Shaktiman RC Series Product manual

WESSEX CULTIVATOR

RC - SERIES

RC-120 –RC-150

OPERATOR'S

AND

PARTS MANUAL

Manual P/N: OM 1121-1 / REV. 05 / 2015

Congratulation for purchasing your new Wessex Cultivator!

This Cultivator has been designed and manufactured following all safety and quality requirements

needed for a safe and satisfactory use over time.

A careful reading of this manual will permit you to familiarize with your new equipment, and will

provide you all the tools needed to use it safely.

A proper maintenance and knowledge of the safety rules of use will allow to obtain the

best performance and a long service life of the machine.

The Safety Alert Symbol used throughout this manual and on safety

decals of the machine indicates the presence of potential hazard to the

operator. When you see this symbol, be alert and carefully read the

message that follows it.

The Safety Alert Symbol is used in conjunction with following Signal Words, according to the

degree of possible injuries that may result operating the implement:

DANGER

Indicates an imminently hazardous situation that, if not avoided, will result in death or serious

injury.

WARNING

Indicates a potentially hazardous situation that, if not avoided, could result in death or serious

injury, and includes hazards that are exposed when guards are removed. It may also be used to

alert against unsafe practices.

CAUTION

Indicates a potentially hazardous situation that, if not avoided, may result in minor or moderate

injury. It may also be used to alert against unsafe practices.

IMPORTANT

Indicates instructions or procedures that, if not observed, can cause damage to equipment or

environment.

NOTE

Indicates helpful information.

READ, UNDERSTAND, and FOLLOW the safety messages following the Safety Alert Symbol and

Signal Words. Failure to comply with safety messages could result in serious bodily injury or death.

TABLE OF CONTENTS

1. ABOUT THIS MANUAL...................................................................

1

2. INTRODUCTION...............................................................................

1

2.1. CULTIVATOR

IDENTIFICATION................................................................................................................

1

2.2. INTENDED USE....................................................................................................................................

1

2.3. MAIN PARTS DESCRIPTION..........................................................................................................

2

2.4. CULTIVATOR

SPECIFICATION...................................................................................................................

3

3. SAFETY...............................................................................................

4

3.1. GENERAL SAFETY INSTRUCTIONS.............................................................................................

4

3.2. EQUIPMENT SAFETY INSTRUCTIONS.......................................................................................

5

3.3. OPERATING SAFETY INSTRUCTIONS........................................................................................

6

3.4. TRANSPORTING SAFETY INSTRUCTIONS...............................................................................

7

3.5. MAINTENANCE SAFETY INSTRUCTIONS.................................................................................

8

3.6. STORAGE SAFETY INSTRUCTIONS..............................................................................................

8

3.7. SAFETY LABELS..................................................................................................................................

9

SAFETY LABELS POSITION AND DESCRIPTION...........................................................

9

4. SET-UP................................................................................................

11

4.1. LOWER HITCHES POSITIONING..................................................................................................

12

4.2. CONNECTING TO THE TRACTOR.................................................................................................

13

4.3. DRIVELINE INSTALLATION...........................................................................................................

13

DRIVELINE LENGTH CHECK.................................................................................................

14

4.4. TRACTOR-CULTIVATOR

STABILITY.......................................................................................................

15

5. OPERATING.......................................................................................

15

5.1. START UP................................................................................................................................................

15

5.2. OPERATING INSTRUCTIONS..........................................................................................................

16

5.3. ADJUSTMENTS.....................................................................................................................................

17

LOWER CLEVISES ADJUSTMENT.........................................................................................

17

FRICTION CLUTCH ADJUSTMENT.......................................................................................

18

SKIDS ADJUSTMENT.................................................................................................................

19

REAR BOARD ADJUSTMENT..................................................................................................

20

5.4. STOPPING AND DISCONNECTION...............................................................................................

20

5.5. TRANSPORTING......................................................................................................................................

21

6. MAINTENANCE.................................................................................

22

6.1. BLADES REPLACEMENT..................................................................................................................

22

6.2. GEARBOX LUBRICATION.................................................................................................................

23

6.3. SIDE CASE LUBRICATION................................................................................................................

24

6.4. BEARING HOUSING LUBRICATION.............................................................................................

25

6.5. DRIVESHAFT MAINTENANCE.......................................................................................................

25

7. STORAGE...........................................................................................

27

8. SCRAPPING.......................................................................................

27

9. TROUBLESHOOTING......................................................................

28

10. TORQUE VALUES TABLE..............................................................

30

11. SPARE PARTS LIST…………………………………………………………

31

12. EC DECLARATION OF CONFORMITY.........................................

46

RC-Series Rotary Cultivators

1

1. ABOUT THIS MANUAL

The operator must read the manual for a correct understanding of the hazards that may present

when operating the Cultivator, as well as for obtain optimum performance from the machine.

The manual is part of the machine, it must be kept in good condition and remain with the machine

even in case of resale, until its demolition. In case of loss or damage, request a new copy to the

Manufacturer or your Dealer.

The information, descriptions and illustrations in this manual describes the state of the product at

the time of its publication, and may not reflect the product in the future.

The Manufacturer reserve the right to make design improvements or changes in specifications

without incurring in any obligation to install them on units previously sold.

Text, illustrations and drawings of this manual cannot be disclosed or transmitted, in whole or in

part, to third parties without the written permission of the Manufacturer. All rights are reserved.

