1

CONTENTS

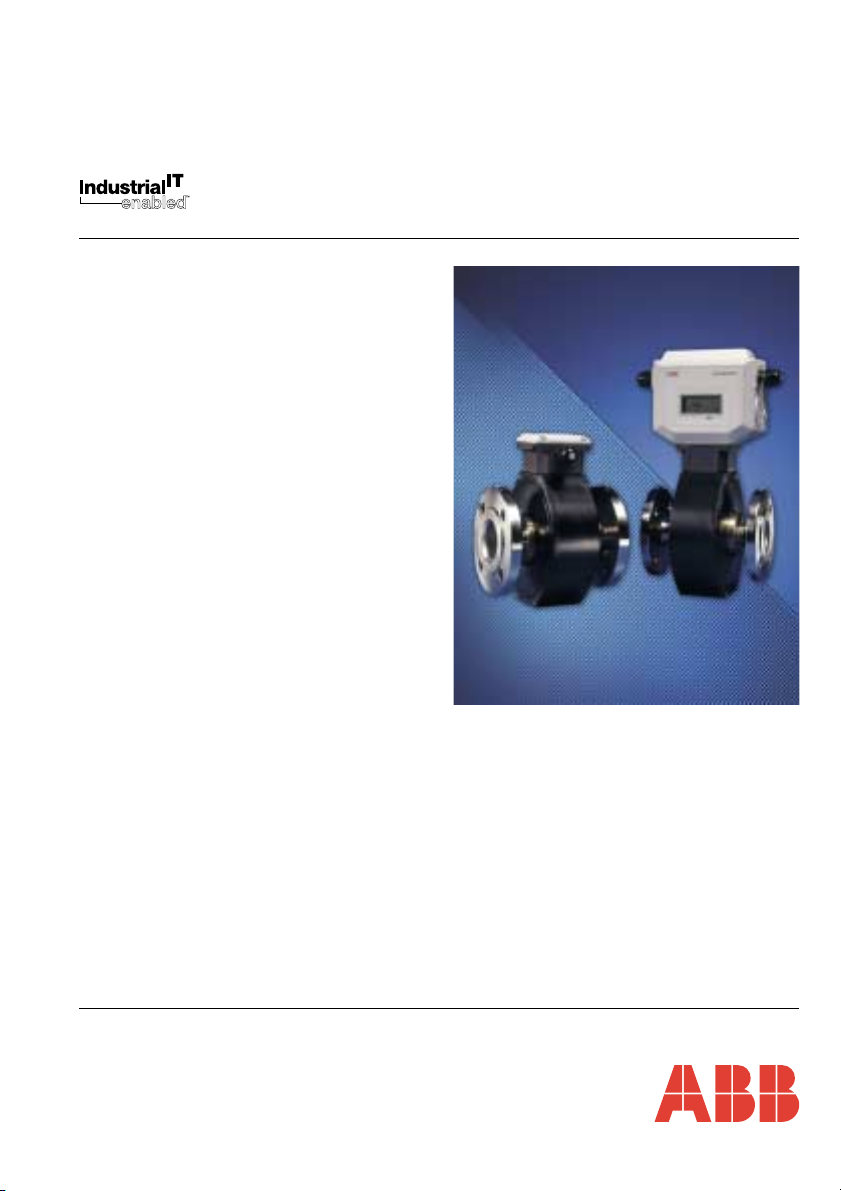

AquaMasterTM is a range of high performance

electromagnetic flowmeters for the measurement

of electrically conductive fluids and are normally

supplied as factory configured, calibrated

systems.

Warning.

• Installation and maintenance must be

carried out only by suitably trained

personnel.

• Read all relevant sections of this manual

before selecting a location.

• The safety requirements of this equipment,

any associated equipment and the local

environment must be taken into

consideration during installation.

• Install and use this equipment in

accordance with relevant national and local

standards.

• Specific safety precautions apply to the use

of the GSM engine which forms part of the

GSM-equipped version of this product. If

the unit purchased has GSM-capability,

read Appendix A on page 30 before

selecting a location.

