Separ Filter LKF-Automotive User manual

D10107-EN-R05

LKF-Automotive

Coalescence filter

Translation of the original instructions

LKF-Automotive

Legal notice

II D10107-EN-R05

Legal notice

Willibrord Lösing Filterproduktion GmbH

Am Walzwerk 2

45527 Hattingen

Germany

Telephone +49 2324 9460-0

Fax +49 2324 40842

e-mail [email protected]

Internet www.separ.de

Owner Ingeborg Lösing

Procurators Boris Lösing

Marcus Hahne

Thomas Held

Commercial Register Essen District Court

Registration number HRB 15543

LKF-Automotive

Table of contents

D10107-EN-R05 III

Table of contents

Legal notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . II

Table of contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . III

Table of figures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . V

Table of tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . VII

Information about this instruction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Copyright . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Handling instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Notes on safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Embedded notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Safety information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Installed situation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Fuel specification and temperature ranges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Predictable misuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Improper handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Opening the bayonet lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Closing the bayonet lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Use of the LKF wrench . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Basic notes on safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Performance data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Mechanical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Safety information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Mounting material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Connection example 1: Inlet left side and outlet right side . . . . . . . . . . . . . . . . . . . . 18

Connection example 2: Inlet right side and outlet left side . . . . . . . . . . . . . . . . . . . . 18

Connection example 3: Inlet and outlet on one side . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Initial commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Disassemble container . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Mount water sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Position container . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Assemble container . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Fill filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Safety information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

LKF-Automotive

Table of contents

IV D10107-EN-R05

Visual inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Assemble disassembled filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Complete drain valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Complete container . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Complete filter element . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Insert filter element into the container . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Assemble container . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Drain filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Discharge filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Change filter element . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Clean container . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Waste disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

LKF-Automotive

Table of figures

D10107-EN-R05 V

Table of figures

LKF wrench, structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Rating plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Individual parts of the filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Mechanical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Mounting dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Connection dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Mechanical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Connection example: Inlet left side and outlet right side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Connection example: Inlet right side and outlet left side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Connection example: Inlet and outlet on one side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Disassemble container . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Tapped hole for the water sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

The four positions of the container . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Assemble container . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Hand fuel pump SEPAR HFP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Individual parts of the filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Admissible maximum water level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

LKF-Automotive

Table of figures

VI D10107-EN-R05

LKF-Automotive

Table of tables

D10107-EN-R05 VII

Table of tables

Explanation of the symbols on the rating plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

LKF-Automotive

Table of tables

VIII D10107-EN-R05

LKF-Automotive

Information about this instruction

D10107-EN-R05 1/35

1 Information about this instruction

This instruction includes information related to the life cycle of the product. It is directed

toward specialist personnel who handle, install and maintain the product.

A specimen in the original language is enclosed with every translation of this instruction.

Should uncertainties or discrepancies be determined in the translation, before the utilisa-

tion of the supplied product the instruction in the original language must be referred to

for clarification and the manufacturer informed.

It is possible that illustrations in this instruction are used as an example and therefore do

not agree exactly with the product supplied.

1.1 Storage

This instruction is a component part of the product. It should be stored near the product

and protected against environmental impacts.

1.2 Replacement

If this instruction should become illegible or be lost, a replacement document can be

acquired from the manufacturer. For this purpose, the reference number of the instruction

must be known, which can be found in the footer on the inside margin of every page.

1.3 Copyright

Willibrord Lösing Filterproduktion GmbH has copyright to all documents with the Willi-

brord Lösing Filterproduktion GmbH company signature. Without approval of the Willi-

brord Lösing Filterproduktion GmbH, such documents may not be either made accessible

to third parties or used in any other manner or improperly.

It is admissible, within a documentation management system, to make it available as an

electronic document or a hardcopy for in-house use.

1.4 Handling instructions

Work and procedures are described by handling instructions:

► This is a prerequisite which must be met.

► A further prerequisite which must be met.

1. This handling step is implemented first.

→ That is the result of the handling step.

2. That is a further handling step.

= That is the result of the handling instruction.

1.5 Notes

Notes draw attention to situations which can lead to object damage or injuries to persons

if certain rules of conduct are not adhered to.

LKF-Automotive

Information about this instruction

2/35 D10107-EN-R05

1.5.1 Notes on safety

Notes on safety draw attention to dangers to health. The general safety symbol in the fol-

lowing examples can be replaced in concrete notes on safety by a hazard-specific symbol.

