashes.

Press the button again to switch on the acoustic signal.

This function is not available in normal mode or in case of faults.

4.5.3 “Test the optical and acoustic alarm” function

Press and hold (for approx. 10 seconds) the “mute” button. The alarm

is triggered until you release the button.

Press the button again to switch on the acoustic signal.

This function is not available in normal mode or in case of faults.

Signal lamp

Operating

status

Alarm status

Alarm, acoustic

alarm acknowl-

edged

Device

malfunction

OPERATION:

green

ON ON ON ON

ALARM:

red

OFF ON FLASHES ON

Design and function

VACUUM LEAK DETECTOR VLX-S 350 M 03/08/2020

- 18 -

5. Installing the system

5.1. Basic instructions

Before starting work, this documentation must be read and un-

derstood. In case of any doubts, contact the manufacturer.

The safety instructions in this documentation must be adhered to.

Installation work may only be performed by qualified companies.

Observe the applicable accident prevention regulations.

Adhere to the applicable regulations relating to electrical installa-

tion and explosion protection.

Feedthroughs for pneumatic and electrical connection lines,

which could create a potentially explosive atmosphere, must be

sealed gas-tight.

Before entering the control shafts, oxygen levels must be

checked and the inspection shaft must be purged.

If metal connection lines are used, it must be ensured that the

mains earth is at the same electric potential as the tank/pipe that

is to be monitored.

A number of relevant points relating to personal protective cloth-

ing and equipment are listed in Chapter 2.4.

5.2. Signalling unit

(1) Wall-mounting is generally performed using dowels and screws.

(housing dimensions and drilling profiles are illustrated in Appen-

dix 10.2)

(2) DO NOT install in potentially explosive zones.

(3) The housing is installed at a suitable position in the building or in

a weather-proof protective cabinet outdoors.

(4) The distance between the leak detector and interstitial space

must be kept as small as possible.

(5) Empty pipes must be laid for feeding the electrical connection

line to the tank.

Empty pipes must be sealed gas-tight on the tank side in order to

prevent the spread of potentially-explosive atmospheres.

Installation

03/08/2020 VACUUM LEAK DETECTOR VLX-S 350 M

- 19 -

5.3. Sensor

The sensor is installed as close as possible to the tank in combina-

tion with the angle bracket and shut-off valve (installation kit).

The sensor cable can be extended using suitable extension tech-

nology.

The maximum cable length (for 2 x 0.75 mm shielded cable) be-

tween the explosion sensor and the VLX-S 350 M leak detector

is 500 m.

The sensor cable is shielded. The shielding is not connected to the

pressure sensor. In general, shielding is not necessary. In case it

is required, extend the shielding along every cable extension and

apply it from the signalling unit to an external connection point.

Terminal boxes for potentially explosive atmospheres must be

used within an Ex-zone. e.g. SGB item no.: 220480 “EX “e” junc-

tion box with three screw-type cable ducts (M 20)”

5.4. Requirements for pneumatic connection lines

Underground metal or plastic pipes or aboveground, outdoor plas-

tic pipes must be routed in protective piping.

Clear width of 6 mm or 8 mm.

Hose/pipe thickness: 1 mm

Resistant to the stored product

At least PN 10 across the entire temperature range.

A distance of 50 m between the sensor and the interstitial space

may only be exceeded slightly, and if this is the case: Use

pipe/hose with a greater clear width, using suitable adapter pieces.

Colour designation: measuring line: red

Prevent build-up of electrostatic charges (e.g. when pulling cables).

5.5. Establishing pneumatic connections (between leak detector and interstitial space)

Select and route a suitable polyamide hose or suitable pipe.

When routing, ensure that the pipes/hoses are protected from

damage that could be caused by people entering the dome shaft.

The full cross section must remain intact; dents and kinks2are im-

permissible.

Observe earthing / equipotential bonding of metallic parts in non-

conductive connection lines.

Seal the protective pipes so that they are gas-tight in order to pre-

vent the spread of potentially explosive atmospheres through the

pipes into buildings and to prevent ingress of liquids.

Establish the respective connection (as per the illustrations in

the following images).

2

If necessary, use standard commercial moulded fittings (with the specified bending radii).

Installation

Sensor

Shut-off valve

Suction port Angle bracket

VACUUM LEAK DETECTOR VLX-S 350 M 03/08/2020

- 20 -

5.5.1 Compression fitting for metal and plastic pipes

(1) Insert a support sleeve (only plastic pipe) into the pipe end

(2) Insert the pipe (with support sleeve) as far as it will go

(3) Tighten the screw connection by hand until there is a resistance,

then turn 1 ¾ turn further with the wrench

(4) Unfasten the nut

(5) Tighten the nut by hand until it touches noticeably

(6) Final assembly of the screw connection by tightening ¼ turn

5.5.2 Quick screw connection for polyamide hose:

(1) Cut the PA hose to length at a right angle

(2) Unscrew the union nut and push it over the pipe

(3) Push the hose onto the nipple up to the start of the thread

(4) Tighten the union nut by hand

(5) Tighten the union nut with a screw wrench until there is a notice-

able increase in resistance (approximately 1 to 2 turns).

5.6. Electrical cables

Mains connection:

Suggested cable: Ölflex Classic 100

2.5 mm2without cable-end sleeve

1.5 mm2with cable-end sleeve and plastic collar

Floating contacts and external signal

Suggested cable: Ölflex Truck 1700

1.5 mm2without cable-end sleeve

0.75 mm2with cable-end sleeve and plastic collar

5.7. Electrical wiring diagram

(1) Lay firmly, i.e. no plug connections or switch connections.

(2) Observe the regulations of the electricity supplier3.

(3) Terminal assignment: (see also 5.9 block diagram)

3

For Germany: VDE regulations also apply

Installation

Table of contents

Other SGB Security Sensor manuals

SGB

SGB DLR-GS Series Operator's manual

SGB

SGB VLR Series Operator's manual

SGB

SGB DLR-G Operator's manual

SGB

SGB DLR-P CV Series Operator's manual

SGB

SGB VLR Series Operator's manual

SGB

SGB DL-4000 Series Operator's manual

SGB

SGB VLX Ex Series Operator's manual

SGB

SGB DLR-P User manual

SGB

SGB VLXE Ex M Series Operator's manual

SGB

SGB DL Series User manual

SGB

SGB VLX A-Ex Series User manual

SGB

SGB VL Series Operator's manual

SGB

SGB VL 330 Installation and operating instructions

SGB

SGB DLR-2 Series Operator's manual

SGB

SGB DLR-GS Operator's manual

SGB

SGB VL Series Operator's manual

SGB

SGB DLR-P Series Operator's manual

SGB

SGB VLXE Series Operator's manual

SGB

SGB VL-H9 User manual

SGB

SGB DL Series User manual