1 INTRODUCTION

1 INTRODUCTION ........................................ 1

2 MECHANICAL INSTALLATION ................. 2

2.1 Unpacking .......................................... 2

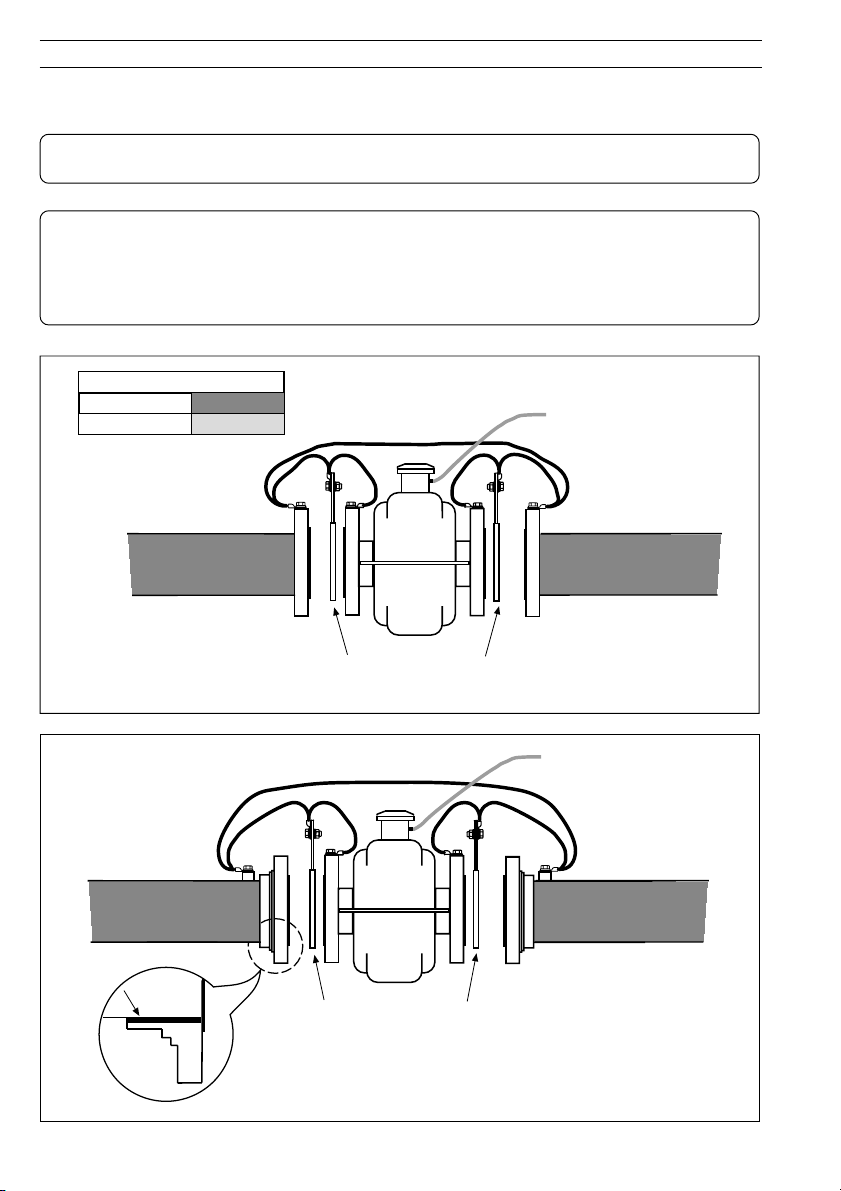

2.2 Installation Conditions ........................ 2

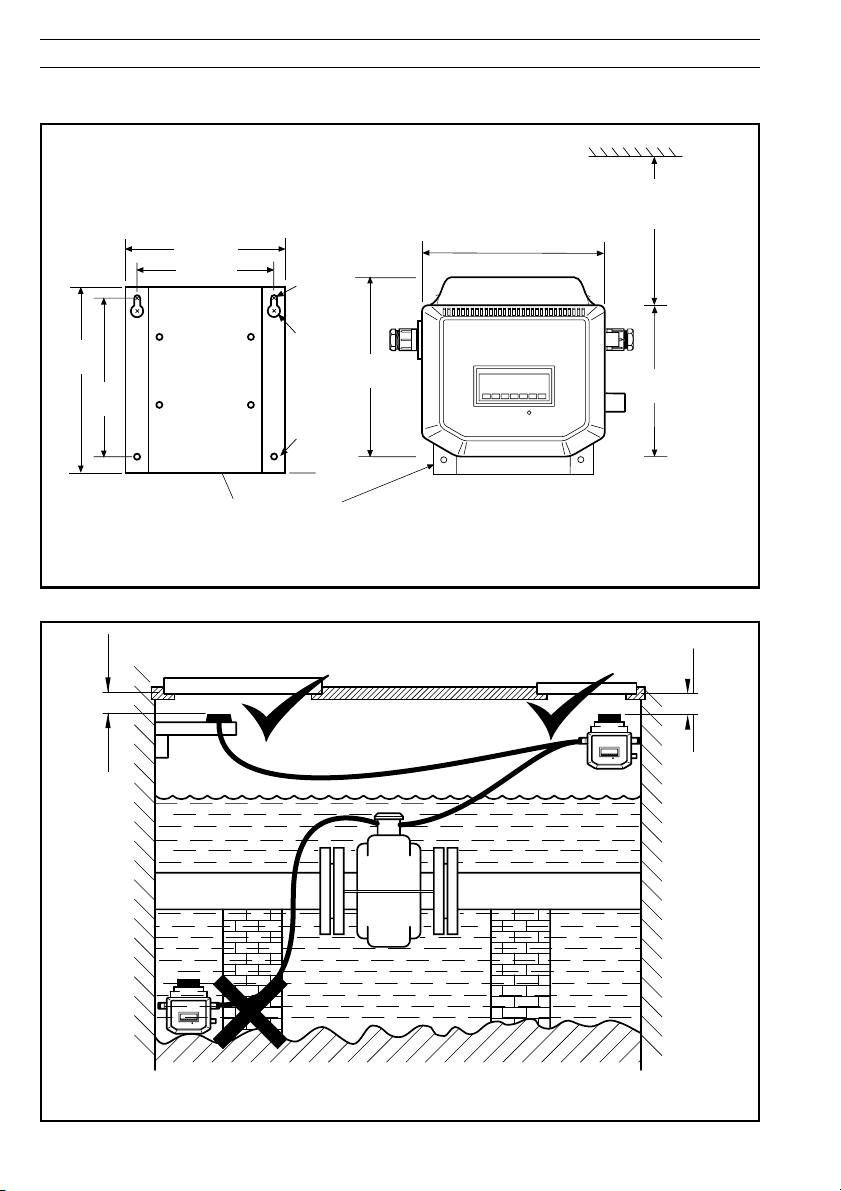

2.3 Transmitter Dimensions ...................... 4

2.4 GSM-equipped Transmitters .............. 5

2.4.1 GSM Antenna Installation ...... 5

2.4.2 Connecting a Remote

Antenna ................................. 6

2.4.3 Installing a SIM Card ............. 7

3 ELECTRICAL INSTALLATION ................... 8

3.1 Bonding/Grounding ............................ 8

3.2 Connections ..................................... 13

3.2.1 Sensor Terminal Box

Connections (Remote

Versions only) ...................... 13

3.2.2 Environmental Protection ..... 13

3.2.3 Transmitter Connections ...... 14

3.3 Input/Output Connections ................ 17

3.3.1 Frequency Outputs .............. 17

3.3.2 Alarm Interface .................... 17

3.3.3 MIL Connector Input/Output

Connections (Option) ........... 18

3.3.4 MIL Connector Input/Output

(Option) – AquaMag™ x10

Pulse Output Compatibility .. 19

3.3.5 ScanReader Interface

(Option) ................................ 19

3.3.6 Local Computer

Connection .......................... 20

3.3.7 Remote Computer

Connection .......................... 21

3.3.8 Power Supply Connection ... 22

3.3.9 Pressure Transducer

(Optional) ............................. 23

3.3.10 Environmental Protection ..... 23

4 START-UP AND OPERATION .................. 24

4.1 Connecting Batteries ........................ 24

4.2 Start-up ............................................ 24

4.3 Display Activation ............................. 26

4.4 Replacing a Battery .......................... 26

4.4.1 Spares Kits. ......................... 27

4.4.2 Battery Changing

Procedures .......................... 28

APPENDIX A – GSM-EQUIPPED UNITS –

SAFETY PRECAUTIONS ............................... 30

APPENDIX B – AQUAMASTER BLOCK

DIAGRAM ....................................................... 31

SPECIFICATION ............................................. 32