Sesamo MILLENNIUM ADVANCED SELECTOR User manual

INSTALLATION MANUAL

MILLENNIUM

ADVANCED

SELECTOR

1

We would like to thank you for choosing this prod-

uct. In order to obtain the best performance from

the automatism, the Sesamo Company recom-

mends that you carefully read and follow the

installation and use instructions provided in this

manual. The installation of this automatism must

be performed only by professionally qualified per-

sonnel to whom this manual is directed. Any

errors in the installation phase may be dangerous

for persons or objects. The packaging material

(wood, plastic, boxes, etc.) should not be dis-

posed of in the environment or left within the

reach of children, as it is potentially dangerous.

Each individual phase of the installation must be

performed in conformity with the current regula-

tions and, in any case, according to the dictates of

general good practices. Ensure, before beginning

the installation, that the product is integral and

has not been damaged during transport or from

improper storage. The product absolutely must

not be installed in environments with inflammable

gases, vapors or fumes. Record on each installa-

tion the identification data of the motorized door.

Verify that the electrical system upstream is cor-

rectly dimensioned and has all the suitable pro-

tections (differential switch and overload protec-

tion). When performing maintenance or repair,

use only the original spare parts. Do not tamper

with or alter for any reason the internal equipment

of the device and all the safeties provided in the

control unit.The manufacturer accepts no respon-

sibility in the event that the internal parts of the

automatism are altered or tampered with or if

safety devices are used in the system other than

those indicated by the manufacturer.The installer

of the automatism is obligated to provide the man-

ager of the automated entrance with the use man-

ual and all the information necessary for the cor-

rect use in automatic operation, manual operation

(also in the case of electric locking) and in emer-

gencies.

This device has been exclusively designed for the

control of automatisms for sliding doors of the

Millennium series produced by SESAMO. Any

other use will be considered contrary to the use

provided for by the manufacturer that, therefore,

cannot be held responsible.

Machines directive

According to directive 98/37/EC, the installer that

motorizes a door becomes the builder of the

automatic door machine and must:

•Prepare the Technical File with the documents

indicated in Annex V of the Machines Directive

and conserve it for at least 10 years.

•Write up the EC declaration of conformity

according to Annex II-A of the Machines

Directive and deliver a copy to the user.

•Affix the EC mark on the motorized door

according to point 1.7.3 of Annex I of the

Machines Directive.

Directive of conformity for machines

(Directive 98/37 EC, Annex II, part B)

Manufacturer: SESAMO S.r.l.

Address: Str. Gabannone 8/10 - 15030

Terruggia - AL

Declares that the product MILLENNIUM

ADVANCED LOGICS SELECTOR

•has been built to be incorporated in a machine

or to be assembled together with other

machinery in order to construct a machine

considered by the Directive 98/37 EC, as mod-

ified;

•thus it does not satisfy all points of the dispo-

sitions of this Directive as it is not yet assem-

bled with the other components.

•satisfies the conditions of the following other

EC Directives:

•89/336/EEC Electromagnetic Compatibility

and subsequent amendments

•73/23/EEC Low Voltage and subsequent

amendments

•and also declares that the machinery is not

allowed to be put into service until the machine

in which it will be incorporated or of which it will

become a component has been identified and

has been declared to satisfy the conditions of

the Directive 98/37 EC and the corresponding

national legislation.

Terruggia, 20/06/2003 Aldo Amerio

(Director)

2

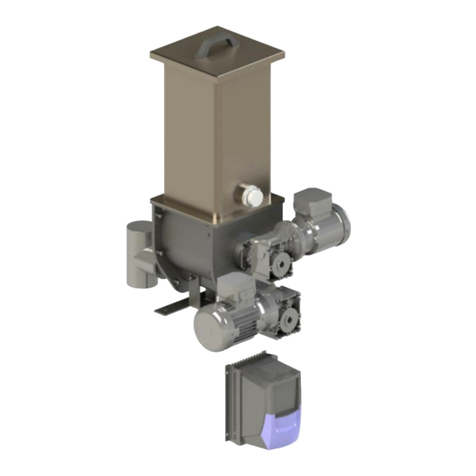

Fastening and arrangement of the casing

The Millennium Advanced Logics Selector has been designed to be connected with SESAMO

automatisms of the Millennium series. It is usually fastened to a suitable support near the automatic

entrance.