2. INTRODUCTION

2.1. IDENTIFICATION

Each Cultivator has a plate for unique identification. Any request for assistance or information

regarding the machine must be directed to the Manufacturer or Dealer always referring to the

model and serial number as shown on the nameplate affixed to the machine:

2.2. INTENDED USE

The RC-SERIES Cultivators are designed to be used uniquely for horticultural, agricultural, or

commercial applications, to till soil for seedbed and planting preparation.

They are designed to be mounted on tractors equipped with hydraulic lift and universal three point

hitch that can support the implement weight, and driven by the power of the tractor through the

PTO driveshaft.

The tractors used to operate the RC-SERIES Cultivators must have the following requirements:

RC-Series Rotary Cultivators

2

Hitch Category: 3-point Cat. I standard

PTO: 540 RPM, 6-spline, 1 3/8 Z6

Horsepower: Cultivator (RC-120): 20-30 HP

Cultivator (RC-150): 25-40 HP

DANGER

Any use of the machine other than the intended use is non-intended use, and is to be considered

as unauthorized and dangerous. The manufacturer assumes no liability for damage resulting from

non-intended use.

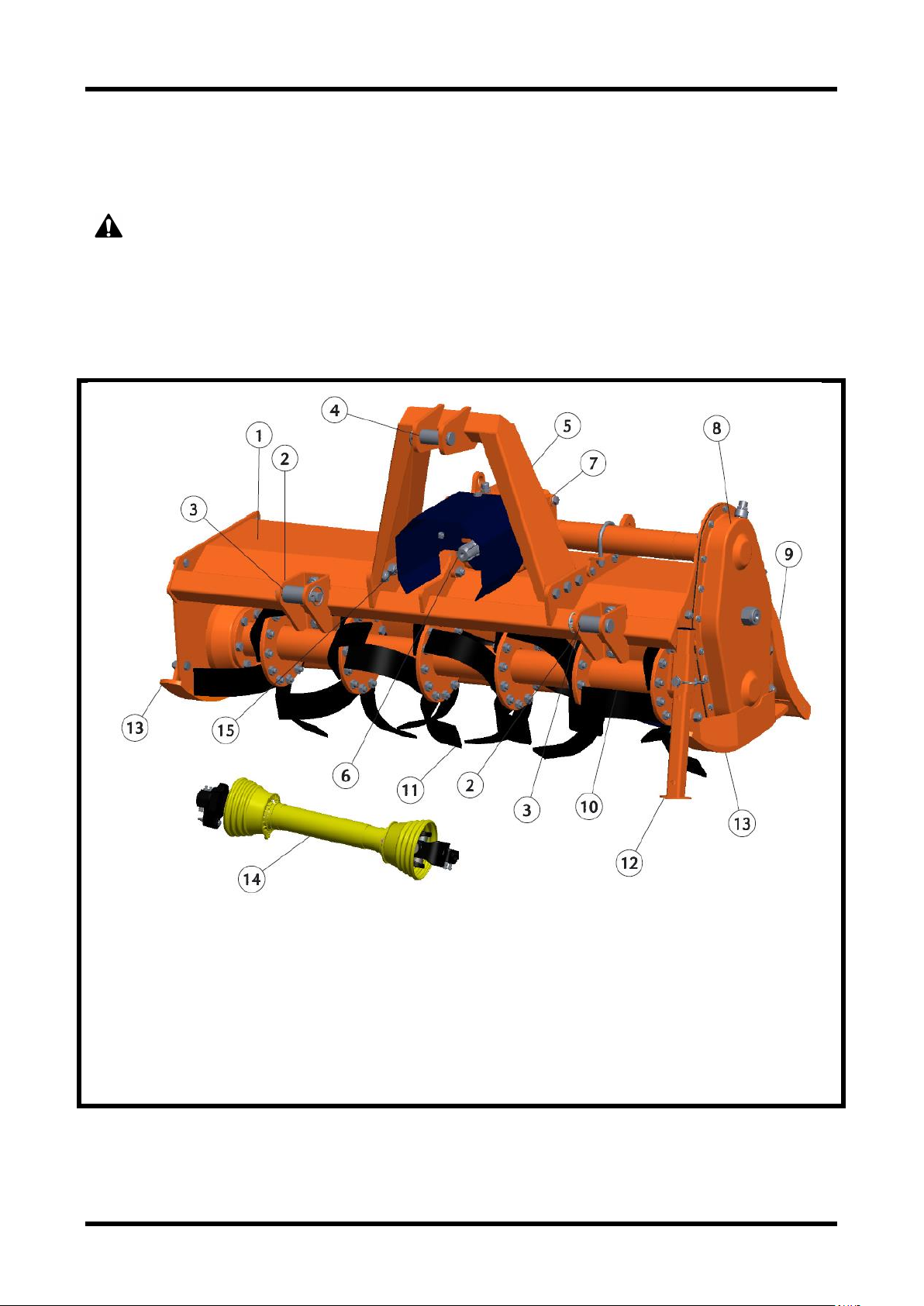

2.3. MAIN PARTS DESCRIPTION

1. Cultivator deck

2. Clevis (lower hitch)

3. Lower hitch pin

4. Upper hitch pin

5. Top mast

6. Implement input connection (Cultivator

PTO)

7. Gearbox

8. Side transmission case

9. Rear board

10. Rotor shaft

11. Tine

12. Parking stand

13. Skid

14. PTO driveshaft

15. PTO shield

NOTE

Unless otherwise indicated, images shown in this manual refer to the RC-150 Cultivator.

