Serafin Ultisow User manual

OPERATOR MANUAL

NARROW FOLD SINGLE DISC

OPERATOR MANUAL

2

Table of Contents

Introduction .................................................................................................................................... 3

IMPORTANT NUMBERS .......................................................................................................... 3

Conservation Agriculture ................................................................................................................ 4

No-Till Systems .............................................................................................................................. 4

General Information ....................................................................................................................... 5

Safety ............................................................................................................................................. 6

Operation of the Machine .......................................................................................................... 6

Disconnecting the Machine ....................................................................................................... 6

Operator Safety ......................................................................................................................... 7

Personal Protective Equipment – PPE ...................................................................................... 8

Crushing Hazards ..................................................................................................................... 9

Connecting or Disconnecting Implement Hazards .................................................................. 10

High Pressure Hydraulic Fluid Hazards .................................................................................. 11

Environmental Hazards ........................................................................................................... 12

Hazards when maintaining the Machine ................................................................................. 13

Before You Start .......................................................................................................................... 15

Checklist ................................................................................................................................. 15

Tighten Wheel Nuts & Bearings .............................................................................................. 15

Guidelines for Use .................................................................................................................. 15

Connecting to the Seed Box ................................................................................................... 16

Checking the Wing Fold Operation ......................................................................................... 16

Seed Unit Hydraulic Down Pressure System .......................................................................... 16

Transport Guidelines .................................................................................................................... 17

Transport on Public Roads ...................................................................................................... 17

Manual/Electric Pressure Valve Setup ......................................................................................... 18

Machine Operation/Field Setup .................................................................................................... 19

Lubrication ................................................................................................................................... 20

Seeding Unit ........................................................................................................................... 20

Grease Points ......................................................................................................................... 21

Maintenance ................................................................................................................................ 23

Maintaining the Machine ......................................................................................................... 23

Replacing Discs/Seed Boot Adjustment ....................................................................................... 23

Disc Wear .................................................................................................................................... 24

Effects of Worn Discs ................................................................................................................... 24

Wheel Studs / Rims ..................................................................................................................... 25

Cleaning & Storage ...................................................................................................................... 26

Tyres ............................................................................................................................................ 26

Gason Quick Reference Guide .................................................................................................... 27

Troubleshooting ........................................................................................................................... 31

PARTS CATALOGUE .................................................................................................................. 33

3

INTRODUCTION

Congratulations on the purchase of your new SERAFIN ULTISOW!

Serafin Machinery is based in Griffith, NSW in the heart of one of Australia’s leading agricultural

centres. Serafin Machinery has more than 20 years’ experience in manufacturing and designing

high quality farm machinery for some of the most demanding farming requirements.

The team at Serafin Machinery are totally committed to the No-Till concept of disc seeders for

cereals and pastures. Serafin Machinery’s dedicated parts support and back up service ensures

customers receive exceptional service every time.

Our aim is to continually improve our machinery to ensure low maintenance costs, reliability and

long-lasting machinery that does the best job possible.

Serafin Machinery work hard to keep developing new models of seeders to meet the demand of

our future customers and strive for continual improvement of our imported components from our

suppliers. We hope you enjoy using your new seeder as much as we enjoyed producing it.

Happy planting!

IMPORTANT NUMBERS

Serafin Machinery – Head Office 02 6963 5588

Spare Parts Manager 0458 635 588

Service Manager 0487 055 588

Sales Manager 0459 755 881

Check us out online – serafinmachinery.com.au

4

CONSERVATION AGRICULTURE

According to the FAO (Food and Agriculture Organization of the United Nations), “Conservation

Agriculture” (CA) aims to achieve sustainable and profitable agriculture and subsequently aims at

improved livelihoods of farmers through the application of the three CA principles: Minimal soil

disturbance, permanent soil cover and crop rotations.

CA holds tremendous potential for all sizes of farms and agro-ecological systems, but its adoption

is perhaps most urgently required by smallholder farmers, especially those facing acute labour

shortages. It is a way to combine profitable agricultural production with environmental concerns

and sustainability and it has been proven to work in a variety of agro-ecological zones and farming

systems. It is been perceived by practitioners as a valid tool for Sustainable Land Management

(SLM).”