To perform the fastening to a wall proceed as follows:

•Dismount the selector by unscrewing the screws D Fig.2 that block the cover to the metal support.

•Insert the cable of connection with the automatism into the hole B Fig.1.

•Use the loops A Fig.1 to fasten the selector with appropriate screws, being careful that the con-

nection terminal box is turned downwards.

•Position the cover by centering it on the appropriate supports C Fig.2 so that the led indicators

are housed correctly in the appropriate seats. Pay particular attention to not damage the led indi-

cators during the insertion.

•Insert the screws D Fig.2 through the slots of the cover E Fig.2 and then screw them into the

threaded holes C Fig.2 until they graze the cover.

•Apply light pressure to the cover in the direction of the arrows of Fig.2 in order to guarantee a

complete resting of the cover on the four spacers provided and simultaneously block the screws D

Fig.2.

•Verify the correct operation of all the keys of the full selector: if problems appear, loosen the

screws D Fig.2 and repeat the sequence for the mounting of the cover.

3

Description

Electric Connections

One advanced selector can be connected simultaneously to several electronic cards up to a maximum of 15.When the

Multi Slave mode is active, every single door connected can be controlled individually. Several selectors can also be con-

nected to a single door (there is no limit to their number).

CAUTION

Before performing the electric connections

insert the battery buffer as indicated in the

figure.

For the connection, use a screened cable

with 4 wires of 0.22 mm (max. 50 m):

connect the 4 internal conductors of the

screened cable respecting the corre-

spondences indicated by the screen

print located both on the terminal box

of the electronic main as well as on

that of the multilogic selector.

Do not connect the screen of the

cable used.

Reset key

Selection button for

operation logics Active operation logic

led indicators

Functions menu

EXECUTE Key

LCD Display

Functions menu

SCROLL UP Key

Functions menu

SCROLL DOWN Key

Battery buffer insertion:

+ pole turned upwards

Advanced selector

connector

SCROLL DOWN Key:permits the user

to scroll downward in the

functions menu.

SCROLL UP Key:permits the user to

scroll upward in the functions

menu.

EXECUTE Key:permits the user to con-

serve the selection chosen.

RESET Key:permits the user to cause

the Reset of the control cen-

ter and the advanced selec-

tor.

SELECT Key:permits the user to select

the wished operating logic

4

Use of the advanced selector

With the advanced selector it is possible to select the following operation logics of the

automatism:

•Stop Close:the automatism controls the complete closure of the door wings. In

this logic the inputs START1 and START2 of the electronic control card are not

monitored; if present, the electric locking system blocks the door wings.

•Stop Open:the automatism controls the complete opening of the door wings. In

this logic the inputs START1 and START2 of the electronic control card are not

monitored.

•Entry-exit radar:both the inputs START1 and START2 of the electronic control card are monitored. A signal originat-

ing from a sensor connected to one of these inputs triggers the opening and consequent closing of the door wings.The

electric locking system, if present, never blocks the door wings.

•Exit-only radar:only the input START1 of the electronic control card is monitored. A signal originating from a sensor

connected to this input triggers the opening and consequent closing of the door wings.The electric locking system, if

present, blocks the door wings every time that these reach the position of complete closure.

•Partial opening with entry-exit radar:like the “Entry-exit radar” logic with the difference that in this case the

opening space of the door wings is reduced with respect to the total by a quantity equal to percentage value set in the

“Partial Opening” parameter. (See “Parameter Adjustment” menu.)