RC-Series Rotary Cultivators

3

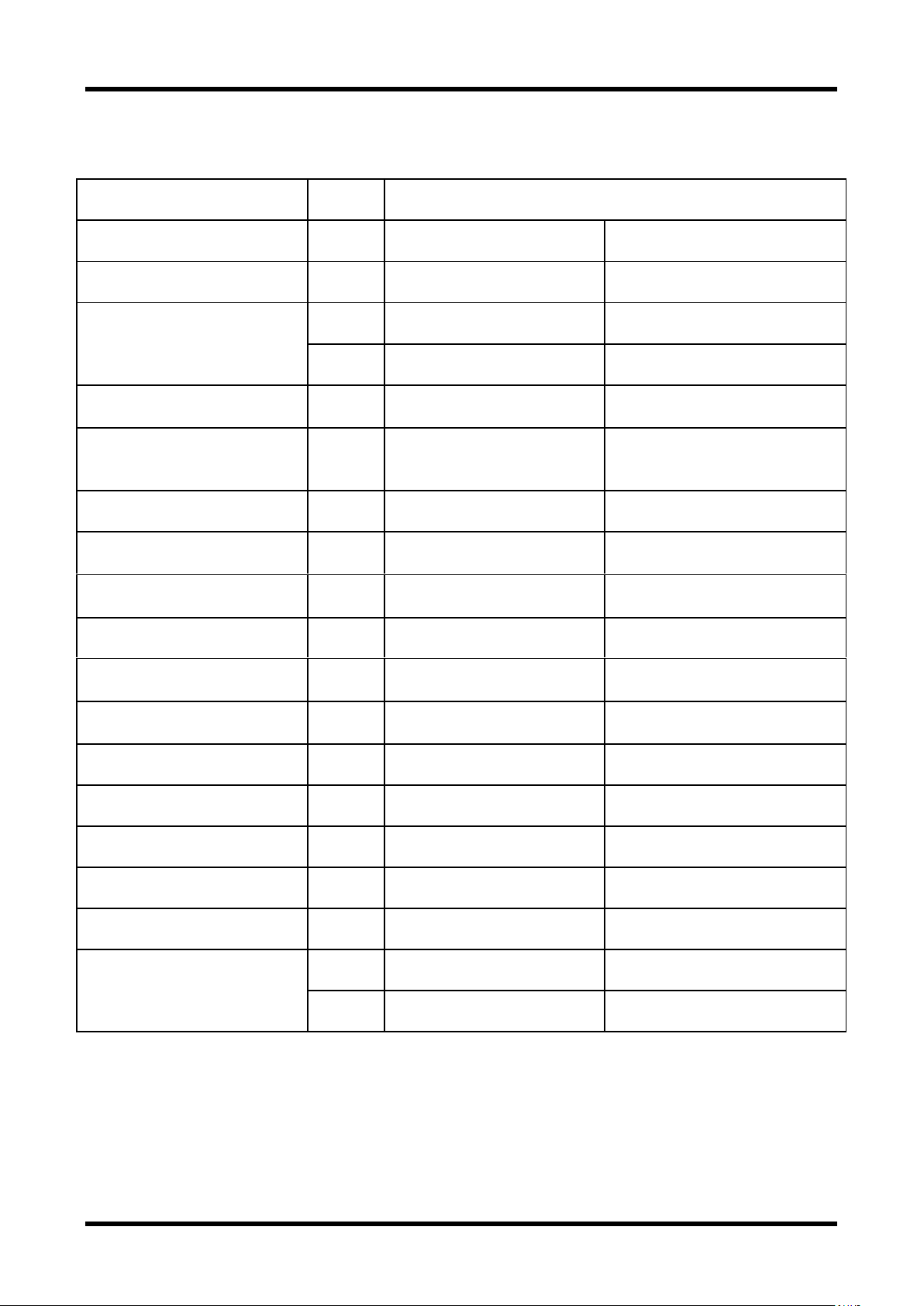

2.4. CULTIVATOR SPECIFICATIONS

CULTIVATOR MODEL

(RC-120)

(RC-150)

Overall dimensions

mm

1340 x 805 x 600

1645 x 805 x 600

Tilling width

in

45.6''

58.2''

cm

115.82

147.83

Recommended

Tractor HP range

HP

20-35

25-40

3-point Hitch type

-

Cat. I,

compat. Quick Hitch I cat.

ASAE

Cat. I,

compat. Quick Hitch I cat.

ASAE

Frame off-set

in

4''

-

Number of Flanges on

Rotor

No.

6

7

Number of tines per

Flange

No.

36

42

PTO Input speed

rpm

540

540

Rotor Shaft Speed

rpm

@540

242

242

Standard Tine

Construction

-

curved

curved

Transmission type

-

gear

gear

Max Working depth

cm

16.51

16.51

Rotor tube diameter

mm

70

70

Rotor Swing Diameter

mm

375

375

Driveline safety device

-

slip clutch

slip clutch

Weight (driveline

excluded)

lbs

397

441

Kg.

181

200

RC-Series Rotary Cultivators

4

3. SAFETY

Proper use of equipment, a strict observance of the safety messages listed below and application

of all reasonable practices to avoid any risks, prevents accidents or injury, allows the machine

working better and longer, and minimize the failures. The manufacturer assumes no liability for

any damage resulting from not applying the behavioral rules indicated into the manual.

3.1. GENERAL SAFETY INSTRUCTION

DANGER

The machine must be used only by authorized and well trained operators. The operator must have

read and understood the instructions of this manual, it must make adequate preparation for the

proper use of the machine and must hold a driving license. In case of doubt about the use of the

machine and/or the interpretation of this manual, the operator must contact the Manufacturer or

the Dealer.