Head to the Food and Agriculture Organisation website for more information:

http://www.fao.org/ag/ca/index.html

NO-TILL SYSTEMS

“No-Tillage” is a ‘cornerstone’ of CA and can be practiced in both large and small farming

systems. With No-Till (also termed zero tillage and direct drilling) the only tillage operations are

low disturbance seeding techniques for the application of seeds and fertilisers directly into the

stubble of the previous crop. Gradually, organic matter of the surface layers of zero tilled land

increases, due to reduced erosion, increasing yields and resulting in more crop residue added to

the soil surface.

Gradually, organic mulch is developed on the soil surface, and this is eventually converted to

stable soil organic matter because of reduced biological oxidation compared to conventionally

tilled soils. No-Tillage is effective in mitigating many of the negative on-farm and off-site effects of

tillage, principally humidity loss, organic matter loss, reduced biodiversity and reduced runoff.

These conditions are replaced with permanent soil cover, improvements in soil structure,

improved organic matter status, improved water use efficiency and improved soil biology and

nutrient cycling.

5

GENERAL INFORMATION

Read this manual carefully to learn how to operate and service your machine correctly. Failure to

do so could result in personal injury or equipment damage and will not be covered by the warranty

and/or insurance.

This manual is part of your machine and must always remain with the machine. Right hand and

left-hand sides are determined by facing in the direction the machine will travel when going

forward.

Warranty is provided as part of the Serafin Machinery support program for customers who operate

and maintain their equipment as described in this manual. The warranty is explained on the

warranty certificate which you will receive when the machine is delivered.

Set up is the responsibility of the operator. Correct seed depth and amount of soil coverage is

adjustable for each sowing situation. Cover and press wheel pressure are also adjustable. There

is no standard factory setting for all situations as each requirement is different.

Serafin Machinery will demonstrate all adjustments necessary on set up of machine.

Serafin Machinery will NOT be responsible or liable for seeding rate, depth of seed/fertiliser

or closing wheel pressures.

Consult your agronomist for sowing depth and seeding rate.

6

SAFETY

Read all safety instructions before operating the machine. If you do not understand any

part of this manual and need assistance, please contact Serafin Machinery.

Operation of the Machine

Carefully read and understand the instruction manual before use.

Serafin Machinery will instruct correct use of the machine during installation/delivery. It is

the owner’s responsibility to train staff/operator prior to using the machine.

Ensure no one is near the machine while it is attached to the tractor and the tractor is

running.

Incorrect handling of this equipment could result in serious or fatal accidents.

Adhere to all working (12km/h) and transport (30km/h) speeds, in rough terrain and turning

speeds will need to be reduced further to prevent damage or roll over.

Unauthorised modifications to the machine may impair the function and/or safety and effect

machine life. This will also void warranty.

Disconnecting the Machine

Be sure to clear the area around the machine before raising or lowering the machine or

wings.

Stop the tractor on level ground before raising or lowering wings.

Operate the machine from the tractor seat only.

Ensure safety locks are fitted to wings if storing in folded position.

Lower machine to the ground

Turn tractor off and remove key.

Release any hydraulic pressure on remotes.

Disconnect hydraulic couplers, electric couplers and any primary hose breakaway couplers

and fold onto machine.

Disconnect hitch from tractor.

7

OPERATOR SAFETY

Read and understand

Operators manual

Wear appropriate Personal

Protective Equipment

Do not operate machine

when under the influence

of drugs or alcohol

Use Seat Belts

WARNING TO AVOID SERIOUS INJURY OR DEATH DO THE FOLLOWING:

READ, UNDERSTAND and FOLLOW Operator's Manual instructions, Warnings and Safety

Messages.

WEAR PERSONAL PROTECTIVE EQUIPMENT when operating or repairing equipment.

DO NOT USE DRUGS or ALCOHOL before or while operating equipment

DO NOT ALLOW anyone to operate equipment under the influence of drug or alcohol.

CONSULT medical professional for medication impairment side effects.

STAY ALERT, prolonged operation can cause fatigue; STOP and REST.

GENERAL OPERATING SAFETY

Visibility Conditions while in use

OPERATE IN DAYLIGHT or with lights that give clear workplace visibility

Tractor operator must be able to see seeder operation without obstruction

Tractor operator must be able to see ahead and avoid obstructions while operating equipment

Ground Speed while operating

Operator should control ground speed to achieve optimum seeding performance

Adjust working speed to suit terrain conditions

Reduce speed near steep slopes, ditches or foreign objects

Safety Signs and Warning Decals

Replace missing, damaged or unreadable safety signs immediately

Safety Shielding and Sensors

Never remove or modify any safety devices

Communication

Verbal communication can be difficult and dangerous near the seeder

Operating instructions and directions should be made prior to operation

Never allow anyone to approach seeder while in operation

Riding Passengers

Never allow passengers

to

ride on

seeder

.

