Serai CR/41/24 Guide

E R A IS

GATE OPENER DIVISION

CR/41/24 I E

DAL 1965

CR/41/24 29.41/24 CONTROL UNIT FOR CONTROL OF 1 OR 2 24 Vdc MOTORS FOR THE

AUTOMATION FOR WING GATES

Page 1/12

INSTRUCTIONS FOR INSTALLATION

Thank you for having chosen SERAI ELETTRONICA, certain that you will obtain the performance necessary for use

from this product.

Remember that you are about to install a system classified as "motorised activation destined to move gates and

automatic doors in commercial and residential buildings, with access of vehicles and persons", which is considered

as potentially dangerous. Normally, it is your task and responsibility to make this system "safe" for how mush this is

reasonably possible.

Installation and maintenance of such a system must therefore by carried out exclusively by train, qualified and exert

staff, with "state-of-the-art" executions, as prescribed by law 37/08 and successive amendments and integrations.

The law prohibits the realisation of these types of plants by unqualified staff.

On realisation of its own products, SERAI has respected the following:

Reference Directives for CE marking:

machinery: 2006/42/EEC

low voltage: 73/23/EEC + 93/68/EEC

electromagnetic compatibility: 2004/108/EEC

General reference Standards:

electrical safety: IEC EN60335-1 + IEC EN60335-2-103

electromagnetic compatibility - emissions: IEC EN61000-6-3

electromagnetic compatibility - immunity: IEC EN61000-6-1

When installing the system, as well as that mentioned previously, please also respect.

General reference Standards:

safety of electrical plants in general environments: IEC 64-8 V2

Reference Standards specific of the product:

safety regarding use of motorised doors - requisites: UNI EN12453

safety regarding use of motorised doors - test methods: UNI EN12445

The SERAI products allow to realise systems that respond to these Standards. The following is very important

THE INSTALLER IS RESPONSIBLE FOR THE SYSTEM AND ITS FUNCTIONING IN COMPLIANCE WITH

STANDARDS

This manual must be read completely before proceeding with installation of the various parts of the plant.

!

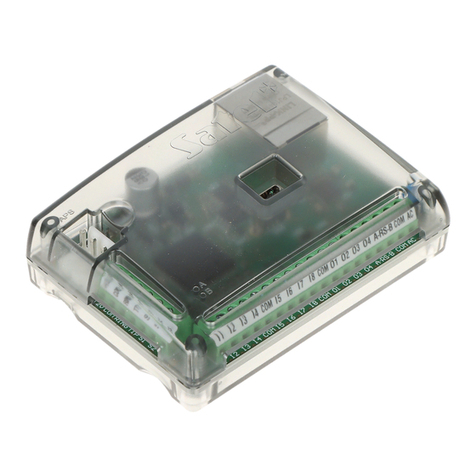

INSTALLATION OF THE CR/41/24 CONTROL UNIT

Position the appliance in proximity of the gate in a way to reduce the length of the connection cable, to the rest of

the system, to a minimum.

For greater protection from atmospheric agents it is recommended to position the control unit under a roof or, even

better, in a room that has two lateral walls. It is also good practice to install the appliance at a height above 1.5 m,

where possible, in order to prevent it being tampered with by children.

WHERE TO POSITION THE CONTROL UNIT

The control unit leaves the factory with the lid positioned to open from the left side.

If you wish to open the lid from the opposite side, proceed as follows:

ATTENTION: This operation must be carried out

before fixing the container to the wall.

Insert a flat tip screwdriver into the fixing recess of the hinges

positioned on the rear of the base and lever on the attachment

notch of the hinge itself; pull the lid at the same time. (see

Fig.1)

Fig.1

Insert a flat tip screwdriver into the fixing recess of the hinge

positioned on the front part of the lid and lever on the notched

attachment of the hinge itself; pull the hinge at the same time.

(see Fig.2)

Fig.2

DAL 1965

Re-mount the hinges on the right side of the base by

inserting them in the relevant seats with the attachment

notch facing towards the inside of the container until the

attachment clicks (see Fig.3)

Fig.3

LID SET-UP FOR LID OPENING TO THE RIGHT

!

Page 2/12

CR/41/24 I E

DAL 1965

Page 3/12

CR/41/24 I E

BATTERY HOUSING AND CABLES INLET

Seats for fairleads PG11 and PG 13,5 which are easy to break through, are envisioned in the lower part of the

container for the passage of input cables

!ATTENTION: Close all inputs well to

prevent the entry of insects, which

may damage the control unit.

Two strips are supplied complete with screws for fixing the two 12V 2 Ah batteries (SERAI BT/15 or BT/20) onto the

lid of the container

!ATTENTION: Considering the weight

of the batteries, it is recommended

to install them at the end of

mounting, before closing the box.

OPENING AND CLOSING THE BOX

When opening the box, make sure that most of the hinges

escape from the guide on the bottom of the control unit in order

to guarantee that the lid remains open without obstructing the

control unit wiring operations.