•Partial opening with exit-only radar:like the “Exit-only radar” logic with the difference that in this case the open-

ing space of the door wings is reduced with respect to the total by a quantity equal to percentage value set in the “Partial

Opening” parameter. (See “Parameter Adjustment” menu.)

The led indicators indicate the logic currently active (led lit up).To change the logic press the SELECT key; each time the key

is pressed the led corresponding to the various logics lights up in sequence.When the desired logic is reached, the led

blinks for a few seconds; when the light remains on, the control card acquires the new logic.

When the Multi Slave mode is active, and the operating logic must be changed, the user is asked on which door the change

must be performed; a particular door can be chosen (select the door’s corresponding number), or the change can affect all

doors (choose the option “All”).

Functions menu

By means of the LCD display and the navigation keys it is possible for the user to move within the functions menu.

EXIT-ONLY RADAR

ENTRY-EXIT RADAR

PARTIAL EXIT-ONLY RADAR

PARTIAL ENTRY-EXIT RADAR

STOP OPEN

STOP CLOSE

5

The menus are structured in a hierarchical manner, and thus each menu may contain submenus; each time the user exits

from a submenu he enters the immediately previous menu in the hierarchical scheme.

Arrows of this type indicate that it is possible to scroll through the menu

both with the SCROLL UP key and with the SCROLL DOWN key.

This means pressing the OK key.

Arrows of this type indicate that by pressing the OK key the user moves

into a menu of a different hierarchical level.

Main Menu

Management Menu (1)

There are two different kind of password: the one for the final user, and the universal password normally used by the

installer.The first by default corresponds to 0000 and can be changed through the Setting Menu; menus shown in gray in

the charts are neither visible nor accessible with this password. The second password is 5392 and cannot be altered; with

this password all menus are accessible.

To enter into the management menu it is necessary to input the user password:

to input, for example, the password 5724 proceed as indicated in the figure:

To select the desired number use the SCROLL UP and SCROLL DOWN keys.

In Multi Slave mode, whenever the Management Menu is accessed, the user is asked to specify on which door he wants to

operate, among those connected to the selector.

Key

Key

OK

Installer Password (universal) = 5392

Default Password (user) = 0000

6

(Management Menu continued)

Language Choice Menu (1.1)

Permits the user to select the language used in the functions menu.

Indicates the value

currently set

7

Parameter Adjustment Menu (1.2)

Permits the user to adjust some operational parameters:

•Opening Speed. Setting range 10 ÷ 70 cm/sec. Default value 70 cm/sec.

•Closing Speed. Setting range 10 ÷ 50 cm/sec. Default value 50 cm/sec.

•Idle Time. Represents the idle time after an opening manoeuvre before starting the closure. Setting range 0 – 120

sec. Default value 0 sec.

•Partial Opening. Represents a percentage of opening achieved by the door wings when a partial opening logic has

been selected.The value represents a percentage of the total opening. Setting range 10 – 90%. Default value 50%.

•Anti-crushing. Represents the anti-crushing sensibility .The values may be set separately for the opening (ANTI-

CRUSH OP) and the closing (ANTI-CRUSH CL). Setting range 1 – 10.The lower values of this parameter correspond

to higher sensibilities and thus less force is transmitted in the case of collision with an obstacle. Default values: opening

9, closing 5.

The submenus for the settings are:

* Indicates the name of the parameter that is being adjusted.

** Indicates the value to be set.

When the desired value has been

reached press the OK key to set

the new value.

Indicates the

value

currently set

The SET DEFAULT

menu allows the

reset of all

parameters to the

original factory

values.

Set-up Menu (1.3)

Battery Menu (1.3.1)

When the control centre is battery powered and the power level is too low, it is necessary to stop the operation of the

automatism; with this menu it is possible to choose if the Stop position is a complete closure or a complete opening.