WARNING

The manual must always remain with the machine. In case of loss or damage, request a new copy

to the Manufacturer or your Dealer.

WARNING

Follow strictly the rules prescribed by the safety pictograms applied to the machine.

WARNING

Be sure that all safety pictograms are legible. If pictograms are worn, they must be replaced with

others obtained from the Manufacturer, and placed in the position indicated by this manual.

DANGER

Before using the machine, make sure that all safety devices are installed and in good working

conditions. In case of damages of shields, replace them immediately.

DANGER

Is absolutely forbidden to remove or alter safety devices.

DANGER

Before starting, and during operation of the Cultivator, make sure there are no people or animals

in the operation area: the machine can project material from the back, with risks of serious injury

or death.

DANGER

Pay maximum attention to avoid any accidental contact with rotating parts of the machine.

DANGER

During operation, adjustment, maintenance, repairing or transportation of the machine, the

operator must always use appropriate Personal Protective Equipment (PPE).

DANGER

Do not operate the implement while wearing loose fitting clothing that can give rise to

entanglement in parts of the machine.

DANGER

RC-Series Rotary Cultivators

5

Do not operate the implement when tired, not in good condition or under the influence of alcohol

or drugs.

CAUTION

If the use of the machine is required at night or in conditions of reduced visibility, use the lighting

system of the tractor and possibly an auxiliary lighting system.

3.2. EQUIPMENT SAFETY INSTRUCTIONS

WARNING

Use the Cultivator for its intended purpose only. Improper use can damage the Cultivator and

cause serious injury to persons, animals, or death.

DANGER

The machine should be used by a single operator driving the tractor.

WARNING

Any unauthorized modification of the machine may cause problems in safety and relieves the

Manufacturer from any liability for damages or injuries that may result to operators, third parties

and objects.

WARNING

Before using the machine, familiarize yourself with its controls and its working capacity.

WARNING

Do not leave the Cultivator unattended with tractor engine running.

WARNING

Do not operate Cultivator on too muddy, sandy or rocky soils.

WARNING

Keep the machine clean from debris and foreign objects which may damage functioning or cause

injury.

WARNING

Do not use the machine if the category of the connecting pins of the Cultivator does not

match that of the tractor hitch system.

WARNING

Do not use the machine with missing bolts, screws, pins or safety pins.

WARNING

Never use the machine to transport or lift people, animals or objects.

WARNING

Make certain, by adding front ballast, that at least 20% of the total weight (tractor, implement and

ballast) is on the front axle of the tractor, to ensure stability.

WARNING

Before engaging the tractor PTO, make sure the tractor PTO speed is set as required for the

Cultivator (540 rpm). Do not over speed PTO or machine breakage may result.

RC-Series Rotary Cultivators

6

DANGER

Do not operate the Cultivator if the driveshaft is damaged. The driveshaft could be subject to

breakage during operation, causing serious injury or death. Remove the driveshaft and replace it

with an undamaged.

3.3. OPERATING SAFETY INSTRUCTIONS

WARNING

Before using the machine, be sure to have cleared the operating area from obstacles (stones,

branches, debris, etc...). Mark all the obstacles that cannot be eliminated (e.g. by means flags).

DANGER

Never engage the tractor PTO in the presence of people close to the driveshaft. The body, hair or

clothing of a person can get caught in rotating parts, causing serious injury or death.

DANGER

Before engaging the PTO and during all operations, make sure that no person or animal is in

immediate area of action of the machine. Never use the Cultivator if people are in his working

area.

DANGER

It's absolutely forbidden to stand near the Cultivator with moving parts.

WARNING

The operator must operate Cultivator lifting/lowering only from the driving seat of the tractor. Do

not perform lifting maneuvers on side or behind the tractor.

WARNING

Before making changes in direction, turns or going in reverse, slightly lift the Cultivator from the

ground after disengaging the power take-off, to avoid damage to the machine.

DANGER

In presence of steep slopes (greater than 15 degrees) the tilling action may cause instability of the

tractor, with risk of tipping and consequent serious injury or death hazard. Consult the manual for

the tractor to determine the maximum slope that the tractor is able to deal with.

DANGER

Always disengage the PTO before raising the Cultivator, and never engage the PTO with the

Cultivator in the raised position. The machine might throw objects at high speed, causing serious

injury or death.

WARNING

Never leave the driver's seat when the tractor is turned on. Before leaving the tractor, lower the

Cultivator to the ground, disengage the PTO, insert the parking brake, stop engine and remove the

key from the control panel.

DANGER

The PTO shields of tractor and implement side, the driveshaft shielding and the driveshaft

retaining chains must be properly installed and in good condition, to avoid risk of entanglement

with serious injury or death.

RC-Series Rotary Cultivators

7

DANGER

Before engaging the PTO of the tractor, always make sure that the drive shaft is mounted in the

correct direction, and that its clamping elements are properly connected both to tractor side and

to Cultivator side.

WARNING

Stop operating immediately if blades strike a foreign object. Repair all damage and make certain

rotor and blades are in good condition before resuming operation.

WARNING

Always disengage the tractor PTO when the driveshaft exceed an angle of 10 degrees up or down

while operating. An excessive angle with driveshaft rotating can break the driveshaft and cause

flying projectiles.

CAUTION

Avoid clutch's overheating caused by too long or frequent slipping of the clutch, since it can

damage the clutch components. Before checking slip clutch, make sure it has cooled. Clutch could

be extremely hot and cause severe burn.

