Techniks EEPM User manual

www.techniksusa.com

EEPM MAGNETIC CHUCKS

OPERATIONS MANUAL

COMPLETE INSTALLATION AND TROUBLESHOOTING GUIDE

Techniks Inc. 9930 E. 56th St. Indianapolis, IN 46236 | 800.597.3921 | www.techniksusa.com | [email protected]

Techniks Inc. is a proud member of Techniks Tool Group.

Connect with TTG

1

Phone: (800) 597-3921 or (317) 803-8000 • Fax: (317) 803-8001

Unpacking And Installation .............................................................................................................2

Controller Installation & Features............................................................................................... 3

Controller Features.................................................................................................................... 3

Power Supply Check Procedure ........................................................................................... 3

Electrical Connections............................................................................................................. 3

Controller-to-Chuck Connections....................................................................................... 4

Interfacing with a CNC Machine Control.......................................................................... 4

Standard Remote Operation........................................................................................................... 5

Powering Up The Controller ................................................................................................... 5

Magnetizing The Chuck............................................................................................................ 5

Adjusting The Magnetic Holding Power ............................................................................ 5

Demagnetizing The Chuck...................................................................................................... 5

Powering Down The Controller And Chuck...................................................................... 5

Standard Remote Troubleshooting ............................................................................................. 6

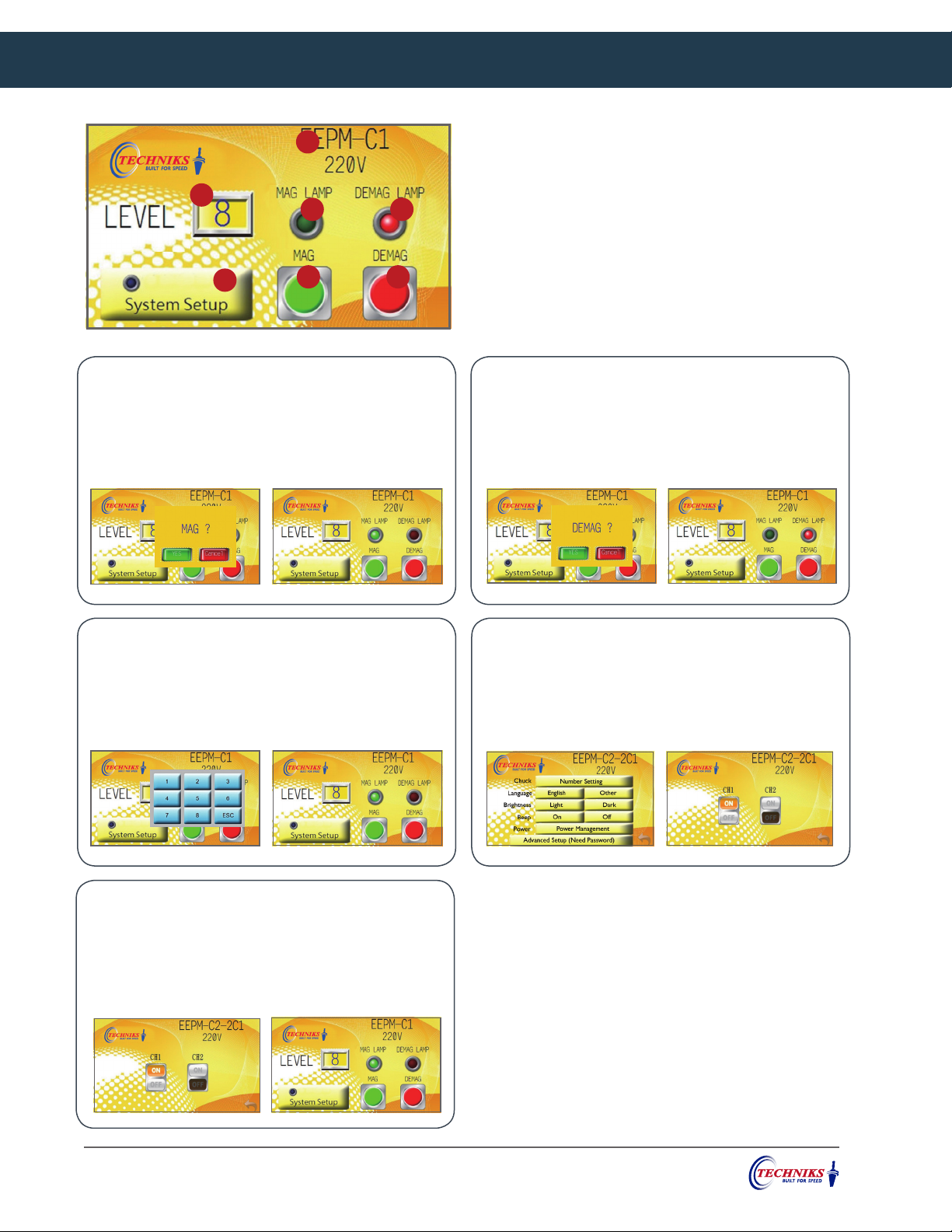

Touch Screen Control Operation ...................................................................................................7

Magnetizing The Chuck.............................................................................................................7

Adjusting Holding Power ..........................................................................................................7

Demagnetizing The Chuck.......................................................................................................7

Multi-Chuck Control Setup......................................................................................................7

One Controller For Two Chucks Setting.............................................................................7

Touch Screen Control Troubleshooting..................................................................................... 8

Magnetic Failure ......................................................................................................................... 8

Demagnetization Failure......................................................................................................... 8

Low Voltage................................................................................................................................... 8

Chuck Cable Disconnected .................................................................................................... 8

Chuck Operations................................................................................................................................ 9

Safety Precautions..................................................................................................................... 9

Controller & Induction Block Maintenance ..................................................................... 9

Part Setup ...................................................................................................................................... 9

Chuck Maintenance ..........................................................................................................................10

Weekly Maintenance ................................................................................................................10

Daily Maintenance.....................................................................................................................10

Storing The Equipment............................................................................................................10

Disposing Of The Equipment.................................................................................................10

Frequent Troubleshooting Solutions..........................................................................................11

TABLE OF CONTENTS

NOTES & TIPS FOR OPTIMUM

PERFORMANCE

• Confirm your power supply meets the

EEPM requirements.