1.5.2 Notes

Notes draw attention to the correct handling of the product in order to avoid material

damage.

DANGER Type and source of risk

Failure to observe the rule of conduct may result in most serious injuries or death!

Rule of conduct.

WARNING Type and source of risk

Failure to observe the rule of conduct may result in serious physical injuries!

Rule of conduct.

CAUTION Type and source of risk

Failure to observe the rule of conduct may result in physical injuries!

Rule of conduct.

NOTICE Type and source of risk

Failure to observe the rule of conduct may result in property damage!

Rule of conduct.

LKF-Automotive

Information about this instruction

D10107-EN-R05 3/35

1.5.3 Embedded notes

If dangerous situations can occur during work or if inappropriate behaviour is possible,

attention is drawn to this by embedded notes in handling instructions:

1. Handling step

2. Handling step

3. Handling step

4. Handling step

DANGER Type and source of risk! Rule of conduct.

WARNING Type and source of risk! Rule of conduct.

CAUTION Type and source of risk! Rule of conduct.

NOTICE Type and source of risk! Rule of conduct.

LKF-Automotive

Safety information

4/35 D10107-EN-R05

2 Safety information

The safety information is to be considered in performing all work.

2.1 Intended use

The filter is suitable for the cleaning and water-removal of light diesel oils, in accordance

with DIN EN 590. It is installed in the supply flow pipe of the fuel circuit.

2.1.1 Installed situation

If the supply flow of the filter is below the maximum filling level in the tank, a blocking

valve must be installed between tank and filter.

If the supply flow of the filter is above the maximum filling level in the tank, a blocking

valve between tank and filter is not required as mandatory.

Basically we recommend to install a blocking valve.

2.1.2 Fuel specification and temperature ranges

DIN EN 590 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -20 °C to 80 °C

DIN V 51603-6 . . . . . . . . . . . . . . . . . . . . . . . . . . -20 °C to 80 °C

DIN EN 16709:2019 (B20 and B30). . . . . . . . . -20 °C to 80 °C

The possible use with fuels not specified here or in other temperature ranges can be

inquired if required.

2.1.3 Predictable misuse

The maximum flow rate of the filter must be greater than or equal to the maximum pump

capacity of the fuel pump.

For the supply pipe to the filter, the following component parts may be used exclusively:

• Straight pipe pieces.

• Pipe bends with a radius which corresponds to at least three times the outer diame-

ter of the pipe.

• Connectors and blocking elements which do not restrict the free cross-section of

the pipe.

LKF-Automotive

Safety information

D10107-EN-R05 5/35

2.1.4 Improper handling

The container is secured by a ring with bayonet lock. The two interlocks are located dia-

metrically on the mounting side and the front side of the filter.

Improper handling of the interlock can lead to damage to the filter and as a consequence

cause malfunctions and environmental damage. The bayonet lock may only be opened

and closed by hand or with the LKF wrench, which is available as an accessory.

The following descriptions explain the basically correct procedure. When working on the

filter, the safety instructions in the respective chapters must also be observed.

2.1.4.1 Opening the bayonet lock

The figure shows the front view of the filter.

Grasp the bayonet ring on both sides and turn

counter-clockwise beyond the resistance.

Turn the bayonet ring further counter-clockwise,

it will lower itself.

The figure shows the view of the filter from the

left side.

Turn the bayonet ring further counter-clockwise

until it can be removed downwards.

The bayonet ring can now be removed down-

wards from the filter.

LKF-Automotive

Safety information

6/35 D10107-EN-R05

2.1.4.2 Closing the bayonet lock

The figure shows the view of the filter from the

left side.

Slide the ring over the container from below.

Turn the ring so that the guide nose is approxi-

mately in the middle of the filter.

Push the ring on completely and without tilting

until it resists.

Maintain pressure and turn the ring clockwise

until resistance is reached.

The figure shows the front view of the filter.

Turn the ring clockwise beyond the resistance.

Turn the ring further clockwise until it stops.

The filter is only correctly closed if the markings

on the lock are aligned.

LKF-Automotive

Safety information

D10107-EN-R05 7/35

2.1.4.3 Use of the LKF wrench

Figure 1: LKF wrench, structure

1Handle 3Guide pin

2Pivot pin

The bayonet ring of the filter is divided into 12

sections at its bottom.