CAUTION

Prolonged use of the Cultivator can cause overheating of the gearbox. Do not touch the gearbox

during use and immediately after, it could be extremely hot and cause severe burn.

WARNING

All adjustment operations on the Cultivator must be performed by qualified and trained operators,

with the tractor engine off, the PTO disengaged, the Cultivator lowered to the ground or on

security stands, the ignition key off and the parking brake set.

3.4. TRANSPORTING SAFETY INSTRUCTIONS

WARNING

Before transporting, determine the stopping characteristics of the tractor and implement.

WARNING

Transport only at speeds where you can maintain control of the equipment.

WARNING

When driving on roads, the implement must be in transport position adequately raised from the

road surface, with tractor lifting hydraulics locked so that the Cultivator cannot be lowered

accidentally.

DANGER

The implement may be wider than the tractor. Pay attention during transporting to persons,

animals or obstacles exposed.

WARNING

When turning, use extreme care and reduce tractor speed.

WARNING

Do not operate the tractor with weak or faulty brakes or worn tires.

RC-Series Rotary Cultivators

8

CAUTION

Always use tractor lighting system and auxiliary lighting system for an adequate warning to

operators of other vehicles, especially when transporting at night or in conditions of reduced

visibility.

DANGER

In case of Cultivator lifting, make sure that the lifting device chosen is suitable to perform the

operation safely, and use only the lifting points prescribed on Cultivator.

3.5. MAINTENANCE SAFETY INSTRUCTIONS

WARNING

All maintenance and repairing operations must be performed by qualified and trained operators,

with the tractor engine off, the PTO disengaged, the Cultivator lowered to the ground or on

security stands, the ignition key off and the parking brake set.

WARNING

Perform repairs and replacements necessary to the machine using only original spare

parts provided by the manufacturer or your dealer.

DANGER

Perform maintenance operations always using appropriate Personal Protective Equipment

(protective eye glasses, hard hat, hearing protection, safety shoes, overall and work gloves, filter

mask).

CAUTION

Before any maintenance operation, make sure that the parts which may become hot during use

(friction clutch, gear box...) have cooled.

WARN4435G

Do not perform repairs that you do not know. Always follow the manual instructions and in case of

doubt contact the Manufacturer or your dealer.

DANGER

Do not swallow fuels or lubricants. In case of accidental contact with eyes, rinse well with water

and consult a doctor.

3.6. STORAGE SAFETY INSTRUCTIONS

WARNING

Never leave the tractor unattended with the Cultivator in lifted position. Accidental operation of

lifting lever or a hydraulic failure may cause sudden drop of unit with injury or death by crushing.

DANGER

Following operation, or before unhooking the Cultivator, stop the tractor, set the brakes,

disengage the PTO, lower the attached Cultivator to the ground, shut off the engine, remove the

ignition key and wait for all moving parts to stop.

WARNING

Make sure all parked machines are on a hard, level surface and engage all safety devices.

CAUTION

RC-Series Rotary Cultivators

9

Place support blocks under Cultivator as needed to prevent unit from tipping over onto a child

and/or an adult. A Cultivator that tips over can result in injury or death.

CAUTION

Store the unit in an area away from human activity.

3.7. SAFETY LABELS

The safety labels applied on the machine give fundamental information for using the machine

safely.

Make sure safety labels are in good conditions. If pictograms are worn, they must be replaced with

others obtained from the manufacturer and placed in the position indicated by this manual.

Make sure the safety labels are legible. If necessary, wipe them by a cloth, with soap and water.

SAFETY LABELS POSITION AND DESCRIPTION

RC-Series Rotary Cultivators

10

1

Disengage the PTO, turn off the tractor engine,

remove the key and ensure that all rotating parts

have stopped before approaching the implement.

Read the operator’s manual before performing any

maintenance operation.

Thrown or flying objects hazard

2

Safety Wear

3

Crushing hazards & Thrown or Flying objects

hazards.

RC-Series Rotary Cultivators

11

4

Operate only with 540 rpm PTO.

5

Rotating Gears

6

Oil filling point

7

Lifting point

8

Grease filling point

9

Hand Hazard

4. SET UP

The Cultivator is delivered fully assembled and equipped with a driveshaft with torque limiter

(clutch discs) and related operating manual.

When the machine is delivered, check that there is no damage to the Cultivator or driveshaft. In

case of damage or missing parts immediately notify the manufacturer or your dealer.