In the closing phase, accompany the lid “especially in the

presence of the battery” until complete return of the hinges. Pay

attention that the gasket is inserted correctly. Close the lid using

the appropriate screws.

FIXING THE CONTROL UNIT TO THE WALL

It is recommended to position the appliance in proximity

of the gate in a way to reduce the length of the

connection cable, to the rest of the system, to a minimum.

The control unit must be fixed via the cable passage

holes facing downwards.

NO NO YES

Ø 6 ÷ 8 mm

Recommendations for connections in general rooms

1. Upstream from the system, prepare an omnipolar isolating switch with distance of 3 mm or more between the

contacts. As an alternative, use a 10Amagnet circuit breaker switch.

2. Make any type of connections always with the system not powered, i.e. with the isolating switch in the "open"

position ("0" symbol). In particular, the control unit must never be powered during wiring or while any expansion

cards are being inserted.

3. When installing the plant, use the following cables:

2

- for the power supplies to the motors: minimum 2.5 mm

2

- for the power supplies of the batteries and the electric locks: minimum 2.5 mm

22

- for the power supplies of the control unit: section 1.5mm for maximum length of 19m, section 2.5mm for lengths up

to 31m,

22

- for the flashing light section 0.75mm for maximum lengths of 3m, section 1.5mm for lengths up to 19m.

- for low voltage and current lines, such as photocells, control buttons, electro-mechanical key, sensitive edges and

22

other safety devices: section 0.5mm for maximum length of 50m, section 0.75mm for lengths up to 100m,

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 2021 22 2324

28 27

34 33

P3P2P1

-+

-+

-+

VELOC.

RALL

AMP

ON

1 2 43

SW1 ON

1 2 43

SW2

25 26

F2F2

F3F3

F1F1

F4F4

SW3

DAL 1965

WIRING DIAGRAM FOR 24Vdc MOTORS

EARTH

(BRAIDING)

ANTENNA

!

DISCONNECT THE POWER SUPPLY

-FROM THE NETWORK AND THE

BATTERY ID PRESENT, BEFORE

INTERVENING ON THE CONNECTIONS

!

2

ATTENTION: to connect the 24Vdc motors, use 2 cables with section of 2.5mm otherwise high voltage drops

will cause the force and speed of the motor to decrease, especially on the motor the furthest away

from the control unit, which could be slower than the other.

+

27 (+), 28 (-)

BUFFER POWER SUPPLY

for 2 12Vdc 2Ah batteries

SERAI BT/15 or BT/20

-battery charger included-

-

2 Batteries

12Vdc 2Ah

OPTIONAL

12

+

-

CLOSURE

PHOTOCELL

RECEIVERTRANSMITTER

OPENING

PHOTOCELL

RECEIVERTRANSMITTER

NC

NC

NA

NC

NA

PEDESTRIAN

START

STOP

NC

EDGE

+

-

24 Vdc

24Vdc OUTPUT

INTERMITTENT

FOR LIGHT

MAX 25W

24 Vdc

+

-

GATE INDICATOR LIGHT

OPEN O

ELECTRIC LOCK

(see SW2 dip2)

"AMP" POTENTIOMETER

regulation of the amperometric control

level. With the potentiometer at

maximum the amperometric control is

excluded”

"RALL" POTENTIOMETER

speed regulation during the slowing

phase, with the potentiometer at

maximum slowing is excluded

"VELOC." POTENTIOMETER

regulation of the velocity during normal

run

SW3 JUMPER

allows to have different sensitivity of the

amperometric control:

SW3 NOT INSERTED: normal

sensitivity

SW3 INSERTED: greater sensitivity

therefore the amperometric control

intervenes before

Page 4/12

CR/41/24 I E

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

28 27

34 33 P3

P2

P1

-+

-+

-+

VELOC.

RALL

AMP

ON

1 2 43

SW1 ON

1 2 43

SW2

25 26

F2F2

F3F3

F1F1

F4F4

SW3

LED

DL6

DL1

PED

DL2

START

DL3

STOP

DL4

FOTO

DL5

FOTO AP

DL7

COSTA

PAUSA LAVORO PROGR.

BATTERY

+-

FR1

F1 = T16A 250Vca - -

-BATTERY-

F2 = T16A 250Vca - -

-SECONDARY TRANSFORMER-

F3 = T2A 250Vca -delayed-

-CLAMPS 11-12, 13-14, 15-16-

F4 = F2A 250Vca -instant-

-PRIMARY TRANSFORMER-

FR1 = 0,5A -resettable fuses-

-CLAMPS 9-10-

delayed

delayed

M1 M2

NC

NC

NC

NC

K/71 E SR.24.71 E

K/71 I SR.24.71 I

230V~ ±10%

50/60Hz

F

N

BI-POLAR SWITCH FOR

THE UNLOCKING OF THE

MOTORS FROM INSIDE

OPTIONAL UNLOCKING

KEY FROM OUTSIDE

DAL 1965

Page 5/12

DEFINITION OF THE CLAMPS

CLAMPS CONNECTIONS DESCRIPTION

23 - 24

NETWORK

POWER SUPPLY

230Vac ±10% 50/60 Hz power supply input, which via fuse F4 powers the primary of the

toroidal transformer - already wired -

13 - 14

FLASHING

17 - 18

MOTOR M1

Motor M1 24Vdc power supply output for single wing or pedestrian wing (to which electric lock

can be connected), delayed closure.

