SET 1501 T User manual

SET 1501 T / 2501 T / 3501 T

SERVICE MANUAL

en Rev. 1.0 • 2021-W12-3

3

Introduction: Table of contents

Introduction

Table of contents

Introduction .....................................................................3

Table of contents......................................................................3

Overview .............................................................................4

Declaration of Conformity .............................................................5

Product description ..............................................................6

Overall description ....................................................................6

Enclosure dimensions .................................................................9

Technical data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Installation environment .............................................................11

Wall mounting .......................................................................12

Floor mounting ......................................................................14

Electrical connection .................................................................15

Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Control panel ........................................................................18

Maintenance and care .......................................................... 20

Preventative maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Software update and log les.........................................................21

Trouble shooting .....................................................................23

Spare parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Schematics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Cooling circuit .......................................................................27

Main PCB ............................................................................28

Wiring diagram ......................................................................29

en

4

Introduction: Overview

Overview

The target group for this service manual is the technicians who install and maintain the SET

1501 T/ 2501 T/ 3501 T dehumidier. Thus the manual covers instructions about installation,

operation and maintenance.

It is the responsibility of the operator to read and understand this service manual and other

information provided and to use the correct operating procedure.

Read the entire manual before the initial start-up of the unit. It is important to know the cor-

rect operating procedures for the unit and all safety precautions to prevent the possibility of

property damage and/or personal injury.

It is the responsibility of the installer to ensure the conformity of all, not supplied cables

towards national regulations.

Copying of this service manual, or part of it, is forbidden without prior written permission

from SET Energietechnik GmbH.

SET Energietechnik GmbH reserves the right to make changes and improvements to the

product and the service manual at any time without prior notice or obligation.

The unit is designed to last for many years. When the time comes for the unit to be recycled, it

should be recycled according to national rules and procedures to protect the environment.

The dehumidiers contain R407C refrigerant and compressor oil. The compressor must be

returned to authorities for disposal according to local regulations.

Type and source of hazard

This symbol in connection with the word “Danger”warns of a high risk or severe injury or

acute danger to life.

• Measures to avert danger or immediate measures if the risk occurs are described in this

way

Type and source of hazard

This symbol in connection with the word “Warning”warns of a risk involving severe injury.

• Measures to avert danger or immediate measures if the risk occurs are described in this

way

Type and source of hazard

This symbol in connection with the word“Caution” warns of a risk of minor or moderate injury

and material damage.

• Measures to avert danger or immediate measures if the risk occurs are described in this

way

In connection with this symbol you will nd further tips and information concerning the use

of the device.

Target group

Safety precautions

Copyright

Reservations

Recycling

Warning

Caution

DANGER

Warning

Caution

WARNING

Warning

Caution

CAUTION

!NOTICE

5

Introduction: Declaration of Conformity

Declaration of Conformity

SET Energietechnik GmbH hereby, declare that the unit mentioned below:

No.: 351510, 351511, 351512

Type: SET 1501 T, SET 2501 T, SET 3501 T

- complies with the following directives:

2006/42/EC Machinery Directive

2014/30/EU EMC Directive

2011/65/EU RoHS Directive

1907/2006/EC REACH Regulation

- and is manufactured in compliance with the following harmonized standards:

DS/EN ISO 12100-2010 Safety of machinery - General principles for design

EN 60 335-1:2012 Household and similar electrical appliances - Safety - Part 1

EN 60 335-2-40:2003 Household and similar electrical appliances - Safety - Part 2-40

EN 60335-2-40: A1 2006 Household and similar electrical appliances - Safety - Part 2-40

