Separ Filter SWK-2000/40/WSA User manual

Doc. No.: D10053.EN Rev.: 14 Page 1of 29

Operating instructions: SWK-2000/40/WSA filter mobile

Willibrord Lösing

Filterproduktion GmbH

W. Lösing Filterproduktion GmbH • Am Walzwerk 2 • 45527 Hattingen

Operating manual

SWK-2000/40/WSA filter mobile

These operating instructions are valid for:

SWK-2000/40/WSA filter mobile

HW Version 0.9 and 1.0

SW Version 19.0

Article No.: 06 2386

Doc. No.: D10053.EN Rev.: 14 Page 2of 29

Operating instructions: SWK-2000/40/WSA filter mobile

Willibrord Lösing

Filterproduktion GmbH

W. Lösing Filterproduktion GmbH • Am Walzwerk 2 • 45527 Hattingen

Contents

1References ............................................................................................................... 4

2General .................................................................................................................... 5

3Notes on safety ........................................................................................................ 5

3.1 Utilisation according to specification............................................................................................. 5

4Scope of delivery ...................................................................................................... 6

5Technical data .......................................................................................................... 8

5.1 Electrical specs............................................................................................................................... 8

5.1.1 Battery operation........................................................................................................................... 8

5.1.2 Mains operation............................................................................................................................. 8

5.2 Temperature range........................................................................................................................ 8

5.3 Mechanical data............................................................................................................................. 8

5.4 Weight and dimensions ................................................................................................................. 9

6Transport grip......................................................................................................... 10

7Electrical connections ............................................................................................. 11

7.1 Mechanical connections ..............................................................................................................11

8Connection ............................................................................................................. 12

8.1 Network or battery connection cable dismantling...................................................................... 13

9Indications and operating elements ........................................................................ 14

10 Function ................................................................................................................. 15

10.1 Fuel filling nozzle.......................................................................................................................... 16

10.2 Pump and filter operation ...........................................................................................................17

10.2.1 Timer function..............................................................................................................................19

10.2.2 Fault reports.................................................................................................................................20

10.3 Selection of the display-language................................................................................................22

10.4 Automatic pump disconnection and dry-running monitoring..................................................... 23

10.4.1 Selection of the automatic pump disconnection and the dry-running monitoring.....................23

10.5 Water sensor................................................................................................................................ 25

11 Notes on use .......................................................................................................... 26

11.1 Maintenance ................................................................................................................................26

11.1.1 Water drain.................................................................................................................................. 26

11.1.2 Filter change ................................................................................................................................26

Doc. No.: D10053.EN Rev.: 14 Page 3of 29

Operating instructions: SWK-2000/40/WSA filter mobile

Willibrord Lösing

Filterproduktion GmbH

W. Lösing Filterproduktion GmbH • Am Walzwerk 2 • 45527 Hattingen

11.1.3 Sensor technology........................................................................................................................26

11.2 Filter bowl cleaning...................................................................................................................... 27

11.3 Water sensor cleaning .................................................................................................................27

12 Declaration of conformity....................................................................................... 28

13 Index ...................................................................................................................... 29

Doc. No.: D10053.EN Rev.: 14 Page 4of 29

Operating instructions: SWK-2000/40/WSA filter mobile

Willibrord Lösing

Filterproduktion GmbH

W. Lösing Filterproduktion GmbH • Am Walzwerk 2 • 45527 Hattingen

1 References

[R1]

Type: Installation instructions

Title: Installation instruction SEPAR english.pdf

Doc. No.: D10053.EN Rev.: 14 Page 5of 29

Operating instructions: SWK-2000/40/WSA filter mobile

Willibrord Lösing

Filterproduktion GmbH

W. Lösing Filterproduktion GmbH • Am Walzwerk 2 • 45527 Hattingen

2 General

The filter mobile is subjected to a detailed final control check in the works. Therefore small

quantities of diesel oil can still be present in the device. These remaining quantities do not impair

either the storage or the function of the device.

3 Notes on safety

The two available connections for the supply voltage (Connection 1: Mains supply line for 115 V AC

or 230 V AC. Connection 2: Connection for 12 V DC battery operation) may not be used

simultaneously. Operation at any operating voltages other than listed in the technical data is not

permissible. Employment in explosion-hazard areas is not allowed. The maximum ambient

temperature for the operation of the filter mobile is 40°C. If the electrical cables should indicate

damage, switch off the filter mobile immediately using the emergency switch and disconnect from

the supply voltage (pull plug or with 12 V operation remove terminals from the battery). In case of

damage to the bus system and the filter, the filter mobile may also not be employed since otherwise

fuel can reach the environment.

The pump motor and the supply line can warm up considerably during operation. Touching these

parts is to be avoided to protect against burn injuries.

If the filter mobile is operated at ambient temperatures above 25°C, the operator interface can

warm up considerably!

In order to avoid the discharge of fuel residues, the fuel filling nozzle and the shut-off valve must be

closed after the use of the filter mobile.

3.1 Utilisation according to specification

Provide diesel oils and mineral oils with a dynamic viscosity < 10 mPas, a flash point > 55°C and a

boiling point > 160°C. The utilisation of liquids which can attack the filter casing (aluminium), the

pumps (steel), the plastic parts (polyamides) and the seals (NBR) is not planned, and can lead to

damage to the filter mobile or to dangerous operating states.