• Stock is of ferrous metals, or any

grade of steel and cast iron.

• Stock is of sufficient thickness and

material type.

• Smooth clean contact between the

magnetic chuck and the workpiece.

• Your results will vary depending

upon the size, shape, thickness and

material type you are holding.

ELECTRICAL NOTES

• Electricity is NOT required to maintain

magnetic holding power.

• Electricity is used only to reverse the

polarity of the alnico magnets.

• When in a magnetized state, holding

power is secure until demagnetized.

• The chuck will NOT lose holding

power in the event of a power loss.

• To prevent injury never put any part of your body (i.e.

fingers, skin, etc) between a metal object and the chuck

surface. Do not wear rings, watches, necklaces, bracelets

etc., while operating the chuck.

• To prevent damage to the chuck and/or controller wait at

least two (2) minutes after magnetizing or demagnetizing

the a

• Always make sure the power receptacle on the chuck and

the plug on the chuck controller cable are free of moisture,

chips, and any contaminants before connecting the chuck

controller cable to the chuck. Failure to do so could result

in damage to the chuck and chuck controller.

• Always verify that the controller is properly connected to

the chuck before operating the controls.

• Always replace the cap on the chuck power receptacle

when disconnecting the power cable from the chuck.

• Always use workstops when operating the chuck at a

power level lower than 8 to ensure the workpiece does not

move during machining.

• High temperatures (176˚F or above) will cause permanent

decay / loss of magnetic power. Do not operate the chuck

under high temperature conditions.

CautionS and warningS

2

Satisfaction guaranteed on all our CNC tooling solutions | www.techniksusa.com

UNPACKING AND INSTALLATION

EEPM CHUCK INSTALLATION

Read this manual completely before installing the chuck and

controller. Always obey the CAUTIONS and warnings instructions

in this manual. Installation should only be carried out by qualified

personnel.

• Make sure all the EEPM components and your machine bed are

clean and dry.

• Use a Techniks EZ-Lift Lifting Magnet to safely transport the

chuck to your machine bed.

• Position the magnetic chuck on to the bed of your machining

center or pallet, securing the chuck using the supplied toe clamps

or T-slots.

toe clamps

Securing EEPM chuck to bed “T” slots

UNPACKING THE CHUCK AND CONTROLLER

Upon receiving the equipment carefully unpack and verify the

following items were shipped with your order:

• 1 EEPM magnetic chuck

• 1 chuck controller with attached power supply cable for the chuck.

• 1 auxiliary hand-held remote & 1 touchscreen HMI remote control.

• 1 set of 4 toe clamps, and this Operations Manual.

Reminder: Review the packing list and confirm that all items listed

arrived intact and undamged. In case of damaged of missing items,

please contact Techniks immediately.

Power Requirements

208-480V/30A single phase

transporting the EEPM chuck

FACTORS THAT AFFECT MAGNETIC HOLDING POWER

• Higher carbon content in the workpiece reduces the magnetic

attraction between the chuck and the workpiece.

• Thickness of workpiece

a) above 1-1/4” = 100%

b) 3/4” – 1-1/4” = 85%

c) 3/8” – 3/4” =50%

• Contact surface between workpiece and chuck. Chips, burrs, oil,

dirt, rough or uneven surfaces will reduce holding power.

• Contact area with the chuck. Holding power is approximately 1 ton

for every 4 poles.

• Temperatures above 176˚ will reduce holding power.

