ServiceMASTER Clean Souls-500 User manual

Owner’s Manual: 19610

Title: Solus-500

Serial number:__________________

The ServiceMaster Company

860 Ridge Lake Blvd.

Memphis, TN 38120

800-756-5656 (Tech Support)

Date: June 2011

Revision: F

ServiceMaster® Manual

Copyright 2004 by

ServiceMaster Clean

All rights reserved

56041971

2- FORM NO. 56041971 - SOLUS 500 S

DO NOT OPERATE MACHINE UNTIL YOU HAVE READ

ALL SECTIONS OF THESE INSTRUCTIONS

IMPROPER USE OF THE MACHINE WILL VOID THE WARRANTY

1. Always use a defoamer when foaming occurs to prevent vacuum motor damage.

2. Keep machine from rain and snow, extremes in temperatures, and store in a heated location.

DO NOT let the machine or the wand freeze. Do not use outdoors.

3. Do not let the pump run dry.

4. Use approved chemicals only. NO SOLVENTS.

5. Wear gloves or use rags when removing quick disconnects to prevent burns.

6. Never use water above 130 ºF/54 ºC in the solution tank.

FORM NO. 56041971 - SOLUS 500 S - 3

IMPORTANT SAFETY INSTRUCTIONS

This machine is only suitable for commercial use, for example in hotels, schools, hospitals, factories, shops and offices other

than normal residential housekeeping purposes.

When using any electrical appliance, basic precautions should always be followed, including the following:

NOTE: Read all instructions before using this machine.

WARNING!

To reduce the risk of fire, electric shock, or injury:

•Do not leave the machine unattended when it is plugged in. Unplug the unit from the outlet when not in use and before

servicing.

•To avoid electric shock, do not expose to rain or snow. Store and use, indoors.

•Do not allow to be used as a toy. Close attention is necessary when used near children.

•Use only as described in this manual. Use only the manufacturer’s recommended attachments.

•Never add water over 130 ºF/54 ºC to the solution tank.

•Do not use with damaged cord or plug. If the machine is not working as it should, has been dropped, damaged, left

outdoors or dropped into water, return it to a service center.

•Do not pull by the cord, use the cord as a handle, close a door on the cord, or pull the cord around sharp edges or corners.

Do not run the machine over the cord. Keep the cord away from heated surfaces. To unplug, grasp the plug, not the

cord.

•Do not handle the plug, the cord or the machine with wet hands.

•Extension cords must be 12/3 and no longer than 50 feet. Replace the cord or unplug immediately if the ground prong

becomes damaged.

•Do not put any object into openings. Do not use with any opening blocked; keep free of dust, lint, hair, and anything that

may reduce air flow.

•Keep loose clothing, hair, fingers, and all parts of body away from openings and moving parts.

•Do not pick up anything that is burning or smoking, such as cigarettes, matches, or hot ashes, or any health endangering

dusts. Do not use to pick up flammable or combustible liquids such as gasoline or use in areas where they may be

present.

•Turn off all controls before unplugging.

•Use extra care when cleaning on stairs.

•Connect to a properly grounded outlet only.

•Liquid ejected at the spray nozzle could be dangerous as a result of its temperature, pressure, or chemical content.

4- FORM NO. 56041971 - SOLUS 500 S

INSPECTION:

Carefully unpack and inspect your SOLUS-500 for shipping damage. Each machine is tested and inspected before shipping.

Any shipping damage incurred is the responsibility of the carrier. You should notify the carrier immediately if you notice dam-

age to the box or to the machine or parts.

CLEANING SOLUTIONS:

We recommend liquid cleaning chemicals. Powder chemicals may be used, but unless mixed very thoroughly they could

cause a build-up in the pump, lines, heat exchanger and/or quick disconnects. Any problem caused by a chemical build-up is

not covered by warranty. Use a neutral cleaner with a pH between 5 and 10 to avoid premature wear of the pump, seals, and/

or other components. Damage caused by the use of strong chemicals is not covered by the warranty.

MAINTENANCE:

For optimum performance flush the machine with clear water at the end of each working day. Once a month, minimum, run

a flushing compound through the machine to break up any mineral or chemical build-up that may have formed. The vacuum

motor, pump motor, and the pump do not require any scheduled maintenance; however, the motors may require replacement

brushes after 1000 - 1500 hours, and the pump and bypass valve may require rebuild kits after 1000 - 1500 hours, typically

(refer to machine part list for numbers). Clean the body with an all-purpose detergent, and protect it with an automobile inte-

rior polish. Lubricate the wheels, castors, and quick disconnects with an all purpose silicone spray.

PARTS AND SERVICE:

Repairs, when required, should be performed by your authorized distributor who maintains an inventory of original replace-

ment parts and accessories. Call the distributor from whom you purchased this machine if you need parts and service. Be

sure to specify the machine model. Have your serial number handy.

SERIAL NUMBER: __________________

MODEL: SOLUS-500-S

PURCHASE DATE: __________________

NAME AND PHONE NUMBER OF YOUR DISTRIBUTOR:

____________________________________________

____________________________________________

(Be sure to register your purchase to activate your warranty)

MODIFICATIONS

Modifications and additions to the cleaning machine which affect capacity and safe operation shall not be performed by the

customer or user without prior written approval from the manufacturer. Unapproved modifications will void the machine warranty

and make the customer liable for any resulting accidents.

