SF SF-H67P User manual

SF-H67P/H52P

SF-67P/52P

Operation Manual

1

Warning: This kind of machine is allowed to cut printed paper, books or soft leathers only. It is

forbidden to cut any metal sheets or other hard objects which do harm to the machine quality.

Children must not operate this machine.

Do not reach beneath the blade.

Do not extract or transport the materials or blade

without protection.

2

Note: Please read this manual carefully before use the machine. It will help you improve the

work efficiency, bring into play the function of the machine, prolong the service life of the

machine.

Do not cut hard materials or materials which may

splinter.

Paper clips or hard materials will damage the

cutting blade.

3

Safety Cautions

According to relevant standards, to avoid accident and injury, only professional operator

is allowed to operate this machine(children or non-professional operators are forbidden to use).

When you use or maintenance these machines, please pay high attention to safety cautions

below:

Handling and Placement

As the machine is heavy, please handle it carefully and put it horizontally on the

clean ground.

Power

The power source should be steady 380V/220V+10 %, 50Hz, 2.5-3.5KW.

Machine may run irregularly if the voltage is too high or too low. We suggest you

use alternating current(AC) power source with steady voltage to improve work

efficiency.

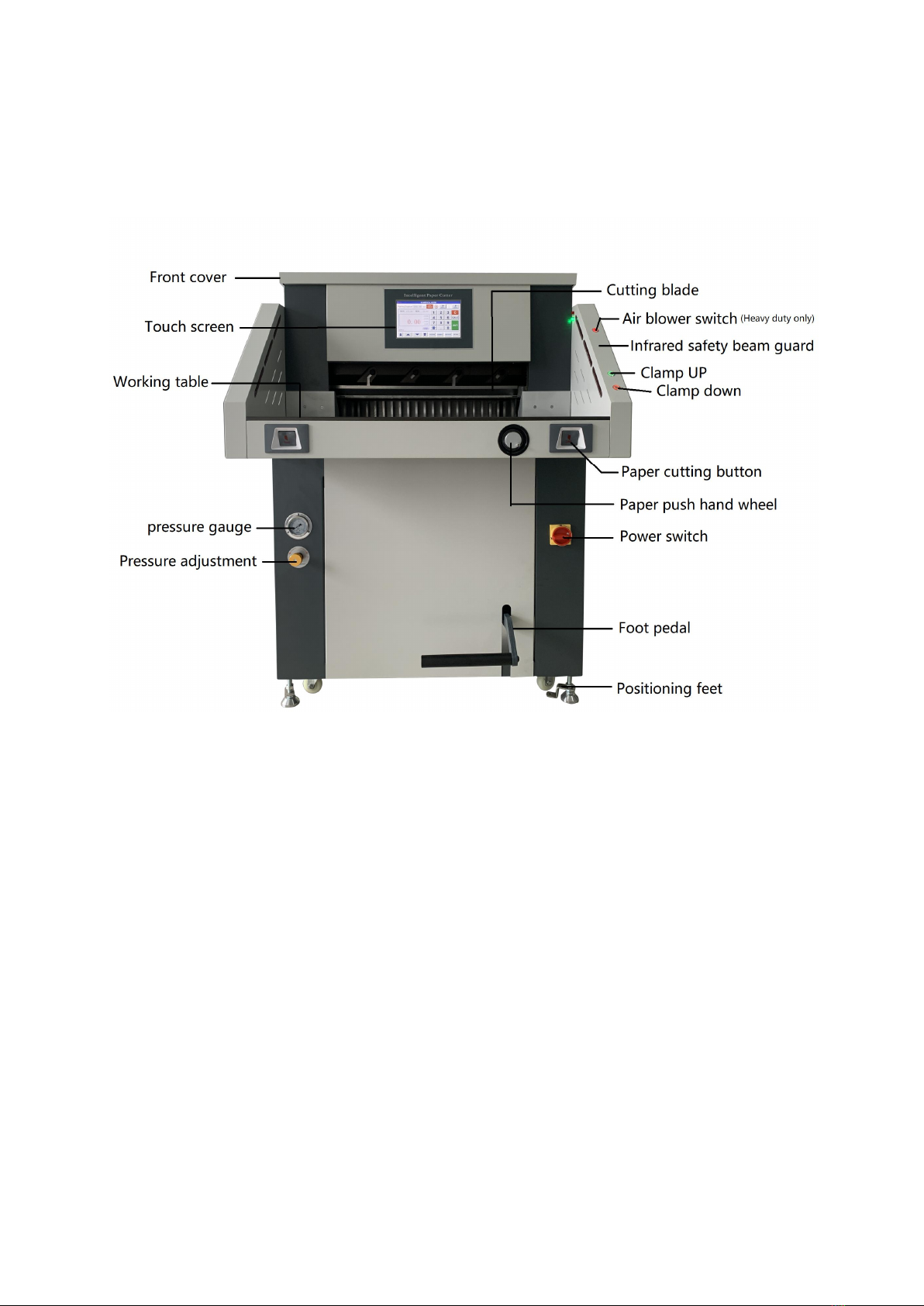

Ground connection

For safety you should use electric supply socket with ground wire connected.

