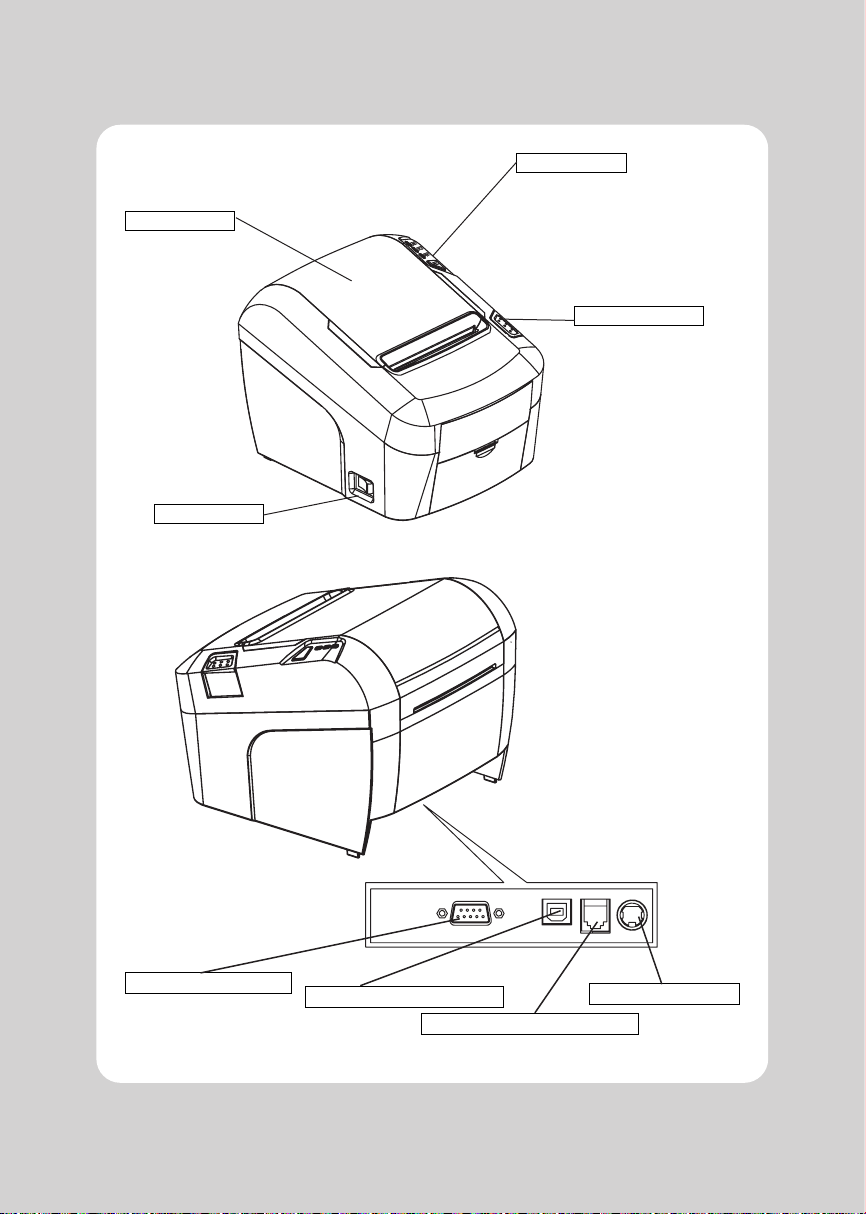

SEWOO SLK-TL32X Series User manual

This manual suits for next models

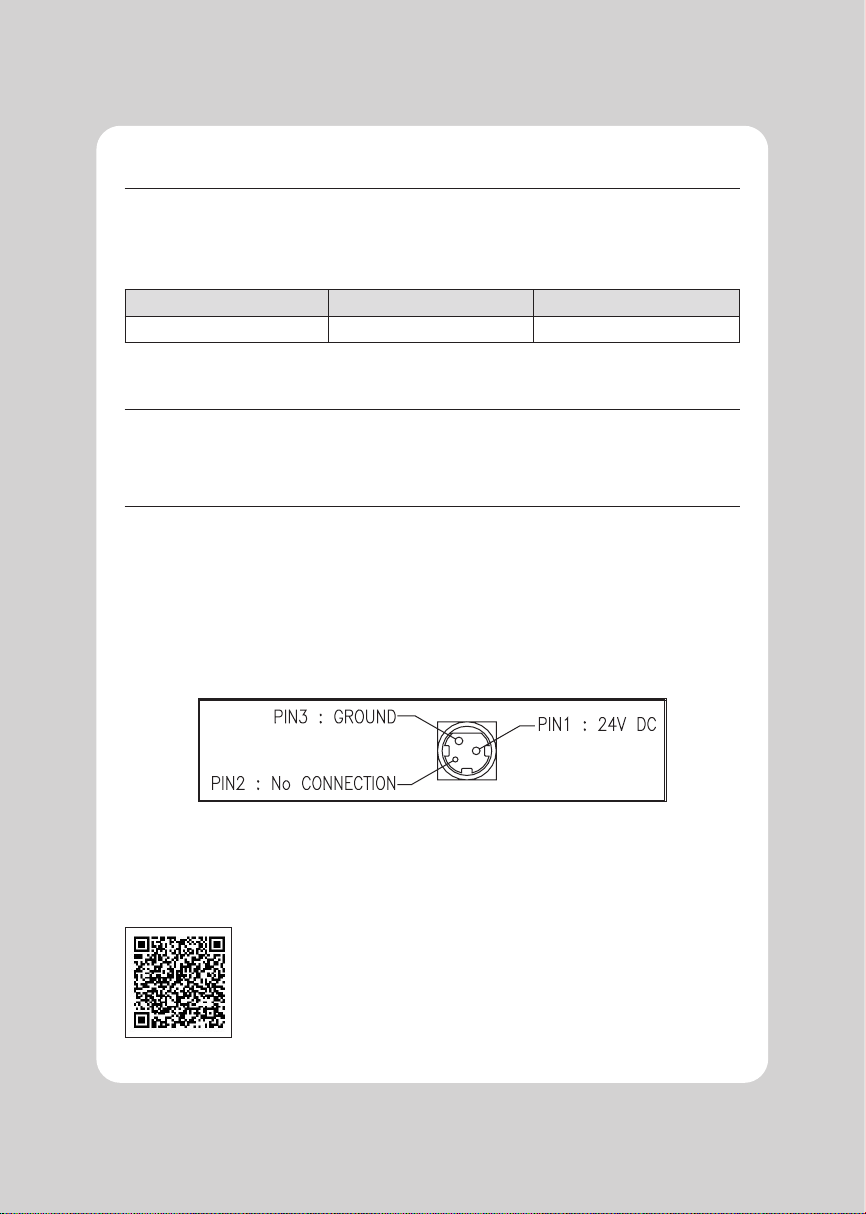

3

Table of contents

Other SEWOO Printer manuals

SEWOO

SEWOO SLK-T32EB Series User manual

SEWOO

SEWOO LK-P30B User manual

SEWOO

SEWOO SLK-TL122 User manual

SEWOO

SEWOO LK-P22 User manual

SEWOO

SEWOO LK-P12 User manual

SEWOO

SEWOO LK-P34 User manual

SEWOO

SEWOO WTP-100 User manual

SEWOO

