seward Stomacher User manual

World leaders in sample preparation

Stomacher® 400 EVO

User Manual

Intro

World leaders in sample preparation

Thank you for purchasing this Seward product

This manual contains operating instructions for the Stomacher® 400 Evo.

The Seward Stomacher® was developed in the early 70’s in response to ever- increasing demands for

sample preparation in a fast, consistent and efficient way. Since then, Seward have continually developed

the Stomacher® to maintain its position as the market leader ensuring exacting performance, high quality

and exceptional reliability.

This manual provides the user with all the information to install, operate and maintain the Seward

Stomacher®. Please read the manual carefully before using this equipment.

CAUTION: - This equipment should not be used if damaged in any way. If in doubt please contact your local

Seward authorised service centre.

Should any other questions arise please do not hesitate to contact the

Seward Customer Service Department on:-

Telephone: +44 (0)1903 524600

The Seward Stomacher® is a unique homogenising instrument in which the sample is blended within a

special disposable bag. The instrument acts on the bag in an action similar to the action of a stomach,

hence the name Stomacher®.

The instrument is comprised of an electric motor-driven worm gear unit with twin output shafts coupled to

flexible crank mechanisms, which in turn operate two reciprocating paddles. The paddles act on the flexible

plastic bag to create the blending forces termed the ‘stomaching’ action. An important feature of the

system is that the working parts do not come into direct contact with the sample being processed.

Protection from the moving parts inside the sample compartment is provided by a protective seal which

automatically closes the bag inside the paddle chamber. A cut-off switch ensures the unit cannot work

while the protective seal is open or the cover is missing.

Stomacher® is a registered Trademark and may not be used without the express permission of Seward Ltd.

www.seward.co.uk

1

Seward is a part of the FermionX Group.

Contents

1. Control panel.............................................................................................3

2. Operation...................................................................................................4

3. Strip down...................................................................................................5

4. Eco bag operation................................................................................... 7

5. Paddle reset...............................................................................................8

6. Warnings/Cautions/Guidance................................................................ 9

7. Specifications.................................................................... .......................11

8. Bags & Accessories.................................. ...............................................12

World leaders in sample preparation

2

C

12

345 67

1. Control panel

Operation

1. Select program slot 1- 8 - press 7

2. Set parameters of speed and time

3. Press lock 4

4. Program will be retained after mains power is switched off

1. Start 2. Stop 3. Clear 4. Lock (Press 4 then 3 to open) 5. Adjust time (9 mins 55 secs in 5 second

increments) 6. Adjust speed - Slow, Medium or Fast 7. Program store - 8 program slots