3

Phone: (800) 597-3921 or (317) 803-8000 • Fax: (317) 803-8001

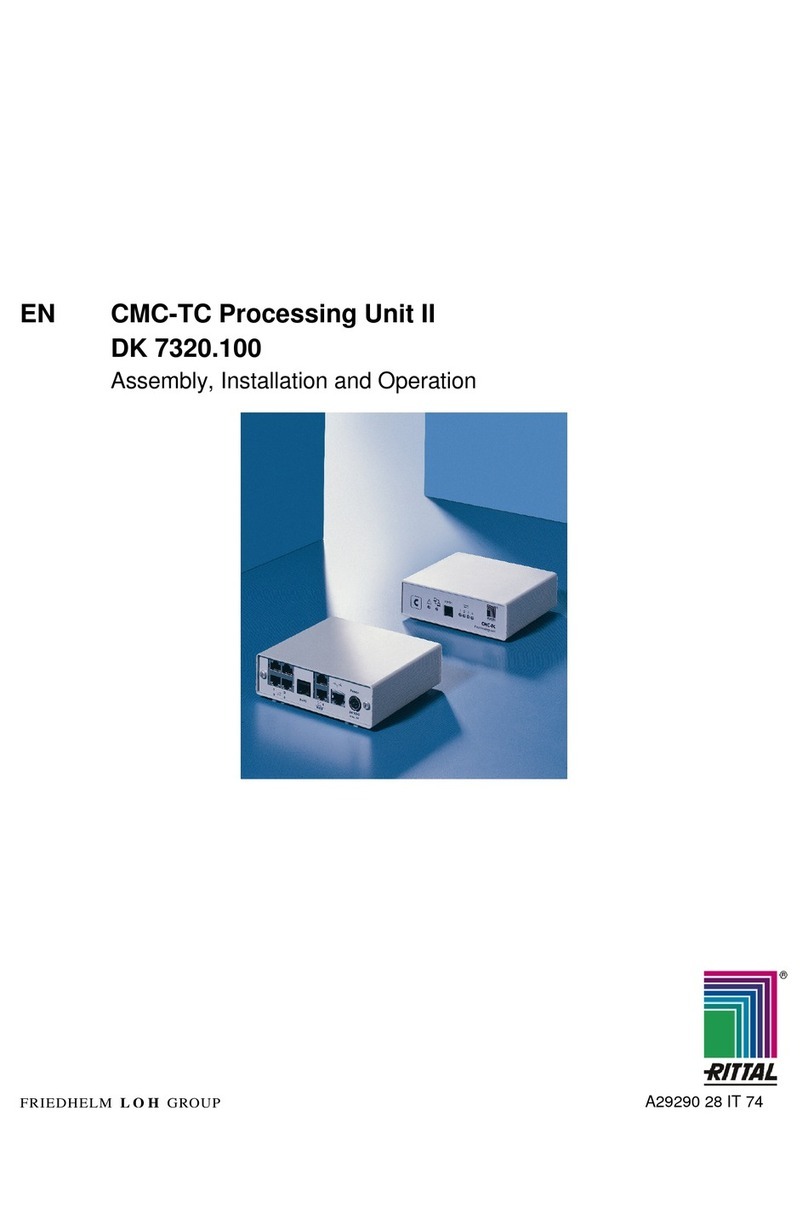

EEPM CONTROLLER INSTALLATION & FEATURES

CONTROLLER FEATURES

1. Product ID: Please confirm if the product specification matches the

specification on the label and your order form after unpack.

2. Magnetize Status (Green): Light is ON, the controller is magnetized.

3. Demagnetize Status (Red): Light is ON, the controller is De-

magnetized.

4. Power Switch: "ON" to start controller power; switch "OFF" to shut

down controller power.

5. Touch Screen Remote (HMI): For connect the controller to control

MAG., DE-MAG and adjust magnetic force level.

6. Touch Screen Remote (HMI) Port: located on side of chuck

7. Standard Remote

8. Standard Remote Port: located on side of chuck

9. Chuck Cable: : Connect to magnetic chuck

10. Power Cord : Connect to a power source.

11. CNC Control Port: Connect with CNC machine center. Can be used

to operate EEPM controller from CNC control.

Warning Sign: Please do

not open the controller

case due to risk of elec-

trical shock.

Please keep this label

on the controller body

and in good condition.

1

23

4

5

6

8

7

9

10

11

POWER SUPPLY CHECK PROCEDURE

The EEPM chuck and controller must have the correct

power supply to operate safely. Have a certified electrician

test and verify that your power supply meets the power

requirements listed below. Write the actual readings in the

spaces below, and fix any problems before attempting to

install and operate your EEPM chuck.

ELECTRICAL CONNECTIONS

The chuck controller requires 208-480V/30A single phase

power. For the single phase input, the cable has three leads.

1. Connect the wires as shown in the connection diagram (right).

2 cable leads are provided for phase/neutral, and one for ground.

2. For your convenience we have installed a NEMA L8-30P plug on the

chuck controller power cord. You will need to provide a NEMA L8-

30R receptacle. See drawing of the NEMA L8-30R.

We recommend having a certified electrician make all electrical connections and complete

the Power Supply Check (below) to ensure proper power supply and wiring connections.

