Pratt Burnerd Atlas EZ Set User manual

1

Atlas EZ Set Manual

3977 Emerald Drive Kalamazoo, MI 49001

PH800-253-0820 Email: [email protected]

WEBSITE:WWW.PRATTBURNERD.COM

2

This instruction manual is for production engineers and

maintenance personnel in charge of operation of this

product. Please make sure that when a beginner uses this

product, they receive instructions from experienced

personnel, the distributor or PBA.

Before installing, operating or maintaining this equipment,

carefully read this manual. Failure to follow these

instructions and safety precautions could result in serious

injury, death, or property damage.

Store this manual near the equipment for future

reference.

3

Index

Please read this manual carefully to ensure an appropriate

use of your Atlas EZ Set chuck and pay special attention to

safety and maintenance instructions.

1. Parts list

2. Spare parts

3. General concepts and usage

4. Safety instructions

5. Technical specifications

6. Clamping capacity

7. Mounting adapter

8. Mounting chuck / EZ Set Feature

9. Maintenance

10. Warranty

4

(1) Parts List

In your box, depending on the acquired chuck, you will find the

following:

Chuck with reversible hard top jaws

Operating key for pinions

Mounting bolts and Allen key

5

(2) Spare Parts

Available spare parts for your chuck are as follows:

(1) Scroll Gear

(2) Pinion Gear

(3) Base/Master jaw set

(4) Hard top jaw set

(5) Micro Adjustment screw

*Please consult factory for part numbers

6

(3) General Concepts

Atlas Workholding chucks are high quality products built

under technical and safety requirements. First class materials

are used in the building process to ensure long lasting life of

chuck. Atlas Workholding holds a large inventory of

replacements to guarantee your chuck is always in its best

possible condition.

Usage

Atlas Workholding chucks are designed to solve clamping

needs in any horizontal or vertical lathe from every brand

worldwide.

However, they can also be used to clamp any piece that

needs to be static in milling machines, machine centers,

drills, grinders and generally in any application that requires

precise concentric clamping.

7

(4) Safety

Ensure that your machine is turned off when installing and

changing the chuck.

Always consider that due to centrifugal force the clamping force

decreases as the revolutions of the lathe increases.

Never work over the maximum revolutions indicated.

Make sure that all the chuck mounting screws and screws

between the base and top jaw have been properly secured &

torqued.

When clamping, ensure hands are out of clamping area.

Always use safety glasses.

Never modify the chuck.

Make sure that jaws used are as light as possible.

Never neglect lubrication.

Never hit the chuck key with other tools or use a pipe to get

greater clamping force. Using the hand key that comes with the

chuck will be enough to get the maximum gripping force.

Use a tail stock when machining a long work piece.

When lifting the chuck use an eyebolt or lifting belt. Never

operate the machine under the influence of alcohol or drugs.

Gloves and ties should not be worn when operating the machine.