Password Menu (1.3.2)

Permits the user to modify the User Password. For the input logic see the Management Menu.

8

Indicates the

value

currently set

The SET DEFAULT

menu allows the

reset of all

parameters to the

original factory

values.

9

Interblock Menu (1.3.3)

Permits the user to

configure the automatism in

MASTER or SLAVE mode in

the interblocked operation.

The submenu SIGNAL

MEMORY permits the user

to use the special interblock

version. (Soon to be

activated.)

Multi Slave Menu (1.3.4)

S5 S6 S7 S8

Porta1 1000

Porta2 0100

Porta3 1100

Porta4 0010

Porta5 1010

Porta6 0110

Porta7 1110

Porta8 0001

Porta9 1001

Porta10 0101

Porta11 1101

Porta12 0011

Porta13 1011

Porta14 0111

Porta15 1111

This menu per-

mits to activate

the multi slave

mode, so that a

number of differ-

ent doors (up to

a maximum of

15) can be con-

trolled by a single

selector.

Once the multi

slave mode is

activated, it must

be decided which

ones and how

many doors are

connected to the

selector.This can

be done setting

the Dip Switch

located on the

Millennium elec-

tronic card,

according with

the table on this page..

Don’t forget to correctly adjust each

card as shown in the table and to use a dif-

ferent address for each card; otherwise multi

slave mode will not work properly.

Indicates the

value

currently set

DIPSWITCH ON/OFF

10

Clock and Date Menu (1.3.5)

Permits the user to change the time and date settings.

Assistance Menu (1.3.6)

The advanced selector features the “assistance” function, which warns the user when it’s time to perform a scheduled

maintenance routine on the automatism.The LCD display shows a request for maintenance once a certain (programmable)

time is elapsed. In such cases the system’s continues operating normally: hitting any key will erase the display, but the

request will reappear two days later.The request will disappear definitively only once the maintenance routine has been

performed and the assistance function has been reset via the “Zero Maintenance” menu.The presence of this function

together with the amount of time between two maintenance sessions can be set only by means of the MillenniumWare PC

connection software (ask Sesamo for further details).

To access the service menu it is necessary to input the Installer Password.

11

•Service Data Menu. Permits the user to input the name and telephone number of the service center: to input the

name or the telephone number use the SCROLL DOWN and SCROLL UP keys to position on the desired letter/num-

ber; confirm the choice with the OK key. Repeat the operation until the last letter/number and in any case until the cur-

sor reaches the last position (16 characters).

•Zero Maintenance Menu. Zeroes all the diagnostics data in the memory of the control card (date of last mainte-

nance, number of breakdowns, last error, number of battery interventions, history of the errors, etc.). This operation

must be executed every time that an assistance intervention is performed on the automatism.

•View Last Maintenance Menu. Permits the user to view the date on which the last maintenance was performed.

AutoReset Menu (1.3.7)

In the case of system breakdown, to restore normal operation it is necessary to perform a Reset manoeuvre. The reset

may be performed with the multilogic selectors or in an automatic manner if the autoReset is active.

By means of this menu it is possible to activate/deactivate the autoReset

12

I/O Menu (1.3.8)

•AUX OUTPUT Signal. Output auxiliary, transistor type PNP for the indication of particular states of the door (reset,

opening, closure, etc.).

•By means of the AUX OUT Type Menu it is possible to configure the logic state, and thus the electronic state, of the

AUX OUT output; see the following table for the logic state/electronic state relationship:

The I/O Menu permits the user to configure the inputs

and outputs of the control center; in particular, it is

possible to define the electric state of each input:

Normally Open or Normally Closed independently of

the Default condition. For example, the Photocell input

is set Normally Closed as Default.With this menu it is

possible to change this setting by configuring the

Photocell signal as Normally Open.