Power Requirements ON-Site Actual

Voltage at outlet: 208 - 480V

Amperage: 30A circuit

Phase: single phase

Hertz (Hz): 60

10 gage wire from

breaker box to outlet

Dedicated circuit

NEMA L8-30R

4

Satisfaction guaranteed on all our CNC tooling solutions | www.techniksusa.com

EEPM CONTROLLER INSTALLATION & FEATURES

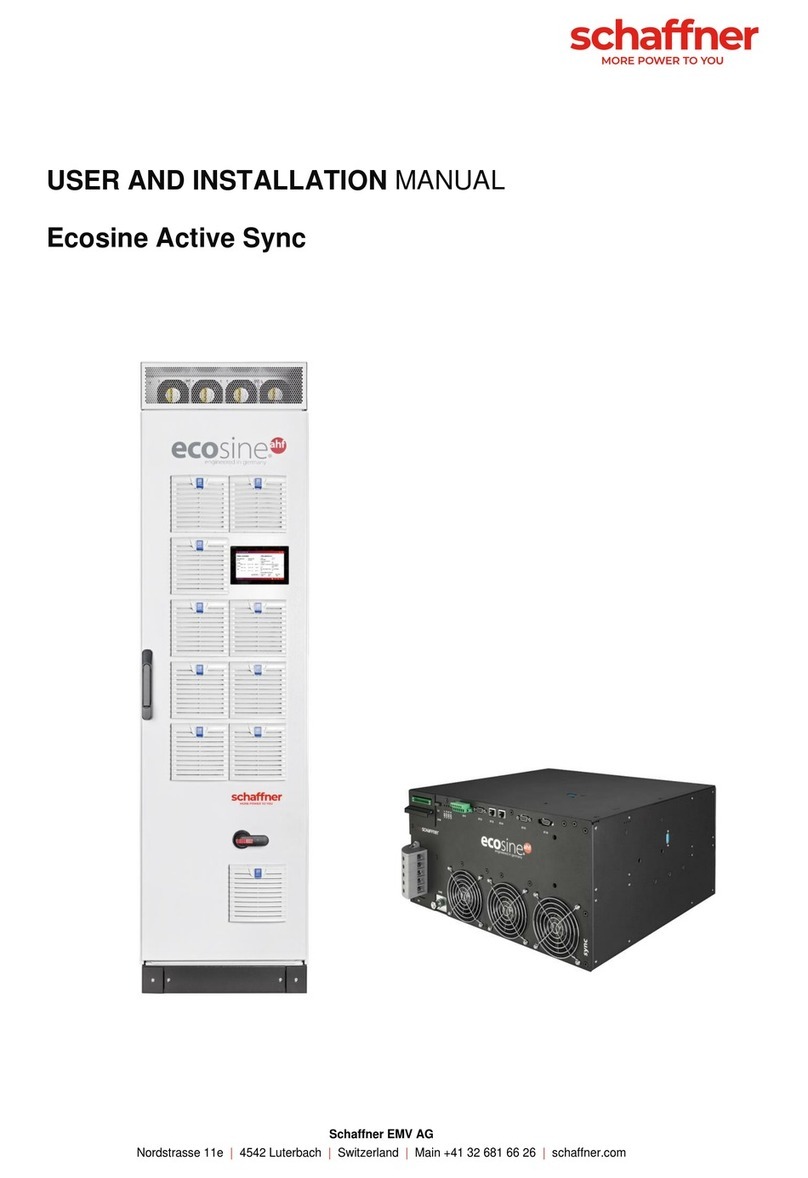

power receptacle

15-pin connector

POWER CABLE

EEPM Chuck

CONTROLLER

REMOTE

CONTROLLER-TO-CHUCK CONNECTIONS

Place the chuck controller next to the CNC machine’s control panel

in a location away from chips, oil, coolant, and any moving parts of

the machine, but near enough to the machine bed and EEPM chuck

for convenient operation.

1. Connect the chuck controller power cable to the correct power source

(208-480V/30A single phase)

2. Connect the standard or touch screen remote cable to the controller.

3. Remove the cap from the EEPM chuck power receptacle and gently spray the

with dry shop air to knock out any unseen contaminants.

4. Connect the power supply cable from the controller to the power receptacle on

the chuck. Make sure it is properly secured.

INTERFACING WITH A CNC MACHINE CONTROL

The EEPM magnetic chuck controller can interface with most CNC

controls via the 9-pin connection on the back of the controller,

allowing the magnetic chuck to be operated from the CNC control

panel.

The magnetic status of the EEPM chuck (demagnetized or

magnetized) is indicated with a set of dry contacts connected to

pins 1, 2, & 3 of the CNC control connector. When the contacts close

between 3 & 1, the chuck status is “demagnetized.” When the same

contacts are open, the chuck status is “magnetized.” The contacts

between 2 & 1 operate in reverse of 3 & 1.

To magnetize the chuck, connect the negative of an external 5-26

VDC supply to Pin 9 and connect the positive 5-26 VDC to Pin 7 for 0.8

to 1.5 seconds. To demagnetize the chuck, connect the negative of an

external 5-26 VDC supply to Pin 9 and connect the positive 5-26 VDC

to Pin 5 for 0.8 to 1.5 seconds.

The pin assignments are as follows:

Pin 1 – Status Relay COM

Pin 2 – Status Relay N.O. Chuck is magnetized

Pin 3 – Status Relay N.C. Chuck is demagnetized

Pin 5 – Demagnetize command

Pin 7 – Magnetize Command

Pin 9 – Command Negative (0V)

5

Phone: (800) 597-3921 or (317) 803-8000 • Fax: (317) 803-8001

STANDARD REMOTE OPERATION

DEMAGNETIZING THE CHUCK

1. Press the blue and the red buttons on the remote

simultaneously for 1 second and release.

2. Check that the red light above the red button on the

chuck controller is lit. This indicates the chuck is

demagnetized (OFF).

3. Verify that the chuck is demagnetized by touching

the surface of the chuck (touch test) with a ferrous

object (screwdriver). You should not feel any magnetic

attraction as the tip of the screwdriver comes in close

proximity to the chuck surface.