8

PERSONAL PROTECTIVE EQUIPMENT - PPE

Wear hearing

protection

Wear Hi-

Visibility

clothing.

Wear eye

protection.

Wear enclosed

footwear.

WE RECOMMEND THIS MACHINERY IS USED WITH A TRACTOR THAT IS FITTED WITH A

CABIN. IF THE OPERATION OF THIS EQUIPMENT IS DONE USING A TRACTOR WITH AN

OPEN CABIN, IT IS SUGGESTED THAT PERSONAL PROTECTIVE EQUIPMENT IS WORN

BY THE OPERATOR.

ALWAYS FOLLOW SUGGESTIONS CONCERNING ALL PROTECTIVE CLOTHING AND

PERSONAL PROTECTIVE EQUIPMENT ISSUED TO YOU, OR CALLED BY FOR THE JOB

CONDITIONS. THIS SHOULD ALWAYS INCLUDE;

USE HEARING PROTECTION if using open cab tractor to stop hearing fatigue when

operation for extended times

WEAR HI VISIBILITY CLOTHING to ensure you are visible to others on the worksite

WEAR EYE PROTECTION if using open cab tractor to stop dust or other foreign matter

entering your eyes

WEAR SAFETY FOOT WEAR to protect feet from crush hazards

RESPIRATION PROTECTION if using open cab tractor to stop dust or other foreign matter

entering your lungs

9

CRUSHING HAZARDS

STAY CLEAR OF MACHINE WHILE HYDRAULIC SYSTEM PRESSURISED

WARNING DEPRESSURISE HYDRAULIC SYSTEM TO AVOID SERIOUS INJURY OR

DEATH FROM ACCIDENTAL MACHINE MOVEMENT CAUSING POTENTIAL

CRUSH INJURIES.

THIS SEEDER USES HYDRAULIC ACTUATION TO MOVE PARTS DURING OPERATION OR WHILE

STATIONARY. BE AWARE OF CRUSHING HAZARDS WHEN THE MACHINES HYDRAULIC SYSTEM

IS PRESSURISED.

TO AVOID CRUSH INJURIES

OPERATE FROM TRACTOR SEAT never operate machine from the ground or in close proximity

to moving parts.

DO NOT OPERATE WHILE MAINTAINING MACHINE ensure all people are clear prior to

operation.

TO AVOID FALLING OFF IMPLEMENT

USE EXTREME CARE WHEN CLIMBING ONTO EQUIPMENT. Always use three-point contact

using available handles and steps on implement while exiting.

Never attempt to mount the implement while unit is moving.

TO AVOID CHILDREN FALLING OFF OR BEING CRUSHED BY EQUIPMENT:

NEVER ALLOW children to play on or around tractor or equipment.

CRUSHING BY TRAPPING FINGERS/HANDS/ARMS in EQUIPMENT

KEEP ARMS AND LEGS CLEAR of hydraulic actuators and ground engaging parts

KEEP SEATED while operating the machinery

LOWER WINGS AND ROW UNITS AND STOP TRACTOR ENGINE before attempting

maintenance

KEEP CLEAR OF TRACTOR DRAWBAR when connecting and disconnecting machine

10

CONNECTING OR DISCONNECTING IMPLEMENT HAZARDS

FOOT CRUSHING HAZARD

HAND CRUSH

STOP TRACTOR, REMOVE KEY

READ OPERATING MANUAL

WARNING TO AVOID SERIOUS INJURY OR DEATH FROM BEING CRUSHED BY

TRACTOR OR

IMPLEMENT

:

WHEN ATTACHING UNIT TO TRACTOR:

DO NOT ALLOW BYSTANDERS between tractor and seeder

KEEP HANDS AND BODY CLEAR of drawbar and fold points

BEFORE CONNECTING OR DISCONNECTING COMPONENTS

STOP TRACTOR ENGINE before connecting hydraulic hoses.