EN 378-1:2016 Refrigerating systems and heat pumps

- Safety and environmental requirements - Part 1

EN 378-2:2016 Refrigerating systems and heat pumps

- Safety and environmental requirements - Part 1

Skive, 18.03.2021

Declaration

Jakob Bonde Jessen

Managing director

Mikkel Haldrup Jensen

Project manager designer

en

6

Product description: Overall description

Product description

Overall description

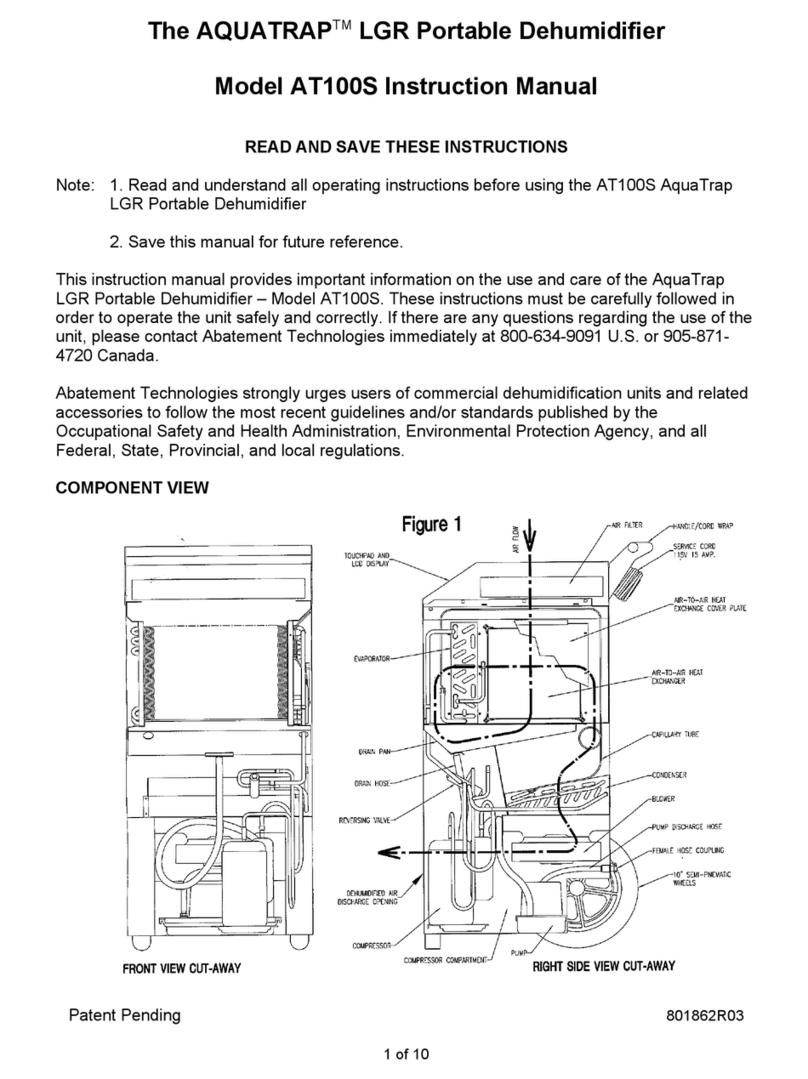

This illustrates the functional principle of the SET 1501 T/ 2501 T/ 3501 T.

Fig. 1

SET 1501 T/ 2501 T/ 3501 T work in accordance with the condensation principle.

Humid air from the pool room is drawn into the unit by one or two fans.

When passing through the evaporator the air is cooled down to below dew point and water

vapour is condensed into water, which is drained.

The dry air is then passed through the condenser where it is heated and returned to the pool

room. As a result of the latent heat from the condensation process and the compressor en-

ergy the return air temperature to the pool room is approx. 5ºC higher than the air from the

pool room.

When the dehumidier is started by the hygrostat, the fan(s) are activated at the same time as

the compressor.

To protect the compressor against overloading there is a timer which prevents the dehu-

midier from starting more than 10 times per hour. It means, that there is at least 6 minutes

between every start up.

This unit is equipped with an intelligent defrosting strategy.

The unit monitors the temperature of the evaporator, and when the temperature has been

below a certain temperature for a period of time, the dehumidier will switch to active

defrosting, the fans will stop, and the magnetic valve will open.

The hot gas can now pass through the evaporator.

When the evaporator has the right temperature again the magnet valve will close and the

dehumidication will continue.

If the temperature in the dehumidier increases to a temperature of more than 55 °C (in case

of fan failure or room air temperature higher than 36 °C), the compressor stops automatically

to avoid damaging it. When the temperature allows it the dehumidication will continue.

Air ow direction

Functionality of

the dehumidier

Fan control

Compressor

control

Defrosting

Safety circuit

7

Product description: Overall description

B

A2

A1

Two cable grooves for accessory make it

easy to guide the cables from the control

panel to the mains electricity connection

and out of the unit.

