Sewhacnm AL101S User manual

1

AL101S Steering GearAlarm System

Chapter 0 - Factory default

Chapter 1 - Operation of AL101S series ECR / FWD / AFT

Description of AL101S series keypad

Description of AL101S series lamp

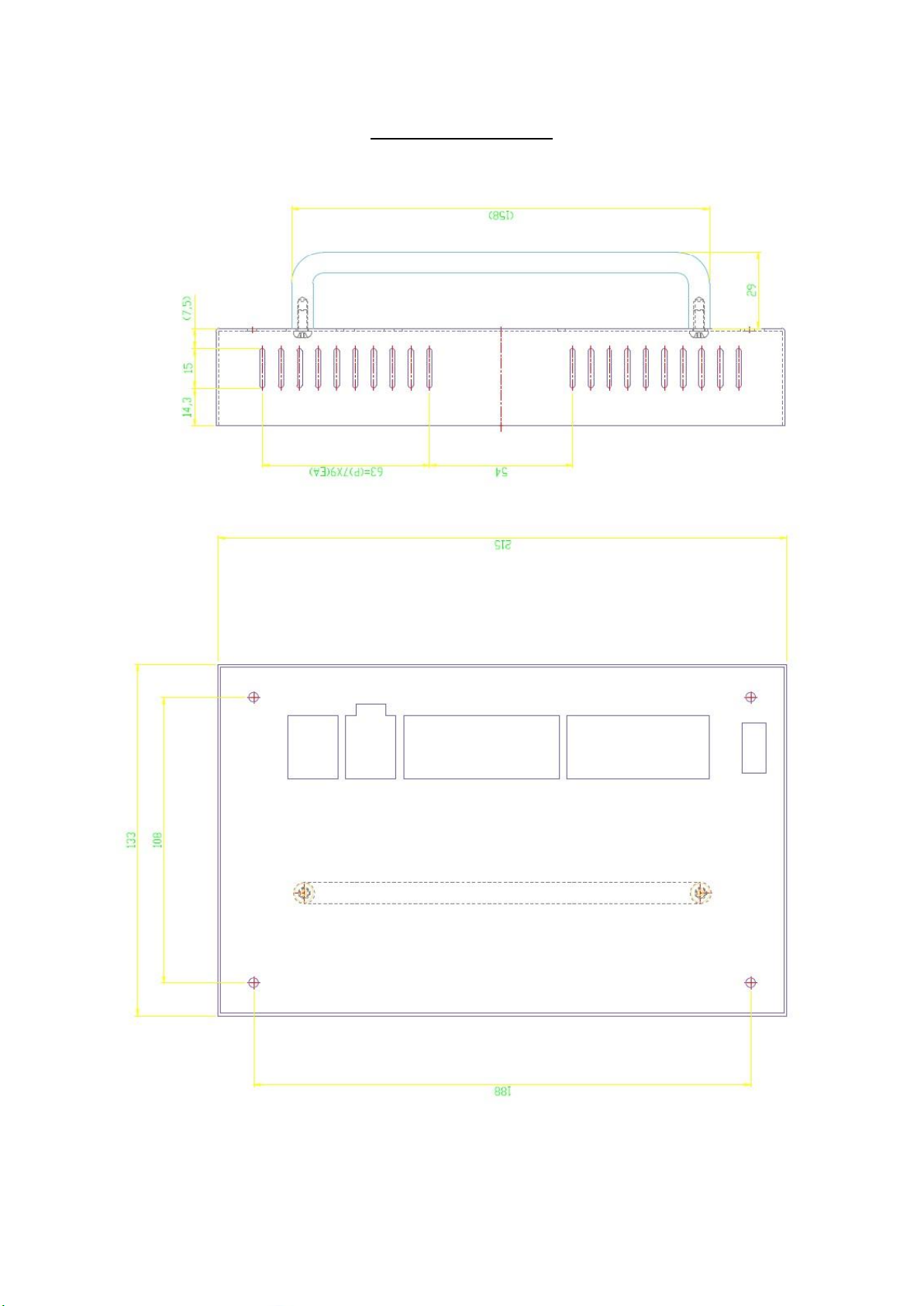