WHEN CONNECTING OR DISCONNECTING SEEDER TO TRACTOR DRAWBAR OR

LINKAGE:

DO NOT CRAWL OR WALK under seeder whilst in storage position

11

HIGH PRESSURE HYDRAULIC FLUID HAZARDS

HYDRAULIC FLUID INJECTION

HAZARD

WARNING TO AVOID SERIOUS INJURY OR DEATH FROM HYDRAULIC FLUID

IN

JECTION INJURY

:

WHEN ATTACHING HYDRAULIC HOSES:

INSPECT HOSES for wear and leaks prior to connecting implement to tractor

INSPECT HYDRAULIC COUPLINGS for leaks and damage whilst connecting to tractor

WHEN USING THE IMPLEMENT

CHECK ALL HOSES FOR WEAR & LEAKS prior to operating implement.

12

ENVIRONMENTAL HAZARDS

DUST HAZARD NOISE HAZARD

DUST HAZARD

IMPORTANT TO AVOID INJURY FROM DUST INJESTION OR TEMPORARY

HEARING ISSUES IS RECOMMENDED

:

We recommend operation of this seeder be done using a tractor with a cabin. If you intend

to use this implement with an open type tractor cabin, observe the following use of

Personal Protective Equipment;

WHEN IMPLEMENT IS IN OPERATION:

USE RESPIRATION PROTECTION to reduce dust ingestion

WEAR HEARING PROTECTION

WEAR GOGGLES to reduce dust irritating the operators eyes

13

HAZARDS WHEN MAINTAINING THE MACHINE

PERIODICALLY INSPECT ALL

MOVING PARTS AND TIGHTEN

ALL FASTENERS

STOP TRACTOR ENGINE &

HYDRAULICS BEFORE

CONDUCTING MAINTENANCE

PLACE UNIT ONTO GROUND

BEFORE DOING ANY

MAINTENANCE

WARNING AVOID SERIOUS INJURY OR DEATH FROM COMPONENT FAILURE BY

KEEPING

IMPLEMENT IN GOOD OPERATING CONDITION BY PERFORMING CORRECT

SERVICE, REPAIRS, AND MAINTENA

NCE.

WARNING BEFORE CARRYING OUT ANY MAINTENANCE ENSURE THE TRACTOR

ENGINE IS SWITCHED OFF, KEY REMOVED AND PARK BRAKE ENGAGED.

BEFORE PERFORMING SERVICE, REPAIRS, AND MAINTENANCE ON THE IMPLEMENT:

SECURE EQUIPMENT FOR SERVICE

STOP TRACTOR ENGINE , engage parking brake, and allow all moving parts to stop

LOWER WINGS ONTO GROUND Before commencing work

CYCLE HYDRAULIC CONTROLS to release any trapped hydraulic pressure

WEAR SAFETY GLASSES, PROTECTIVE GLOVES AND FOLLOW SAFETY PROCEDURES WHEN

PERFORMING SERVICE, REPAIRS, AND MAINTENANCE ON THE IMPLEMENT:

Always WEAR GLOVES to guard against worn component with sharp edges.

Always WEAR SAFETY GLASSES when servicing components

AVOID CONTACT with hot hydraulic oil.

SECURELY support or BLOCK UP raised implement, framework, and lifted components before

working underneath equipment.

STOP any implement movements and SHUT-OFF TRACTOR engine before doing any work

procedures.

USE stepladder or raised stands to reach high equipment areas inaccessible from ground.

ENSURE good footing by standing on solid flat surfaces when getting on implement to perform

work

FOLLOW manufacturer's instructions in handling oils, solvents, cleansers, and other chemical

agents.

DO NOT change any factory-set hydraulic calibrations to avoid component or equipment failures.

DO NOT modify or alter implement, functions or components.

14

HAZARDS WHEN MAINTAINING THE MACHINE (CONTINUED)

PERIODICALLY INSPECT ALL

MOVING PARTS AND TIGHTEN

ALL FASTENERS

STOP TRACTOR ENGINE &

HYDRAULICS BEFORE

CONDUCTING MAINTENANCE

PLACE UNIT ONTO GROUND

BEFORE DOING ANY MAITENANCE

WARNING AVOID SERIOUS INJURY OR DEATH FROM COMPONENT FAILURE BY

KEEPING

IMPLEMENT IN GOOD OPERATING CONDITION BY PERFORMING

CORRECT

SERVICE, REPAIRS, AND MAINTENANCE.