World leaders in sample preparation

3

2. Operation

Drop Stomacher bag into the machine

Press the start button

World leaders in sample preparation

4

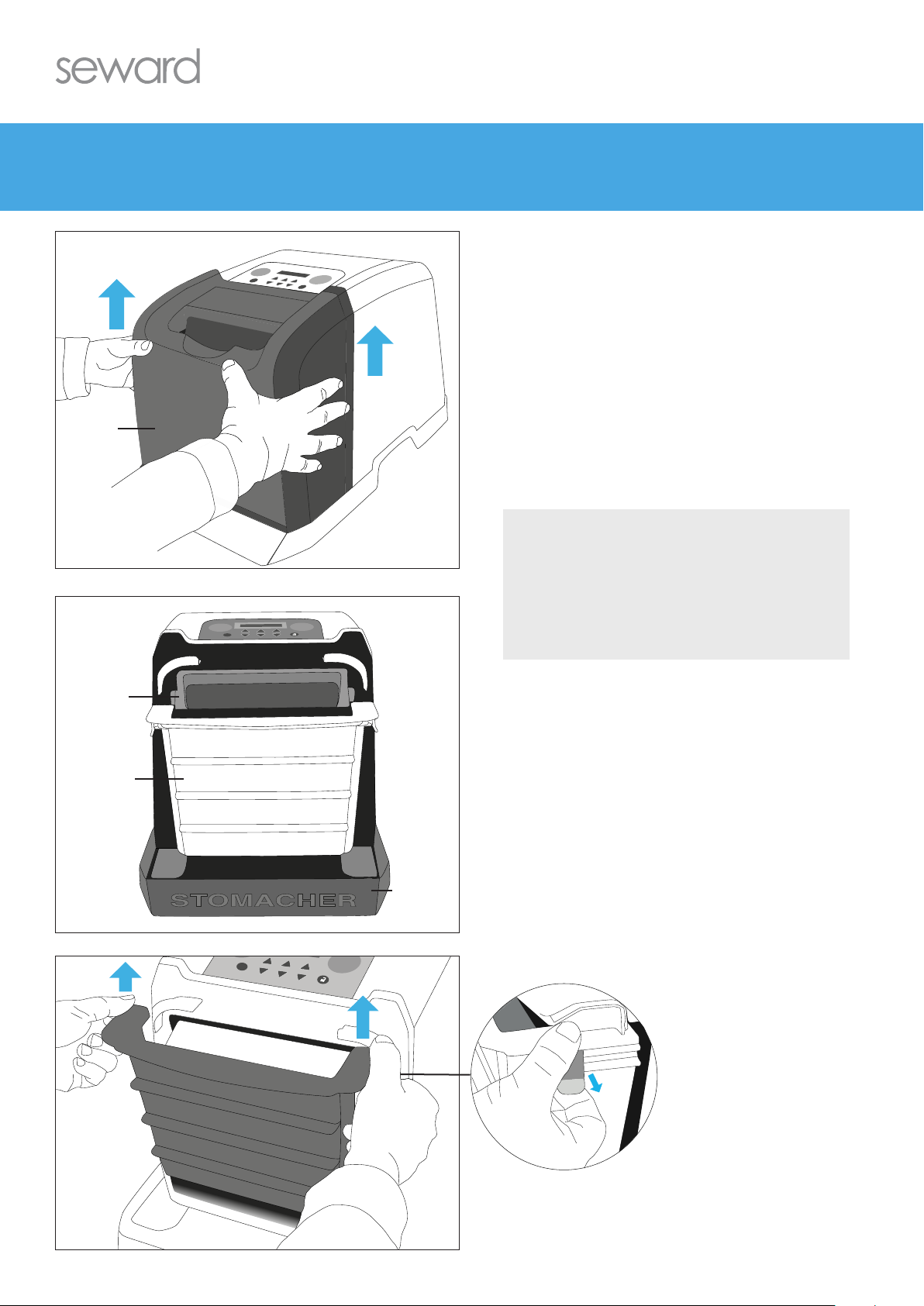

3. Strip down and clean

C

C

World leaders in sample preparation

Bag seal

Strike plate

Drip tray

Cover

Remove cover

Remove strike plate

5

CLEANING INSTRUCTIONS

DISCONNECT from mains when cleaning

DO NOT immerse or spray with water

Wipe with damp cloth or anti bacterial wipes

Use only non phenolic cleaning products

Strip down and clean

Remove bag seal

Pull paddles off

Pull drip tray off

World leaders in sample preparation

6

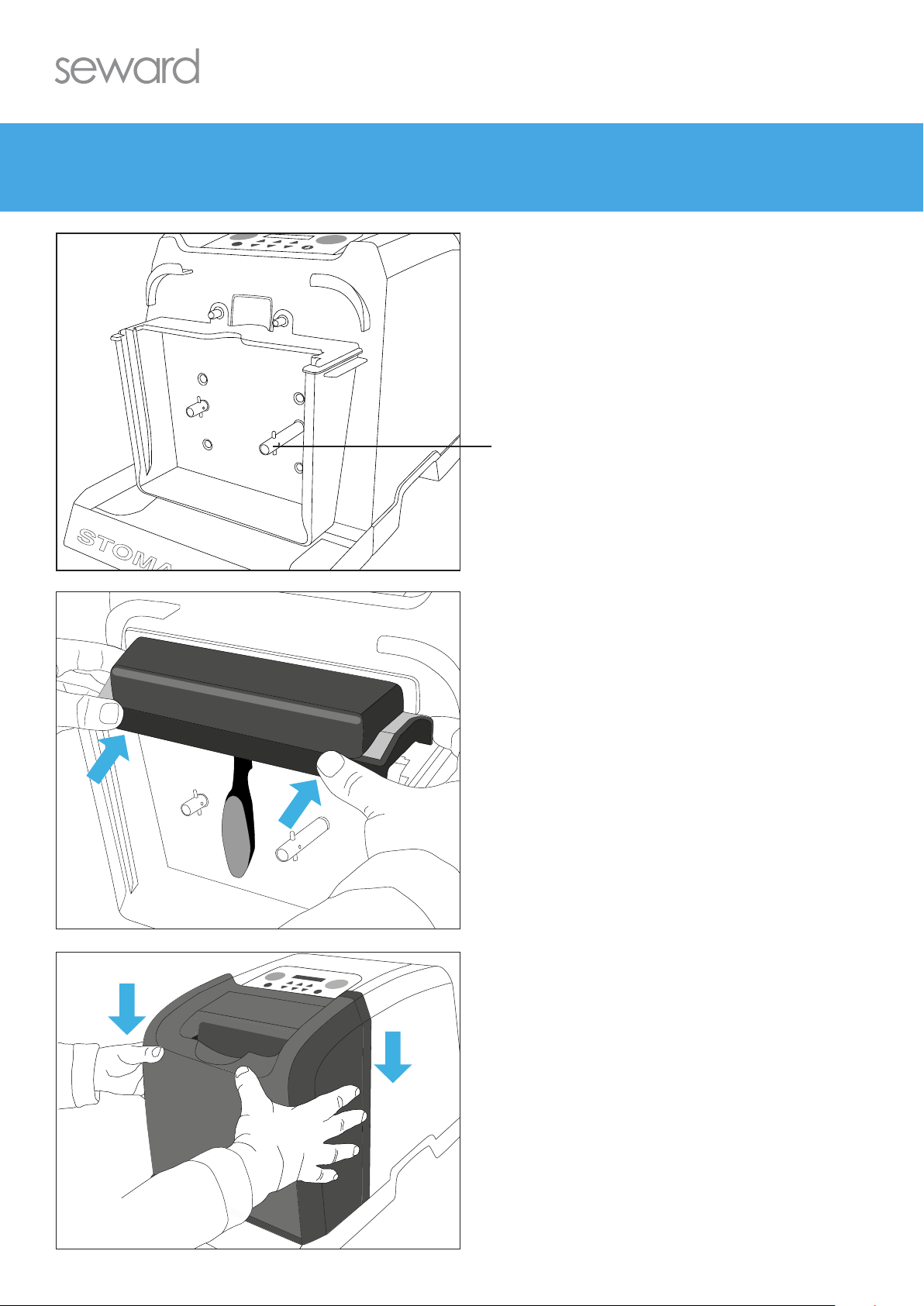

4. Eco bag operation

C

Install small paddles

Install bag seal

Install bag platform and replace

strike plate

World leaders in sample preparation

7

5. Paddle reset

If the paddle shafts prevent the strike plate being

reattached then:

Reattach the bag seal

World leaders in sample preparation

8

C

Reattach the cover

Switch the machine off and on again at the

mains filter outlet

The machine will go through it’s set up processes

including levelling the paddles

Once it has done this, remove the cover,

reattach the strike plate and replace the cover

6. Warnings/Cautions/Guidance

World leaders in sample preparation

9

THIS EQUIPMENT MUST ONLY BE USED IN ACCORDANCE WITH THESE INSTRUCTIONS OR SAFETY PROTECTIONS