Groove B is for use with cable from ex-

ternal RH sensor as it requires a separate

groove to avoid interference.

All other accessory cables are to be

placed in groove A1-A2.

An LED is placed on the top inside the

unit. The LED light indicates dierent

modes of the unit.

Find a description of the dierent

modes in section “LED light and trou-

bleshooting”on page 24.

Cable groove

(accessory)

LED

en

8

Product description: Overall description

Pos. Part Illustration

1 Air inlet

2 Air outlet

3 Drip tray

4 Control panel

(behind the cover)

5 Cable groove

(for accessory only)

6 Humidity sensor

7 LED lamp

8 Wall bracket

9 Wall mounting

spacers

(incl. in delivery -

only used for wall

mounting)

10 Floor mount

(incl. in delivery

-only used for oor

mounting)

11 Water drain

12 Mains electricity

connection

(behind the lid)

Presentation

Fig. 2

Bottom view

11

12

1

Front cover

2

6

5

3

4

Inside (front cover removed)

7

8

92x

10

Rear view

9

Product description: Enclosure dimensions

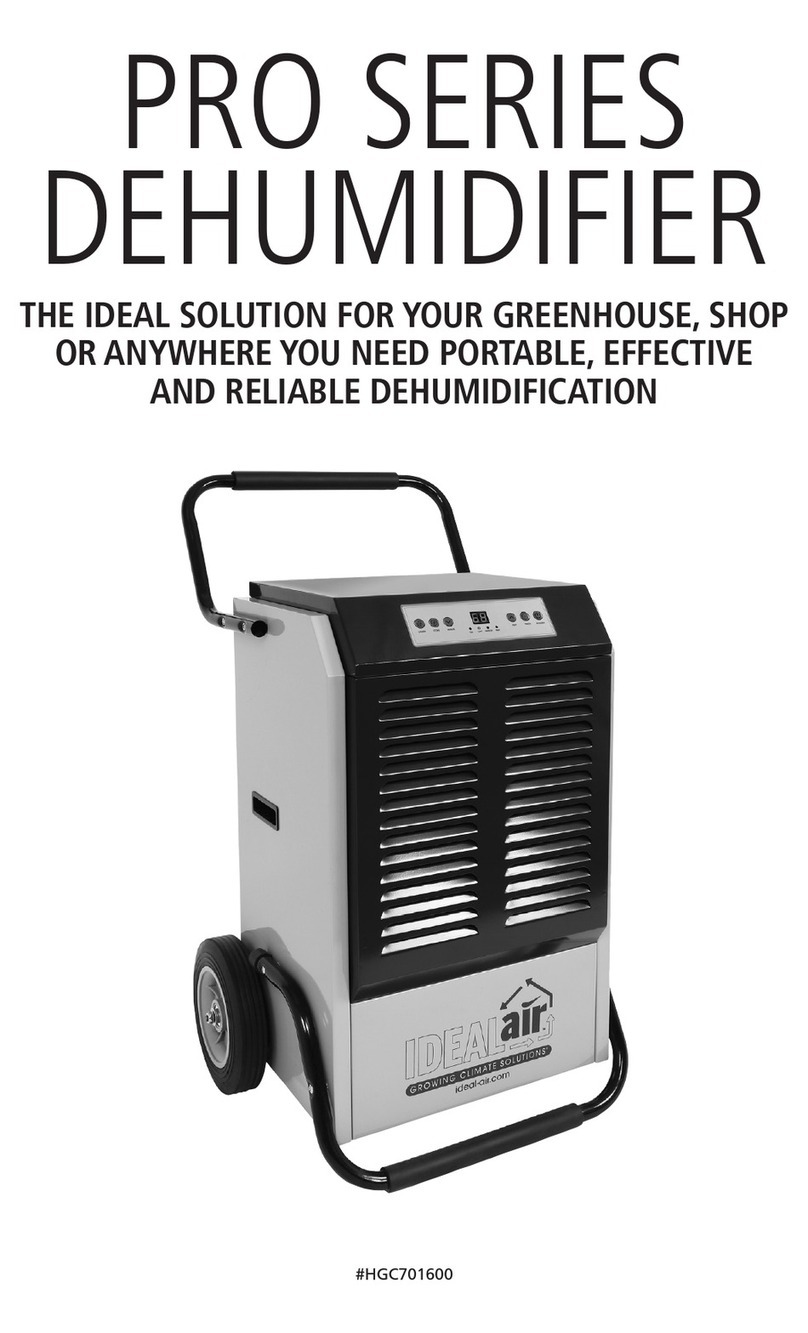

Enclosure dimensions

770

75

-

27904g

SCALE: NOT TO SCALE

MATERIAL:

THICKNESS:

WEIGHT:

REV. BY:

DATE:

REF.:

DATE:

PART NO

REV.:

REV.:

PART NO

Sheetmetal atstate is based on Dantherm Air Handling A/S

process equipment and is only intended as a guide.

8

This Drawing is furnished with the understanding that the

essence there of will not be reproduced in whole or in part

without written authorization by Dantherm A/S.

All designs originated by Dantherm A/S are the

property of said Company and will be protected by Patents.

Surface appearance according to reference

table LZT 142 0001, category

Linear dimensions without tolerances according to

DS/ISO 2768-m. Angular dimensions without tolerances: ± 1°

308

308

SET 3501 T - 1488

SET 2501 T - 1154

SET 1501 T - 1004

695

434,2

59,2

308

SET 3501 T - 1488

SET 2501 T - 1154

SET 1501 T - 1004

695

434,2

59,2

Front view

Bottom view

Side view

Fig. 3

Dimensions

en

10

Product description: Technical data

Technical data

Specication unit SET 1501 T SET 2501 T SET 3501 T

Operating range, humidity %RH 40-100 40-100 40-100

Operating range, temperature °C 10-36 10-36 10-36

Air volume at max. external pressure m/h 400 680 900

Capacity at 28ºC - RH 60 l/day 34 52 69

SEC 28ºC - RH 60 kWh/l 0,47 0,48 0,43

Power supply V/Hz 1 × 230/50 1 × 230/50 1 × 230/50

Max. power

consumption kW 0.9 1.5 1.8

Max Ampere

consumption A 3,8 6,6 8

Refrigerant -R407C

Quantity of refrigerant kg 0.7 0.9 1.2

GWP (Global Warming Potential) -1774

Noise level* (1 m from unit) dB(A) 45 47 48

Weight kg 56,5* 66,0* 76,5*

Filter Type PPI 15

Protection class IPX4

*Hanging weight (excl. oor mounts)

Data sheet

11

Installation: Installation environment

Installation

Installation environment

The correct combination of chemicals in an indoor swimming pool is crucial, both for the

health of users and for the inventory inside the pool room and the swimming pool’s technical

room. Insuciently treated water results in poor hygiene, while water that has been exces-

sively treated results in gases in the air that contain chlorine, which can irritate the eyes and

cause breathing diculties.

At the same time, the incorrect composition of chemical ingredients in the water can destroy

all of the inventory in a very short space of time, including the dehumidier and other equip-

ment that have been installed to process the air.

Shown below are the threshold values, which apply to products for indoor swimming pools

in accordance with EN/ISO 12944-2, protection class C4. These threshold values must be com-

plied with for the warranty to be valid.

The following guideline values are applicable to swimming pools with the addition of chemi-

cals.

Chemicals ppm

Free chlorine content 1.0-2.0

Combined chlorine content Max. 1/3 of free chlorine content

pH 7.2-7.6

Total alkalinity 80-150

Calcium hardness 250-450

Total dissolved solids < 2000

Sulphates < 360

The following guideline values are applicable to swimming pools with self-production of

chlorine:

Chemicals ppm

Salt (NaCl) < 30,000

Total dissolved solids < 5500

pH 7.2-7.6

Total alkalinity 80-150

Calcium hardness 250-450

Sulphates < 360

It is advisable to use the Langelier Saturation index to ensure that the combination of the

dierent water parameters is acceptable.

Contact SET Energietechnik GmbH if necessary.

• Do not place the dehumidier close to a heating source, e.g. a radiator.

• Doors and windows must be kept closed when the dehumidier is in function.

• To make sure that the room air passes freely through the dehumidier, air inlet and air

outlet openings must be free.