PERFORM SERVICE, REPAIRS, LUBRICATION AND MAINTENANCE OUTLINED IN

IMPLEMENT

MAINTENANCE SECTION:

INSPECT before each use for loose fasteners, worn or broken parts, leaky or loose fittings

and all moving parts for wear.

REPLACE any worn or broken parts with new parts.

LUBRICATE unit as specified by maintenance checklist.

NEVER lubricate, adjust or remove material while it is running or in motion.

TORQUE all bolts and nuts as specified.

CHECK tire conditions.

AVOID CONTACT with recently used equipment that may still be hot.

DO NOT MODIFY or alter equipment

DO NOT CRAWL or walk under unsecured raised equipment.

SAFETY SHIELDS, GUARDS AND SAFETY DEVICES INSPECTION:

MAINTAIN SAFETY SIGNS and Decals in good readable condition.

REPLACE any missing, broken or worn safety shields, guards and safety devices.

15

BEFORE YOU START

Check List

1. Read and understand operator’s manual on how to operate correctly.

2. Check tyre pressure and inflate to required pressure minimum (40 PSI). Refer to page 26

3. Lubricate frame and units with recommended grease at stated service intervals. Refer to

Page 20

4. Inspect for loose, damaged or missing parts. Repair or replace before use.

5. Make sure air and hydraulic hoses do not interfere with moving parts. If there is

interference, relocate hoses and secure in position.

Tighten Wheel Nuts & Wheel Bearings

Tighten all wheel nuts after first 4 hours and wheel bearings during the first week of operation and

check periodically after that. Refer to page 25. This is a part of general servicing.

To adjust wheel bearings:

1. Jack up machine.

2. Remove centre hub cap and split pin.

3. Tighten nut until there is a slight drag on the bearings, while turning wheel.

4. Back nut off until split pin can be placed in hole.

5. Replace hub cap.

6. Torque wheel nuts to 255ftlb as per recommendation page. Refer to page 25.

Guidelines for Use

1. Ensure units are fully raised before lowering or raising the wings.

2. Clear wing area of people and obstacles and ensure locking pins are removed before

lowering or raising the wings.

3. Raise units fully out of the ground before making sharp turns, such as at row ends or

turnarounds or when backing up the machine.

4. Have machine moving forward before lowering units, to avoid blockages.

5. When units are in working position, operate at a maximum ground speed of up to 12 km/h.

If conditions are rough or unfavourable you will need to reduce your ground speed to suit.

6. Travelling speed with units raised and wings folded is a maximum of 30km/h. It is desirable

to run machine in straight lines and refrain from 90 degree turns. As this will create excess

wear of the seeding unit and possible damage to the cover wheel arm.

16

Connecting to the Seed Box

Ensure all hydraulic lines and machine connections are in correct position before operation.

Check that couplers are clicked in correctly, especially on low pressure return or case drain

hoses to avoid blowing motor seals on fan.

Checking the Wing Fold Operation

1. Ensure units are fully raised and locking pins removed before lowering or raising the wings.

2. Keep all persons away from the machine when raising or lowering wings.

3. Always locate machine on level ground when raising or lowering wings.

4. Never raise or lower wings when moving.

5. Use with care when raising wings near electricity lines to avoid contact. Serious injury or

death can result from contact with electricity lines.

Seed Unit Hydraulic Down Pressure System

NOTE: The active hydraulic system requires a tractor with closed-centre or pressure/flow

compensated hydraulics. Valve set up is on page 18.

The active hydraulic system keeps the depth wheels in contact with the soil surface to follow

ground contours over uneven terrain. The setting of the depth wheels determines seed depth,

NOT the hydraulic pressure.

The amount of hydraulic pressure needed to keep the depth wheels in contact with the surface

depends upon soil compaction, moisture and stubble covering. Too little pressure causes

insufficient spring compression and inconsistent disc penetration resulting in uneven seed depth.

Excess pressure can cause premature damage to the depth wheel tyre, rim and shaft.

17

TRANSPORT GUIDELINES

1. Proceed cautiously under overhead power lines and around utility poles.

2. Know the transport height and width of your machine.

3. Electrocution can occur with direct contact to overhead electrical lines.

4. Always fold wings fully and install transport locks before transport.

5. Do not transport with tractor that under specified for this seeder - EG: Too light.

6. When transporting, latch the tractor brakes together.

7. To improve stability when travelling through the field, wings should be unfolded from

transport position as soon as possible after leaving the roadway.