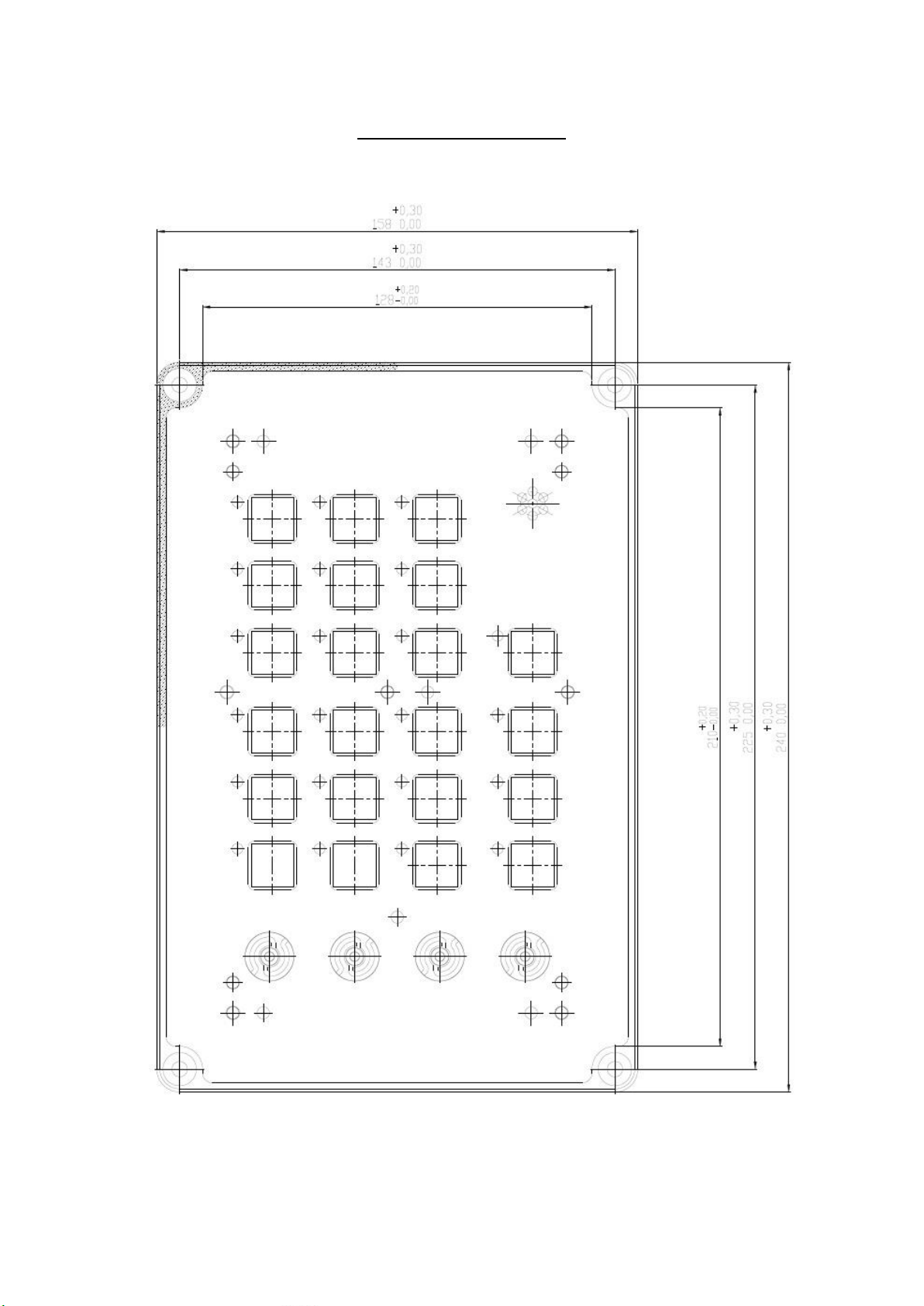

Chapter 2 - Size of AL101S series ECR / FWD / AFT

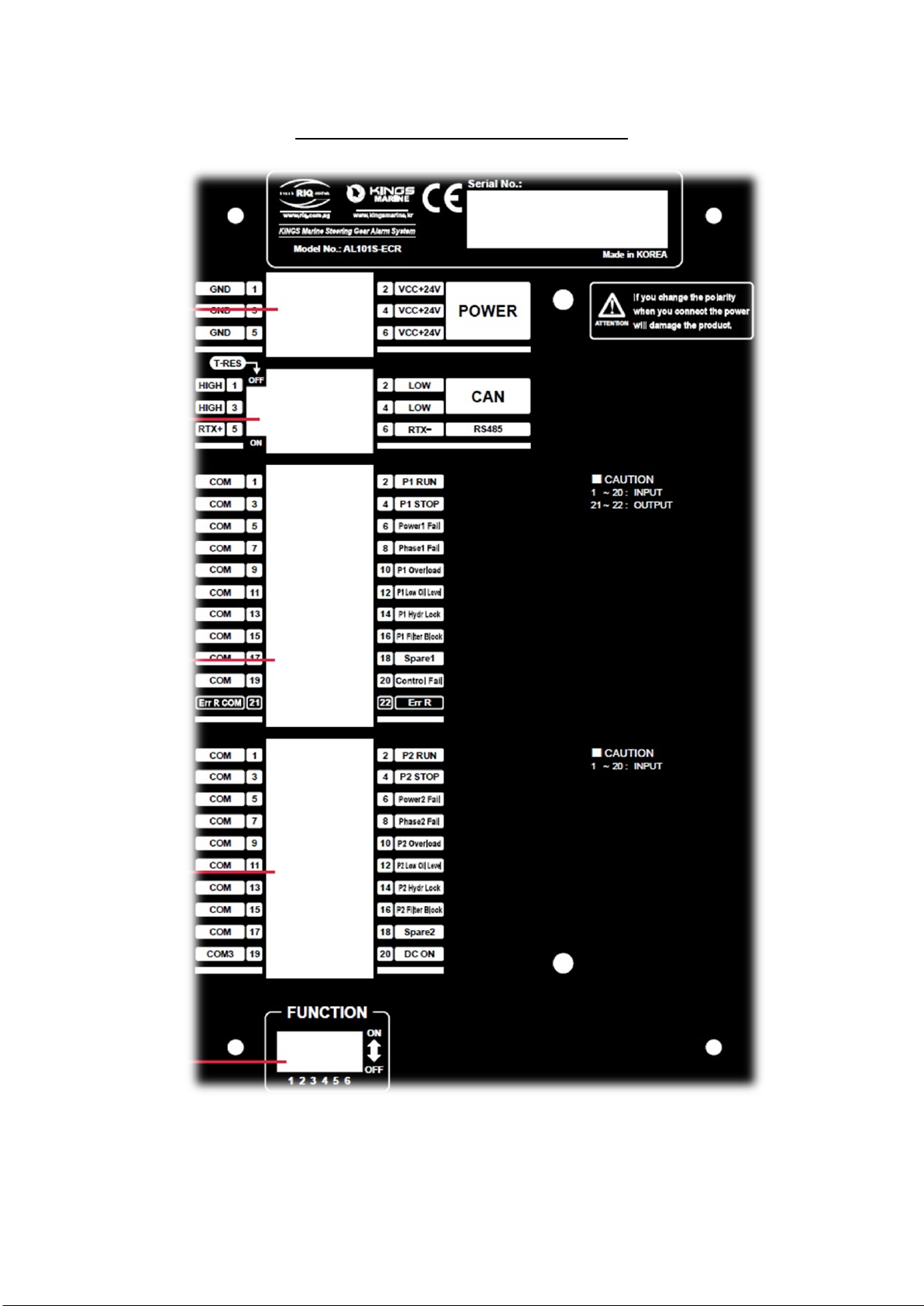

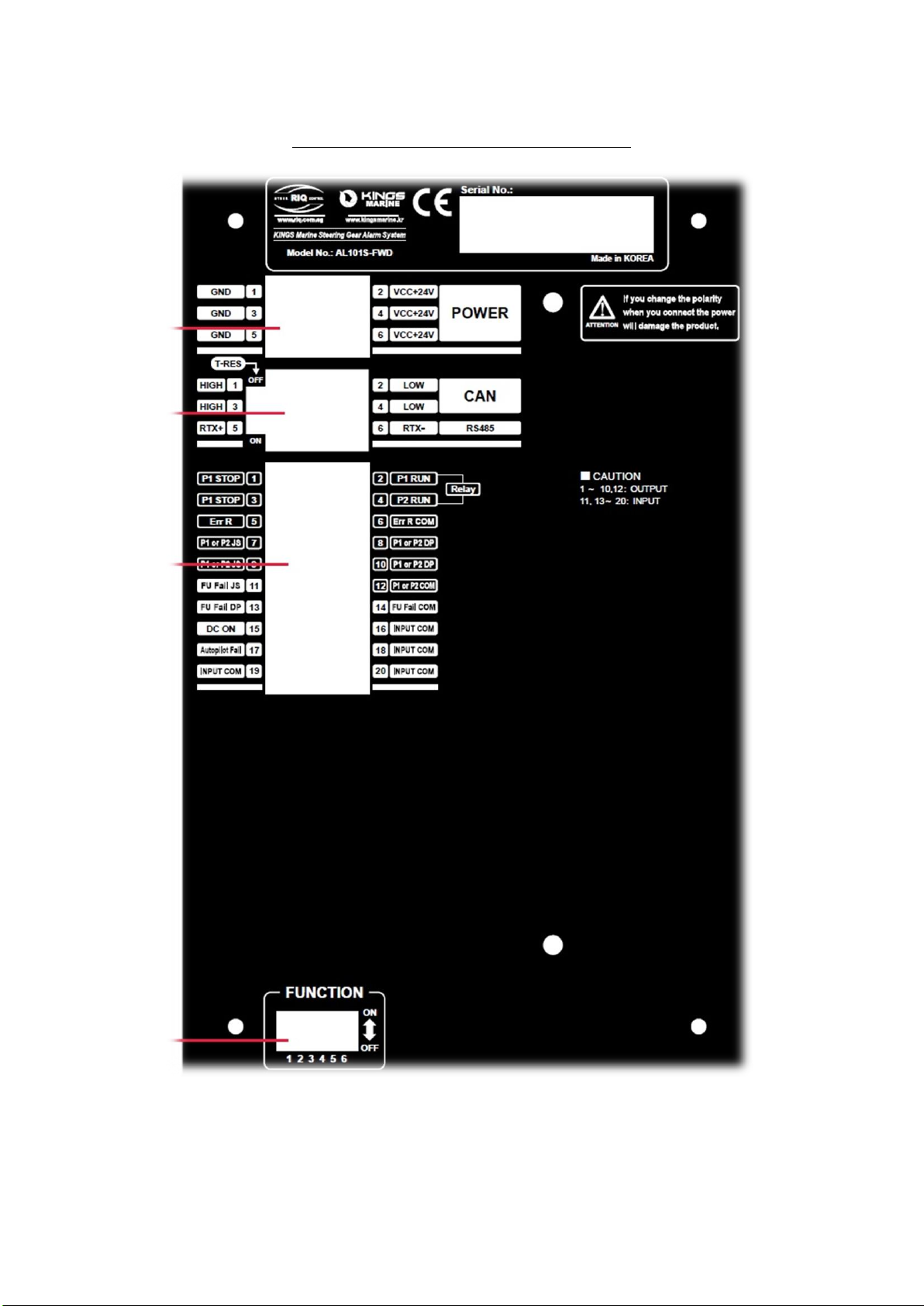

Chapter 3 –Input & Output signal terminal of AL101S ECR / FWD / AFT

Chapter 4 –Test flow chart of AL101S

2

Chapter 0

Factory Default

1. ECR

1.1 Dip Switch

1.2 Resistor Termination ON/OFF switch: OFF

Switch

ON

OFF

Default

1

Operation Mode

Test Mode

ON

2

No DC blinking

DC blinking Available

ON

3

Full Relay output Mode

Half relay output Mode

ON

4

-

-

-

5

-

-

-

6

Operation Mode

Download Mode

ON

3

2. FWD / AFT

1.1 Dip Switch

1.2 Resistor Termination ON/OFF switch: OFF

CAUTION!

ECR / FWD / AFT Relay output mode(Full / Half) run independently.