RC-Series Rotary Cultivators

12

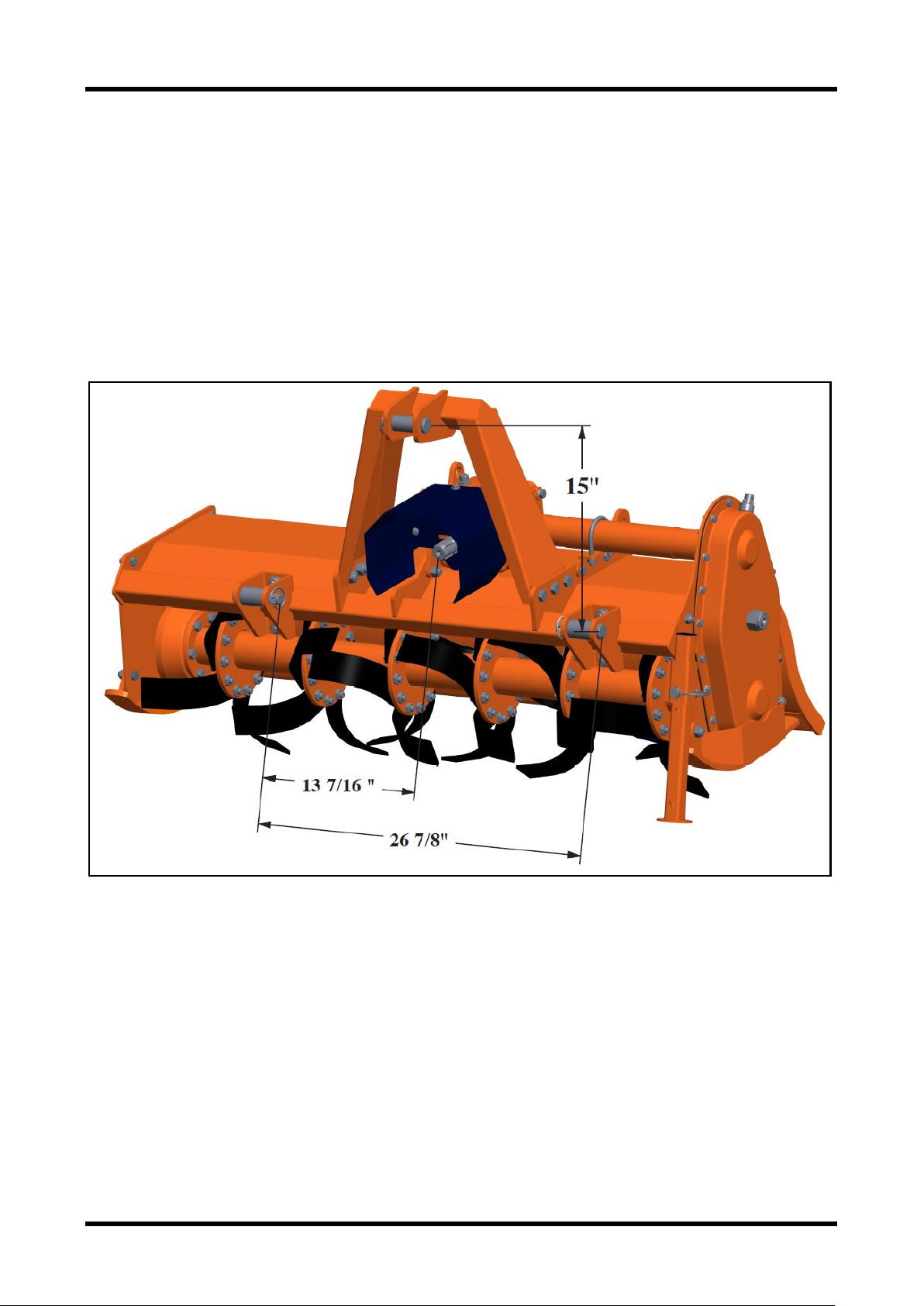

4.1. LOWER HITCHES POSITIONING

The RC-SERIES Cultivators are designed to be mounted on tractors equipped with:

3-point Hitch Category I (ISO 730 standard);

Quick Hitch Category I (ASABE Standard).

The position of the lower hitches must be adjusted accordingly.

If the tractor is equipped with a Quick Hitch Category I (ASABE Standard), verify that the lower

clevises show the pins oriented up (see figure), so that the distance between upper and the lower

pins is 15'' (381 mm), as required from the standard.

If this not occurs, proceed as follows for each of the two clevises::

remove the U-bolt and the clevis from the square tube;

invert the clevis orientation and reposition it on the square tube at distance of 13 7/16'' from

the center of Cultivator PTO. At the end of the operation the lower clevises should be positioned

symmetrically respect to Cultivator PTO, at distance of 26 7/8'' (683 mm);

re-tighten the U-bolt, referring to the tightening table of this manual.

If the tractor is equipped with a 3-point Hitch Category I (ISO 730 standard), verify that the lower

clevises show the pins oriented down (opposite than figure above), so that the distance between

upper and the lower pins is 18'' (460 mm approx), as required from the standard.

If this not occurs, proceed as follows for each of the two clevises:

remove the U-bolt and the clevis from the square tube;

RC-Series Rotary Cultivators

13

invert the clevis orientation and reposition it on the square tube at distance of 13 7/16'' from

the center of Cultivator PTO. At the end of the operation the lower clevises should be positioned

symmetrically respect to Cultivator PTO, at distance of 26 7/8'' (683 mm);

re-tighten the U-bolt, referring to the tightening table of this manual;

remove from upper and lower pins the bushings provided for coupling with Quick Hitch, through

the extraction of elastic pins. Replace the elastic pins when finished. Store the bushings for

possible future use.

4.2. CONNECTING TO THE TRACTOR

To connect the Cultivator to the tractor the operator must do the following:

drive the tractor in reverse, up to align the rear lifting arms to lower hitches of the Cultivator in

parking;

set the tractor's parking brake, stop engine, remove the ignition key and get off the tractor;

connect the lifting arms of the tractor to the lower hitches of the Cultivator, through the use of

the pins and the relative safety split pins;

raise the Cultivator until PTOs of tractor and machine are at the same height, then adjust the 3-

point top link so that the front of the machine is leveled to the back (the axis of the Cultivator

PTO must be parallel to the ground), in order to limit stress transmitted to the Cultivator

through the cardan shaft;

make sure that left side of the Cultivator is leveled with the right, by adjusting the tractor lifting

arms, then lock the arms to prevent swinging that could compromise the stability of tractor and

machine;

finally adjust the parking stand, placing it at the highest point by means of the related elastic

pin.