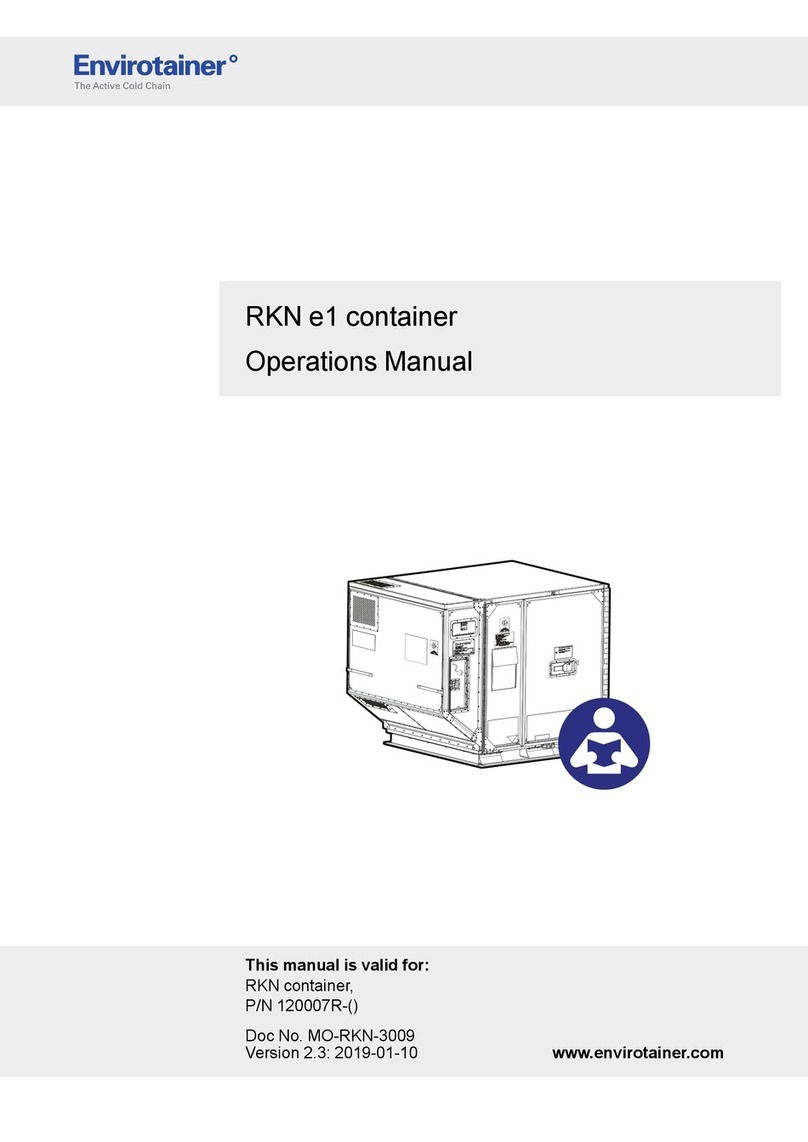

POWERING UP THE CONTROLLER

1. Turn the power switch on the chuck controller to “On”

2. Watch mag/demag light on controller is activated.

MAGNETIZING THE CHUCK

1. Press both the blue and green buttons on the remote

simultaneously for 1 second and release.

2. Check that the green light above the green button is lit.

This indicates the chuck is magnetized (ON).

3. Perform a Touch Test to verify magnetization. With a

small ferrous object (screwdriver) you should feel a

magnetic attraction.

ADJUSTING THE MAGNETIC HOLDING POWER

1. Adjust the power level as needed using the + or - keys.

Magnetize the chuck and verify that it is magnetized.

3. Perform the touch test to verify that the magnetic field

is no longer strong at the surface of the workpiece.

POWERING DOWN THE CONTROLLER AND CHUCK

1. Demagnetize the chuck and verify it is demagnetized.

2. Turn OFF the power switch on the chuck controller.

3. Disconnect the power cable from the chuck and gently

blow out the receptacle with dry shop air to remove

any contaminants. Replace the power receptacle cap

making sure it is properly secured.

The controller has 8 power levels. Level 1 is the weakest, and 8 is strongest. We recommend using level 8 for general operation. Using

the control panel or hand-held remote, you can adjust magnetic power levels to compensate for stock thickness or to provide better

chip evacuation.

You only need to adjust the holding power if a strong magnetic field extends beyond the surface of the workpiece. This is more likely

when workpieces are under ¾” thick. Perform a touch test to determine if it is necessary to reduce the magnetic power.

6

Satisfaction guaranteed on all our CNC tooling solutions | www.techniksusa.com

STANDARD REMOTE TROUBLESHOOTING

NUMBER DISPLAY FLASHES “0” (DETECT TIME: 5 SEC.)

IF number flashes “0”- the input voltage is

lower than the Controller’s lower limit. Your

voltage is not meeting the controller's minimum

requirement.

NUMBER DISPLAY FLASHES “8”

When operating the Controller to magnetize

a chuck, if the red and yellow lights stay lit

and the green light and number “8” flash, this

indicates an SCR failure.

YELLOW LIGHT FLASHES FOR 15 SECONDS AND RED

LIGHT REMAINS ON

During the magnetization process, if the red

light remains on and the yellow light flashes

for 15 seconds, this indicates the chuck cable

is disconnected from the chuck.

YELLOW LIGHT FLASHES FOR 15 SECONDS AND THEN

GREEN LIGHT REMAINS ON FLASHES

During the magnetization process, if the yellow

light flashes for 15 seconds and then green light

remains on flashes, this indicates one block has

malfunctioned and cannot be magnetized or

demagnetized.