All work on the SWK-2000/40/WSA filter mobile must be implemented in voltage-free status.

Doc. No.: D10053.EN Rev.: 14 Page 6of 29

Operating instructions: SWK-2000/40/WSA filter mobile

Willibrord Lösing

Filterproduktion GmbH

W. Lösing Filterproduktion GmbH • Am Walzwerk 2 • 45527 Hattingen

4 Scope of delivery

•SWK-2000/40/WSA filter mobile

•12 V supply line with crocodile clips, plug connector, fuse holder and fuse protection

(50 A).

Doc. No.: D10053.EN Rev.: 14 Page 7of 29

Operating instructions: SWK-2000/40/WSA filter mobile

Willibrord Lösing

Filterproduktion GmbH

W. Lösing Filterproduktion GmbH • Am Walzwerk 2 • 45527 Hattingen

•230 V supply line with plug incorporating grounding contact and PowerCon plug

connector

•Operating manual

Doc. No.: D10053.EN Rev.: 14 Page 8of 29

Operating instructions: SWK-2000/40/WSA filter mobile

Willibrord Lösing

Filterproduktion GmbH

W. Lösing Filterproduktion GmbH • Am Walzwerk 2 • 45527 Hattingen

5 Technical data

These operating instructions describe the module assembly in the following implementation:

Hardware version: 0.9 and 1.0

Software version: 19.0

5.1 Electrical specs.

5.1.1 Battery operation

Operating voltage: 12 V DC

Maximum operating voltage: 15 V DC

Maximum current consumption: 30 A

5.1.2 Mains operation

Operating voltage: 100 V AC to 240 V AC

Mains frequency: 50 Hz to 60 Hz

Maximum current consumption: 5 A (at 115 V AC)