Water quality in

indoor pools

When adding

chemicals

With own

production of

chlorine

Langelier

Saturation index

Optimal

conditions

!NOTICE

en

12

Installation: Wall mounting

Wall mounting

Please follow this procedure to mount the SET 1501 T/ 2501 T/ 3501 T to the wall:

Step Description Illustration

1 Find the right spot for the de-

humidier and measure where

the wall suspension bar has to

be mounted.

Recommended distance from

dehumidier to:

• Ceiling: min 225 mm

• Floor: min 225 mm

Min. 225 Min. 225198

Min. 727

A

2 Fix the wall suspension bar sup-

plied with the unit to the wall.

NB: It is important to x it

horizontally to ensure correct

condensate outlet.

Mounting

procedure

13

Installation: Wall mounting

3 Fasten the two wall mounting

spacers (included in the deliv-

ery) on the back of the unit.

4Drain outlet:

Connect a drain hose and make

a condensate outlet through

the wall.

Connect a 3/4”exible or xed

water hose to the spigot at the

base of the dehumidier. Make

sure the drainage has a drop of

at least 2 %.

Alternatively:

• A condensate pump can be

tted at the water outlet in

order to pump the water to

a drain.

5 Hang the dehumidier on the

wall suspension bar.

2x

!

en

14

Installation: Floor mounting

Floor mounting

Please follow this procedure to x the oor mounts to the SET 1501 T/ 2501 T/ 3501 T unit:

Step Description Illustration

1 Fasten both oor mounts

to the bottom of the

dehumidier with screws

and nuts (incl. in deliv-

ery).

2 Place the dehumidier

with either

a. a min. space of 225

mm above the unit

or

b. a min. angle of 45°

a) b)

3 If you connect a drain

hose, you have to make

sure that the drain has a

drop.

Avoid a wavy laid hose.

c.

Mounting

procedure

min. 45°

min.

225mm

min. 45°

min.

225mm

15

Installation: Electrical connection

Electrical connection

Risk of damaging the dehumidier, if it has been lying down.

The compressor can be damaged permanently, when the unit is started up just after it has

been lying down.

• Wait 1 hour with the start up of the dehumidier, if the unit has been lying down (e.g.

during transport or installation).

Risk of electric shock

An electric shock can cause severe burning and in most extreme cases shock to the brain,

strain to the heart, injury to other organs or result in death.

• Switch o the power on the main switch, while you open the dehumidier.

• Remember also to switch o the power, while you close the dehumidier.

Step Description Illustration

1 Loosen the two screws that

secure the lid to the mains

electricity connection. Tilt the

lid in order to get access to the

terminals.

2 Guide the cable for the power

supply through the PG cable

restrainer.

3 Connect the power to the unit in

accordance with the description

stated on the name plate.

See also “Wiring diagram”on

page 29.

4 Close the lid and x it with screws again.

Warning

Caution

CAUTION

Warning

Caution

DANGER

Connection of

power supply

2,5 mm

Min Ø9

Max Ø18

en

16

Installation: Electrical connection

It is the responsibility of the installer to ensure the conformity towards national regulations of

all, not supplied cables.