7

Phone: (800) 597-3921 or (317) 803-8000 • Fax: (317) 803-8001

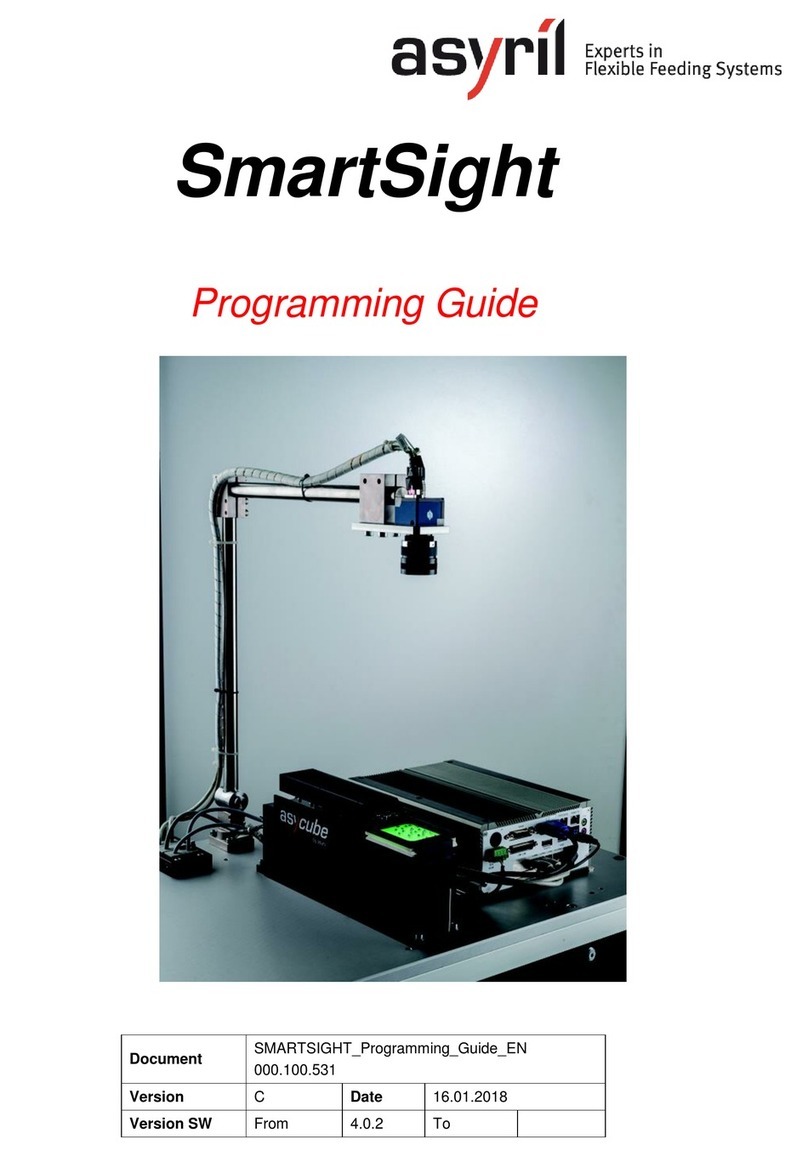

TOUCH SCREEN CONTROL OPERATION

1. Specification: Controller Type.

2. Magnetic Force Level: Display current magnetic force level.

3. System Setup : Touch button to enter setting page. Includes

language setup, brightness, buzzer switch, power management,

and advance setting.