Power overload

Please do not connect many electric equipment at one socket. It is dangerous and

may cause fire or electric shock.

Maintenance

Must turn off the power and remove the power plug before you clean or

maintenance the machine.

Waterproof

Prevent water or other liquid flow into machine inner side.

4

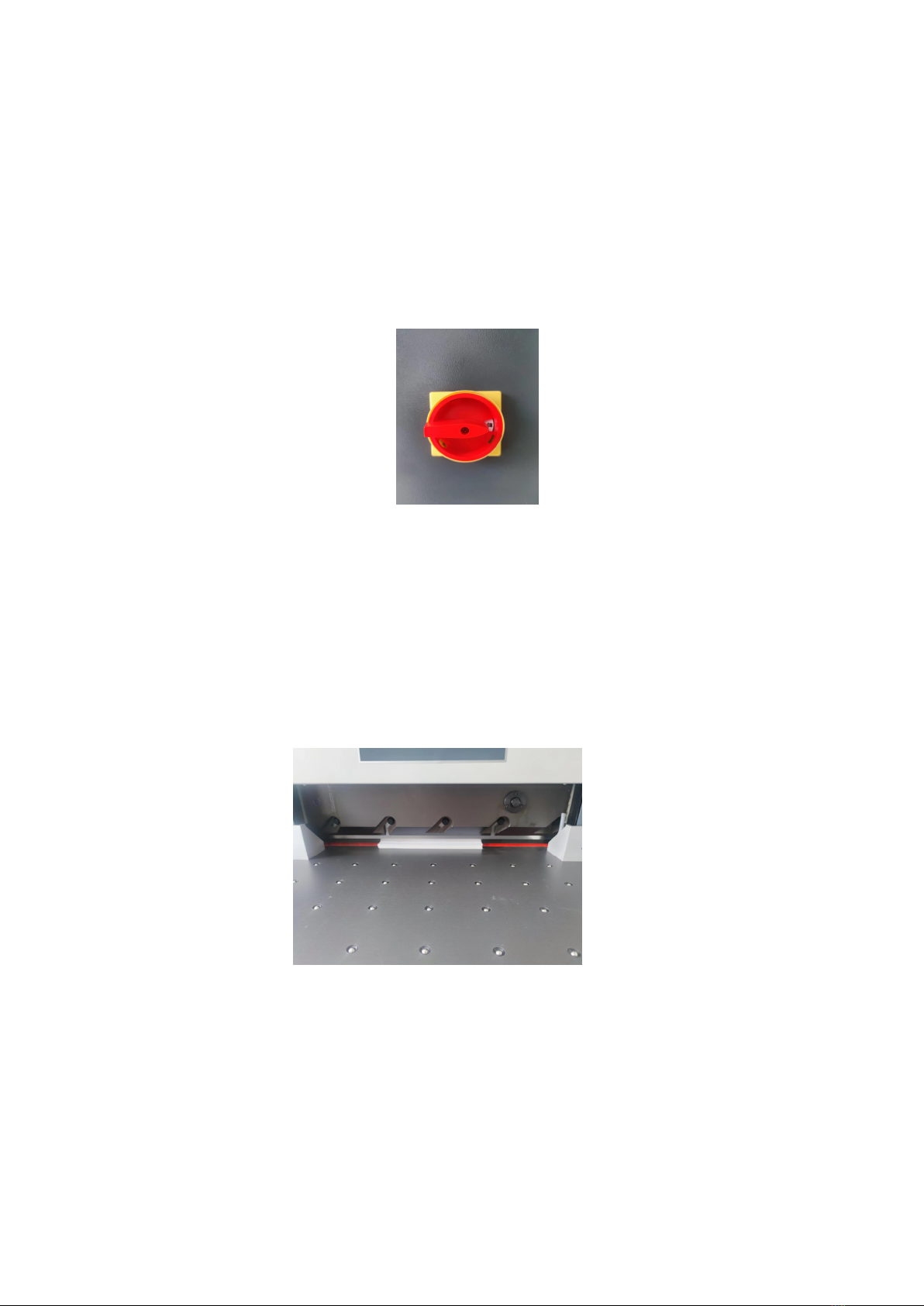

Must use socket with ground wire connected.

Leakage protection switch, non-professional person is

not allowed to open, avoid dangerous.

QC670BC/QC520BC Electrical control cabinet

SF-H67P/SF-H52P Electrical control cabinet

5

Content

Warning.......................................................................................................................................1

Safety Cautions...........................................................................................................................3

Chapter I Safety cautions before installation...........................................................................6