5.2 Temperature range

Operating temperature: -40°C to 40°C

Storage temperature: -40°C to 80°C

5.3 Mechanical data

IP Protection Type: IP41

Maximum supply capacity of the pumps: approx. 40 l/min

Maximum net positive suction head: approx. 2 m

Doc. No.: D10053.EN Rev.: 14 Page 9of 29

Operating instructions: SWK-2000/40/WSA filter mobile

Willibrord Lösing

Filterproduktion GmbH

W. Lösing Filterproduktion GmbH • Am Walzwerk 2 • 45527 Hattingen

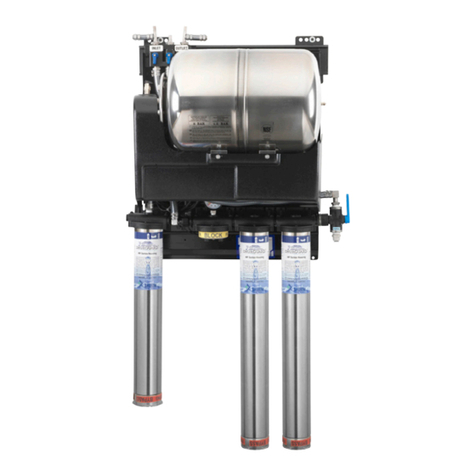

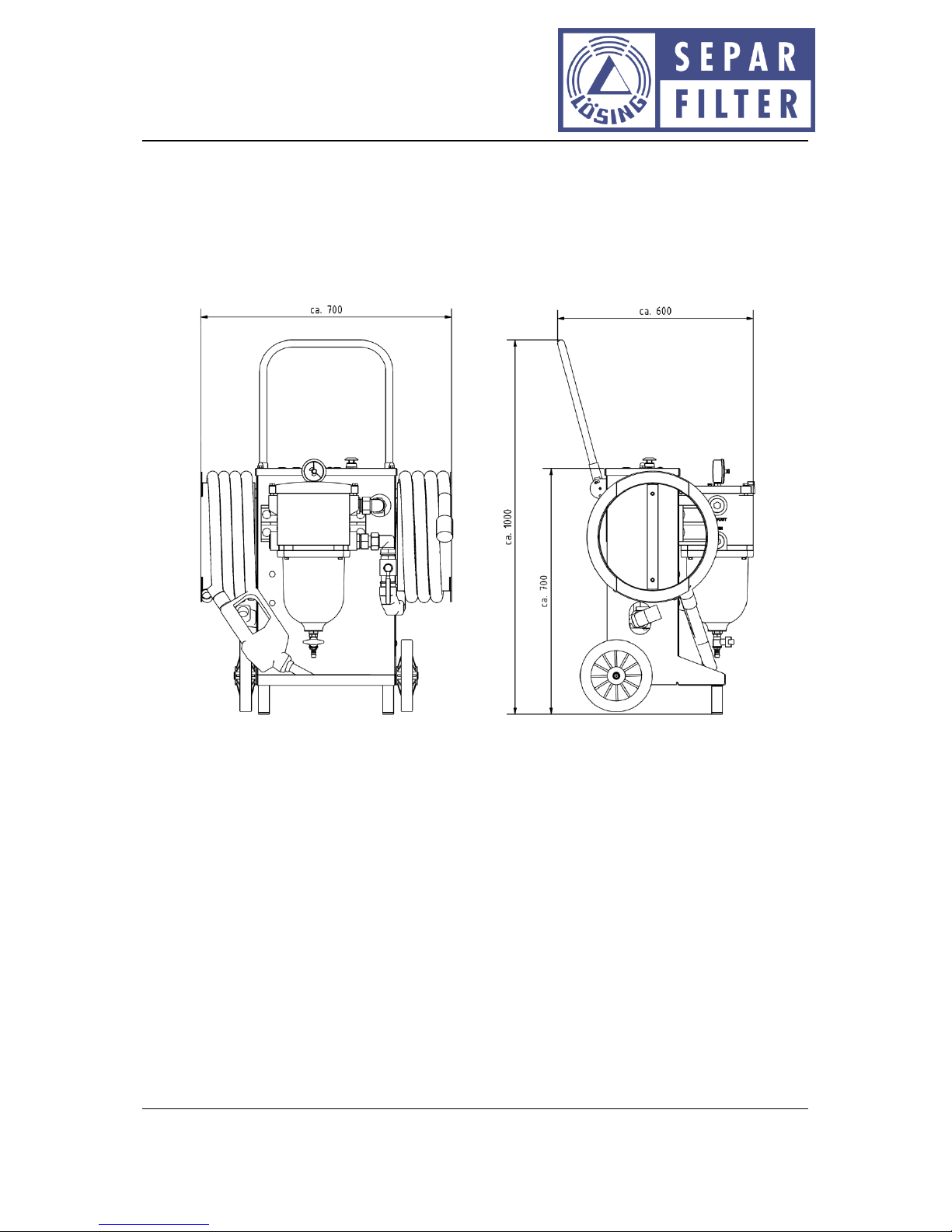

5.4 Weight and dimensions

Dead weight (without fuel): 65 kg

The dimensions (tolerances < 5 mm) can be taken from the following drawing.

