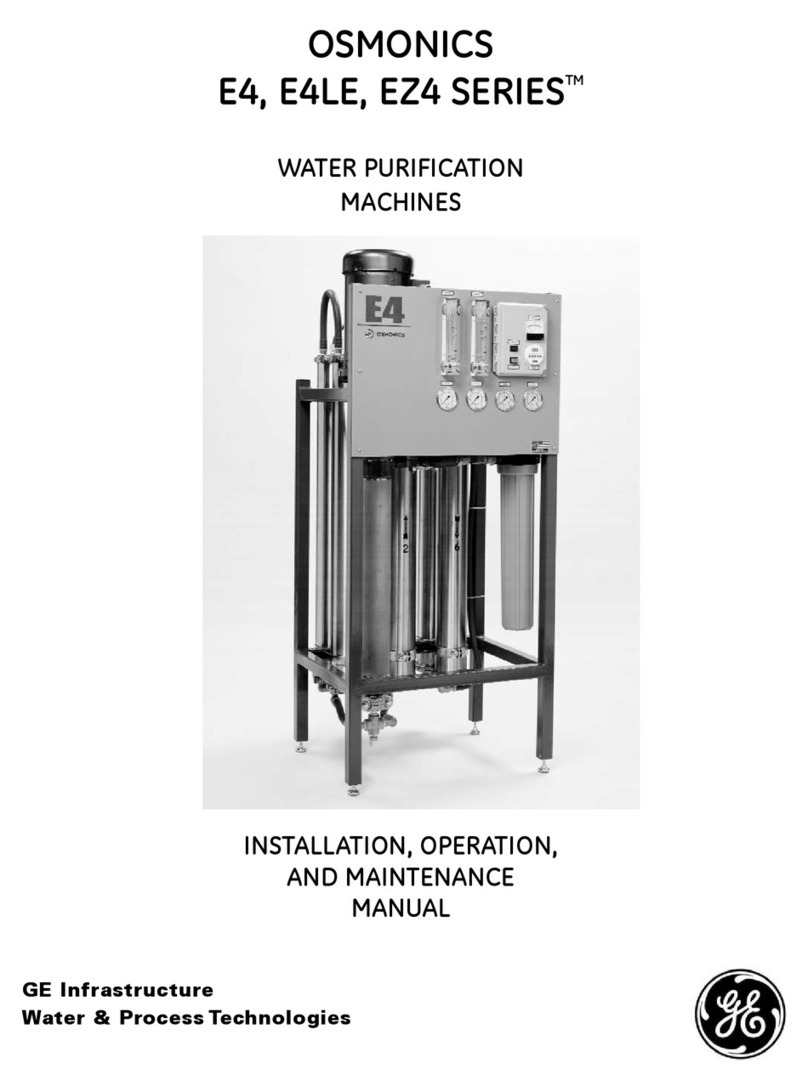

E4H Series

Operation & Maintenance Manual 2

TABLE OF CONTENTS

1. DESCRIPTION.......................................................................................................................................... 5

1.1. Definitions...................................................................................................................................... 5

1.1.1. Permeate Rate (Product Water Rate) [Qp] ............................................................. 5

1.1.2. Concentrate Rate (Reject Rate) [Qc] ......................................................................... 5

1.1.3. Feed Rate [Qf]..................................................................................................................... 5

1.1.4. Reverse Osmosis (RO)..................................................................................................... 5

1.1.5. Membrane Elements....................................................................................................... 6

1.1.6. CIP ........................................................................................................................................... 7

1.1.7. Average Pressure [PAVG]................................................................................................. 7

1.1.8. Concentration.................................................................................................................... 7

1.1.9. Salt (Ionic) Passage.......................................................................................................... 7

1.1.10. Recovery............................................................................................................................... 7

1.1.11. Salt (Ionic) Rejection ........................................................................................................ 7

1.2. Flow Description ......................................................................................................................... 8

1.3. Machine Nomenclature........................................................................................................... 9

1.4. Economy (ECN) Model and Deluxe (DLX) Model Options........................................... 9

1.4.1. ECN Model ........................................................................................................................... 9

1.4.2. DLX Model Option...........................................................................................................10

1.5. Specifications for E-Series Machines ..............................................................................10