AUX OUT Normally Closed Transistor closed, voltage between AUX OUT and GND = 12 Vdc

AUX OUT Normally Open Transistor open, voltage between AUX OUT and GND = 0 Vdc

Indicates the

value

currently set

Indicates the

value

currently set

13

NOTE: the maximum output current is 100 mA. If this output is used to drive a relay, pay attention to the current absorbed

and add a protection diode in parallel with the relay coil as shown in the figure:

The Signal Menu permits the user to select when the output signal is active; the possible options are:

•When the door is completely closed

•When the door is completely open

•When there is a breakdown of the door

•When the door is in Reset phase

•Interblock operation

Contrast Menu (1.3.9)

Permits the user to regulate the contrast of the Display.

Calendar Menu (1.4)

This menu permits the user to set changes of the operation logic (events) in automatic mode at a fixed hour and day of the

week (up to a maximum of 4 events daily).

It is possible, for example, to set that at 8:30 in the morning a door that is in Stop Close logic shifts automatically into Two

Radar logic (event 1). At 12:30 it shifts into Stop Close logic (event 2). At 14:00 it returns to Two Radar logic (event 3).

Finally, at 19:00 it shifts again into Stop Closed logic.

The example given above could be a classic application of a door mounted at the entrance of a shop or an office that is not

manned during the lunch break.

Select the day of the week for

which the event is to be set

Relay coil

Protection diode

14

Select the event to be set;

the second line indicates if the event

has already been set (ACTIVATED) or not (DEACTIVATED).

A maximum of four events may be set.

For each event it is possible to set:

•STATE: indicates if the event is activat-

ed or not

•HOUR: indicates the hour of the event

beginning

•MINUTES: indicates the minutes of the

event beginning

•EVENT TYPE: it is possible to choose

the event type: Stop Close, Stop Open,

One Radar, Two Radar, Partial One

Radar, Partial Two Radar.

Keyboard Lock Menu (1.5)

Permits the user to lock the keyboard; by selectingYES

from the menu the keyboard becomes locked and on

the display there appears the phrase “SELECTOR:

UNLOCK KEYBOARD?”

In this situation it is not possible to change the

operation logic and move inside the selector menu.

To unlock the keyboard press the OK key and insert the

User Password.

Diagnostics Menu (2)

The Diagnostics menu is for reading only and permits the user

to have some information concerning the state of the control

centre:

For each event it is possible to set:

•LOGIC SW VERS.: indicates the software version

currently loaded in the microprocessor of the control centre.

•SELECT SW VERS.: indicates the software version

currently loaded in the microprocessor of the advanced

selector.

•HW VERSION: indicates the hardware version of the

control card.

•NUMBER MANOEUVRES: indicates the total number of

manoeuvres performed by the door from the moment in

which the centre left SESAMO. This value cannot be

zeroed. Manoeuvre is understood as a complete cycle of

opening and closing: a possible inversion increases the

number of manoeuvres.

•BATTERY INTERV.: indicates the number of times in

which the centre has been battery driven and thus the

number of blackouts of the external power source.This

value is zeroed each time that the maintenance is zeroed

(See Service Menu).

•TOTAL BREAKDOWNS: indicates the total number of

breakdowns.This value is zeroed each time that the

maintenance is zeroed (See Service Menu).Through the

connection with the PC it is possible to have the description

of the last thirty breakdowns that have occurred.

•LAST BREAKDOWN: indicates the code of the last

breakdown occurring on the system.This value is zeroed

each time that the maintenance is zeroed (See Service

Menu).

•REGISTRATION N.: indicates the registration number of

the control centre.

When Multi Slave mode is active, the operator - accessing the

setting menu - is asked to specify to which door, among those

connected to the selector, the successive commands will apply.

SESAMO srl Str. Gabannone, 8/10 • 15030 Terruggia (AL) • Italy

Tel: +39 0142 403223 • Fax: +39 0142 403256 • www.sesamo.org • E-mail: [email protected]

MAN SAM - E 06-04

Table of contents