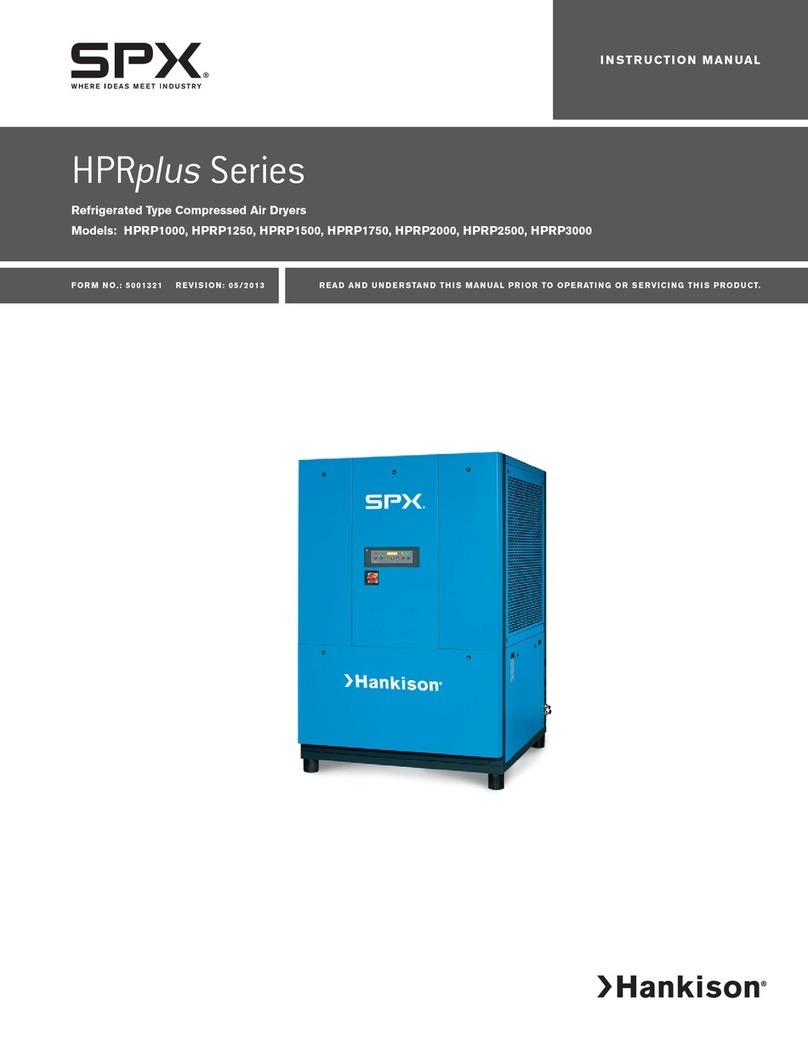

The interfaces and terminals on the control panel make it possible to communicate with the

dehumidier and connect accessory such as a RH/T sensor, an alarm and a heating coil. The

gure and table below describe the dierent functions of the interface.

+v

TH

TH

GND

GND

+

GND

+

RH

ON

ON

USB RS485 EXT RH/T ALARM 12V DC

RUN FAIL HEAT1 HEAT2

GND

+

GND

+

RH

ON

ON

OK

1 2 3 4 5

Fig. 4

Pos. Interface Description

1 USB USB is used for datalogging/ software update. See more information

in section “Software update and log les” on page 21.

2 Modbus RTU

(RS-485)

Connection via modbus. A list of data for the Modbus interface can be

downloaded on support.dantherm.com

3 External

RH/T sensor

Terminals for connecting an external humidity/ temperature sensor.

See wiring example in Fig. 5

4 Alarm An external alarm can reveal, if the dehumidier is operating normally

or has an error. See wiring example in Fig. 6

512 VDC

Heat control

Connection of LPHW (water) or electric heating helps controlling the

indoor temperature. Contact your SET dealer for more information.

There is an option for connecting an external RH/T sensor, which makes it possible to overrule

the internal sensors. In Fig. 5 there is an example on how it could be connected.

Fig. 5

*Switch in position: 0 = Internal sensors in use, 1 = External sensors in use

**Note, operational range is within 40-99% RH, if out of range the dehumidier will be in

stand by mode

!NOTICE

Control panel

interfaces

External RH/T

sensor connection

(Optional)

External temperature sensor

(or resistor)

ON/OFF switch for

external sensors*

(Optional)

EXT RH/T

External humidity sensor

(or control unit)

EXT RH/T

V+

TH

TH

RH

GND

10kΩ NTC

0V = 0% RH

5V = 50% RH

10V = 100% RH**

0

1

GND

0-10V

17

Installation: Electrical connection

There is an option for connecting an external alarm, which makes it possible to see, when the

dehumidier is operating normally or has an error. In order to use this option you must create

your own external electrical circuit and connect it to the run/fail terminal on the main PCB

(see page 28).

This illustration is an example of how the run/fail circuit could be used.

RUN FAIL

1234

VDC

(Max. 50V, 500mA)

GND

GND

VDC (Max. 50V, 500mA)

RUN FAIL

1234

VDC (Max. 50V, 500mA)

GND

GND

VDC (Max. 50V, 500mA)

NORMAL MODE ERROR MODE

Operational Mode

RUN FAIL

Error Mode

RUN FAIL

Fig. 6

Alarm

Run/ fail

connection

(Optional)

en

18

Operation: Control panel

Operation

Control panel

Risk of electric shock

An electric shock can cause severe burning and in most extreme cases shock to the brain,

strain to the heart, injury to other organs or result in death.