SEWOO SLK-TE21 Series User manual

SEWOO

SEWOO SLK-T32EB II User manual

SEWOO

SEWOO SLK-T12EB User manual

SEWOO

SEWOO LK-P11B User manual

SEWOO

SEWOO LK-P43II User manual

SEWOO

SEWOO LK-T41 User manual

SEWOO

SEWOO SLK-TS400 Instruction Manual

SEWOO

SEWOO SLK-TS100 User manual

SEWOO

SEWOO SLK-TE25 User manual

SEWOO

SEWOO LUKHAN LK-P21B User manual

SEWOO

SEWOO LK-P21 User manual

SEWOO

SEWOO SLK-TS400 User manual

SEWOO

SEWOO LK-P400 User manual

Popular Printer manuals by other brands

Brother

Brother DCP-7030 user guide

Epson

Epson PictureMate Show - PM 300 - PictureMate Show Digital... user guide

Canon

Canon imagePROGRAF iPF765 Specifications

MUTOH

MUTOH Rockhopper II Series Maintenance manual

Canon

Canon iP1700 - PIXMA Color Inkjet Printer quick start guide

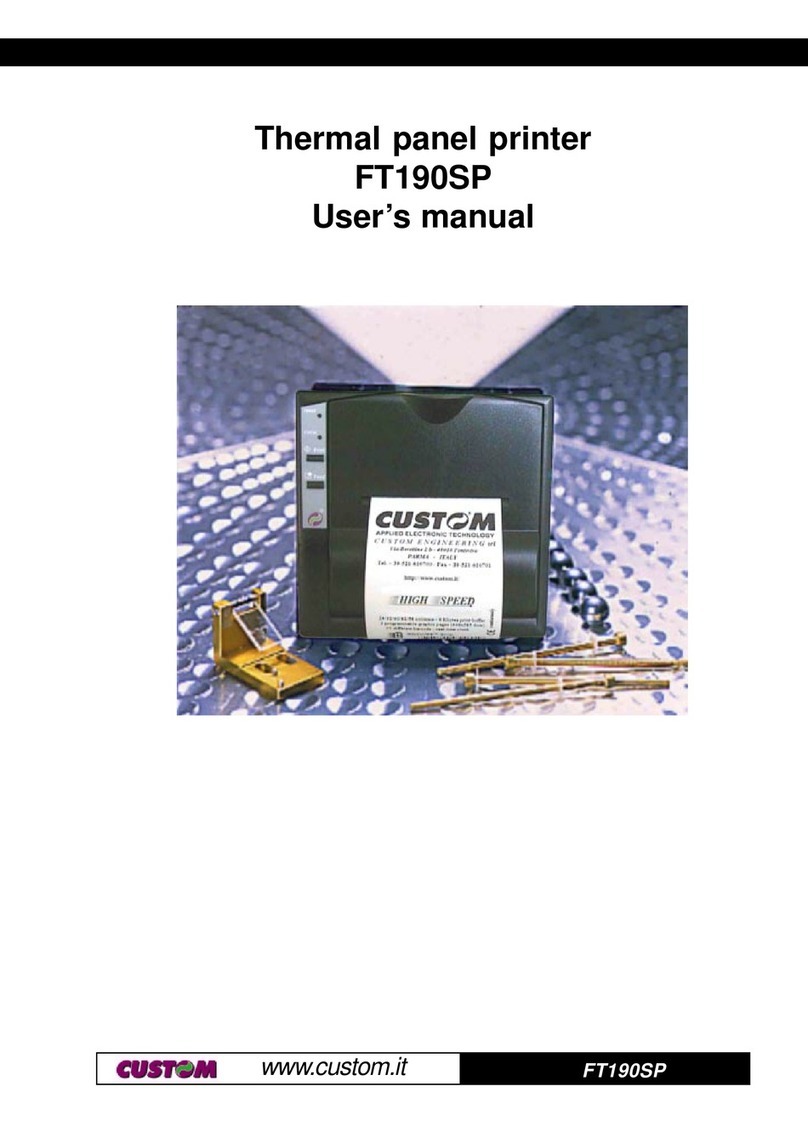

Custom Audio Electronics

Custom Audio Electronics FT190SP user manual