Doc. No.: D10053.EN Rev.: 14 Page 10 of 29

Operating instructions: SWK-2000/40/WSA filter mobile

Willibrord Lösing

Filterproduktion GmbH

W. Lösing Filterproduktion GmbH • Am Walzwerk 2 • 45527 Hattingen

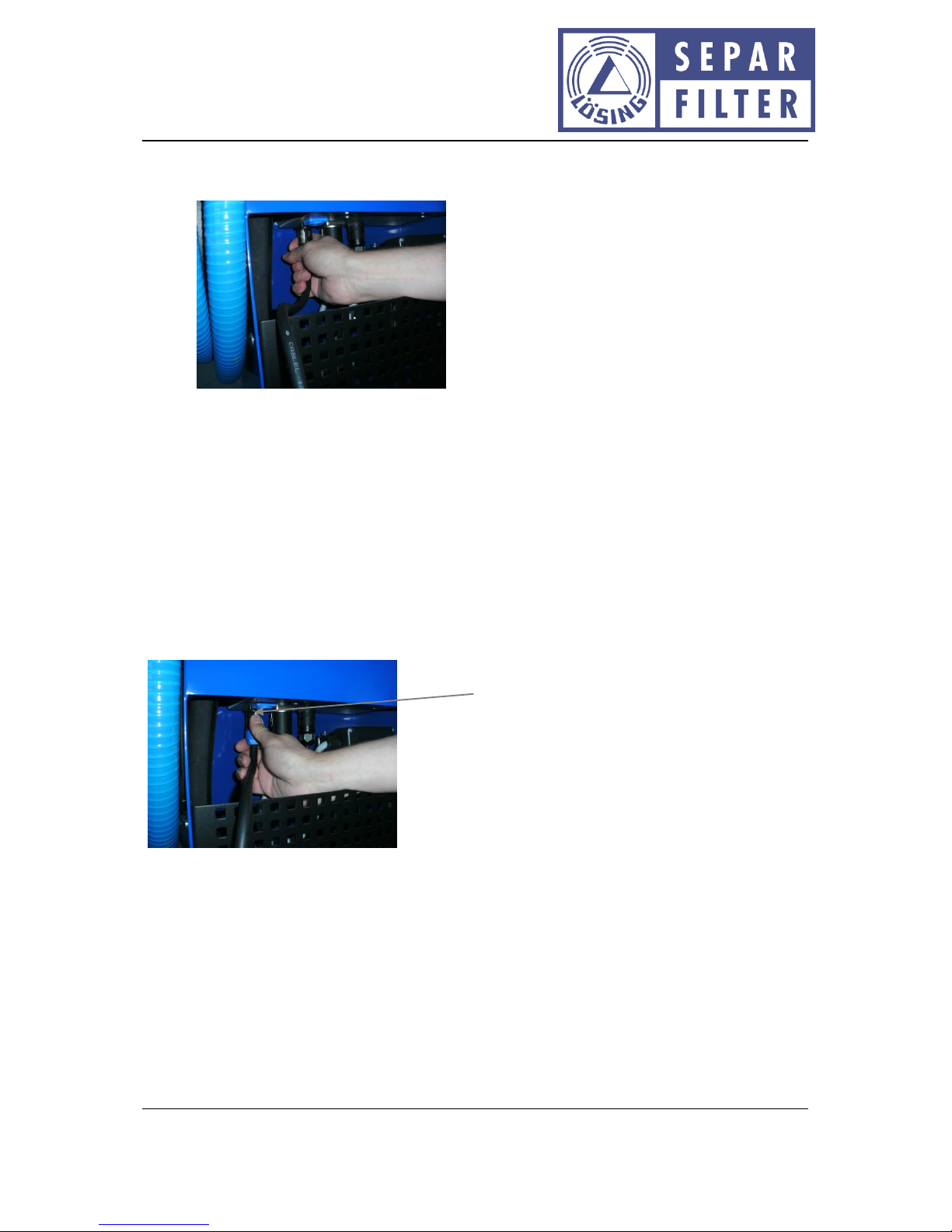

6 Transport grip

The filter mobile is equipped with a hinged transport grip. The transport grip can be fixed in three

settings. In the folded-in status (lowest position) the total height is approx. 750 mm.

For transport, the grip is lifted upwards (maximum height approx. 1000 mm). For that, the two

knurled screws must be loosened anti-clockwise so far until the transport grip can be pivoted

upwards. Pivot the transport grip up until the knurled screws can be turned into one of the upper

two bores. Tighten both knurled screws clockwise hand-tight for the fixing of the transport grip.

Folded-in transport grip

Knurled screws (one per side)

Opened-out transport grip

Knurled screws (one per side)

Doc. No.: D10053.EN Rev.: 14 Page 11 of 29

Operating instructions: SWK-2000/40/WSA filter mobile

Willibrord Lösing

Filterproduktion GmbH

W. Lösing Filterproduktion GmbH • Am Walzwerk 2 • 45527 Hattingen

7 Electrical connections

The SWK-2000/40/WSA filter mobile is provided with two connections for supply voltages:

Connection 1: Plug connector for mains cables with plug incorporating grounding contact,

operating voltage 115 V AC to 230 V AC (removable)

Connection 2: Plug connector for cables with crocodile clips (battery operation), operating

voltage 12 V DC (removable)

The SWK-2000/40/WSA filter mobile is protected against incorrect polarity of the operating voltage

(12 V DC). However, any operation in case of pole-inversal of supply voltage is not possible.

The SWK-2000/40/WSA filter mobile is supplied as standard with plug incorporating grounding

contact. Operation with other mains power connections is also possible with separately available

adapter cables, as long as the electrical connected loads are maintained. The supply line for battery

operation is included in the scope of delivery. Further design implementations on request.