Switch

ON

OFF

Default

1

Operation Mode

Test Mode

ON

2

No DC blinking

DC blinking Available

ON

3

Full Relay output Mode

Half relay output Mode

ON

4

-

-

-

5

-

-

-

6

Operation Mode

Download Mode

ON

4

AL101S Steering GearAlarm System

Chapter 1

ECR / FWD / AFT

Operation

5

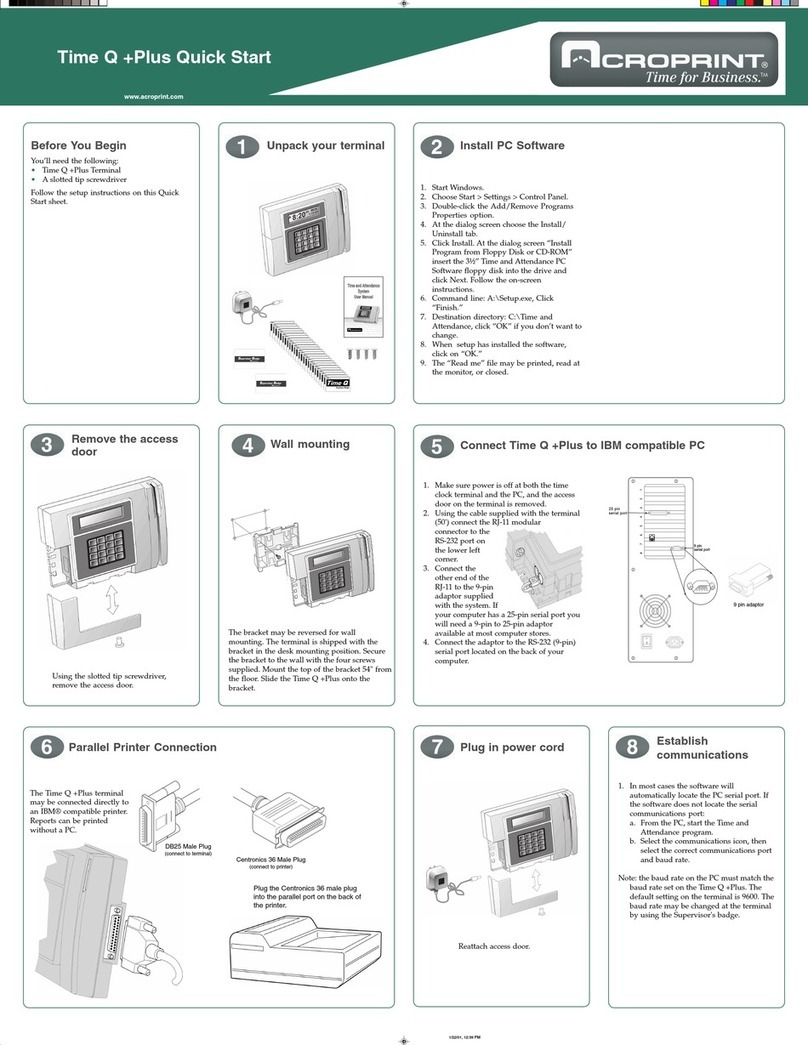

AL101S-ECR

AL101S-FWD

AL101S-AFT

6

AL101S-FWD

7

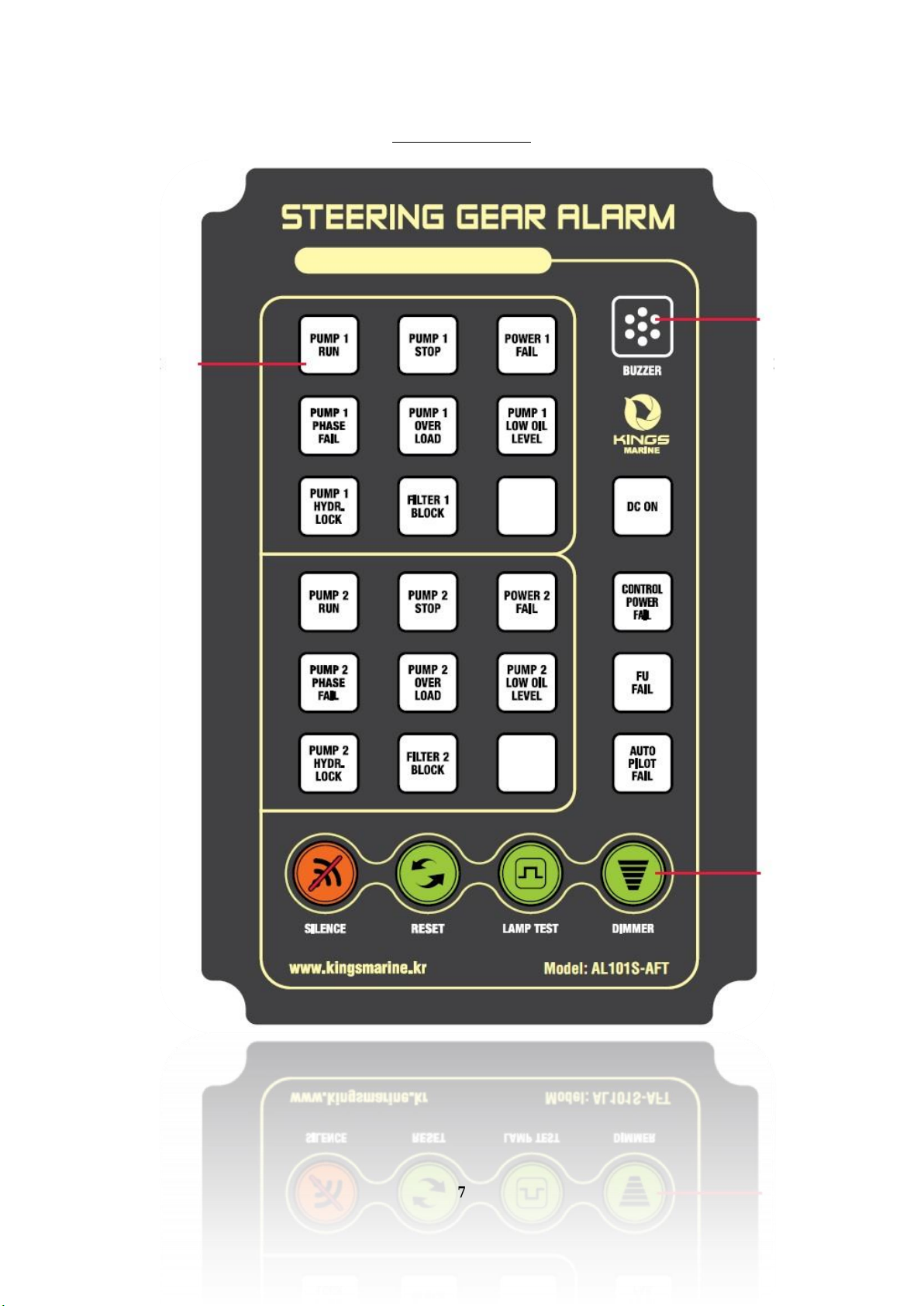

AL101S-AFT

8

1) SILENCE Key

This key able to maintain to each lamp’s activation or deactivation

After buzzer has activation, this key able to stop to buzzer sound

CAUTION!