1. Check machine ……………………………………………………............................6

2. Settlement of the machine………………………………………………………........6

3. Environmental conditions…………………………………………………………....6

4. Special suggestion…………………………………………………………………....7

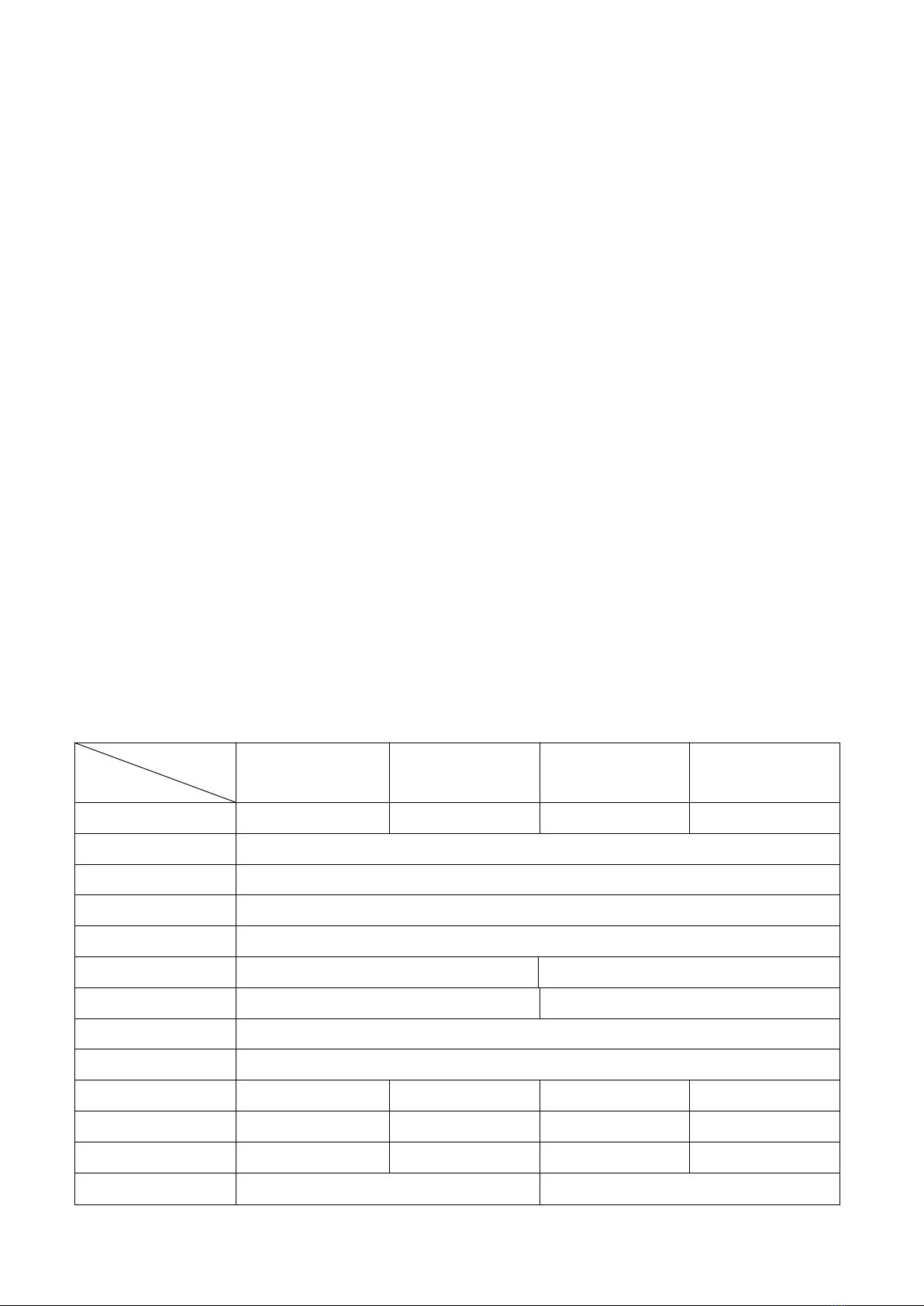

Chapter II Brief instruction of the paper cutter......................................................................8

1. Parts description……………………………………………………………………...8

2. Performance features………………………………………………………………...8

3. Principal technical parameter………………………………………………………...9

4. Operating the cutter………………………………………………………………......9

4-1 Operating button and functions …………………………………........................9

4-2 Operation for the touch screen...................................…………..........................10

Chapter III Basic operation and adjustment.........................................................................12

1. Basic operation...........................................................................................................12

1-1 Turn on the machine............................................................................................12

1-2 Operation instruction...........................................................................................12

2. Basic adjustment.........................................................................................................13

2-1 Cutting depth adjustment......................................................................................13

2-2 Blade replacement................................................................................................14

2-3 Cutting stick adjustment.......................................................................................15

2-4 Clamping pressure adjustment.............................................................................15

2-5 Hydraulic system troubleshooting........................................................................15

Chapter IV Lubrication and maintenance.............................................................................16

1. Lubrication...................................................................................................................16

2. Maintenance.................................................................................................................16

Chapter V General failures and troubleshoot........................................................................17

6

Chapter I Safety cautions before installation

1. Check machine

When you open the package of the machine, firstly please check the machine with relevant

accessories. Please contact the dealer if there is any damage or shortage.

1Machine 1 set

2Operation Manual 1 set

3Tool 1 set

4Maintenance warrant 1 piece

5Cutting blade 1 piece

6Cutting stick 1 piece

7Discharge blade rod 2 pieces

2. Settlement of the machine

8Open the wooden case, take out the machine’s packaging and discharge fixed screws

on the base plate of the main machine; The hydraulic machine should be unloaded by forklift.