4. MAG. Button Push button to conduct chuck magnetization.

5. MAG. Lamp: Green light ON is chuck magnetized.

6. DE-MAG. Button: Push button to conduct chuck demagnetization.

7. DE-MAG. Lamp: Red light ON is chuck demagnetized.

1

2

34 6

5 7

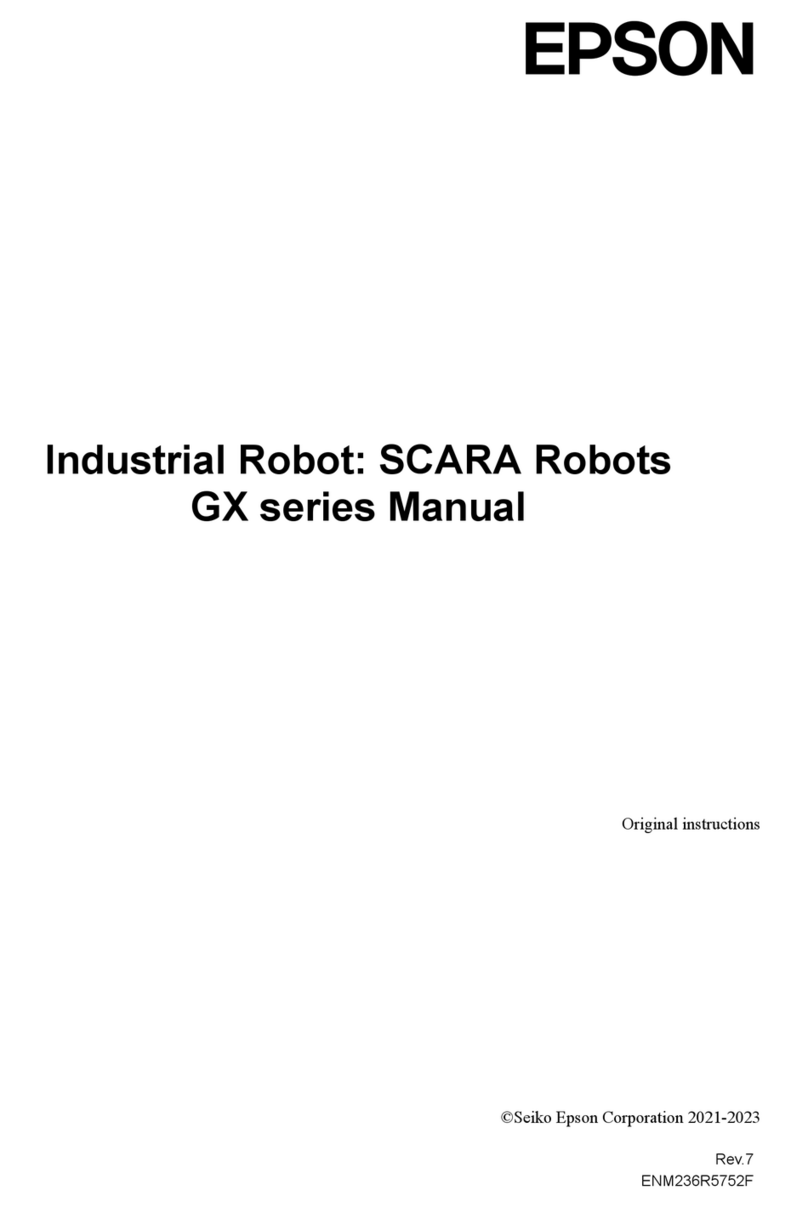

MAGNETIZING THE CHUCK

1. Touch green MAG button.

2. Confirmation prompt will appear, touch YES.

3. Watch for green MAG LAMP light to activate.

ADJUSTING HOLDING POWER

1. Touch "LEVEL" setting.

2. Power level pad will appear, touch desired level.

3. Watch for green MAG LAMP light to activate.

MULTI-CHUCK CONTROL SETUP

1. Touch System Setup. Enter Chuck Number Setting.

2. Touch On to activate your chucks.

3. Touch Off to de-activate your chucks.

ONE CONTROLLER FOR TWO CHUCKS SETTING

1. For EEPM-C2-2C1 can control two EEPM-C1 chucks.

2. Touch "System Setup". Enter Chuck Number Setting.

3. Touch CH1 ON, then go back to Home and Touch MAG.

DEMAGNETIZING THE CHUCK

1. Touch red DE-MAG button.

2. Confirmation prompt will appear, touch YES.

3. Watch for red DE-MAG LAMP light to activate.

8

Satisfaction guaranteed on all our CNC tooling solutions | www.techniksusa.com

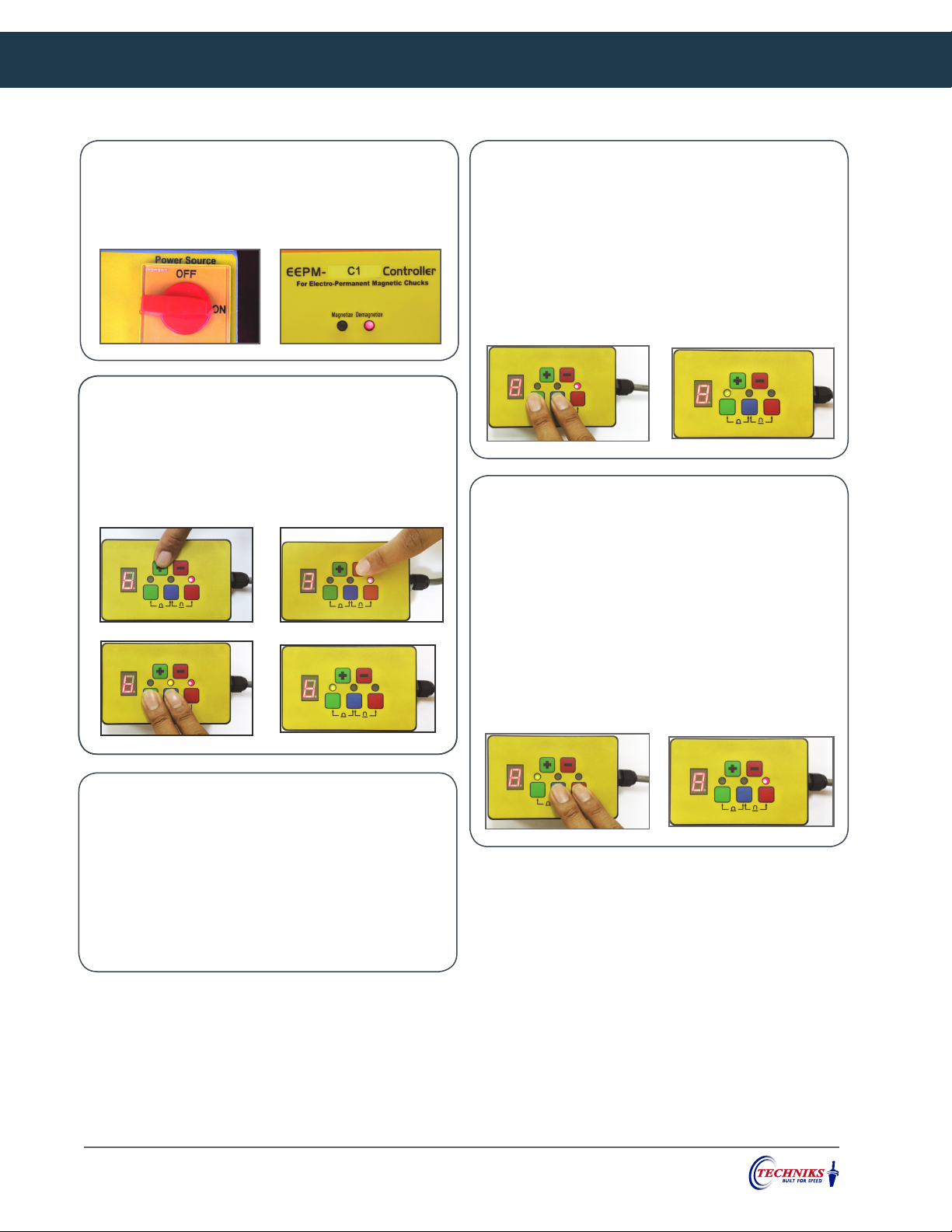

TOUCH SCREEN CONTROL TROUBLESHOOTING

MAGNETIC FAILURE

1. Touch MAG green button.

2. CH1 magnetization failure is displayed.

3. Check if the chuck cable is connected or damaged,

then touch confirm button.

4. Re-start the power, if no warning message is displayed,

the situation is normal.

DEMAGNETIZATION FAILURE

1. Push DE-MAGred button.

2. CH1 demagnetization failure is displayed.

3. Check if the chuck cable is connected or damaged,

then touch confirm button.

4. Re-start the power, if no warning message is displayed,

the situation is normal.

LOW VOLTAGE

1. A low voltage is displayed if the voltage drops below

186VAC.

2. Check whether the power voltage is within the

acceptable voltage range,Confirm the voltage

improved, then touch disable button.

3. Re-start the power, if no warning is displayed, the

situation is normal.

CHUCK CABLE DISCONNECTED

1. Touch MA red. button.

2. Chuck cable disconnected message displayed.

3. Check whether the chuck cable is connected, or if the

connector is damaged, then touch confirm button.

4. Touch MAG. button again, if no warning is displayed,

the situation is normal.

CH1 MAG ERROR

LOW POWER (AC220V)

CH1 DEMAG ERROR

MISSED LINE

9

Phone: (800) 597-3921 or (317) 803-8000 • Fax: (317) 803-8001

EEPM CHUCK OPERATIONS

CHUCK CONTROLLER MAINTENANCE

Regular routine maintenance includes keeping the exterior of

the controller, hand-held remote, and cables clean and dry.

Every time you use the chuck make the following inspections.

1. Carefully inspect all electric connections and condition

of the cables between the chuck and controller, and

the hand-held remote too. Make sure that no part of the

power supply circuit or connections has become loose or

show signs of overheating.

2. Make sure all cycle lamps are functioning well and the

keypad covers are all in good shape.

INDUCTION BLOCK MAINTENANCE

1.

Holding power of the chuck is greatly influenced by

the contact area between the chuck (or induction

blocks) and the workpiece. Regularly check the

condition of all induction blocks and remove any

gouges, rust, or other signs of wear.