• Switch o the power on the main switch, while you open the dehumidier.

• Remember also to switch o the power, while you close the dehumidier.

Follow the steps below in order to access the control panel.

Step Description Illustration

1 Open the dehumidier:

a) Loosen the two screws at

the bottom of the unit.

Check that the locks release

the front cover.

b) Pull upwards and remove

the front cover.

2 Loosen the two screws and re-

move the upper plate (covering

the control panel).

4 digit Display divided into 2 sections: The rst 2 digits show the code and the last 2 show the

value of the code.

Code Value

By default the display will show the relative humidity RH %. This reading can be from the

external humidity/temperature sensor when available, if not the RH will be from the internal

humidity sensor.

Example

Warning

Caution

DANGER

Accessing the

control panel

a

b

Display

Default view

19

Operation: Control panel

48 rH60 OK

OK

>40

<99 OK

COF

o

>05

<34

OK OK

EFOF >40

<99

OK OK

SIOF >1

<99

OK OK

d001 >1

<255

OK OK

Update to latest software version, if the menu looks dierent.

Code Function Default

value

Value

range

Description

rH Relative

humidity (%)

60 40-99 The unit will start dehumidifying, when the sen-

sor measures a relative humidity higher than the

set value. (Note the +/- 2% hysteresis)

°C°Celcius

(accessory only)

OF

(OFF)

5-34 The el/water heating coil (accessory) will start

to heat, when the temperature is lower than the

set value. (Note the +/- 2 °C hysteresis)

EF Extractor fan

(accessory only)

OF

(OFF)

40-99 The extractor fan (accessory) will start, when the

humidity is higher than the set value, complete-

ly independent of the dehumidier. The value is

measured in % relative humidity.

(Note the +/- 2% hysteresis)

SI Service Interval

(weeks)

OF

(OFF)

1-99 When the Service Interval function is enabled,

the unit will display SEr, when it is time for

service.

d001 Modbus Slave ID 001 1-255 Connection via modbus is possible. The default

modbus slave ID of the unit is 1 and can be

changed to a value between 1-255.

Press and hold OK button for 3 sec to enter menu mode

Toggle Menu Page / change value

Note: If no button is pressed for 10 seconds it will return to Standard view.

Menu overview

Default view

Example

Menu description

OK

Menu buttons

en

20

Maintenance and care: Preventative maintenance

Maintenance and care

Preventative maintenance

The dehumidier requires very little attention for trouble free running. All the necessary

safety and control functions have been built in. The fan motor(s) and the compressor have

permanent lubrication and require no particular maintenance.

Injury - risk of cuts and minor skin burns, when you access the inside of the unit

Be cautious of sharp edges when opening the unit. Internal parts can be very hot or cold.

• Switch o unit for half an hour prior to opening it. Avoid touching very hot and cold parts

as e.g. the pipes or evaporator.

• Avoid touching sharp edges or wear gloves.

The air inlet lter is to be cleaned once a month. The lter is placed in a stand behind the grill

of the air inlet duct. Drip tray and outlet should also be cleaned, so water can run o freely.

Please follow this procedure to perform the monthly service:

Step Action

1 Unlock the two locks underneath the dehumidier

2 Dismount the front cap by lifting it up and take out the lter.

The lter is located on the rear of the front cap

3 Wash the lter in tepid soapy water or vacuum clean thoroughly.

If the lter is faulty, replace it.

4 Insert lter in the lter holder, reattach the cap and lock the two locks. (From Step 1)

NB: If the lter (one size PPI lter with order no. 094686) has to be replaced, you can order it

through a SET dealer.

The dehumidier should be inspected once a year.

Please follow this procedure to perform the annual service:

Step Action

1 Remove the front from the dehumidier

2 Inspect the inside of the dehumidier

3 Vacuum clean the dehumidier to remove any dust or debris

Important: Vacuum clean the condenser thoroughly

4 If necessary wash the lamella evaporator in tepid soapy water if it is badly soiled

Introduction

Warning

Caution

CAUTION

Monthly service

Annual service

Other manuals for 1501 T

1

This manual suits for next models

5

Table of contents

Other SET Dehumidifier manuals