MAY BE IMPAIRED

ALWAYS USE THE POWER LEAD SUPPLIED. IF THIS IS REPLACED ENSURE THAT A POWER LEAD OF THE SAME RATING

IS EMPLOYED OR CONTACT THE MANUFACTURER

INSTALLATION QUALIFICATION

ENVIRONMENT AND SITING

Make sure the instrument has been acclimatised after transportation or storage by allowing it to stand 12 hours

at room temperature.

CAUTION to avoid minor injury take care when unpacking and lifting the unit to prevent injury.

Site the instrument on a solid level surface able to take its weight.

Site the instrument with sufficient space at the rear to allow the mains power switch to be accessed and the

power cable to be unplugged.

To isolate the unit switch off the mains power inlet at the rear and unplug the cable.

Only use the machine in areas free from aggressive/explosive chemical mixtures.

This equipment shall be connected to a supply containing a protective earth.

CERTIFIED STANDARDS

This instrument conforms to the following standards and is supplied fully tested by the manufacturer:

EMC Directive 2014/30/EU

Low Voltage Directive 2014/35/EU

Machinery Directive 2006/42/EC

IEC 61010-1:2010 Safety Requirement for Electrical Equipment for Measurement, Control and Laboratory Use

IEC 61010-10-051 ed.3.0(2015-03): Particular requirements for laboratory equipment for mixing and stirring

PAT testing should be carried out by a competent person after installation.