8

(5) Technical Specifications

Note: Maximum revolutions indicated are under optimal

machining conditions, with the center of gravity of the piece

placed at the center of the lathe bore

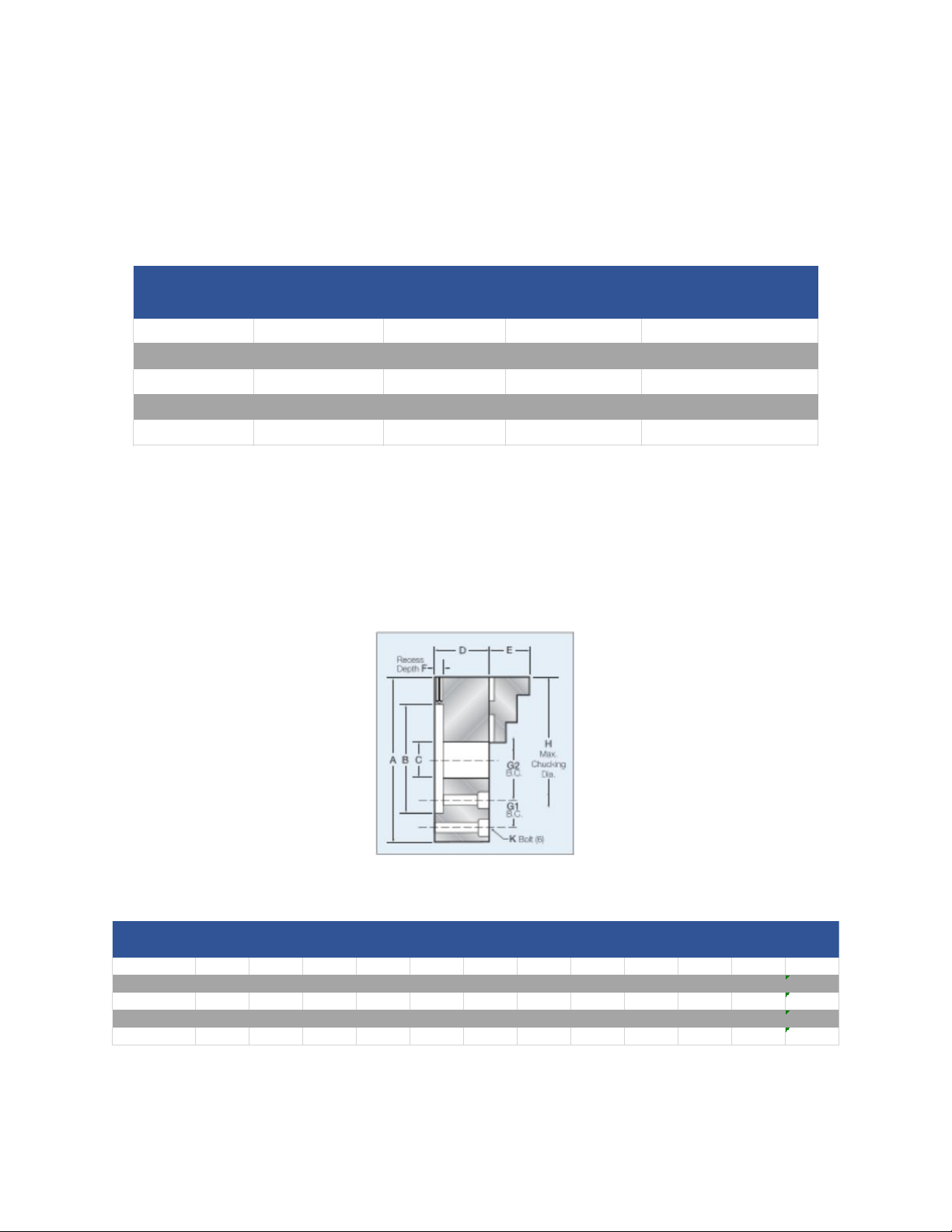

Chuck Max Input Output Force RPM Max Aproximate

Size Torque lbs/f lbs/f Weight

6 inch 55 7500 3000 20

8 inch 85 10500 2500 43

10 inch 115 12500 2000 67

12 inch 140 15000 1500 115

15 inch 140 16500 1000 225

Chuck

GRIPPING

CAPACITY

Size A B C D E F G1 G2 H K MIN MAX

6 inch 6 3.125 1.54 2.52 1.728 0.69 5.34 6.5 1/4 1/8 5

8 inch 8.25 4.75 2.362 3.122 1.141 0.732 7.5 8.5 3/8 3/16 6 1/2

10 inch 10 6.375 3.031 3.504 2.118 0.803 4.38 11 7/16 15/32 8

12 inch 12 7.906 4.055 4.035 2.492 0.799 5.25 12.5 1/2 27/64 10

15 inch 15 11.781 4.567 5.362 2.866 1.091 6.75 16 5/8 9/16 15

9

(6) Clamping capacity

Scroll chucks minimum clamping dimension may change based

on the thru bore of the chuck. The max clamping capacity will

not change. The maximum amount of master jaw extended

outside the chuck body should never exceed 25% of its length.