1.5.1. Feed Water Specifications .........................................................................................11

1.5.2. Permeate Flow Rate......................................................................................................11

1.5.3. Concentrate Flow Rate................................................................................................11

1.5.4. Operating Final Pressure ............................................................................................11

1.5.5. Pump....................................................................................................................................11

1.5.6. RO Membrane Rejection .............................................................................................12

2. INSTALLATION......................................................................................................................................12

2.1. Mounting......................................................................................................................................12

2.2. Piping.............................................................................................................................................12

2.2.1. Inlet Piping.........................................................................................................................12

2.2.2. Valves Required for CIP, ECN Models Only..........................................................13

2.2.3. Concentrate Outlet Connection...............................................................................13

2.2.4. Permeate Outlet Connection ....................................................................................13

2.3. Electrical.......................................................................................................................................13

2.3.1. ECN Electrical System ..................................................................................................13

2.3.2. DLX Electrical System...................................................................................................14

3. PREPARATION AND START-UP ......................................................................................................14

3.1. Pretreatment for Water Purification................................................................................14

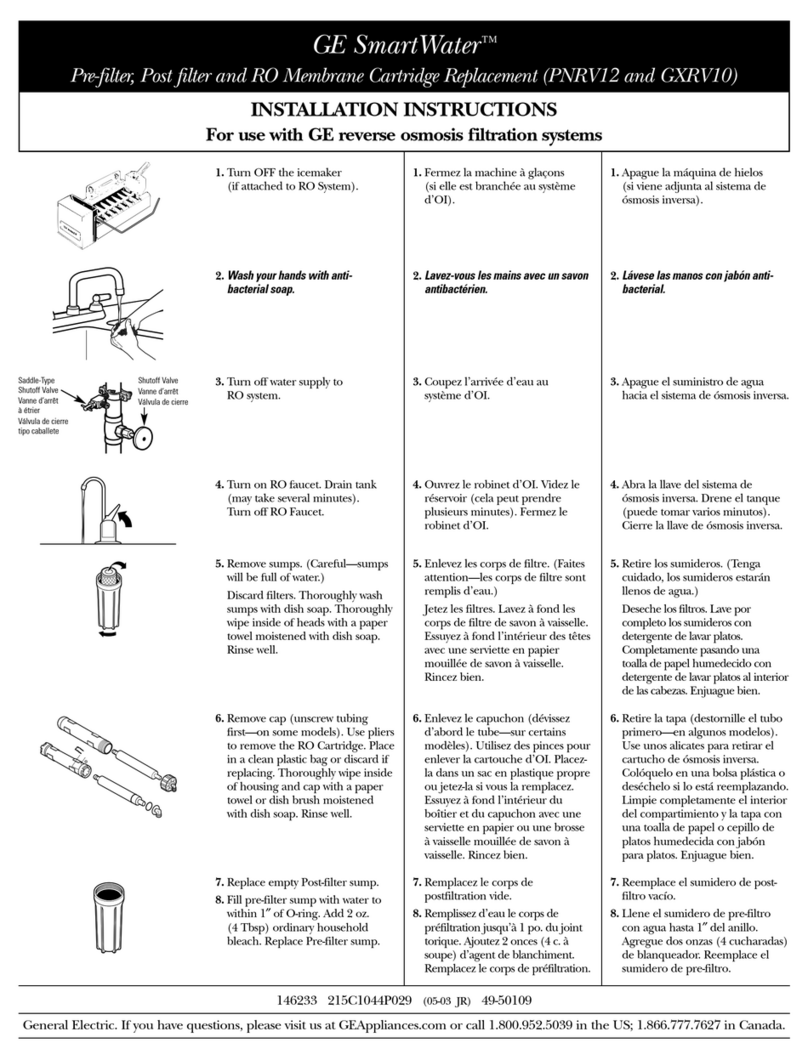

3.2. Start-Up........................................................................................................................................15

4. OPERATION AND MAINTENANCE.................................................................................................18

4.1. Daily Log Sheets .......................................................................................................................19

4.2. Pre-Filter.......................................................................................................................................19

4.3. Flushing ........................................................................................................................................19

4.4. Cleaning........................................................................................................................................20

4.4.1. CLEANING PROCEDURE ...............................................................................................20