9 - 10

PHOTOCELLS

POWER SUPPLY

Power supply output 24Vdc (9 = -, 10 = +) max 500mA for accessories such as photocells

6

OPENING

PHOTOCELL

5

CLOSURE

PHOTOCELL

1

4

PEDESTRIAN

CONTROL

STOP KEY

Stop control input (NC contact). When pressed it blocks functioning of the motors, if pressed

during the open gate pause time it annuls automatic closure.

2

START

COMMAND

Start control input (NO contact), controls the opening and closure in step-by-step mode.

N.B. This function can be modified as described in "modify controls".

Photocell input active in opening and closing (NC contact).

If blacked-out in the opening phase, the gate stops, re-starts opening as soon as the photocell

is no longer engaged.

If blacked-out in the closure phase, the gate stops, re-opens as soon as the photocell is no

longer engaged.

Photocell input active only in closing (NC contact). If blacked-out in the closure phase, the

gate stops and then re-opens.

COMMON

INPUTS

Inputs common clamps

11 - 12

CONTROL FOR

ELECTRIC LOCK

OR GATE OPEN

INDICATOR LIGHT

33 - 34

RECEIVER

ANTENNA

INCORPORATED

Flashing light power supply output (24Vdc-max 25W) to be used with flashing light without -

SERAI RZ/24F- internal electronics. Flashing is fast during closure, slow during opening and

very slow when functioning with battery.

8

3 - 7

24Vdc output (11 = -, 12 = +) with the following functioning:

With SW2dip2 OFF: impulse control for electric lock -SERAI M/83/1-.

With SW2dip2 ON: control with the gate open indicator light function

Input for the connection of the antenna for the built-in receiver.

(33=BRAIDING/EARTH, 34=ANTENNA)

Sensitive edge input (NC contact), inverts movement by 10cm.

SENSITIVE

EDGE

LEDS INDICATION

LED

DL5=PH OP

DL4=PHOTO

DL3=STOP

DL1=PED

DL2=START

ON OFF

FUNCTION

Internal photocell

External photocell

Stop button

PEDESTRIAN button

Open/Close button

Opening photocell free from

obstacles

Closure photocell free from

obstacles

Stop button in normal state

Pedestrian button pressed

Open/Close button pressed

Opening Photocell blocked out

(presence of an obstacle)

Closure Photocell blocked out

(presence of an obstacle)

Stop button pressed

Pedestrian button in normal state

Open/close button in normal state

DL6 Programming Indicates the various phases of the programming

DL7=COSTA Sensitive edge Sensitive edge in normal state Sensitive edge pressed

ATTENTION: this voltage is not present in battery functioning with

gate at a standstill.

15 - 16

AUXILIARY

POWER SUPPLY

Power supply output 24Vdc (15 = +, 16 = -) max 200mA for accessories that must always be

powered, for example external radio receivers.

19 - 20

MOTOR M2

M2 motor 24Vdc power supply output for delayed wing opening

21 - 22

TRANSFORMER

SECONDARY

INPUT

20Vac input for power supply of the circuit board supplied via a toroidal transformer- already

wired-

27 - 28

OPTIONAL

BATTERIES

Input for the connection of N°2 12V 2Ah buffer batteries (optionals, e.g. SERAI BT/15 or

BT/20) to guarantee functioning of the automation in the case of a power cut. In presence of

the circuit board network voltage, it recharges the batteries via the built-in battery-charger

CR/41/24 I E

Pedestrian control input (NO contact). With DIP1 SW1 OFF only the wing connected to M1

opens. With DIP1 SW1 ON the single wing opens (M1) for 7s.

N.B. This function can be modified as described in "modify controls".

DAL 1965

SETTING OF EACH INDIVIDUAL MICRO SWITCH

DESCRIPTION OF THE FUNCTIONING

FUNCTIONING

Single wing logic: just the output indicated with M1 is controlled

Double wing logic: outputs M1 and M2 are controlled (M2 wing

opening delay)

GATE CONFIGURATION

1 2 3

ON

4 1 2 3

ON

4

1 2 3

ON

4 1 2 3

ON

4

ENABLES/DISABLES

IMMEDIATE CLOSURE

FUNCTIONING WITH

PASSAGE ON

CLOSURE PHOTOCELL

1 2 3

ON

4 1 2 3

ON

4

1 2 3

ON

4 1 2 3

ON

4

Immediate closure function enabled: the engagement and

disengagement of the closure photocell makes the gate re-close (when

the gate is open) automatically after 5s.

Immediate closure function disabled

Hammering activated: the electric lock is activated during a brief

closure phase against the stops and is deactivated after the start-up of

M1.

Hammering deactivated: The electric lock is activated just after the

start-up of M1 and is deactivated a little after the start-up of M1.

