vii

TABLE OF CONTENTS

PRECAUTIONS .........................................................................................xi

1 Intended Audience.....................................................................................................................................xii

2 General Precautions...................................................................................................................................xii

3 Safety Precautions.....................................................................................................................................xii

4 Operating Environment Precautions..........................................................................................................xii

5 Application Precautions............................................................................................................................xiii

6 EC Directives............................................................................................................................................xiv

1 SPECIFICATIONS AND PERFORMANCE..................................15

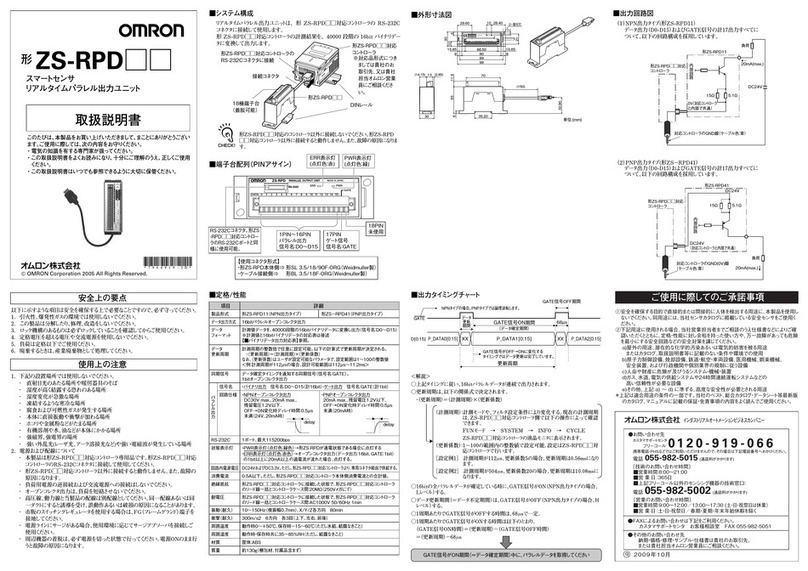

1-1 Overall Specifications............................................................................................................................................16

1-2 Dimensions.............................................................................................................................................................17

1-3 Performance...........................................................................................................................................................18

2 INSTALLATION................................................................................23

2-1 Physical layout of the Unit.....................................................................................................................................24

2-2 Mounting the C200HW-CORT21..........................................................................................................................27

2-3 Network cabling.....................................................................................................................................................27

3 PLC INTERFACE..............................................................................29

3-1 Unit Settings...........................................................................................................................................................30

3-2 Control and Status area ..........................................................................................................................................32

3-3 LEDs, 7-Segment Display......................................................................................................................................37

4 MESSAGE COMMUNICATION, IOWR / IORD.........................39

4-1 Message communication........................................................................................................................................40

4-2 IOWR / IORD........................................................................................................................................................40

4-3 Error log.................................................................................................................................................................41

4-4 Reading the error log..............................................................................................................................................43

4-5 Transmitting a user defined CAN message............................................................................................................43

4-6 Receiving a user defined CAN message ................................................................................................................44

5 TROUBLESHOOTING AND MAINTENANCE...........................49

5-1 Error Indicators......................................................................................................................................................50

5-2 Troubleshooting .....................................................................................................................................................50

5-3 Maintenance...........................................................................................................................................................52

Appendices

Appendix A CS1 PLC series compatibility ..............................................................................................55

Revision History.........................................................................................57