Fixing screws

Check the packing list is complete or not.

Check all the parts of machine and clean them.

3. Environmental conditions

The machine should be placed in clean working environment, keep away from

direct sunlight and wind;

Temperature of the operating environment: 10-30℃, can not higher than 32℃;

Humidity level of the operating environment: 50-80%;

Power supply:380V/220V+10%, 50-60Hz, 2.0-3.0KW;

Connect the ground wire correctly.

7

4. Special suggestions

Remember only one professional operator is allowed to work on the machine;

When your hands or other things into the cutting area, turn off the power

immediately;

Two hands operation is needed;

Please do not disassembly infrared safety cover;

When replace cutting blade, you should firmly comply with the blade replace

instruction;

You are not allowed to re-equip the inner construction and circuit of the

machine by yourself.

8

Chapter II Brief instruction of the paper cutter

1. Parts description

2. Performance features

◆Standard models

1. Steel knife holder

2. Ductile iron adjustment plate

3. Aviation aluminum hard anodized platform

4. Double ball screw and double guide rail

5. Stepping closed-loop motor to push paper, 0.28KW

6.10 inch touch screen

7. Enclosed safety photoelectric, 15 channels

8. Mechanical pedal

9.220V, single-phase, 2.2KW motor, with silent oil pump

10. Dual hydraulic system

11. Optional air pump

9

12. Optional auxiliary platform

◆Heavy duty models

1. Thickened beam

2. Aluminum hard anodized tool holder

3. Wear-resistant nylon adjustment plate

4. Thicken and increase the column

5. Thicken the bottom plate

6. Aviation aluminum hard anodized platform

7. Double ball screw double guide rail

8. Servo motor push paper, 0.4KW

9.10 inch touch screen

10. Enclosed safety photoelectric, 15 channels

11. Mechanical pedal

12.220V, single-phase, 2.2KW motor input, with inverter, to 380V, three-phase output

13. Dual hydraulic system

14. Configure the air pump

15. Optional auxiliary platform

3. Principal technical parameter

SF-H67P SF-H52P SF-67P SF-52P

Max cut width (mm) 670 520 670 520

Min cut depth (mm) 30

Max cut height (mm) 80

Cut accuracy (mm) 0.2

Clamp and cut system Hydraulic + Foot pedal

Back gauge control Servo motor+Programmable Stepper motor+Programmable

Air table Yes No

Display mode 10 inch touch screen

Safety protection Enclosed safety photoelectric, 15 channels

Power supply 220V, 50-60Hz, 2.6Kw 220V, 50-60Hz, 2.2Kw 220V, 50-60Hz, 2.4Kw 220V, 50-60Hz, 2.0Kw

Dimension (W*D*H) 1450x1150x1470mm 1300x1000x1470mm 1430x150x1460mm 1280x1000x1460mm

Net weight (kg) 465 415 405 355

Blade carrier material Aluminum hard anodized blade carrier Steel blade carrier

10

4. Operating the cutter

4-1 Operating button and functions

Wired up, turn the power switch “ON”. Screen and cut position light work, back gauge

reset automatically, which means the machine is ready for working.