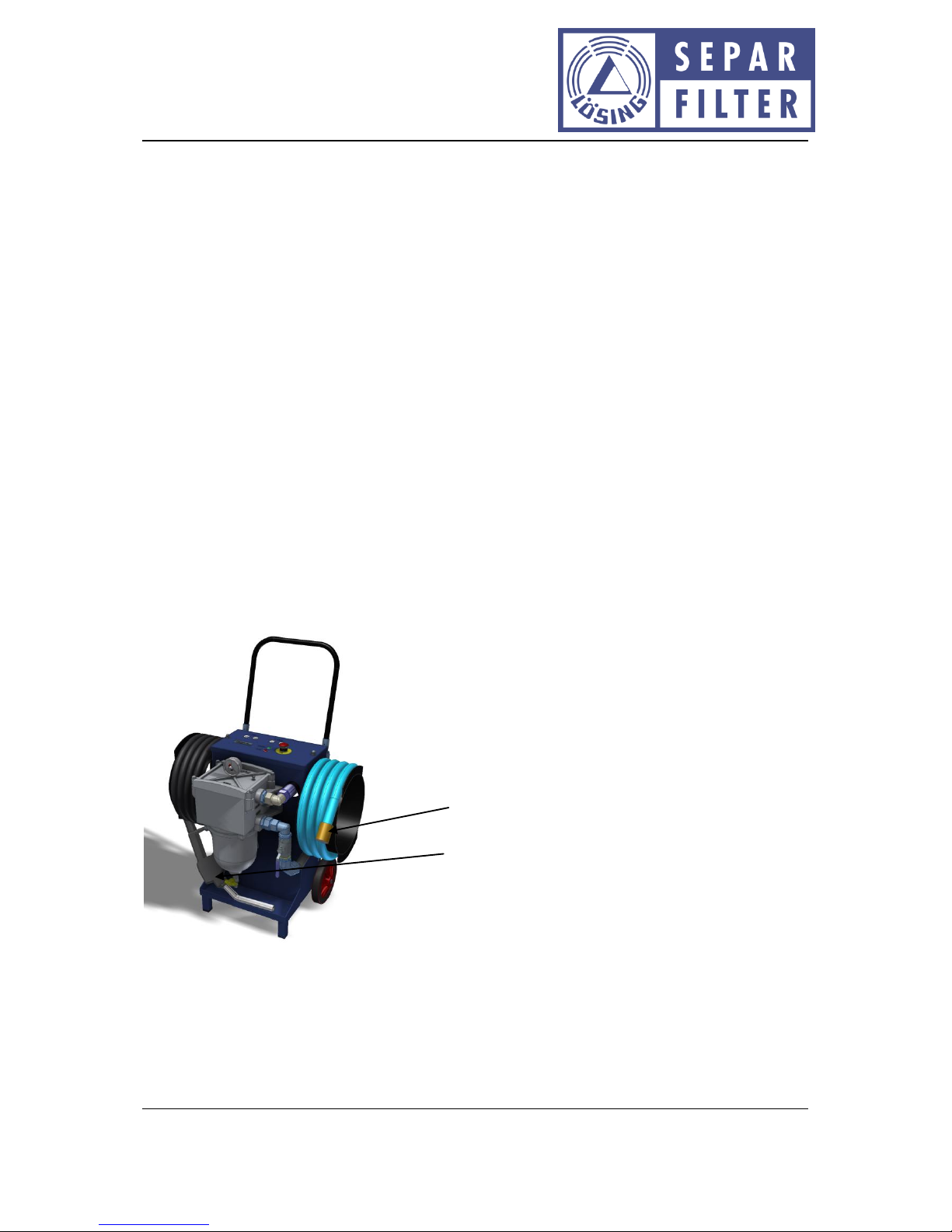

7.1 Mechanical connections

The SWK-2000/40/WSA filter mobile is provided with two fuel lines. The fuel suction pipe is

equipped filter-sided with a shut-off valve and at its end with a check valve, and the output line is

equipped with a fuel filling nozzle,

Check valve

Fuel filling nozzle

Doc. No.: D10053.EN Rev.: 14 Page 12 of 29

Operating instructions: SWK-2000/40/WSA filter mobile

Willibrord Lösing

Filterproduktion GmbH

W. Lösing Filterproduktion GmbH • Am Walzwerk 2 • 45527 Hattingen

8 Connection

The SWK-2000/40/WSA filter mobile is connected with a suitable voltage supply.

Mains connection via delivered power cable (115 V AC; 230 V AC):

Insert power cable into the blue socket on the filter mobile and rotate clockwise until

engagement:

Battery connection using delivered battery lead (12 V DC):

Doc. No.: D10053.EN Rev.: 14 Page 13 of 29

Operating instructions: SWK-2000/40/WSA filter mobile

Willibrord Lösing

Filterproduktion GmbH

W. Lösing Filterproduktion GmbH • Am Walzwerk 2 • 45527 Hattingen

Insert battery leads into black socket on the filter mobile and rotate clockwise until

engagement:

Clamp crocodile clips onto the battery. The red clamp onto the positive terminal and the

black clamp onto the minus pole. In case of batteries which are switched in series, it is to be

ensured that the crocodile clips are connected to only one battery (12 V).

8.1 Network or battery connection cable dismantling

Both the plug connector of the power cable and the plug connector of the battery lead are equipped

with a mechanical interlocking.

For the dismantling of the network or battery connection cable, pull the interlocking of the plug

connector on the filter mobile with the thumbs downward and rotate plug connectors anti-clockwise

up to the stop. After that, the plug connector can be pulled simply from the socket.