1 2 3

ON

4 1 2 3

ON

4

1 2 3

ON

4 1 2 3

ON

4

1 2 3

ON

4 1 2 3

ON

4

1 2 3

ON

4 1 2 3

ON

4

ELECTRIC LOCK

HAMMERING

1 2 3

ON

4 1 2 3

ON

4

1 2 3

ON

4 1 2 3

ON

4

PEAK ON START-UP

Peak on start-up activated: on start-up, the motors are powered at

maximum voltage for 2s.

RECOMMENDED ESPECIALLYIN THE WINTER PERIODS

Peak on start-up deactivated: on start-up, the motors are powered at

the voltage set with the potentiometer.

ATTENTION: in this case, there may be difficulties on

start-up if the force is regulated low

1 2 3

ON

4 1 2 3

ON

4

1 2 3

ON

4 1 2 3

ON

4

CLAMPS 11-12

FUNCTIONING MODE

Open gate indicator light output: flashing during gate movement, on

with gate open and off with gate closed

!

ATTENTION:

The micro switches must be regulated when the control unit is not powered. The regulations made

to the micro switches become active on switch-on.

We recommend, after having adjusted the micro switches, to program the work times (see control

unit programming).

!

MICRO SWITCHES

SETTING

SW 2SW 1

1 2 3

ON

4 1 2 3

ON

4

1 2 3

ON

4 1 2 3

ON

4

DO NOT USE

DO NOT USE

Leave in OFF

ENABLES/DISABLES

STEP-BY-STEP

FUNCTIONING

Step-by-step function disabled

During opening: the sending of a START control is ignored, the gate

continues to open

During closure: the sending of a START control blocks the gate for a

few seconds and then it re-opens

During the gate open pause: a START control annuls the pause time

and makes the gate close immediately

Step-by-step function enabled

During opening: sending a START control causes the movement to

stop, a successive one causes the gate to close

During closure: sending a START control causes the movement to

stop, a successive one causes the gate to open

During the gate open pause: a START control annuls the pause time

and makes the gate close immediately

Electric lock output: impulse control for electric lock whose

functioning depends on the position of SW1dip3

Leave in OFF

Page 6/12

CR/41/24 I E

DAL 1965

Page 7/12

PROGRAMMING THE CONTROL UNIT

The programming must be carried out point by point. In the case of errors during this phase, it is necessary to

proceed with new programming, which will delete the first.

Before programming, the system must be complete with all electrical devices and safety devices connected

(buttons, photocells, flashing lights etc.).

Check their correct functioning:

All signal LEDs of the NC inputs (stop, photocells, etc) are on.

All signal LEDs of the NO inputs (start, pedestrian) are off.

In the case of anomalies check and remove the cause.

ATTENTION: The normally closed (NC) inputs that are not used must be jumpered.

Regulate the "AMP", "RALL", "VELOC." potentiometers according to requirements.

With the control unit powered, press and hold down button P3 (PROGR) until the motors start the closure

action (about 10s). If the gate is already closed, the board makes this search anyway, forcing on the stops for a

few seconds. The DL6 LED starts to flash to indicate that the control unit is in the programming state.

After the gate is closed, the M1 motor wing is opened and after about 3 s, the wing connected to M2 is also

opened.

When the wings reach the stops, the motors shutdown automatically. In this way, the run is calculated and the

slowing points are defined (about 4s before the mechanical stops) which are the same in opening and closure

modes.

Successively, the gate automatically closes with phase difference between the wings of about 3 seconds and

performs slowing before stopping against the stops.

The control unit automatically leaves the programming phase, switching the DL6 LED off and is ready for

normal functioning

ATTENTION: - If any potentiometer is varied, the programming must be repeated.

The functioning time of the motors is controlled by two independent digital timers. If any control interrupts the run of

the wing before the end, the timer stops and the time passed is memorised. The appliance is therefore able to

establish the partial work time necessary to terminate the wing run, with a certain approximation, always slowing in

the programmed point.

ATTENTION: The lack of power supply to the circuit board (network or battery) causes the loss of the memorised

position. Successively to commissioning, a start control is for opening without activation of the

amperometric control, therefore the gate re-aligns on the opening stops.

AUTOMATIC PROGRAMMING FOR GATE WITH TWO WINGS (DIP1 SW1 OFF)

Automatically sets work times, slowing point and phase differences of the wing when opening and closing

Regulate the "AMP", "RALL", "VELOC." potentiometers according to requirements.

With the control unit powered, press and hold down button P3 (PROGR) until the motor starts the closure

action (about 10s). If the gate is already closed, the board makes this search anyway, forcing on the stop for a

few seconds. The DL6 LED starts to flash to indicate that the control unit is in the programming state.

After the gate is closed, the wing of motor M1 is opened and on arrival against the stop, the motor shuts down

automatically. The run is calculated and the slowing points are defined in this way (about 4s before the

mechanical stroke) which are the same in opening and closure modes.

Successively, the gate closes automatically, slowing before stopping against the stop.