CALIBRATION

Stomacher® is supplied fully calibrated by the manufacturer using equipment traceable to national standards.

Calibration by the user directly following installation is not required.

Following the expiry of the warranty period service packages are available from your authorised dealer or from

Fermionx Limited.

STOMACHER® PROCESS

For best results only use Stomacher® Bag products.

Flammable solvents should NEVER be used in the machine.

Do not overload the machine with bags or load with items that may pierce bags. Contact the manufacturer for

advice on the suitability of samples.

Processing time can be set up to 9 minutes 55 seconds in 5 second increments.

Duty cycle 2 minutes with 45 seconds change over time at full speed.

The Stomacher will not restart after a fault or power interruption.

PERFORMANCE QUALIFICATION

REMOVAL OF THE REAR COVER OF THE MACHINE BY UNQUALIFIED PERSONNEL SHOULD NEVER BE ATTEMPTED.

THERE ARE NO USER SERVICEABLE COMPONENTS INSIDE.

Return to the manufacturer for repair.

Removal of the rear cover will invalidate the warranty.

ROUTINE MAINTENANCE

Wipe casing with damp cloth every month or as required with non-phenolic disinfectant solution. Do not apply

solvents. If in doubt please contact the manufacturer.

Apply mineral oil annually to the paddle shafts.

ERROR MESSAGES

These error messages may appear on the display and this is what they mean and what action should be taken.

“Levelling Error” - paddle level failed, contact the manufacturer.

“Cover Absent”, “Affix Cover” - front cover missing, replace the cover.

“Paddle Motor Error”, “Halting machine” - over current on paddle motor, the machine has stalled because it can

not cope with the load. Remove the bag and reduce the sample. Contact the manufacturer if error persists.

“Seal Error”, “Obstruction” - seal can’t close properly, look inside the paddle chamber to make sure there is no

obstruction and that the seal is mounted properly.

“Seal Error”, “No strike plate” - strike plate missing, replace the strike plate.

“Seal Absent”, “Affix Seal” - seal magnet not detected, check magnet is in position and replace seal.