Interlocking

Doc. No.: D10053.EN Rev.: 14 Page 14 of 29

Operating instructions: SWK-2000/40/WSA filter mobile

Willibrord Lösing

Filterproduktion GmbH

W. Lösing Filterproduktion GmbH • Am Walzwerk 2 • 45527 Hattingen

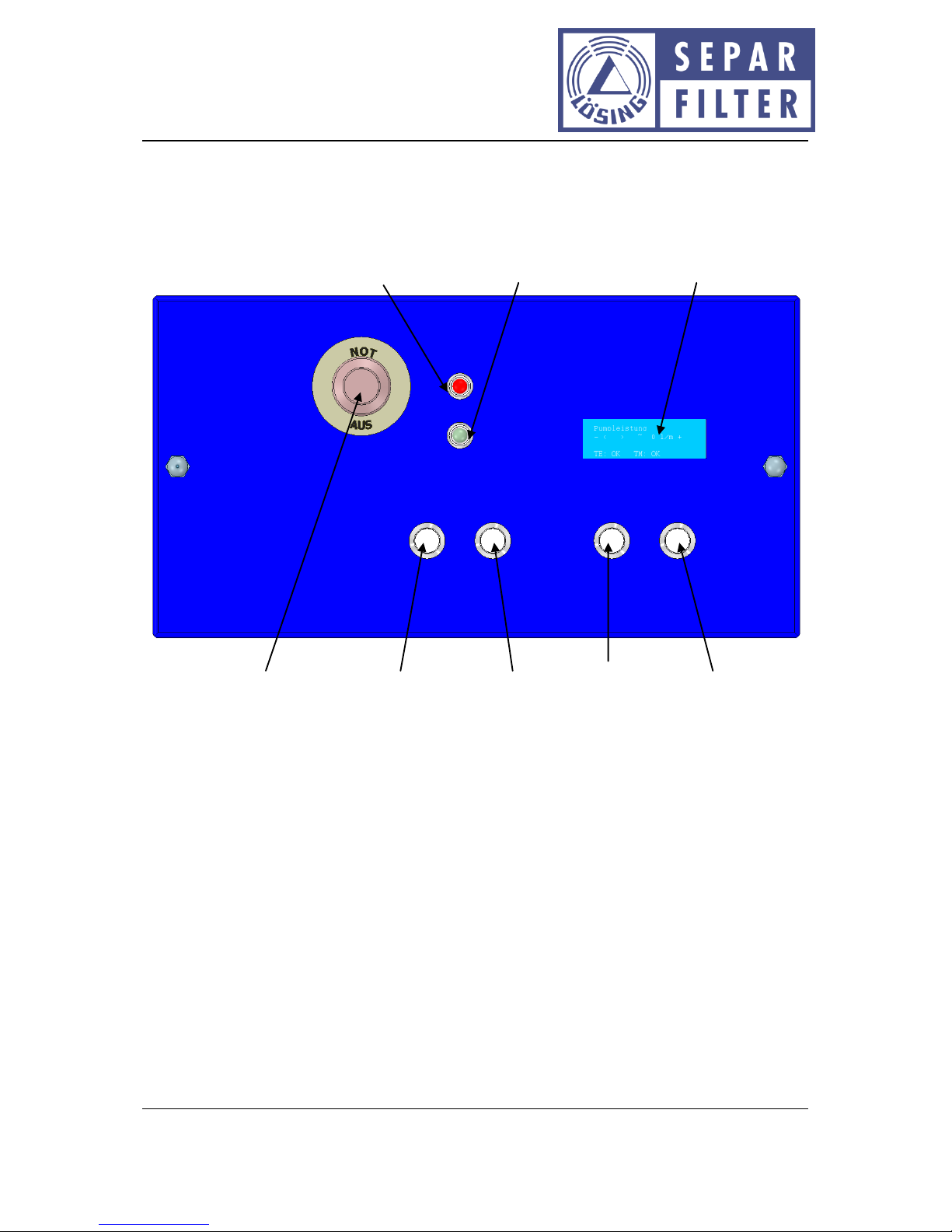

9 Indications and operating elements

For the operation of the SWK-2000/40/WSA filter mobile two buttons, an emergency switch, two

indication LED's, one display, one pressure indication and a shut-off valve are available.

Illustration 1: Indications and operating elements

Error

Power

-Timer +

-Motor +

Error indication

Ready to operate

Display

Emergency Off switch

Timer “-”

Timer “+”

“-”; slower

“+”; faster

Doc. No.: D10053.EN Rev.: 14 Page 15 of 29

Operating instructions: SWK-2000/40/WSA filter mobile

Willibrord Lösing

Filterproduktion GmbH

W. Lösing Filterproduktion GmbH • Am Walzwerk 2 • 45527 Hattingen

The SWK-2000/40/WSA filter mobile is equipped with a pressure indication. A dirt accumulation of

the filter element can be identified in good time using this instrument by the pressure decrease in

the filter system. This pressure indication is located in the cover of the filter casing.

10 Function

Attention! Before operational start-up of the pumps, the shut-off valve is to be opened.

Pressure

indication

Shut-off valve

closed

Shut-off valve

opened

Doc. No.: D10053.EN Rev.: 14 Page 16 of 29

Operating instructions: SWK-2000/40/WSA filter mobile

Willibrord Lösing

Filterproduktion GmbH

W. Lösing Filterproduktion GmbH • Am Walzwerk 2 • 45527 Hattingen

10.1 Fuel filling nozzle

The fuel filling nozzle is equipped with a latching mechanism. In the engaged status, the fuel filling

nozzle is open. As soon as the fuel filling nozzle dips into the fuel during pump operation, the

interlocking is released and the fuel filling nozzle closed.

Push tapping lever of the gun

Engage interlocking lever. Fuel filling nozzle is now open.

Doc. No.: D10053.EN Rev.: 14 Page 17 of 29

Operating instructions: SWK-2000/40/WSA filter mobile

Willibrord Lösing

Filterproduktion GmbH

W. Lösing Filterproduktion GmbH • Am Walzwerk 2 • 45527 Hattingen

10.2 Pump and filter operation

After connection to the supply voltage, the operating voltage is switched on by acknowledgement of

the emergency switch (pull switch button upwards).

The green operation indication (LED) and the display light up. After the initialisation (initialisation

signals always in German), the following switch-on signal is indicated on the display for approx. 2

seconds:

The version numbers, the serial number and the date of manufacture can also be other numerical

values, according to implementation.

After that, the selected operating modes are displayed for approx. two seconds:

You can find an explanation of the operating mode in Chapter 10.4.

After successful self-test, the display indicates:

The ”-” character in the second line at the left edge indicates the function of the left key and the ”+”

character in the second line at the right edge indicates the function of the right key. Dependent on

the font of the display employed, the characters can vary slightly at the left and right line edge. In

the lower line is displayed the temperature status of the electronics and pump motor. In this case

”TE: OK” means: the temperature of the electronics is within the planned range, and ”TM: OK”

means: the temperature of the pump motor is within the planned range. Before beginning the pump

and filter operation, the shut-off valve and the fuel filling nozzle are to be opened.

The filter mobile is now ready for operation.

