PAGE 7

PAGE 6

OPERATION OPERATION

When completed, release the trigger then turn off the air supply. As a

precautionary measure, ALWAYS pull the trigger before opening the lid.

There are no hard or fast rules governing nozzle sizes and air pressures

used with different abrasives. With experience and experimentation you

will quickly learn the best combinations for the required result.

On more delicate parts, start with minimal air pressure to avoid

unnecessary peaning or excessive abrasion, and work up to a setting to

produce the desired finish.

Should any abrasive be spilled, ensure it is cleaned up immediately, as its

slippery properties can be hazardous.

OPERATION

Plug the transformer into the power supply and switch the power ON.

Switch the lamp ON by pushing the rocker switch on the switch box ‘I’.

Switch OFF by pushing ‘O’.

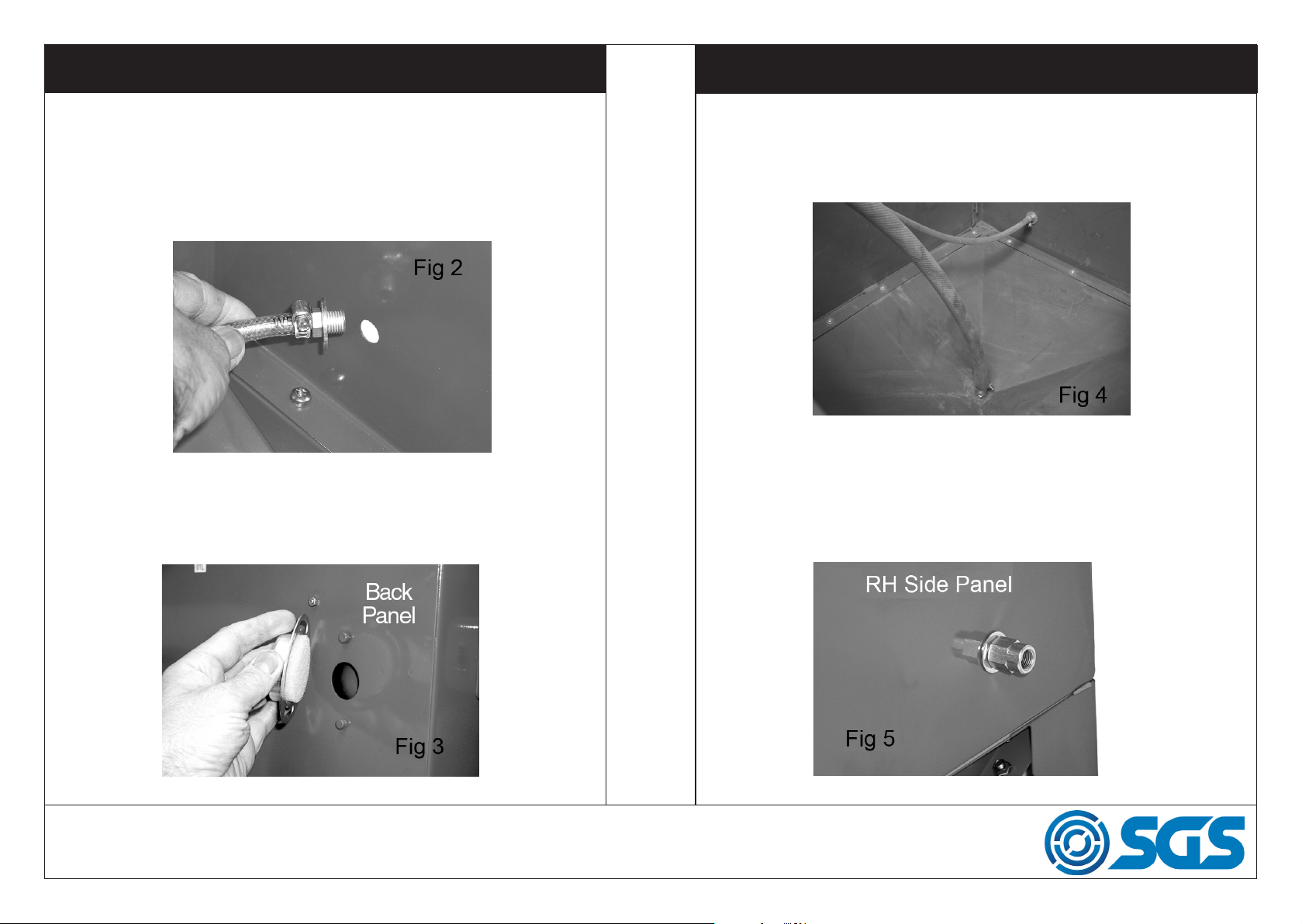

Ensure all air connections are secure, and the pick up is correctly located

beneath the grid, before filling the cabinet with abrasive media. Do not fill

higher than the level of the grid.

NOTE: PTFE tape is provided which may be used on the threads of the

various connectors to ensure an airtight connection. Select the ceramic

abrasive nozzle to produce the jet required for the abrasive media being

used, and assemble according to the instructions given below.

Place the object to be cleaned in the cabinet, and close the lid, securing

with the two swivel clips.

Set the pressure to the required value, but not higher than 100lbf/in2, and

check to ensure there are no air leaks. Should there be any, turn off the air

supply and repair where necessary, before turning the supply back on. Pull

the trigger on the gun and proceed to blast the object to be cleaned.

Keep the jet facing the object and away from the clear plastic lid. Do not

allow the jet to train on the rubber gloves, the air hose within the cabinet

or the fluorescent lamp.

WWW.SGS-ENGINEERING.COM