The control unit automatically leaves the programming phase, switching the DL6 LED off and is ready for

normal functioning

AUTOMATIC PROGRAMMING FOR GATE WITH SINGLE WING (DIP1 SW1 ON)

Automatically sets work times and wing slowing point

CR/41/24 I E

CONTROLS MODIFICATION

It is possible to modify the functioning of the 1 and 2 inputs in this way:

- Input 2 functions as "START": with control unit off, press and hold keys P3 (PROGR) and P2 (WORK)

simultaneously and apply power supply.

- Input 2 functions as "CLOSE only": with control unit off, press and hold keys P3 (PROGR) and P1 (PAUSE)

simultaneously and apply power supply.

- Input 1 functions as "PEDESTRIAN": with control unit off, press and hold keys P2 (WORK) and P1 (PAUSE)

simultaneously and apply power supply.

- Input 1 functions as "OPEN only": with control unit off, press and hold keys P1 (Pause) and P2 (WORK) and P3

(PROGR) simultaneously and apply power supply.

Regulate the "AMP", "RALL", "VELOC." potentiometers according to requirements.

With the control unit powered and gate closed, press and release button P3 (PROGR), the DL6 LED starts to

flash to indicate that the control unit is found in the programming state.

Press and release key P2 (WORK), the wing connected to M1 starts to open.

When Motor M1 should start slowing (we recommend at least 50cm before the stop) press key P2 (WORK). The

motor M1 slows down.

ATTENTION: skip this point if slowing has been excluded ("RALL" potentiometer at maximum)

When the motor M1 reaches the opening stop, the motor shuts down automatically (motor shutdown control

intervention)

Press and release key P2 (WORK), the DL6 LED starts to flash quickly to indicate the start of the time difference

count when opening

When the desired phasing time has passed in opening (max 15s), press the P2(WORK) key and the motor M2

starts in opening mode and the DL6 LED starts to flash normally

ATTENTION: if you want a nil phase difference in opening, hold key P2 (WORK) down until M2 starts

When Motor M2 should start flowing (we recommend at least 50cm before the stop) press key P2 (WORK). The

motor M2 slows down.

ATTENTION: skip this point if slowing has been excluded ("RALL" potentiometer at maximum)

When the motor M2 reaches the opening stop, the motor shuts down automatically (motor shutdown control

intervention)

Press and release key P2 (WORK), the motor M2 starts to close

When Motor M2 should start flowing (we recommend at least 50cm before the stop) press key P2 (WORK). The

motor M2 slows down.

ATTENTION: skip this point if slowing has been excluded ("RALL" potentiometer at maximum)

When the motor M2 reaches the closing stop, the motor shuts down automatically (motor shutdown control

intervention)

Press and release key P2 (WORK), the DL6 LED starts to flash quickly to indicate the start of the time difference

count when closing

When the desired phasing time has passed in closing mode (max 15s), press the P2(WORK) key and the motor

M1 starts in closure mode and the DL6 LED starts to flash normally

ATTENTION: if you want a nil phase difference in closure, hold key P2 (WORK) down until M1 starts

When Motor M1 should start slowing (we recommend at least 50cm before the stop) press key P2 (WORK). The

motor M1 slows down.

ATTENTION: skip this point if slowing has been excluded ("RALL" potentiometer at maximum)

When the motor M1 reaches the closing stop, the motor shuts down automatically (motor shutdown control

intervention)

The control unit automatically leaves the programming phase, switching the DL6 LED off and is ready for normal

functioning

MANUAL PROGRAMMING FOR GATE WITH TWO WINGS (DIP1 SW1 OFF)

The installer sets work times, slowing point and phase difference time according to requirements

Regulate the "AMP", "RALL", "VELOC." potentiometers according to requirements.

With the control unit powered and gate closed, press and release button P3 (PROGR), the DL6 LED starts to

flash to indicate that the control unit is found in the programming state.

Press and release key P2 (WORK), the wing connected to M1 starts to open.

When Motor M1 should start slowing (we recommend at least 50cm before the stop) press key P2 (WORK). The

motor M1 slows down.

ATTENTION: skip this point if slowing has been excluded ("RALL" potentiometer at maximum)

When the motor M1 reaches the opening stop, the motor shuts down automatically (motor shutdown control

intervention)

Press and release key P2 (WORK), the motor M1 starts to close

When Motor M1 should start slowing (we recommend at least 50cm before the stop) press key P2 (WORK). The

motor M1 slows down.

ATTENTION: skip this point if slowing has been excluded ("RALL" potentiometer at maximum)

When the motor M1 reaches the closing stop, the motor shuts down automatically (motor shutdown control

intervention)

The control unit automatically leaves the programming phase, switching the DL6 LED off and is ready for normal

functioning

MANUAL PROGRAMMING FOR GATE WITH SINGLE WING (DIP1 SW1 ON)

The installer sets work times and slowing point according to requirements

DAL 1965

Page 8/12

CR/41/24 I E

MANUAL PROGRAMMING VIA REMOTE CONTROL

When a remote control has been programmed, it is possible to perform manual programming of the remote

control key replacing button P2 (WORK) of the control unit

To do this, follow the same procedures mentioned above, only instead of entering programming by pressing button

P3 (PROGR), press P3 (PROGR) + P2 (WORK) at the same time.