Pump operation mode

Automatic

Dry-running monitor.

manually

Pump flow rate

- < > ~ 0 l/m +

TE: OK TM: OK

Lösing –Filtermobil

HW-V 1.0

SW-V 13.0

SNr.:000099-18.06.14

Doc. No.: D10053.EN Rev.: 14 Page 18 of 29

Operating instructions: SWK-2000/40/WSA filter mobile

Willibrord Lösing

Filterproduktion GmbH

W. Lösing Filterproduktion GmbH • Am Walzwerk 2 • 45527 Hattingen

For the start of the fuel pump, the right-hand key ”+” must be pressed shortly. The pump ramps

slowly up to a supply capacity of approx. 15 l/min. Smaller flow rates cannot be adjusted. If the key

”+” is pressed longer, the supply capacity of the pump can be increased to approx. 40 l/min. The

instantaneous supply capacity can be read off in the display behind the brackets in l/min. The actual

supply capacity depends on many external influences, and can therefore deviate from the indicated

supply capacity. An actuation of the key ” – ” reduces the supply capacity. With an indication of 15

l/min, an actuation of the key ” – ” results in the disconnection of the pump. If both keys are pressed

simultaneously, the pump is also switched off. For the duration of the key activation, the key

function is displayed between the brackets.

Key ”+” activated:

Key ”-” activated:

Key ”+” and key ” – ” activated:

An actuation of the emergency switch (press down forcefully in the direction of front panel) ends all

pumping procedures and the electrics and electronics disconnect from the supply voltage.

Pump flow rate

- < + > ~ 24 l/m +

TE: OK TM: OK

Pump flow rate

- < - > ~ 22 l/m +

TE: OK TM: OK

Pump flow rate

- < + > ~ 24 l/m +

TE: OK TM: OK

Doc. No.: D10053.EN Rev.: 14 Page 19 of 29

Operating instructions: SWK-2000/40/WSA filter mobile

Willibrord Lösing

Filterproduktion GmbH

W. Lösing Filterproduktion GmbH • Am Walzwerk 2 • 45527 Hattingen

10.2.1 Timer function

The filter mobile is equipped with a timer function, with which allows the pump to be operated for a

preselected time. The pumping procedure is ended automatically after this time.

10.2.1.1 Adjusting the required runtime

The runtime can be adjusted in intervals of 15 minutes, up to a maximum of 2 hours. In order to

initiate this setting-adjustment process, the key ”Timer +” must be pressed with pump operation

switched off. In the display, the following indication appears:

A minimum runtime of 15 minutes is already preset. As a result of actuation the keys ”Timer +” and

”Timer –”, the required runtime can be adjusted. If the keys ”Timer +” and ”Timer –” are activated

simultaneously, the procedure is interrupted and the control returns to the basic status. When the

timing has ended, this setting menu can be exited with the key ”+; faster”.

With the keys ”+; faster” and ”-; slower”, the required pumping capacity can be adjusted as

described in Chapter 8.2. The residual runtime of the pumps is updated continuously in the display.

After this time the pump switches off automatically and the filter mobile returns to the basic status.

Every time-controlled pump operation is implemented only once.

10.2.1.2 Timer operation interruption

The simultaneous actuation of the keys ”+; faster” and ”-; slower” or the actuation of the Emergency

Off switch interrupt the timer operation and end the pumping procedure. The filter mobile returns to

the basic status.

Pump flow rate

- < - > ~ 0 l/m +

Time left: 00:15:00

TE: OK TM: OK

timer adjustment:

runtime: 00:15:00

Doc. No.: D10053.EN Rev.: 14 Page 20 of 29

Operating instructions: SWK-2000/40/WSA filter mobile

Willibrord Lösing

Filterproduktion GmbH

W. Lösing Filterproduktion GmbH • Am Walzwerk 2 • 45527 Hattingen

10.2.2 Fault reports

If the operation indication does not light up with proper connection of the supply voltage and after

the reset-acknowledging of the emergency switch, there is an internal defect. In this case, the repair

must be implemented by the manufacturer.

10.2.2.1 Operating voltage too high

If, in battery operation, a voltage of more than 15 V is connected by mistake (e.g. 24 V through series

switching of two 12 V batteries), a fault report appears in the display:

The fault report is deleted by connection of the correct operating voltage and a new start.

10.2.2.2 Operating voltage too low

If, in battery operation, a voltage of less than 10 V is connected by mistake (e.g. 6 V battery, as in

very old vehicles), a fault report appears in the display:

The fault report is deleted by connection of the correct operating voltage.

A T T E N T I O N

Failure: < 10 V!

A T T E N T I O N

Failure: > 12 V!