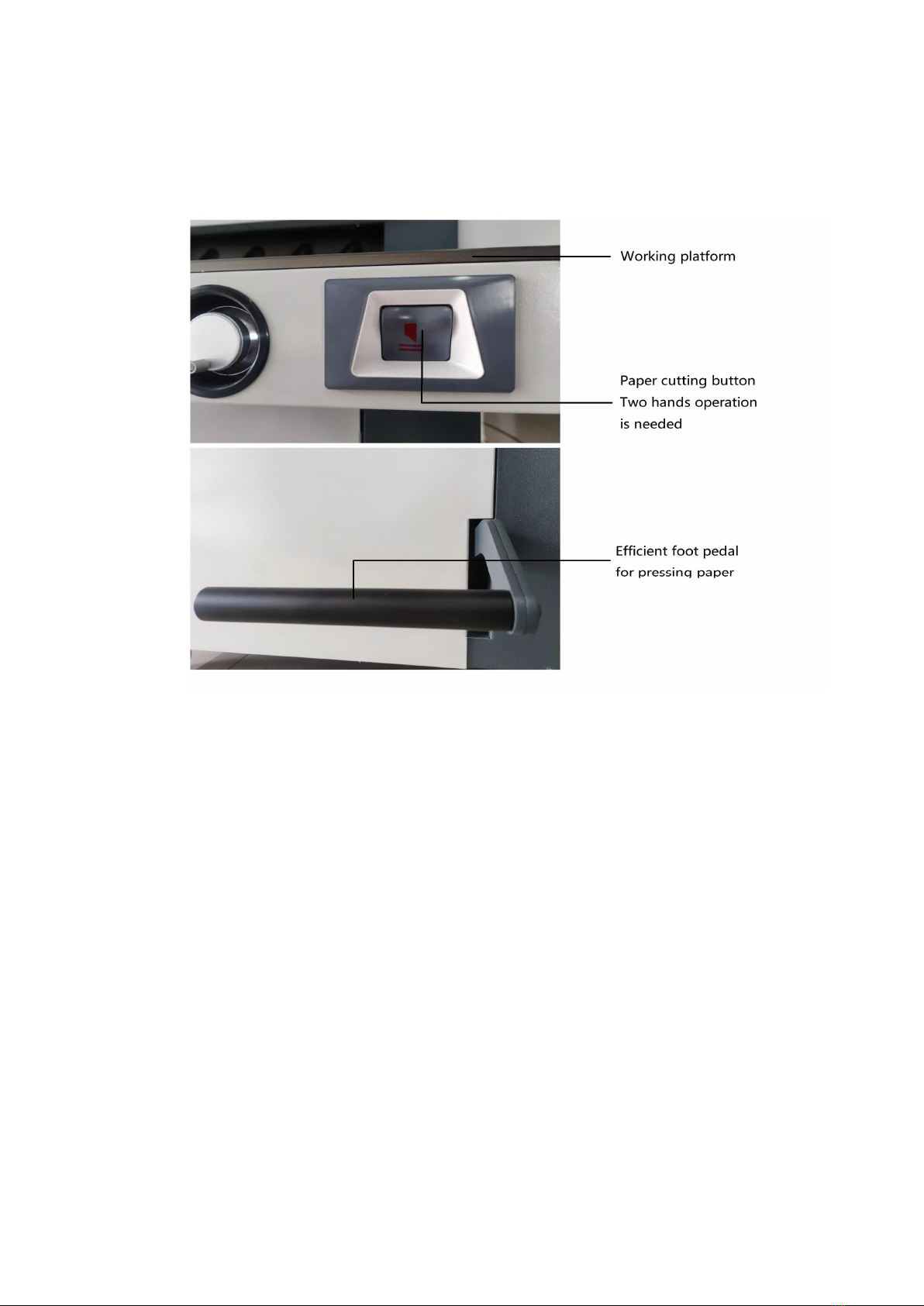

Operate Way: Stand in front of the machine, with both hands pressing two CUT Buttons

at same time. (or downward the foot pedal for clamping make sure cutting position is

accurate, then cut the papers) As shown:

11

4-2 Operation for the touch screen

4-2-1 Touch screen

1. Numerical mode

Enter the number you want, press “ENT”, the back gauge will go to the position you want

and machine gets to cut, for example, if you want to cut a length of 270.50, enter the number

270.5 in the touch screen and press “ENT” will make the back gauge go to this dimension

and ready for work.

2. Program mode:

100 programs , with 30 steps each. On touch screen, it is production number, production

model, number of segments. For A3 paper, you can set the first step to be 297, press

“ENTER” to confirm, then set the second step to be 422, press “ENT” to confirm, for the

third step to be 420, press “ENT” to confirm, select 3 in the numbers of segments. It means

this production you have 3 lengths can be set, then press “ENT” to get machine to cut. In

program mode, there is a PUSH key, when it is available, the machine will push the paper 15

cm forwards after each cut (for customers to take out the paper easily). To cancel the

function, press the PUSH key then it will be invalid.

12

3. Segment mode

4 parameters to be set: the max length, first length, the second length and third length.

Set the max length same with current size.

After setting the max length, another three lengths can be set: for example, the first one is

10mm, second one is 20mm, the third one is 25mm. As it is, the machine can cut one by one

until the paper left is less than 30mm( Minimum cut depth ia 30mm ), the back gauge will be

back to the original position you set and gets to do next cuts repeatedly. It means the cutter

will cut the papers for 10mm, 20mm, 25mm step by step repeated.

4-2-2 System setting

1. Cutting depth

When customers want to cut, if there is one or two papers in the bottom can not be cut

completely, you can adjust the cutting depth, there are totally 64 positions to be set. The

bigger number set, the deeper cutting does.

2. Original position ( Start position ) set

When the paper cut dimension is different from the display dimensions, you can adjust the

number to fix it

For example, the cut paper dimension is 110 mm, while it shows 120 mm on the display. Enter

110 in the size calibration box to complete the size calibration

4-2-3 Exchange between mm and inch

In display, when the paper size is 152.5mm, press the number for inch, same way for change

from inch to mm.

13

Chapter III Basic operation and adjustment

1. Basic operation

1-1 Turn on the machine

◆Make sure there is nothing else but the papers to be cut, clean the machine firstly;

◆Plug the machine to socket for 380V/220V +/- 10%, 50Hz, 4Kw;

◆Turn on the electric control, turn the main power to “ON” position, screen is on, light of

the machine is on, means it is ready for work.

1-2 Operation instruction

1) Electronic wheel use. Clockwise rotation makes the back gauge move forwards.

Anticlockwise rotation makes the back gauge move backwards. The accuracy can reach

0.1 mm.

2) When put the paper or books on the machine, make sure they are tidy and aligned against

the left side of the machine and scale.

3) After the cut size confirmed and paper put in the right position, downward the foot pedal,

clamp the papers, both two hands on the cut buttons to start cutting. Or you don’t have to

use the foot pedal, only to press the cut buttons with two hands to start the clamp and cut

automatically. If you find anything wrong, release the cut bottom to stop the clamp and

blade, press only clamp back switch to make the clamp up, make sure everything is right

then cut.