2. Machine the top surface of the inductions blocks as

needed to restore them to a smooth, even surface.

PART SETUP

1. Power Up and Demagnetize the EEPM chuck following the

procedures and CautionS and warningS.

2. If you are using fixed or spring-loaded induction blocks

install these on the chuck before loading your workpiece.

Then, machine flat the top surface of the fixed induction

blocks only.

3. Center your workpiece on the chuck. Position it so it covers

an even number of poles (4, 8, etc.) as evenly as possible.

4. Install workstops as needed. Small or thin workpieces

may require workstops to prevent the part from moving

during machining. For best results we recommend using

workstops whenever possible.

5. Adjust the power level as needed using the + or - keys. We

recommend using power level 8 for standard operation.

Magnetize the chuck and verify that it is magnetize.

6. Perform a touch test to verify that the magnetic field is no

longer strong at the surface of the workpiece. If a strong

magnetic field is present on the top of the workpiece adjust

the power level as necessary following the procedures

listed.

7. Verify that the workpiece is properly secured by gently

tapping it on the side with a soft hammer, or striking a

block of wood with a regular hammer while checking for

any movement.

8. After the machining is complete,

Demagnetize the

EEPM chuck.

You may now remove the workpiece.

SAFETY PRECAUTIONS

Follow these precautions while servicing the chuck and/or

controller:

• Only qualified personnel should carry out maintenance

operations

• Always make sure the receptacle on the chuck and plug

on the chuck controller cable are free of moisture, chips,

and any contaminants before connecting the chuck

controller cable to the chuck. Failure to do so could result

in damage to the chuck and chuck controller.

• Always replace the cap on the chuck power receptacle

when disconnecting the power cable from the chuck

• Disconnect the equipment from the power supply before

attempting any repairs or maintenance. Never touch

connections or components unless the power supply is

disconnected

• Do not wear rings, watches, necklaces, bracelets etc.

while performing maintenance operations

• Always use protective gloves, safety shoes, and any other

protective gear needed

10

Satisfaction guaranteed on all our CNC tooling solutions | www.techniksusa.com

EEPM CHUCK MAINTENANCE

STORING THE EQUIPMENT

If the need arises to store the equipment for a certain amount of time observe the following instructions.

1. Demagnetize the chuck.

2. Turn the power switch on the chuck controller to “OFF”

3. Disconnect the chuck controller from the power supply

4. Disconnect the controller from the chuck

5. Remove any moisture or debris from the chuck receptacle and replace the cap over the receptacle

6. Clean all components and coat the surface of the chuck in a protective, rust inhibitive solvent.

7. Cover the equipment with a waterproof sheet (plastic)

8. Keep equipment in a dry environment. To preserve all electric parts the room temperature must be between 45°F to 80°F

DISPOSING OF THE EQUIPMENT

If the need arises to dispose of the equipment, it is mandatory to observe a few fundamental rules for the

safeguarding of the environment.

1. Protective covering, flexible pipes, plastic or non-metal material should be dismantled and disposed of separately.

2. The electric components should be disassembled and if in good condition, re-used or recycled, or if that is not possible

properly disposed of according to local municipal regulations.

3. This equipment contains polluting oils that must be disposed of at authorized waste disposal sites.

There are no user-serviceable parts inside the chuck. Chuck maintenance is limited the surface finish of

the chuck face and verifying that the electrical connection is clean and uncontaminated by chips or liquid.

Proper maintenance increases the life expectancy of your chuck and controller and keeps them in safe

working condition.

WEEKLY MAINTENANCE

For proper operation the chuck surface must be clean and smooth. Regularly check the surface condition

of all magnetic poles for damage. Remove any gouges or roughness using 250 grit sandpaper with a

backing block. Finish the surface using 400 grit. Remove any rust or scale deposits with 400 grit sandpaper

and a backing block. Remove all dust or other contaminants before storing the chuck or returning it to

operation.

DAILY MAINTENANCE

Unscrew the cap and inspect the electrical socket connection on the front of the chuck. Make sure there

are no chips or other contaminants in the socket. Gently spray the socket and cap with dry shop air. Make

sure the socket and cap are clean and dry, and the cap functions properly and makes a tight seal. Any

contaminants or liquid in the socket may cause damage during magnetize / demagnetize operations.

11

Phone: (800) 597-3921 or (317) 803-8000 • Fax: (317) 803-8001

FREQUENT TROUBLESHOOTING SOLUTIONS

Problem:

The controller is ON but the lamp in the remote is not lit.

Solution:

(a) The power supply cable is loose or is not connected properly.

Problem:

The chuck does not magnetize / demagnetize when the correct buttons are pushed.

Solution:

(a) The chuck cable is not properly connected to the controller, or the receptacle contains moisture or debris.

(b) The power supply does not meet the required specifications, or is incorrectly wired to

the controller.

Problem:

Insufficient holding power

Solution:

(a) Verify that the power supply meets the requirements stated in the Power Requirements

section of this manual.

(b) Verify that the power setting on the chuck controller is set to the maximum value(8). The power setting must be

changed when the chuck is in a demagnetized state.

(c) Verify that both the blue and green buttons on the chuck controller or hand-held

remote unit are pressed at the same time for a period of one full second. Do not hold the

buttons down for more than 2 seconds.

(d) Verify that the workpiece covers at least 4 poles and is thick enough, and has enough

iron content to be magnetically attracted to the chuck.

(e) Verify that the mating surfaces of the chuck and the workpiece are clean, smooth, and

free of burrs.

(f) Machine the surface of the fixed pole extensions to ensure a uniform, flat surface.

(g) Remove any oil or coolant from the workpiece and chuck surface before positioning

workpiece on chuck.

(h) Install workstops as needed to prevent slippage.

Table of contents

Other Techniks Industrial Equipment manuals