DAL 1965

Page 9/12

PROGRAMMING OPEN GATE PAUSE TIME (AUTOMATIC RE-CLOSURE)

With the control unit powered and gate closed, press key P3 (PROGR.) once. The LD6 LED starts to flash

indicating that the board has entered the programming phase.

Press key P1 once (PAUSE), the control unit starts the open gate pause count, highlighted with fast

flashing of the DL6 LED and of the flashing light.

When the desired time has passed, press key P1 (PAUSE) again, the control unit automatically memorises

the time passed between the two times the key P1 (PAUSE) was pressed and leaves programming, going

back to normal functioning.

If key P1 (PAUSE) is not pressed a second time, after 120s the control unit escapes from the programming

memorising the max time of 120s.

ACTIVATE AUTOMATIC RE-CLOSURE (maximum time that can be set 120s)

Press and hold key P1 (PAUSE) until LED DL6 switches off.

The control unit leaves the programming phase and sets itself for normal functioning.

Automatic re-closure is deactivated in this way.

DEACTIVATE AUTOMATIC RE-CLOSURE

With the control unit powered and the gate closes, press key P3 (PROGR.) once to enter programming.

LED DL6 starts to flash, indicating that the board has entered the programming phase.

BEHAVIOUR WHEN

STRIKING AN

OBSTACLE

FOLLOWING THE

INTERVENTION OF

THE AMPEROMETRIC

CONTROL

during closing at

normal speed

during opening/closing at

slowed speed

during opening at

normal speed

The gate blocks, i.e. the obstacle is interpreted as the

stop

AMPEROMETRIC SAFETY CONTROL

The control unit has a current absorption control able to intervene in the case of a blow with an obstacle during

movement at normal speed. The current level, above which the amperometric control intervenes, is set by

regulating the "AMP" potentiometer. The intervention of the amperometric control can be more or less rapid

depending on the sensitivity set with the SW3 jumper.

The gate inverts movement for about 5cm. It re-closes

(part M2 and after the phasing time in closure mode M1

starts) after the open gate pause time (if automatic re-

closure is activated) or after 30s (if automatic re-closure

is deactivated).

!

MOTOR SHUTDOWN CONTROL

The control unit has "shutdown motor" control able to intervene with the same consequences as the amperometeric

control, when the motor remains completely at a standstill for a couple of seconds.

It is a control that cannot be regulated or excluded - it also intervenes with amperometric control excluded - which is

used to identify the stops during slowing and any gate blocks during the normal run.

ATTENTION:

- Setting an amperometric level that is too low varies external factors - e.g. gusts of wind, the

increase of friction between day and night etc.- can be interpreted as a blow with an obstacle

with intervention of the amperometric control. For this reason it is possible to exclude the

amperometric control - with "AMP" potentiometer at maximum- even if the motor shutdown

control remains.

- If the amperometric control is excluded the safety of the blow is less -the gate continues to push

with maximum force- and therefore it is the responsibility of the installer to use all other

safety systems -for example, edges- according to that established by the Standards in

force.

CR/41/24 I E

The gate inverts movement for about 5cm and then re-

opens (first M1 and after the phase difference time in

opening M2 starts) up to the opening stops. It closes

again after the gate open pause time (if automatic re-

closure is active) or after 30 s (if automatic closure is

deactivated).

N.B. After 2 consecutive blows in closure, the gate

blocks and remains in stand-by for a closure

control

DAL 1965

LEARNING THE RADIO CONTROL CODE

The circuit board incorporates a dual-channel radio receiver at 433.92 MHz, which allows to control the gate at a

distance via micro switch remote controls from the OG/02, OG/04 range and self-learning remote controls from the

OG/62, OG/64, OG/28, OG/48, OG/52, OG/54, OG/82/1 and OG/84 range. Both of the channels are used exclusively to

control the gate. In particular channel 1 of the radio receiver acts from start, while channel 2 acts from the pedestrian.

DELETING CODES IN THE MEMORY

The deleting of all radio codes memorised is carried out by pressing and holding the P3 (PROGR.) and P1

(PAUSE) keys at the same time until the DL6 LED switches off (about 10s) without sending any radio code.

!ATTENTION: - before using a remote control, perform the programming procedure.

- the maximum number of codes that can be memorised is equal to 32 as start

control + 32 for pedestrian control (other combinations are not possible e.g. 40

start + 24 pedestrian etc.) . Below two examples of codes that can be memorised:

- example A: 32 self-learning remote controls OG/62, OG/64, OG/28, OG/48, OG/52,

OG/54, OG/82/1 and OG/84 as start control (e.g. left button) + 32 self-

learning remote controls OG/62, OG/64, OG/28, OG/48, OG/52, OG/54,

OG/82/1 and OG/84 as pedestrian control (e.g. right button)

- example B: 31 self-learning remote controls OG/62, OG/64, OG/28, OG/48, OG/52,

OG/54, OG/82/1 and OG/84 as start control (e.g. the left button) + 1 micro

switches remote control OG/02, OG/04 as start control (the others do

not have to be memorised OG/02 and OG/04 just set the micro switches in

the same sequence as that memorised) + 31 self-learning remote

controls OG/62, OG/64, OG/28, OG/48, OG/52, OG/54, OG/82/1 and

OG/84 as pedestrian control (e.g. the right button) + 1 micro switches

remote control OG/02, OG/04 as pedestrian control (the others do not

have to be memorised OG/02 and OG/04 just set the micro switches in the

same sequence as that memorised)

!