8. Adhere to recommended MAX speed 30km/h.

Transport on Public Roads

1. Always travel at a reasonable and safe speed. Never exceed 30 km/h.

2. Always use the flashing warning lights when transporting on public roadway. Keep

reflective material and flags clean and visible. Ensure oversize signs are fitted and visible –

front and rear.

3. Prevent collisions between motorist and slow-moving equipment on public roads.

4. Frequently check for traffic from the rear, especially in turns and use the turn signals.

5. Shift the tractor into a lower gear when transporting down steep slopes or hills.

6. It is not recommended to transport with seed or fertiliser in bins.

7. Never transport the machine with air seeder fan running.

8. It is recommended you check the Roads and Maritime Services website for rules and

regulations while transporting agricultural machinery in your area.

Head to the RMS website for more information: https://www.rms.nsw.gov.au/

18

MANUAL/ELECTRIC PRESSUE VALVE SET UP

Down pressure is important to ensure even seed depth across the machine on variable soil

conditions. But the depth wheel is the main control for depth. Each paddock can vary in soil

hardness, so adjust accordingly.

There is a Hex head screw under the manual valve. See image below.

Loosen the lock nut, to reduce pressure turn the screw anti clockwise, to increase pressure

turn clockwise.

To set pressure lower the units, drive forward five metres then check the depth wheels.

Optimum pressure you should be able to just turn the depth wheel while the disc is in the

ground. This way most of the pressure is on the disc not the depth gauge wheel. The depth

wheel is designed to follow the ground, not carry the unit or the machine.

Excess pressure will cause damage to the depth wheel rims and tyres and may void your

warranty.

Pressure ranges between 500psi and 800psi are considered to be in the acceptable range.

In some sandy and lighter soils pressures of 350 psi is recommended.

Avoid running pressures exceeding 1000psi especially for extended periods. This may

cause premature wear of the units and void your warranty.

When setting pressure, it is normal to see the pressure gauge drop 150 – 200psi quickly

and settle. This is because you are overloading the valve with oil and it will drain back to

where you have set the valve. EG. If you have set the valve at 500psi it may build up to

700psi and when you let the remote go it will quickly settle back to 500psi.

Electric Valve

Electric valve pressure is controlled by the dial on the control box in the cab. Adjust the dial

and push the remote, this will build the pressure up to where it is set on the dial and divert

the rest of the oil back to tank.

DO NOT run electric or manual pressure valves in constant flow.

Hex Head

Screw to adjust

down pressure

Manual Valve Electric Valve

19

MACHINE OPERATION/FIELD SET UP

Ensure all hydraulic hoses have been correctly fitted.

Ensure all primary breakaway couplers are correctly connected where necessary. (Tow

behind models)

Connect all electrical plugs.

Power up monitor and run fan, walk around seeder to ensure air is getting to all units and

there are no blockages. Turn fan off when you are happy with even air distribution.

Calibrate product (it is recommended to use clean graded seed to prevent blockages or

bridging).

Once desired rate is achieved you can fill bins.

Assess paddock to be planted for conditions and stubble/trash load.

Set estimated down pressure.

Adjust 4 row unit depth wheels to desired depth, drive forward 20m stop and check depth

wheel is touching the surface. Try to turn the depth wheel, if the depth wheel can be turned

with some resistance pressure is ok. If the depth wheel is not touching the surface more

pressure will need to be applied. If you cannot turn the depth wheel excess pressure is

being applied and will need to be reduced.

Check correct depth directly behind the disc is being achieved, if not change position on the

depth adjuster handle to achieve desired depth. Once desired depth and pressure are

achieved set all row units to the same position ready to plant.

Check press wheel behind the disc is pressing over the seed in the furrow. There are

washers either side of the press wheel which can be swapped to achieve this.