Warnings/Cautions/Guidance

World leaders in sample preparation

10

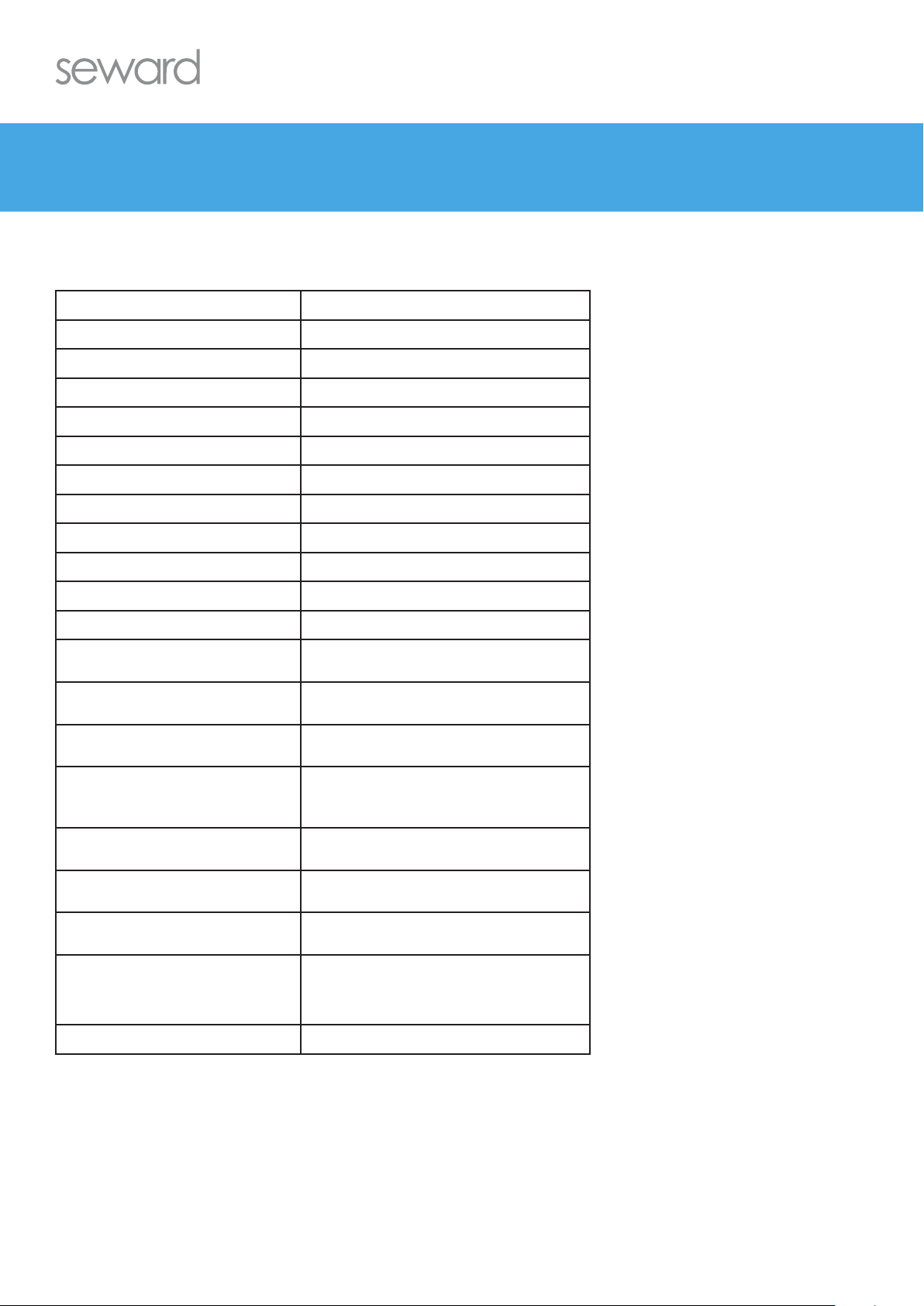

7. Specifications

World leaders in sample preparation

Cat No. 0400/002

Dimensions H300mm x W310mm x D480mm

Weight (unpacked) 18.8kg

Supply voltage 100-240V

Supply frequency 47-63Hz

Max rated power 100W

Plug top fuse F5A (UK chord set)

Mains inlet fuse 1.0A, 250V, anti surge

Insulation Class 1 (Earthed)

Installation Over voltage category II

Pollution Pollution Degree 2

Disposable bag sizes Various

Minimum recommended

capacity 80ml

Maximun recommended

capacity 400ml

Maximum recommended

sample temperature 60° C

Recommended operating

ambient temperature

range

10-40°C

Recommended operating

relative humidity range 10-89%

Recommended maximum

operating altitude 2000m

Timer 9 minutes 55 seconds in 5 second

increments

Paddle speed

Slow - 150 rpm (400 equivalent)

Medium - 180 rpm (400 equivalent)

Fast - 210 rpm (400 equivalent)