FORM NO. 56041971 - SOLUS 500 S - 5

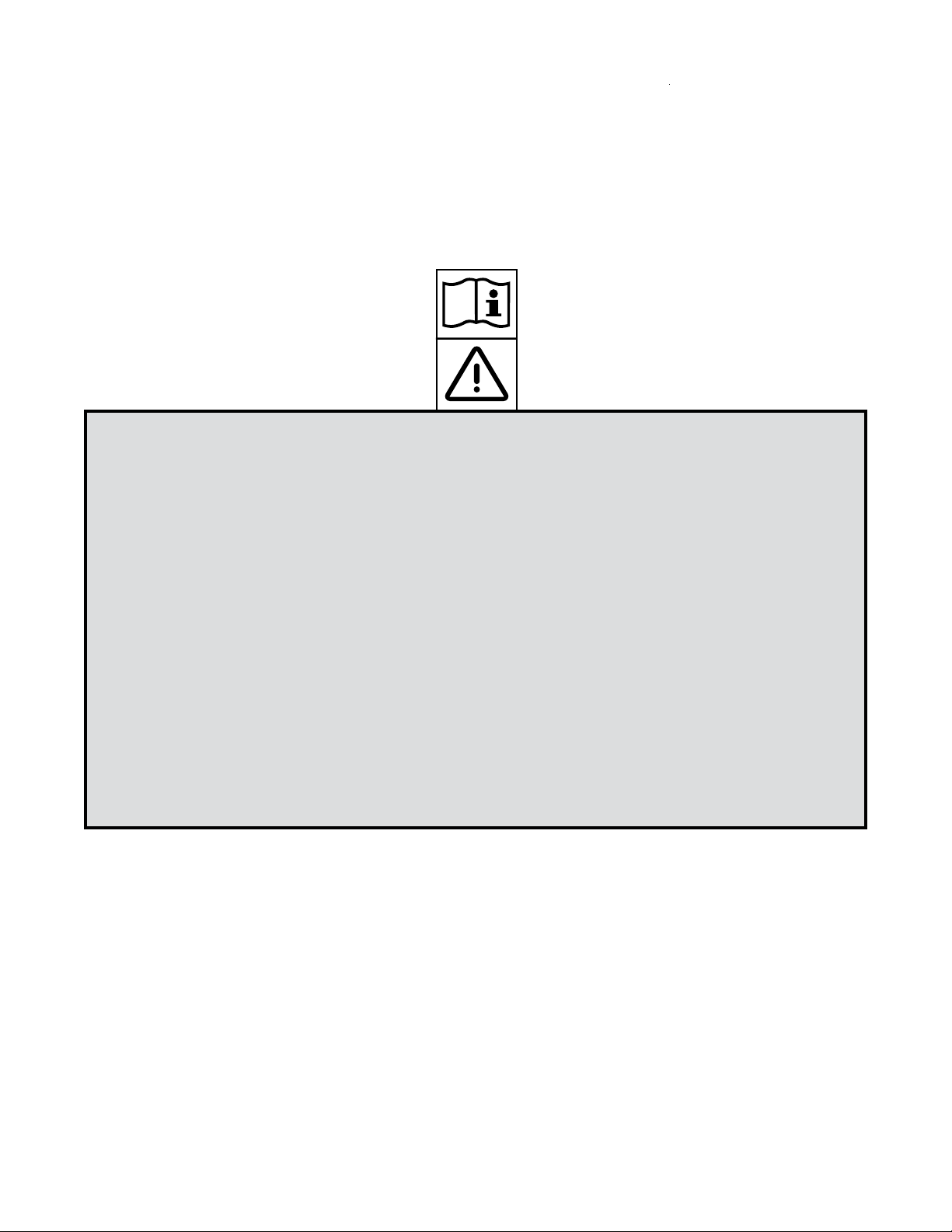

DRAIN

HOSE

HANDLES

VACUUM HOSE

BARB

FAN

POWER CORD

RECEPTICLES

VACUUM

LID

LATCH SOLUTION HOSE

QUICK COUPLING

SWITCH

PLATE

CASTOR

SOLUTION TANK

FILL HOLE

PSI

GAUGE

12” WHEEL

KNOW YOUR MACHINE

VACUUM LID - This lid provides access into your recovery tank so that you can clean the tank. The lid must be closed

before you try to clean.

SOLUTION TANK FILL HOLE - This is where you fill the tank with water and cleaning solution.

VACUUM HOSE BARB - This is where you connect your vacuum hose to the machine. A tight connection is necessary

to prevent a vacuum leak which would reduce the amount of suction.

DRAIN HOSE - This is how you empty the dirty water from your recovery tank. Place the hose over a drain, and open

the cap. When cleaning out the tank at the end of a job, simply place this hose into a drain and use clean water to

rinse out the dirt and debris from the tank. NOTE: be sure to close the cap tightly before using the machine again.

HANDLES - The handles are used to move the machine. These handles allow you to tilt the machine back onto its

12” wheels for easy maneuvering, and/or for moving on stairways.

SWITCH PLATE - The switches are located on the rear of the machine, out of the way of water.

FAN - Removes warm air from the component compartment.

PSI GAUGE - indicates the pump pressure. Look at the pressure while you spray.

LATCH - The latch holds together the tank and the base compartment.

SOLUTION HOSE QUICK COUPLING- This is where you connect the solution line that runs from the machine to the

carpet wand or hand tool.

POWER CORD RECEPTACLES - The receptacles are where the two power cords connect to the machine.

CASTOR - Swivel castor provides easy maneuverability.

WHEEL - The rear wheels are 12 inches in diameter to provide superior ease of transportation and stair climbing.

Table of contents