The LKF wrench can be inserted there in steps of

approx. 30° around the centre axis of the bayo-

net ring.

Position the wrench so that the bayonet ring can

be turned in the correct direction.

The wrench can be used in any position to open

or close the bayonet ring.

Turn the wrench so that the two pivot pins can

be inserted from below into two of the sections

in the bayonet ring.

The guide pin must be on the outside of the

bayonet ring.

Insert the wrench into the bayonet ring as far as

the stop.

Make sure that the wrench is not tilted in its lon-

gitudinal and transverse axis when turning the

bayonet ring and that the pivot pins remain

completely in the bayonet ring.

LKF-Automotive

Safety information

8/35 D10107-EN-R05

2.2 Basic notes on safety

CAUTION Skin and eye irritation!

In case of contact with diesel oil, skin and eyes can become irritated!

When working with fuels, the following must always be observed:

1. When indicated, wear protection gloves that protect against diesel oil.

2. When indicated, wear eye protection.

3. In case of skin contact, wash off the affected areas of the skin thoroughly

and apply skin protection ointment.

4. In case of eye contact, flush the eye immediately with flowing water and

then consult a doctor.

CAUTION Environmental damage!

Fuel discharging into the environment can cause damage!

When working with fuels, the following must always be observed:

1. Protect the work area so that any leaking fuel is safely collected.

2. Prior to commencement of work, exclude any leakage of fuel by suitable

measures.

3. Collect any residue of leaked fuel completely with suitable materials on

completion of the work.

4. Implement non-polluting waste disposal of any collected fuel, as well as

materials impregnated with fuel.

LKF-Automotive

Technical data

D10107-EN-R05 9/35

3 Technical data

The manufacturer reserves the right to change the technical characteristics as a result of

product improvements without special announcement.

3.1 Scope of delivery

Filter, optionally with

• 4 M14×1,5 sealing plugs and 1 PG7 sealing plug

• 4 M14×1,5 sealing plugs and water sensor

3.2 Mechanical data

Figure 2: Dimensions

Mass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . approx. 500 g

Ambient temperature range . . . . . . . . . . . . . . . -40 °C to 85 °C

Media connectors

Screw tap . . . . . . . . . . . . . . . . . . . . . . . . . . . . M14×1.5 / ISO 9974-1

Screw-in-capable length of thread . . . . . . ≤15 mm

Tightening torque. . . . . . . . . . . . . . . . . . . . . 14 Nm ±1 Nm

Water sensor connector

Internal thread. . . . . . . . . . . . . . . . . . . . . . . . PG7

Tightening torque. . . . . . . . . . . . . . . . . . . . . screw in manually until the limit stop is

reached

LKF-Automotive

Technical data

10/35 D10107-EN-R05

3.3 Performance data

Performance data items are limit values. By the integration of the filter into an existing

infrastructure, the indicated performance data can be limited under certain circumstances.

Volume flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . ≤3 l/min

Operating pressure (with reference to ambient pressure)

Continuous pressure . . . . . . . . . . . . . . . . . . -0.8 bar to 5 bar

Maximum pressure. . . . . . . . . . . . . . . . . . . . 6 bar ≤15 s

Inflow-outflow differential pressure . . . . . . . . ≤500 mbar

3.4 Identification

Figure 3: Rating plate

1Type designation 4QR code for the downloading of the

instruction

2Address of the manufacturer 5Performance data

3Serial number

Table 1: Explanation of the symbols on the rating plate

Symbol Meaning

Special waste, dispose of environmentally correctly

Suitable only for diesel oil

The device is equipped with a transponder which is activated with a

radio frequency

Technical data Technical data

Date of production Date of manufacture

Serial no Serial number

Filling volume Filling volume of the filter

Flow rate Volume flow

Temperature range Ambient temperature range

Instructions Note on the QR code for the downloading of the instructions

LKF-Automotive

Technical data

D10107-EN-R05 11/35

3.5 Structure

Figure 4: Individual parts of the filter

1Filter body with media connectors 9O-ring seal container/drain valve

2O-ring seal filter element/filter body 10 Drain valve

3Filter element 11 Sealing plug PG7 for screw-in thread water

sensor

4O-ring seal container/filter element 12 Sealing plug M14×1,5

5O-ring seal container/filter body 13 Sealing plug M14×1,5

6Container 14 Sealing plug M14×1,5

7Bayonet ring 15 Sealing plug M14×1,5

8O-ring seal for drain valve seating

LKF-Automotive

Technical data

12/35 D10107-EN-R05

3.6 Mechanical connections

Figure 5: Mechanical connections

1For future expansion 5Nozzle for drain hose

2Medium supply flow, right 6Medium flow, left

3Medium flow, right 7Medium supply flow, left

4Screw-in thread for water sensor 8For future expansion

Table of contents

Languages:

Other Separ Filter Water Filtration System manuals

Popular Water Filtration System manuals by other brands

Evolution

Evolution EVOCHLOR A50G Installation and operation manual

Philips

Philips Pure Taste WP3861 user manual

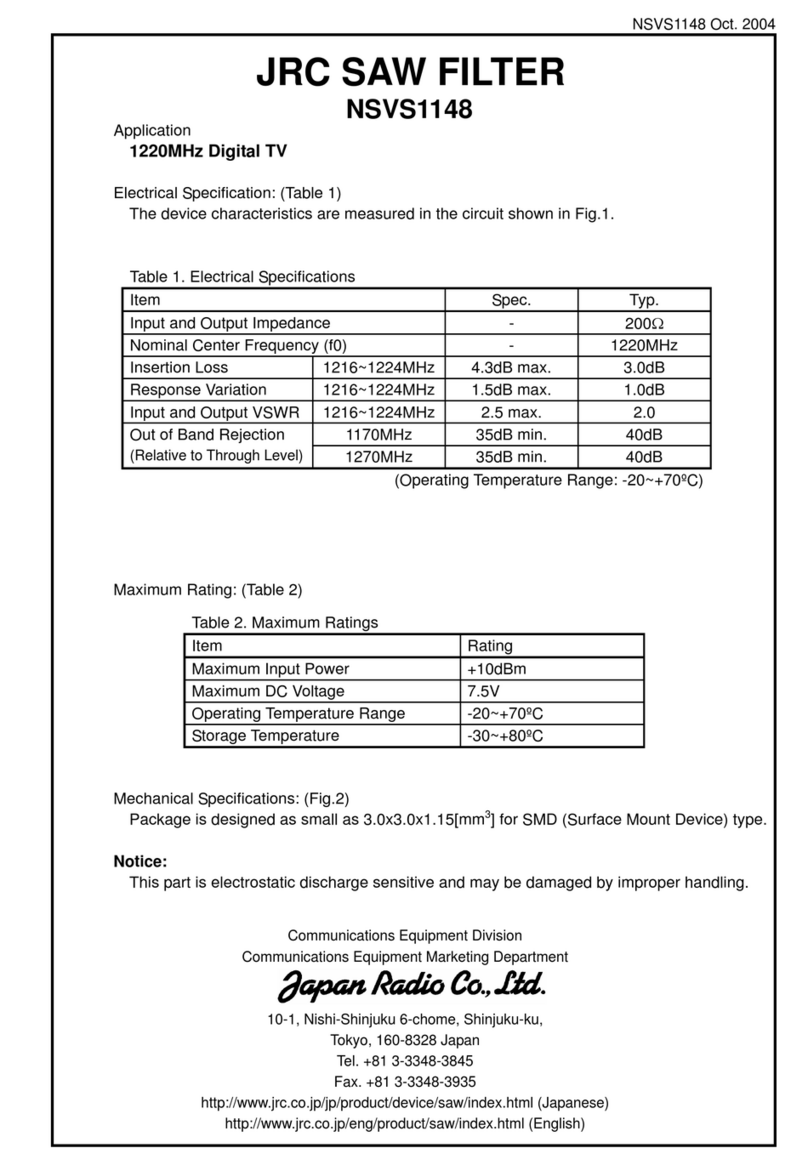

JRC

JRC NSVS1148 manual

Premier Tech Aqua

Premier Tech Aqua Ecoflo ST-500 owner's manual

Terra Universal

Terra Universal WhisperFlow 6601-24A-UR-220 product manual

Clean Water Systems

Clean Water Systems Tannin 5900e Series Installation & start?up guide

Vixen Air

Vixen Air VXF3938SR installation guide

Eljen

Eljen Mantis M5 Series Installation and System Design Guide

Neptun

Neptun Classic NCTF-O 8000 operating instructions

Sera

Sera UV-C-System Assembly instruction

Watts

Watts PVI AquaSolve M8414TM-COM Operation & maintenance manual

Carel

Carel ROC025500N user manual