14

4) When finishing cut, press “PUSH” key to push the papers or books out(if you have set push

function it will be done automatically after every cut), then a cut is completed.

2. Basic Adjustment

2-1 Cutting depth adjustment

B◆Turn to blade change, as follows

◆Enter data in the blank of “Cutting Depth Adjust”. The larger the value, the

deeper the crop.

◆After fixed well, take another one piece paper to test, until the paper can be

cut completely.

◆Then press and hold “Back” 3s for new cut.

Three functions:

1.Blade depth adjustment: When the last sheet can not be cut completely, this function can be

choose, there are 64 number to adjust with

2.Blade start position set: When the real cut dimension is not same with dimension the

screen display, we need to amend the start position. Directly enter the size of the actual

cutting measurement in the size calibration box

3.Pressing delay time adjustment, the range is between 20-200. The larger the value, the

Down arrow key to adjust cutter depth

increase

Up arrow key to adjust cutter depth reduction

15

longer the pressing time.

2-2 Blade replacement( Be more careful to operate)

◆Go to “System Setting” as follows, press “Cutter change”

◆Press cut buttons, the blade comes down;

◆Release two open notched fasten screw(see 1) on the blade carrier;

◆Take off the fasten screws, except No 2 screw;

◆Press cut buttons, blade rises, revolve two screws clockwise,take off

other fasten screws including No 2;

◆Revolve the two screw stems anticlockwise for half circle, then take out

the blade. Please wear gloves or use cotton cloth to wrap the blade to

avoid being hurt;

◆Be careful when taking a new blade out. The blade cutter pointing must

not be to the body. When installing the blade, screw up the screw stems.

Set the blade on the blade carrier, use screw strip to fasten and fix up, then

adjust it according to cutting depth adjustment method.

◆Do blade sharpening in a professional factory.

Note: Cutting thick paper or pasteboard frequently will make the blade dull.

Prepare one replacement on hand.

Be careful when change the blade.

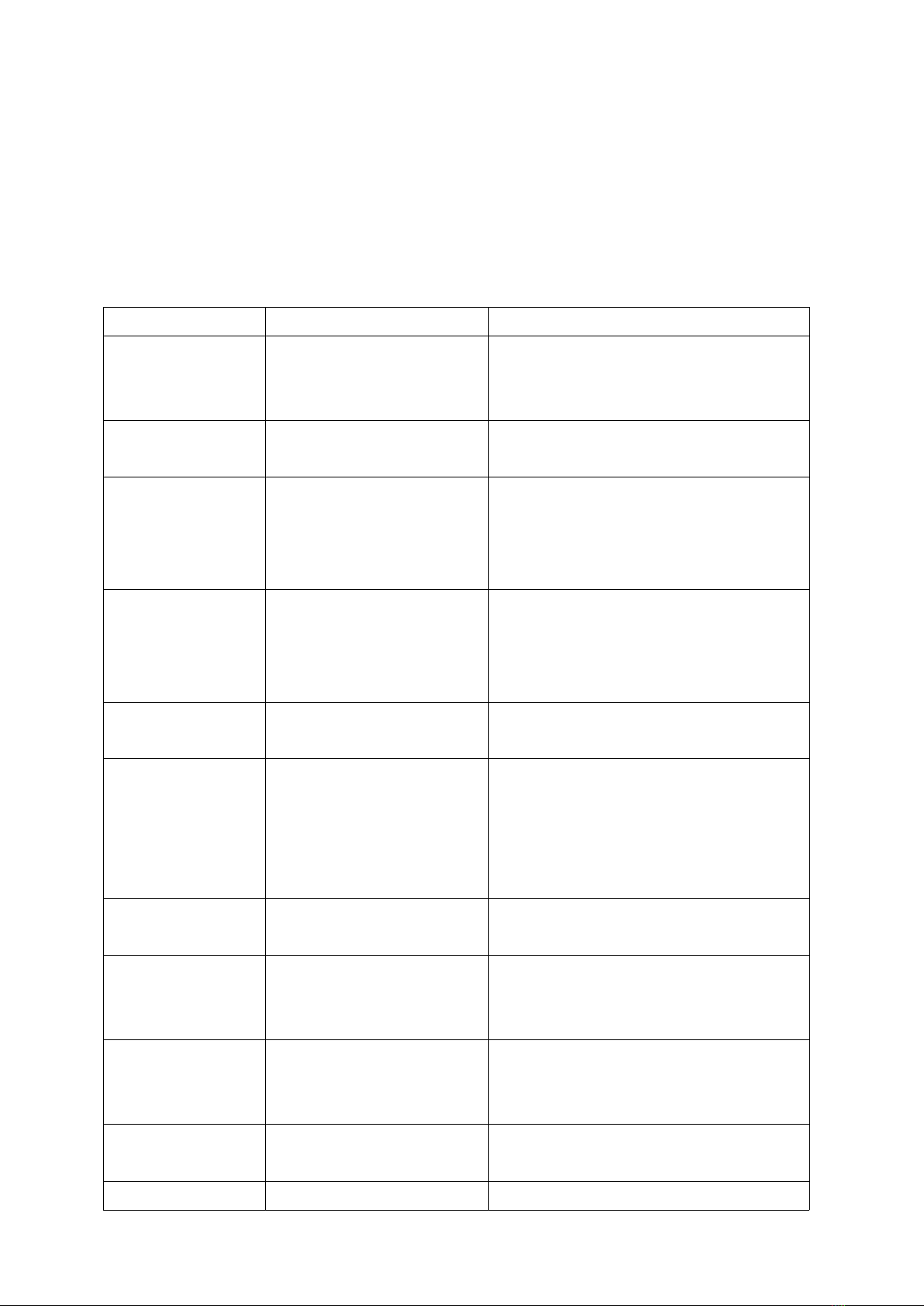

2-3 Cutting stick adjustment

◆One cutter stick can be used for 4 times;