4.3. DRIVELINE INSTALLATION

Before installing the driveshaft, the operator must read the manuals of driveshaft and tractor,

checking in particular that rpm and direction of rotation of the tractor PTO match those of the

Cultivator.

If the direction of rotation of the PTO tractor does not match that of the Cultivator, contact the

manufacturer or your dealer.

To connect the driveshaft to the tractor and implement, the operator must:

park tractor and Cultivator on a flat surface, with parking brake set, engine off, and ignition key

removed;

check that safety devices of driveshaft, Cultivator and tractor are in good condition, otherwise

provide for their replacement;

remove the PTO shield of the Cultivator through the fixing screws;

position the driveshaft with clutch turned towards the implement side;

insert the clutch hub on the Cultivator PTO, then ensure its tightening onto shaft through

its fastener;

replace the PTO shield of the Cultivator through the fixing screws;

insert the driveshaft yoke on the tractor PTO, then ensure its tightening onto shaft through its

fastener;

RC-Series Rotary Cultivators

14

hook to the tractor and Cultivator the two retaining chains of the the driveline shielding, to

prevent shielding rotation during functioning of the machine.

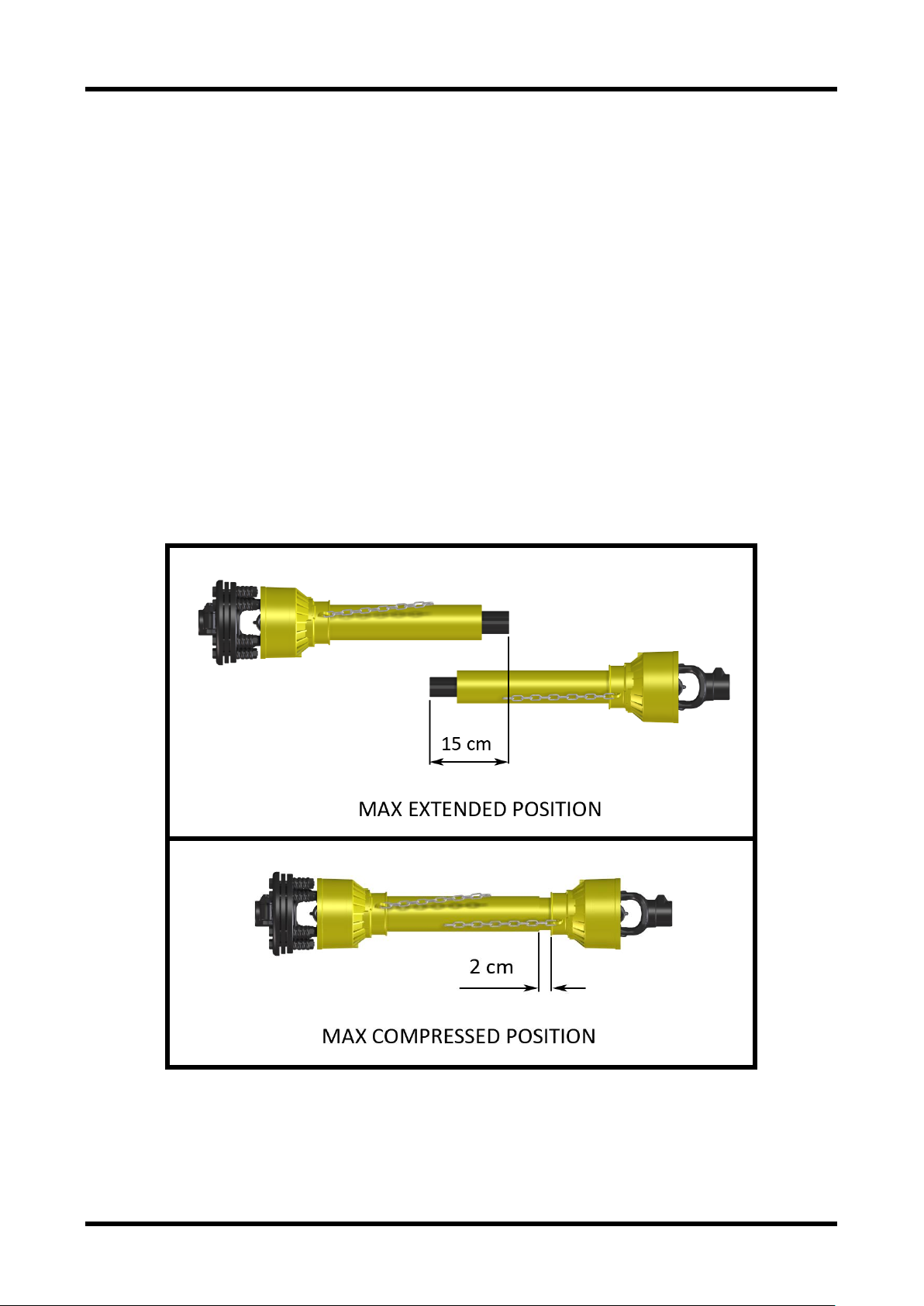

DRIVELINE LENGTH CHECK

Before operating the Cultivator, ensure that the size of driveshaft is adequate. The driveshaft

supplied with the machine has a standard length, therefore it may need an adaptation of the

length, depending of the tractor which the Cultivator is combined.

The length of the driveshaft must be such to:

avoid bottom out of the transmission tubes, when the driveshaft is in compressed position

(when Cultivator is raised up off the ground);

ensure an overlapping of the transmission tubes enough to transmit the torque required, when

the driveshaft is in max extension (when Cultivator is in its lowest position in the ground).