Table of contents

Other Separ Filter Water Filtration System manuals

Popular Water Filtration System manuals by other brands

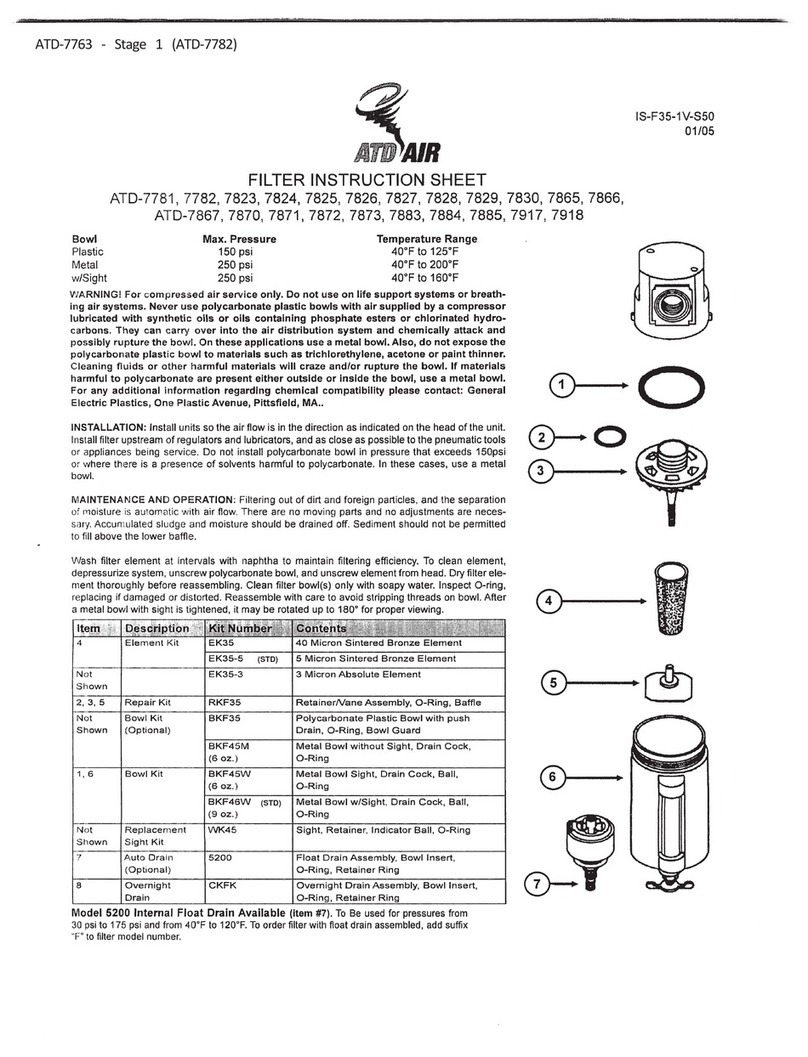

ATD AIR

ATD AIR ATD-7781 instruction sheet

Plymovent

Plymovent Smart"one" user manual

Pentair

Pentair INTELLICHLOR COMSYS-10 installation guide

Best Pool Supplies

Best Pool Supplies RetroChlor Series Installation & operating instructions

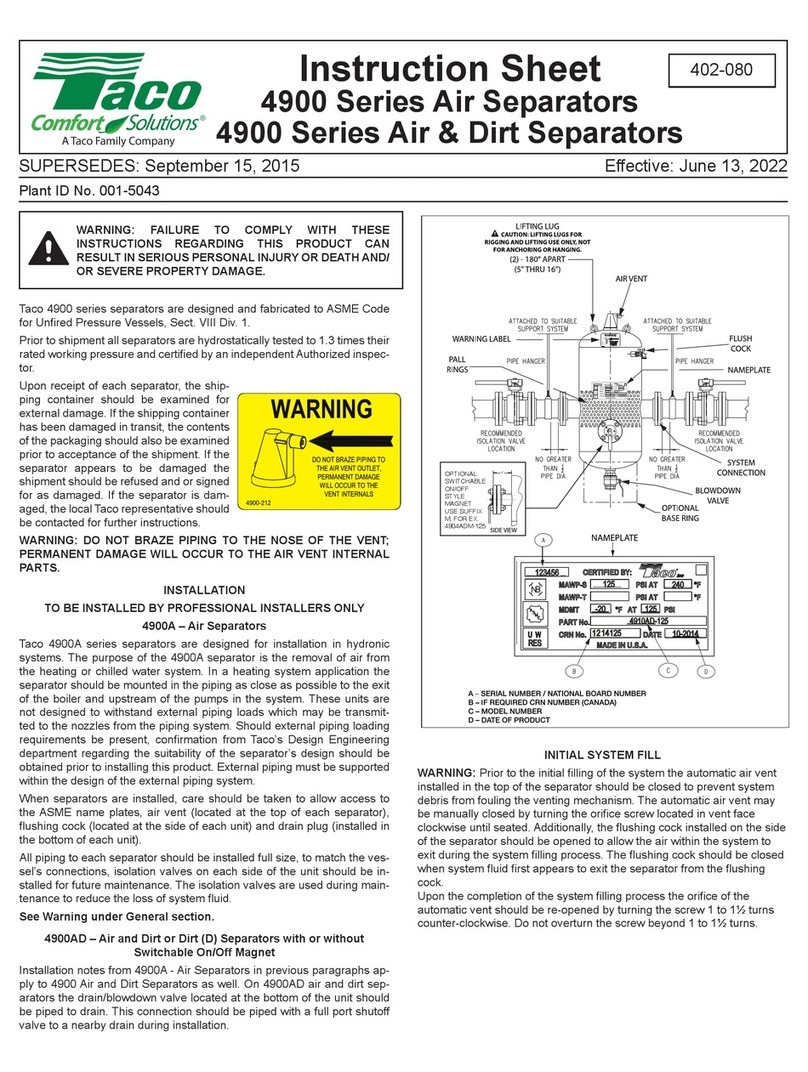

Taco Comfort Solutions

Taco Comfort Solutions 4900 Series instruction sheet

InSinkErator

InSinkErator F-201R installation instructions