Manual – MOVIPRO® SDC with DeviceNet Interface 3

Contents

Contents

1 General Information ............................................................................................ 5

1.1 Use of the manual....................................................................................... 5

1.2 Structure of the safety notes ....................................................................... 5

1.3 Right to claim under limited warranty.......................................................... 6

1.4 Exclusion of liability..................................................................................... 6

1.5 Copyright notice .......................................................................................... 6

1.6 Other applicable documentation ................................................................. 6

1.7 General safety notes for bus systems......................................................... 6

1.8 Safety functions .......................................................................................... 7

1.9 Hoist applications........................................................................................ 7

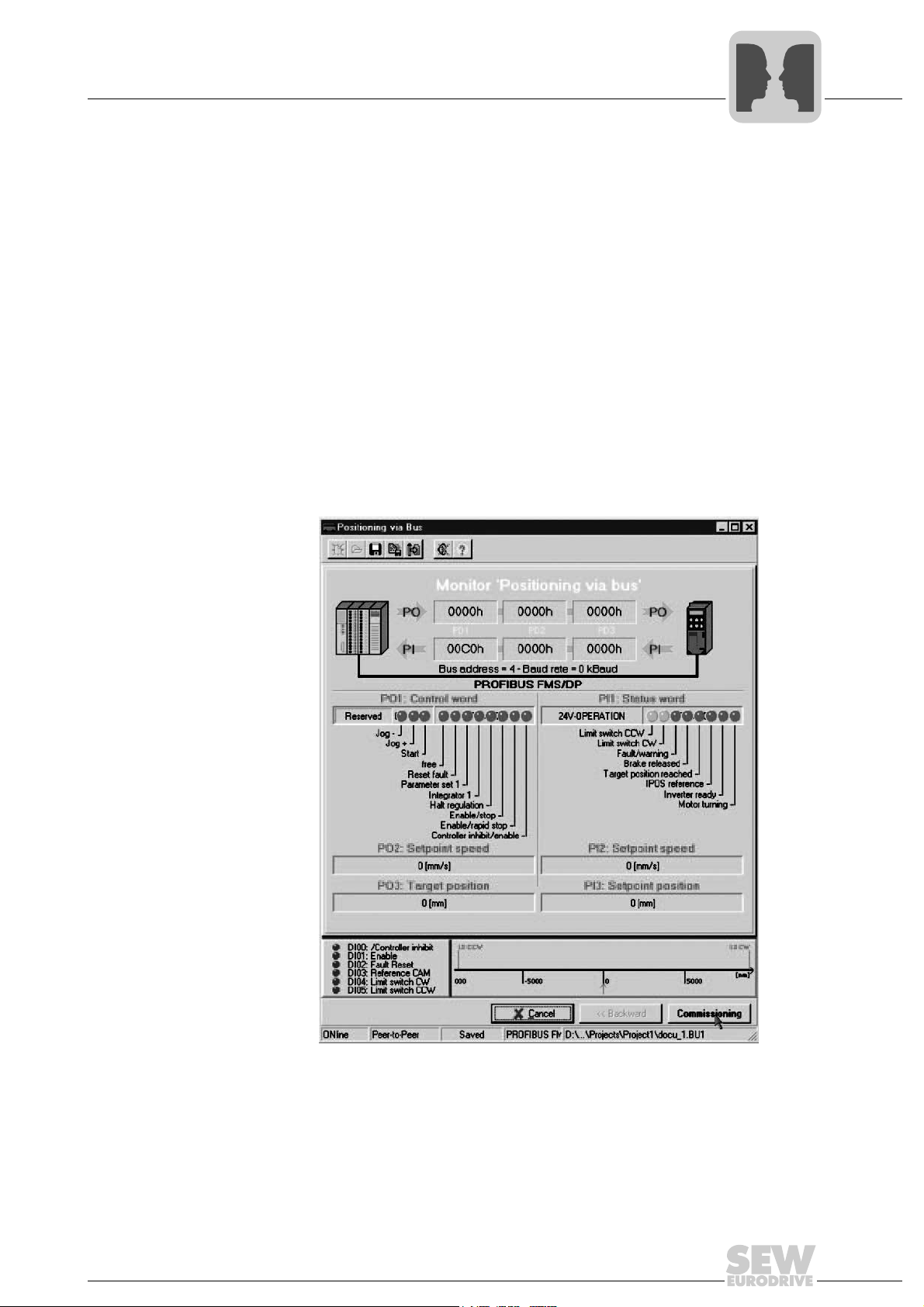

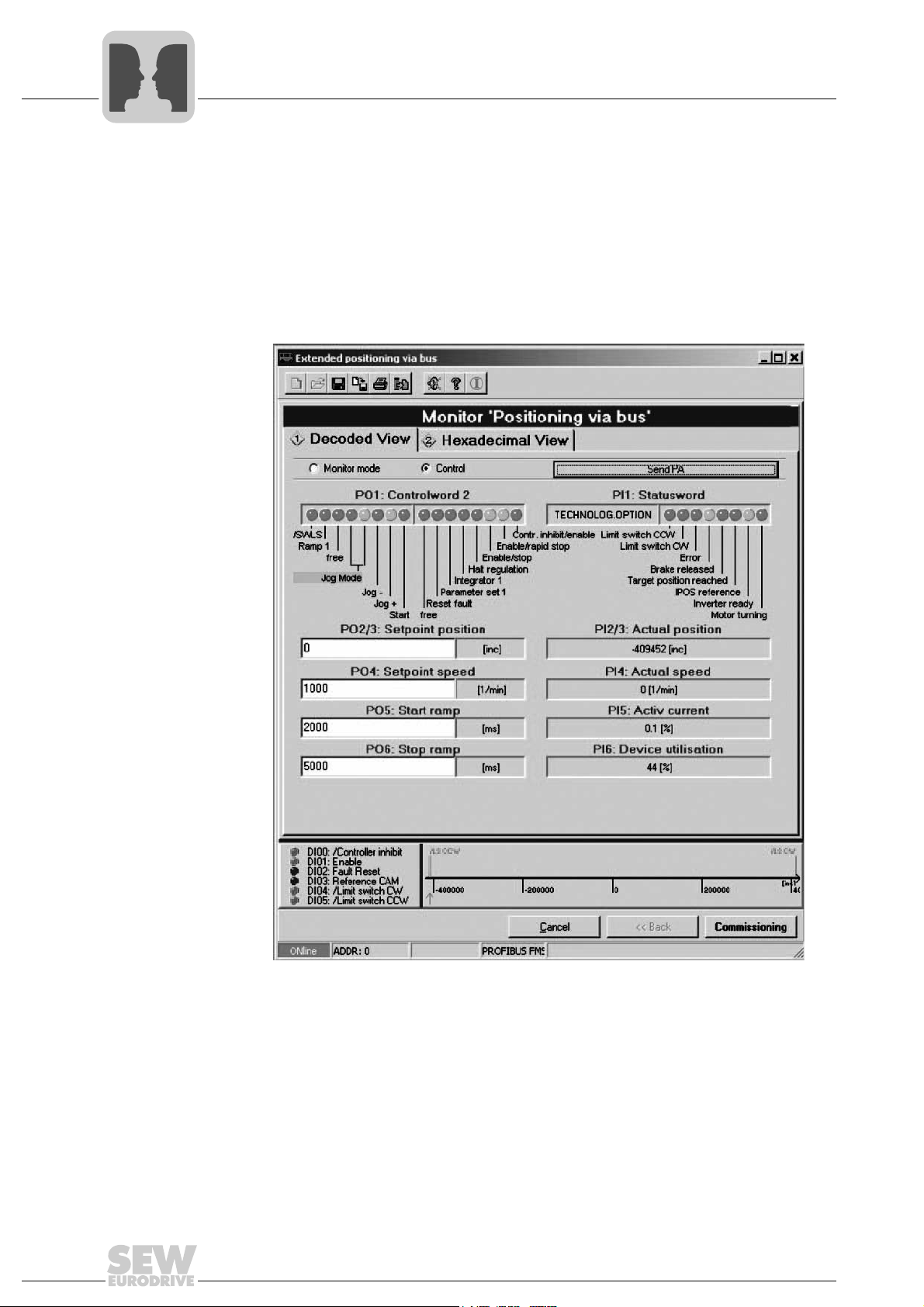

2 Application Modules in MOVITOOLS®MotionStudio ..................................... 8

2.1 Application modules for MOVIPRO®SDC .................................................. 8

3 Startup................................................................................................................ 14

3.1 Startup procedure ..................................................................................... 14

3.2 Check list for startup ................................................................................. 14

4 Installation Notes .............................................................................................. 16

4.1 Fieldbus connection .................................................................................. 16

4.2 Shielding and routing the bus cables ........................................................ 18

4.3 Setting the station address (DeviceNet) ................................................... 19

4.4 Status and error messages....................................................................... 21

5 Configuration and Startup on the DeviceNet Fieldbus.................................. 25

5.1 Validity of the EDS files for MOVIPRO®................................................... 25

5.2 Configuring the PLC and master (DeviceNet scanner)............................. 26

5.3 Configuration examples in RSLogix 5000 ................................................. 29

6 DeviceNet Operating Characteristics ............................................................. 37

6.1 Process data exchange ............................................................................ 37

6.2 Common Industrial Protocol (CIP) ............................................................ 39

6.3 Return codes of the parameterization via explicit messages.................... 46

6.4 Definitions ................................................................................................. 50

7 Error Diagnostics for Operation on the DeviceNet Fieldbus ........................ 51

7.1 Diagnostic procedure ................................................................................ 51

8 Process Data Description................................................................................. 52

8.1 Overview of process data ......................................................................... 52

8.2 MOVIPRO®control word .......................................................................... 52

8.3 MOVIPRO®status word............................................................................ 53

8.4 Digital inputs and outputs.......................................................................... 54

8.5 Process data of power section.................................................................. 55