When the driveshaft is at its minimum length (max compressed position), there must be at least a

2 cm of distance between the ends of each transmission tube and the yokes side.

When the driveshaft is at its maximum operational extension, there must be an overlap between

the tubes profiles of 15 cm at least.

A driveshaft that is too long may cause structural damages to the tractor and machine. If the

driveshaft is too long, it may be adapted by removing it and shortening the tubes according to the

instructions provided by the manufacturer in its use and maintenance manual.

A driveshaft too short can cause disengage of the tubes during operation, with severe hazard for

the operator and structural damage to the tractor and machine. If the driveshaft is too short, it

must be replaced with a longer one. In this case contact the manufacturer or your dealer.

RC-Series Rotary Cultivators

15

IMPORTANT

before operating the Cultivator the first time, make sure that the driveshaft is lubricated in

accordance with how indicated in the instruction booklet;

before operating the Cultivator the first time, and after long periods of inactivity, make sure that

the driveline clutch has run a short "run in" in accordance with what indicated in the instruction

manual of the manufacturer, removing the possible oxidation of the components that may

compromise the correct slipping during the usage (see also section "Maintenance");

always engage the tractor PTO at low rpm to minimize the effect of the peak torque on the

driveline and the machine.

4.4. TRACTOR-CULTIVATOR STABILITY

The weight of the machine modifies the stability of the system tractor-Cultivator, resulting in loss

of steering control and braking.

The front axle of the tractor should always loaded with at least 20% of the overall weight of the

system tractor-Cultivator.

CAUTION

Check the lifting capacity and stability of the tractor and, if necessary, applying the front ballast.

To determine the appropriate characteristics of the ballast, refer to the manual of the tractor.

5. OPERATING

Before operate the Cultivator, make sure you have read and understood the operating manuals of

the Cultivator, tractor and PTO shaft, and followed what is described in the section "Set Up".

DANGER

During operation, adjustment, maintenance, repairing or transportation of the machine, the

operator must always use appropriate Personal Protective Equipment (PPE).

Before starting work, ensure that all machine guards are in good conditions and fully functional.

During operation, the machine can throw material from the back: prevent people and animals to

approach the operational area.

5.1. START UP

Before the start up and before each use, perform the following pre-operation inspections and

service of the implement:

check that the Cultivator has not damaged functional parts and has all mechanical parts in good

condition. Repair and / or replace the damaged parts;

check that the Cultivator has no missing parts (pins, safety pins, plugs oil ...). Restore the

missing parts;

check that all guards and safety devices have no damages and are properly positioned. Repair

and / or replace the damaged shieldings, restore the correct position;

verify that the PTO driveshaft is properly installed (see section: Connection of the drive shaft);

RC-Series Rotary Cultivators

16

check that the driveshaft clutch is in good condition, and that its components are not subject to

"sticking" (see section: Maintenance / Driveline);

check the presence of lubricant in all greasing points of the Cultivator (driveshaft, supports...)

(see sect. Maintenance / Driveline and Maintenance / Support rotor);

check for oil leaks from the gearbox or the transmission side cover. Identify the reason of loss,

then repair and / or replace the damaged components;

check the correct oil level in the gearbox and in transmission side box (see section

maintenance);

check that blades are not excessively worn and the relating hardware is correctly tightened (see

sect. Maintenance);

check that all the Cultivator hardware is properly tightened. Refer to the tightening table in the

manual for proper torque values;

check that all safety decals are correctly positioned, in good condition and legible. Replace any

damaged decals;

check that there is no constraints that may prevent the movement of equipment. Remove any

constraint.

Before the start up and before each use, make the following checks on the operating area

identified for tillage:

check that area is clear of foreign objects (rocks, branches or debris). Remove any obstacle and

visibly highlight obstacles that cannot be eliminated (e.g. by means flags);

make sure in the working area exposed there are no people or animals;

make sure the soil to be worked is not too grassy, muddy, sandy or rocky.

WARNING

Before conducting the above inspections and service, make sure the tractor engine is off, all

rotation parts are completely stopped and the tractor is in park with the parking brake engaged.

Make sure the Cultivator is resting on the ground or securely blocked up and the tractor lifting

hydraulics locked.

Once all the checks above have been done, start tractor and the Cultivator as follows:

start the tractor and engage the tractor PTO at low rpm, making sure that the Cultivator is NOT

in the raised position but close to the ground, then increase speed engine until to 540 rpm;

lower the Cultivator on the ground and simultaneously start driving the tractor at low speed.

Subsequently increase the ground speed depending on ground conditions;

If the environmental temperature is very cold , it's recommended to wait a few minutes with the

PTO of the tractor at low rate before lowering the Cultivator completely on the ground;

drive for a while operating the Cultivator, then stop the tractor to check the quality of the work

performed. If you need to get off the tractor, lift the Cultivator just out of the ground, reduce

engine speed and disengage PTO, set the parking brake, stop engine and remove the ignition

key;

If the working depth and/or soil texture are not as desired, correct them by adjusting the skids

and/or the rear cover (see section Adjustments).

This manual suits for next models

2

Table of contents

Popular Farm Equipment manuals by other brands

Schaffert

Schaffert Rebounder Mounting instructions

Stocks AG

Stocks AG Fan Jet Pro Plus 65 Original Operating Manual and parts list

Cumberland

Cumberland Integra Feed-Link Installation and operation manual

BROWN

BROWN BDHP-1250 Owner's/operator's manual

Molon

Molon BCS operating instructions

Vaderstad

Vaderstad Rapid Series instructions