If setting Dip Switch “3”setting done ON, relay output will be working full mode.

Meanwhile if setting Dip switch “3”OFF relay output will be working half mode

2) RESET Key

This key able to re-boot to all lamp’s activation and deactivation.

Press this key then press SILENCE Key again to maintain to each

lamp’s activation and deactivation. Or check buzzer sound activation

9

3) LAMP TEST Key

This key able to all LAMP ON even each lamp has activation or deactivation

This key check to LAMP itself working.

If on pressing this key both of activation and deactivation lamp ON at once.

Then if release this key the deactivation lamp will be OFF

4) DIMMER Key

This key able to adjust to LAMP brightness

Brightness has total 5 steps.

10

Description of AL101S-ECR/FWD/AFT LAMP

1) FU FAIL LAMP

Input signal “1”second later LAMP activate

2) PUMP HYDR. LOCK LAMP

Input signal “1”second later LAMP activate

3) PHASE FAIL LAMP

Input signal “2”second later LAMP activate

4) PUMP LOW OIL LEVEL LAMP

Input signal “3”second later LAMP activate

5) DC ON LAMP

Depend on input signal LAMP will be activate to “RED”or “GREEN”

(Please see the chapter 3 Input & output signal terminal)

CAUTION!

Except above FU FAIL / PUMP HYDR. LOCK / PHASE FAIL /

PUMP LOW OIL LEVEL these “4”kind LAMP, the other all

LAMP will be activate once it input signal activate.

11

AL101S Steering GearAlarm System

Chapter 2

ECR / FWD / AFT

Case size

12

Cut hole dimension

13

Fontal case dimension

14

AL101S Steering GearAlarm System

Chapter 3

ECR / FWD / AFT

Input & output signal terminal

15

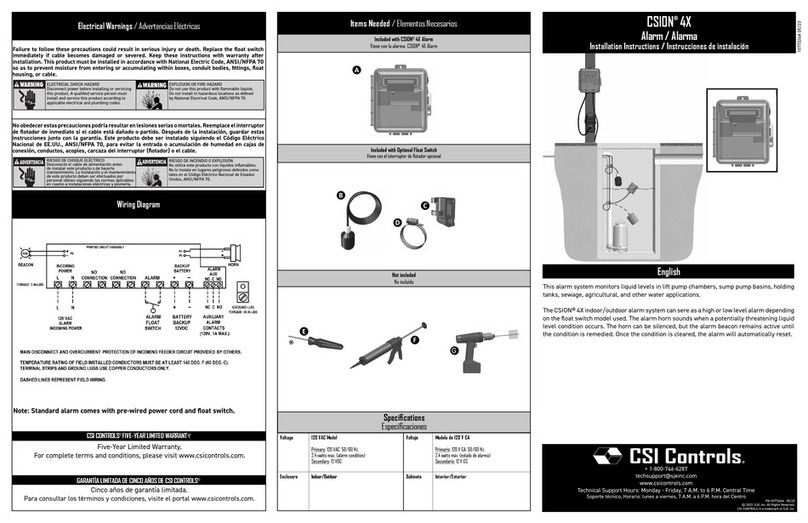

ECR input & output signal terminal

16

FWD input & output signal terminal

17

AFT input & output signal terminal

18

AL101S Steering GearAlarm System

Chapter 4

Test flow

19

4.1 Purpose

: This alarm testing procedure is to check and confirm that the alarm system is

working and meet the design requirement.