Paddle clearance 4mm

11

STOMACHER 400 EVO

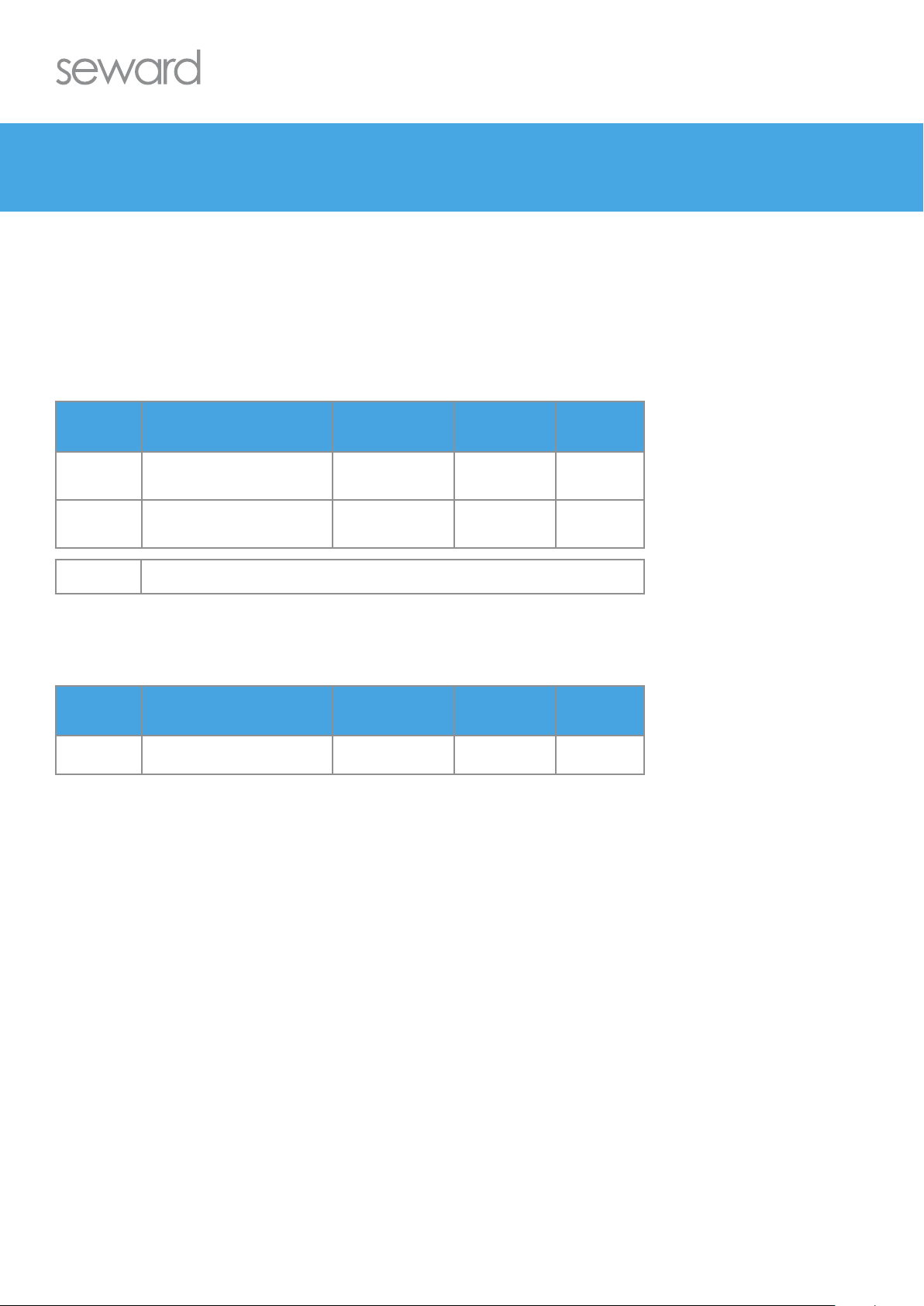

8. Bags & Accessories

World leaders in sample preparation

12

BA6195 Bag opener for Stomacher 400 Eco bags

Contact Seward for further information on our range of products including the

Stomacher® 400 EVO, and see how much you could save on your consumable costs.

Stomacher 400 Eco Bags and Accessories

®

Stomacher 400 Standard Bags

for all Seward Stomacher 400 (EVO, Circulator and Classic)

®

®

for Seward Stomacher 400 EVO only

®

Product

Code

Description Test Volume Dimensions

(mm)

Bags per

pack

BA6241 Stomacher 400 Eco bag

(PATH.)

1:10 PATH Test

(25g:225ml) 177 x 200 500

BA6341 Stomacher 400 Eco bag

(TVC)

1:10 TVC Test

(10g:90ml) 155 x 200 500

Product

Code

Description Test Volume Dimensions

(mm)

Bags per

pack

BA6041 Stomacher 400 Classic

Bag 400ml 177 x 305 500

Full range of Stomacher® bags and accessories available at www.seward.co.uk/stomacher-bags/

®

®

®

®

®

To get the optimum performance from the Stomacher® EVO 400 we recommend that only genuine Seward

Stomacher® bags and accessories as shown in the table below, are used.

Contact Us

World leaders in sample preparation

Seward Limited

Technology Centre

Easting Close

Worthing

West Sussex, BN14 8HQ

United Kingdom

Phone +44 (0)1903 524 600

Email [email protected]

Seward Laboratory Systems Inc. (USA)

155 Keyland Court

Bohemia

NY 11716

USA

Phone +1 631 337 1808

Email [email protected]

Our offices

www.seward.co.uk

Seward is a part of the FermionX Group.

FermionX GmbH

Münstertäler Straße 12

Eschbach

DE-79427

Germany

Email [email protected]

This manual suits for next models

1

Table of contents

Other seward Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Belden

Belden HIRSCHMANN RPI-P1-4PoE installation manual

Koehler

Koehler K1223 Series Operation and instruction manual

Globe Scientific

Globe Scientific GCM-12 quick start guide

Getinge

Getinge 86 SERIES Technical manual

CORNING

CORNING Everon 6000 user manual

Biocomp

Biocomp GRADIENT MASTER 108 operating manual