Check the rear cover wheel is closing the furrow correctly. If the ground is heavily

compacted, you may need to swap spacers on the shaft to move the wheel closer to the

furrow edge. There is also spring adjustment around the pivot at the top of the arm which

can be tightened to press firmer. If you are in soft or sandy soil you may need to move the

wheel further away from the furrow and reduce spring pressure. Image Below: Press and

Cover Wheel

PW Spaces

CW Spaces

20

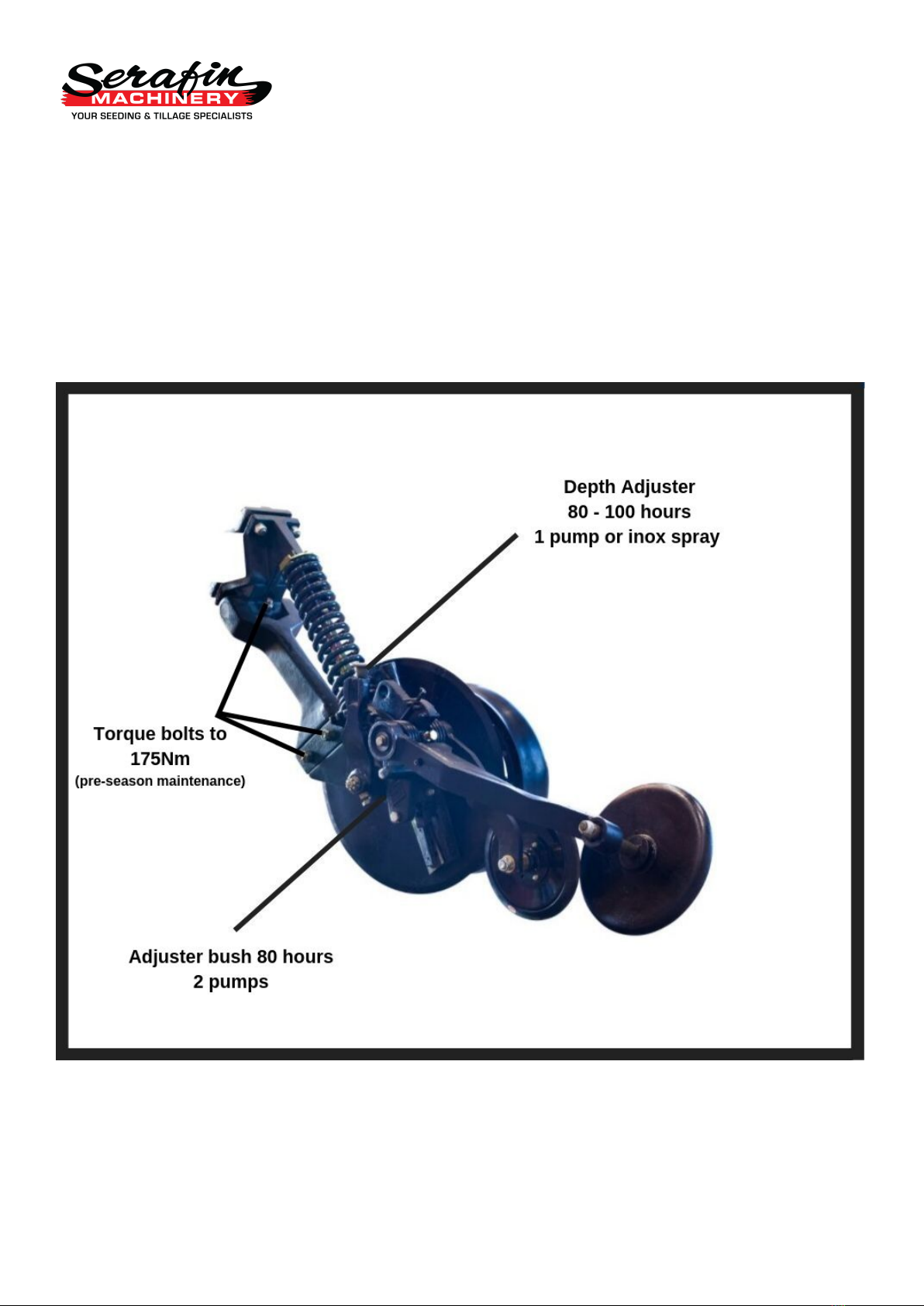

Lubrication

HI-TEC super red grease EP2 or equivalent recommended. Lubricate grease points shown below

between 80 and 100 working hours. Shown below.

Apply recommended pumps of grease below to each to grease point.

Seeding Unit

Table of contents

Popular Farm Equipment manuals by other brands

Schaffert

Schaffert Rebounder Mounting instructions

Stocks AG

Stocks AG Fan Jet Pro Plus 65 Original Operating Manual and parts list

Cumberland

Cumberland Integra Feed-Link Installation and operation manual

BROWN

BROWN BDHP-1250 Owner's/operator's manual

Molon

Molon BCS operating instructions

Vaderstad

Vaderstad Rapid Series instructions