16

◆Adjust or change the stick if deep slash;

◆Reinstall the stick flat on cutting desk after taken out;

◆Set cutter stick lean to the left side;

Note: Adjust blade after changing cutter stick for service life.

2-4 Pressure adjustment

◆Press cut switches with both two hands, the clamp will be down to compress the paper,

showing pressure in the pressure meter. Standard pressure is: 30KG/CM2~50KG/CM2.

◆Clockwise rotation, higher pressure; anticlockwise rotation, lower pressure.

◆New pressure will be show after press clamp or cut buttons

2-5 Hydraulic system troubleshooting

1. System noisy after starting the machine

1) Lack of oil, add 32# or 46# hydraulic oil

2) Oil filter blocks, clean up the oil filter

2. Under pressure

1) Check connect joints of the hydraulic system to avoid leak.

2) Abnormal electrical motor or wrong voltage.

Chapter IV Lubrication and maintenance

1. Lubrication

Check machine every month. Open the cover plate, clean and fasten parts and oil in

17

moving parts. Don’t drop oil on electric circuit or electronic components.

2. Maintenance

1) Before work, Keep machine clean to avoid hard objects to damage the blade.Don’t cut

book with staples.

2) Work done, clean machine, remove debris, wax cutting blade and cut off the power.

Chapter V General failures and troubleshoot

Error Phenomenon Troubleshoot

No power Indicate light doesn’t

bright

1. Check the power socket

2. Check the switch

3. Check the power wire

Motor capacitor is

damaged

Abnormal pressure or

motor sound

Change the capacitor

Papers being cut

are not vertical

Papers are not neat Displacement of block gauge, loosen

the fastening screws, with straightedge

to adjust the angle of scale and pushing

cardboard, fixed screws again.