LEARNING START CODE

- With the control unit powered and the gate closes, press key P3 once (PROGR.) to enter programming. The DL6

LED starts to flash to indicate that the control unit is in the programming state.

- Press the remote control button (e.g. on the left), which wants to act as start control and hold it down until the DL6

LED switches off. The control unit has memorised the radio code received and automatically leaves programming,

setting itself for normal functioning.

- Repeat the procedure if several remote controls must be memorised.

LEARNING PEDESTRIAN CODE

- With the control unit powered and the gate closes, press key P3 twice (PROGR.) to enter programming. The DL6

LED starts to flash quickly to indicate that the control unit is in the programming state.

- Press the remote control button (e.g. on the right), which wants to act as pedestrian control and hold it down until

the DL6 LED switches off. The control unit has memorised the radio code received and automatically leaves

programming, setting itself for normal functioning.

- Repeat the procedure if several remote controls must be memorised.

12 34 56 78910

123 45 67 8 910

!

MODIFY THE FACTORY

CONFIGURATION TO PREVENT

UNDESIRED CONTROLS

CONFIGURATION OF MICRO SWITCHES ONLY IN THE CASE OF OG/02 AND OG/04 REMOTE CONTROLS

Only if OG/02 and OG/04 remote controls with micro switches are used, before performing learning of the codes on

the receiver, the factory configuration of the micro switches must be modified to prevent undesired controls

ATTENTION: before starting first programming or deleting the remote controls, temporarily

disconnect the antenna to prevent the receiver from acquiring other signals during this phase,

which may cause incorrect functioning of the automation. Re-connect the antenna when the

procedure has ended.

Page 10/12

CR/41/24 I E

TECHNICAL DATA OF THE CR/41/24 CONTROL UNIT

EXPANSION OF THE MINITRANSMITTER NUMBER

If the 32 remote controls that can be memorised in the built-in receiver are not sufficient, it is possible to increase them

by inserting the SOG/4A receiver (that takes the number of remote controls to 40) eventually with the addition of the

SOG/2A expansion (that takes the number of remote controls to 794).

After having inserted the SOG/4A receiver, all codes memorised in the built-in receiver must be deleted and all

of the remote controls must be re-programmed on the new SOG/4A receiver, see specific instructions. The

antenna must be moved from the clamp on the control unit - 33/34 - to the clamp found on the SOG/4A.

2ND CHANNEL

OUTPUT

CONTROL

AUXILIARY

ANTENNA

NC

C

NA

Channel 2 output (relay contact)

Max voltage applicable= 24Vac/dc

Max current applicable= 1A

Install additional relay relevantly

dimensioned for the specific case.

ELECTRIC LOCK

LIGHTS

OTHER AUTOMATIONS

OTHER

INSERT THE

SOG/4A

RECEIVER

1ST CHANNEL OUTPUT

START COMMAND

OF THE CONTROL UNIT

PEDESTRIAN CONTROL

ON CR/41/24 -CLAMPS 1-3-

DISCONNECT THE POWER

SUPPLY BEFORE INTERVENING

ON THE CONNECTIONS

1 2 3 4 5 6 7 8 9 10 11 12 13 14 1516 17 18 19 20 21 22 23 24

28 27

34 33 P3

P2

P1

-+

-+

-+

VELOC.

RALL

AMP

ON

1 2 43

SW1 ON

1 2 43

SW2

25 26

F2F2

F3F3

F1F1

F4F4

SW3

LED

DL6

DL1

PED

DL2

START

DL3

STOP

DL4

FOTO

DL5

FOTO AP

DL7

COSTA

PAUSA LAVORO PROGR.

BATTERY

+-

Power supply transformer: 230/20 Vac, 130VA

Internal battery charger capacity 28Vdc, 0.5A

Optional battery capacity: 2x12Vdc 2Ah

Motors power supply: 24Vdc 4A

Accessories power supply: 24Vdc 500mA

Flashing light power supply: 24Vdc, max 25W

Electric lock power supply: 24Vdc

Pause time adjustment: from 1 to 120s

Regulation delay in opening/closure: from 0 to 15s

Amperometric control regulation: "AMP" potentiometer

Slowing speed regulation: "RALL" potentiometer

Normal speed regulation: "VELOC" potentiometer

Operating temperature: -20°C ÷ +60°C

Dimensions (H x L x D) and weight: 270x212x118mm, 2.5Kg

DAL 1965

Page 11/12

CR/41/24 I E

BATTERY FUNCTIONING

If there is a power cut, the system continues to function with the batteries, if they are connected. In this case, to

save energy, the only differences are:

- flashing is very slow

- the photocells output -clamps 9-10- is removed with gate at standstill, therefore they reactivated on the open control

- the start control is taken while the batteries are charged. When the battery is not charge the control unit remains

powered until the batteries are flat but do not take the start control.