Extended length jaws can be used to grip smaller diameters.

Refer to technical specifications for Max and Min clamping

capacities.

10

(7) Adapter Mounting

Atlas EZ set chucks are precision manufactured for adapter

plate mounting. We offer a full line of mounting plates to fit

types “D”, “A”, “L” and threaded spindles. Special adapters to

fit different applications are also available, including rotary

table adapters.

Every surface of lathe spindle and adapter should be clean,

making sure that neither of them have been damaged.

Lathe spindles should be checked radial and axially.

Maximum error should be less than .0002”.

Adapter should be checked on the chuck side face, close to

the mounting holes. Error should be less than .0005”

If the error exceeds the .0005” take a truing cut across the

face of the adapter to true it with your spindle.

11

(8) Chuck Mounting / EZ Set

Feature

The Atlas EZ set feature has been designed to compensate

for any inaccuracy which may be introduced in mounting

the chuck and spindle nose adapter.

At the rear of the chuck body periphery there are 4 dog

point screws. These control float between the chuck body

and the spindle nose adapter.

The Atlas EZ set feature is easy to use. After following the

instructions in section (7) mounting. Ensure all mating

surfaces are thoroughly cleaned. The chuck should be

mounted with the through mounting bolts lightly hand

tightened. Check the runout on the chuck periphery using

a suitably positioned dial indicator. Adjust the 4

adjustment screws to obtain optimum accuracy. Fully

tighten the mounting bolts to the specification below.

Once set the chuck will require no further adjustment.

The chuck will repeat on duplicate parts within .0005”

Chuck Bolt Max mount bolt

Size Size Torque lbs/f

6 inch 1/4" 10

8 inch 3/8" 20

10 inch 7/16" 25

12 inch 1/2" 30

15 inch 5/8" 35

12

(9) Maintenance

Treating your chuck carefully applying grease to friction

areas periodically will make the chuck last longer and with

greater precision. To get the best possible precision in

second operations, soft jaws should be machined to the

chuck. It should be remembered that to turn the soft jaws,

all slack of the mechanism must be eliminated. Use of a

boring ring or pin would be recommended.

Clean and lubricate the chuck regularly with Pratt Burnerd

Americas PB160Z chuck lubricant. To obtain greater

efficiency, old grease and dirt should be removed before

lubricating again.

Chuck damages are mostly due to improper usage. Most

common damages could be avoided if:

oOnly the correct key is used in the pinion

oCheater bars/pipes are not used to turn the chuck key

oLathe is not turned on until everything is in its place

oKey is removed from pinion before turning of lathe

oChuck is not used for too heavy or too large parts

oNever grip pieces that are larger than the chuck diameter

A chuck is a precision tool that deserves to be treated the best

possible way. Pratt Burnerd America is not liable for damages

due to misuse of the chuck.

13

(10) Warranty

PBA/Atlas Workholding guarantees the correct functioning

of its products under normal conditions for a period of 1

year. This covers workmanship, specified accuracy and

material defects.

PBA/Atlas Workholding will repair or replace at our

discretion the part, or the entire product and include labor

if found defective.

PBA/Atlas Workholding is not responsible for any resulting

down time or resulting physical damage caused from a

defective product.

The warranty is void if the product is found to be misused

or used in a way it was not intended for.

All warranty claims are subject to inspection by PBA/Atlas

Workholding in our facility in Kalamazoo, Michigan.

Any item returned for warranty claim MUST be freight

prepaid.

14

Table of contents

Other Pratt Burnerd Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Endress+Hauser

Endress+Hauser Hart Proline Promag P 500 Special Documentation

Showa Denki

Showa Denki CRN Series Operation manual

ABB

ABB HT581063 Operation manual

Shini

Shini SAL-810 manual

Raychem

Raychem nvent CE16-05 installation instructions

Global Industrial

Global Industrial B237006 Assembly instructions