Blade won’t go

back to the top

position

Blade is in the bottom

position

1. 1. The lower limit sensor of the cutter

is damaged or the solenoid valve is

blocked

2. motherboard failure

Touch screen is

abnormal

Power supply is invalid Check the touch screen, motherboard

and power supply

The back gague

cannot be reset

automatically

when the machine

is turned on

The back gague doesn’t

work when the machine is

turned on

1. Check the power supply of the paper

push motor

2. Check the driver

3. Check the motherboard

Button is invalid and can

not cut

1. Check the security photoelectric

2. Check the motherboard

Can cut, but blade can not

go back to the to position

1. Check the lower limit sensor of the

cutter

2. Check the motherboard

Can be cut, but the paper

press cannot be returned

1. Check the upper limit sensor of the

cutter

2. Check the motherboard

Clamp can’t be in the

normal position

1. Check the top clamp limit sensor

2. Check the motherboard

Can cut, but back gauge is 1. Check the rear limit sensor of the

18

abnormal back gauge

2. Check the motherboard

SUNFUNG TECHNOLOGY CORPORATION LTD

NO 259 Wensan Road, Xihu District, Hangzhou, 310012 CHINA

Tel:(86)571 85175095

Website:https://.sunfung-tech.com

Email:info@sunfung-tech.com

This manual suits for next models

3

Table of contents

Popular Industrial Equipment manuals by other brands

Siemens

Siemens SIRIUS 3RV29 Series operating instructions

Techniks

Techniks EEPM Operation manual

Interactive Instruments

Interactive Instruments Jet Stream 500 instruction manual

Autonics

Autonics AiCA-D-EC Series product manual

SCHUNK

SCHUNK EGN 80 Assembly and operating manual

MAKSIWA

MAKSIWA CBC.P user manual

ABB

ABB HT846414 Operation manual

Siemens

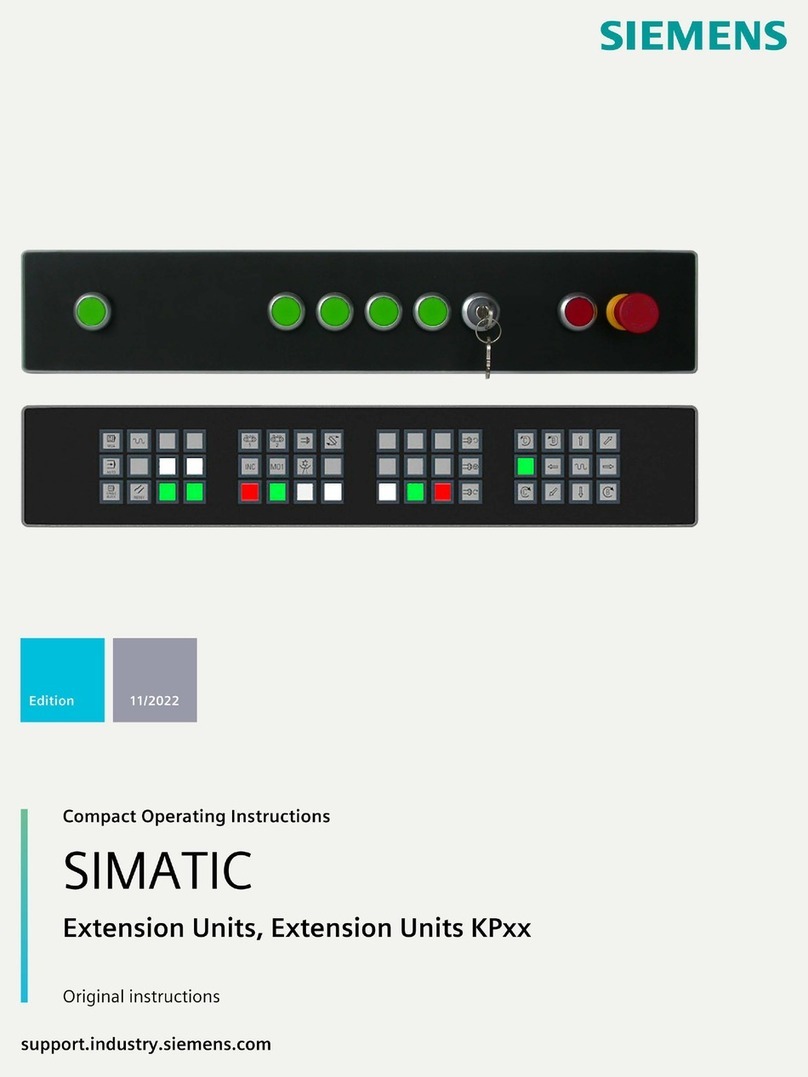

Siemens SIMATIC KP Series Original instructions

Freedom

Freedom HP6 Setup, operating, maintenance instructions

NuAire

NuAire FumeGard E Series Operation and maintenance manual

Pratt Burnerd

Pratt Burnerd Atlas EZ Set manual

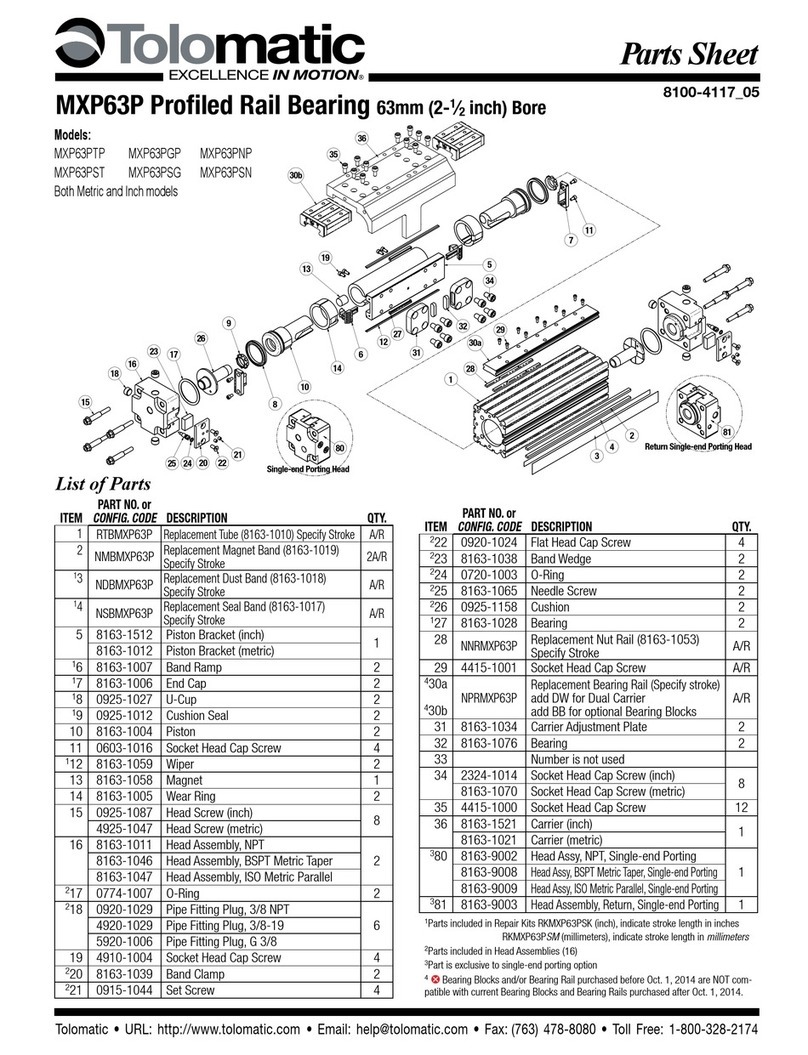

Tolomatic

Tolomatic MXP63PTP quick start guide