When the mains voltage returns, the built-in battery charger charges and maintains the batteries in this state.

Twenty-four hours are required for complete re-charging.

TROUBLESHOOTING

PROBLEM CAUSE SOLUTION

The motor reducer

does not work

No voltage to

the motors

Check the presence of voltage at the input clamps

power supply to the motor

Check that the power supply cable is not interrupted.

(the power supply cable must be replaced

by an authorised technician)

Check the fuses on the control unit

Incorrect regulation

of the slowing point

Repeat the programming of work times, paying attention to set

slowing at no less than 50÷70cm from the stop.

No voltage to the

control unit

Check the network fuse and the presence of network voltage

Check the network voltage -if present-

Meeting the stops

makes movement

reverse

Slowing speed set with

"SLOW" potentiometer

too low

INCREASE THE "RALL" POTENTIOMETER: the "RALL"

potentiometer, as well as the speed also decreases the power to

the motor. For this reason a regulation that is too low can cause

the gate to stop before reaching the mechanical stops. This stop

also depends on the external environmental features, which vary

greatly between summer and winter and between the first hours

of the day with respect to the central hours. For this reason the

gate may stop occasionally.

Repeat work times programming by setting a quicker speed with

the "RALL” potentiometer.

The gate

occasionally does

not complete the

entire slowing

period, but blocks

before

Intervention of the

amperometeric

control

During movement

and normal speed

the gate inverts

movement

The motor moves

with difficulty

Insufficient motors

power supply

THE POWER SUPPLY CABLES TO THE MOTORS MUST

HAVE ADEQUATE SECTION: we recommend cables measuring

2

2.5mm for 24vdc motors. cables with smaller section cause

large voltage drops that make the motor speed force decrease,

especially on the motor furthest away from the control unit

INCREASE THE "AMP" POTENTIOMETER: the "AMP"

potentiometer regulates the amperometeric control intervention,

which intervenes every time that the gate stops moving for a brief

period of time due to external factors-such as gusts of wind for

example-. Therefore, in the case of particularly windy areas, it is

recommended to exclude the amperometric control by taking the

potentiometer to MAX

INCREASE THE "VELOC" POTENTIOMETER: the "VELOC"

potentiometer regulates the speed of the motors, decreasing the

voltage. check the correct functioning by taking the

potentiometer to MAX

CR/41/24 I E 03 12 110321 A4Vf/r -IS CR41-24-E

Intervention of the

amperometric control

INCREASE THE "AMP" POTENTIOMETER: the "AMP"

potentiometer regulates the amperometeric control intervention,

which intervenes every time that the gate stops moving for a brief

period of time due to external factors-such as gusts of wind for

example-. therefore, in the case of particularly windy areas, it is

recommended to exclude the amperometric control by taking the

potentiometer to MAX

ELETTRONICA PADOVA

I

SINCE 1965

MADE IN ITALY

VIA ENRICO FERMI, 22

35020 LEGNARO - PADOVA

I T A L I A

PHONE +39 049 79 08 58

FAX +39 049 88 30 529

E-MAIL [email protected]

WEB www.serai.com

TERMS OF GUARANTEE

The company reserves the right to make modifications to the equipment without prior notice thereof. SERAI products are covered by a standard guarantee with a term of 24 months.

Coverage starts on the date on which the tax document constituting proof of purchase is issued and guarantee services shall be provided on the company's premises at Legnaro - PD -

or at the Authorised Service Centres. Carriage costs shall be borne by the Customer.

CE CONFORMITY DECLARATION

SERAI spa declares that the product CR/41/24 has been desifned and manufactured according to the above mentioned directives and standards

WEEE DIRECTIVE 2002/96/EC

This appliance was manufactured after 13/08/2005. To protect the environment: when the equipment is no longer needed, take it to a special WEEE (Waste Electric and

Electronic Equipment) collection centre. Do not dispose of it with normal household waste.

Table of contents

Popular Control Unit manuals by other brands

ETC

ETC SmartModule 2 installation guide

National Instruments

National Instruments PXIe-6591R user manual

PEHA

PEHA PHC 940 JRM diag Installation and operating instructions

Keysight

Keysight M8192A user guide

Nice

Nice MC424L Instructions and warnings for installation and use

Agilent Technologies

Agilent Technologies G1323B user guide

Pickering

Pickering 40-574 user manual

American Standard

American Standard SELECTRONIC 6067.111 installation instructions

iseg

iseg NHS Series Technical documentation

Rockwell Automation

Rockwell Automation AB quality Allen-Bradley 1746-INT4 user manual

National Instruments

National Instruments 6587 Getting started guide

GatesAir

GatesAir PT-353 Installation and operation manual