4.2 Testing Procedure

4.2.1 Connect the FWD, AFT & ECR panel as single line drawing.

4.2.2 Connect ECR panel to external alarm signals. The alarm signal can be turned off

And on by a toggle switch. The signal is +24V DC. Put the switches in off position

for all the alarm signals before testing.

4.3 Lamp test: Press the lamp test button, all the lamps on the panel should be on.

4.4 Dimmer test: When the lamp test button is pressed, press the dimmer button and the

bright level will be change accordingly.

4.5 Individual alarms and indications test

DC ON

Step 1: Provide +24V DC at the FWD alarm panel input terminal+.

Step 2: DC ON indicator Green light is on all the panels.

Step 3: No alarm activated.

Step 4: Remove the input signal at +

Step 5: The indicator light color changes to Red and alarm activated.

Step 6: check output signal to other equipment at ECR panel when alarm activated

AUTOPILOT FAIL

Step 1: Close AUTOPILOT FAIL contact at the FWD panel input.

Step 2: Autopilot fail indicator Red light is blinking for all the panels.

Step 3: Buzzer sound.

Step 4: Press the Silence button, the autopilot fail indicator light is steady in Red and

Buzzer is off.

Step 5: Press the alarm reset button, the buzzer sound again and indicator is blinking

again

Step 6: Repeat Step 4.

Step 7: Cut off theAUTOPILOT FAIL contact, the autopilot fail indicator is still on

Step 8: Press alarm reset button again, theAutopilot alarm indicator light off.

Step 9: Check out signal to other equipment at ECR panel when alarm activated.

FU FAIL

Step 1: Close FU FAIL contact at the FWD panel input

Step 2: FU FAIL indicator light is blinking for all the panels.

Step 3: Buzzer sound.

Step 4: Press the silence button, the FU FAIL indicator light is steady and buzzer is off.

Step 5: Press the alarm reset button, the buzzer sound again and indication is blinking

Step 6: Repeat Step 4 .

Step 7: Cut off the FU FAIL contact, the autopilot fail indicator is still on.

Step 8: Press alarm reset button again, the alarm indicator light off

Step 9: Check out signal to other equipment at ECR panel when alarm activated

20

Step 1: Close PUMP 1 RUN switch

Step 2: PUMP 1 RUN indicator light ON

Step 3: Buzzer not on.

Step 4: Open the PUMP 1 RUN switch

Step 5: Indicator light off

Step 1: Close PUMP 1 STOP switch

Step 2: PUMP 1 STOP indicator light on

Step 3: Buzzer not on.

Step 4: Open the PUMP 1 STOP switch

Step 5: Indicator light off

PUMP 2 RUN & STOP

-To repeat PUMP 1 RUN & STOP test.

POWER 1 FAIL

Step 1: Provide + 24V DC to the ECR input terminal at P4A

Step 2: POWER 1 FAIL indicator light is blinking for all the panels.

Step 3: Buzzer sound.

Step 4: Press the silence button, the POWER 1 FAIL indicator light is steady and buzzer is off

Step 5: Press the alarm reset button, the buzzer sound again and indicator is blinking again

Step 6: Repeat Step 4.

Step 7: Stop supply +24V DC to the terminal input, the power 1 fail indicator is still on.

Step 8: Press alarm reset button again, the alarm indicator light off.

Step 9: Check out signal to other equipment at ECR panel when alarm activated.

*All the other alarm testing has the same testing procedure as POWER 1 FAIL test procedure.

TIME DELAY TEST

LOW OIL LEVEL: 3 second

HYDRAULC LOCK: 1 second

PHASE FAIL: 2 second

FU FAIL: 1 second

*The testing steps are same as POWER 1 FAIL.

Step 1: Provide alarm input signal to the respect alarm input terminal.

Step 2: Count the time between signal input and alarm activate.

Step 3: Compare the time between the setting an count.

Step 4: The time delay setting and count should follow the setting time

PUMP 1 RUN

PUMP 1 STOP

Table of contents

Other Sewhacnm Security System manuals