shanghai koolspace Vinage Keeper 500 Supplement

ASSEMBLY & OPERATION MANUAL

500

~ 2 ~

LOCATING YOUR WINE CELLAR

Provide 2 1/2” minimum clearance for both sides and back; keep the top clear.

Never locate your wine cellar outdoors or in an area with extremes of temperature and humidity. These units

must be placed/located/operated in air-conditioned environments which do not “trap” the warm air exhaust.

Temperatures in surrounding area must not exceed 80 °F (25 °C) with relative humidity levels not to exceed 70%

R.H.. Never set your temperatures below default (57ºF) whenever ambient conditions are warm (above 75ºF) or

humid (above 50%R.H.).

Outlet power must be a DEDICATED separately fused, grounded, 15 Amp 110 - 120 V line or 7.5 Amp - for 240 V

models (CHECK BOX OR SERIAL NUMBER LABEL ON UNIT FOR YOUR LINE VOLTAGE REQUIREMENTS).

You must monitor your unit DAILY. If unit is in “Alarm”, unplug the unit immediately.

Koolr Products Inc. will not be liable or responsible for incidental or consequential damages. (See Warranty).

Place unit in a clean area and allow access to the exterior surfaces for periodic vacuuming of the condenser coil.

(See troubleshooting for details.)

Clean using a damp cloth and no detergents or polishes under any circumstances.

Always remove all bottles before relocating your wine cellar.

AREA FOR ASSEMBLING YOUR WINE CELLAR

TOOLS

Rubber mallet, hex wrench (included), phillips screwdriver.

Helper is needed.

TEST THE COOLING UNIT

Plug it in on a table top, to verify that controls and display are functional, and that the unit is producing cool air

after a few minutes of operation.

Note that the electronic controller has a one-minute safety delay between initial plug-in and start-up of the

compressor.

BEFORE YOU START !

of the unit or on the light cord.

~ 3 ~

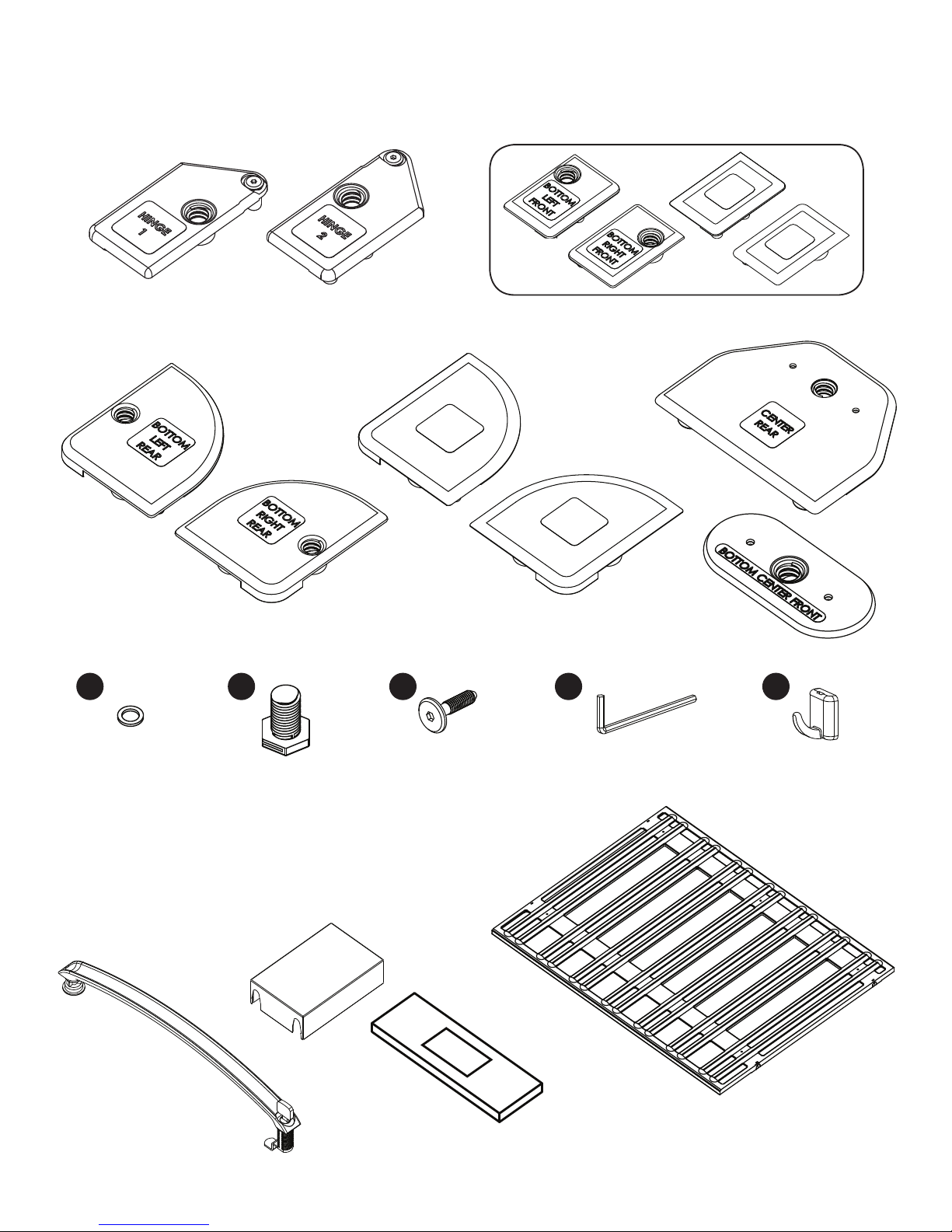

x 2 x 2

x 1

x 1

B

Legs

x 6

A

Hinge Washer

x 2

Shelves

x 26

Handle and Lock

x 2

Cooling Unit Bolt

in cooling unit box

x 2

C

Allen Key

in cooling unit box

x 1

D E

Hook

x 2

TOP

LEFT

REAR

TOP

RIGHT

REAR

x 1

x 1 x 1

x 2

SPACER

Spacer

x 2

CONNECTOR PLATES

HINGES

TOP

LEFT

FRONT

TOP

RIGHT

FRONT

DISCARD !

HARDWARE

( OPEN ALL BOXES AND PACKAGES FIRST! )

Brace

x 4

~ 4 ~

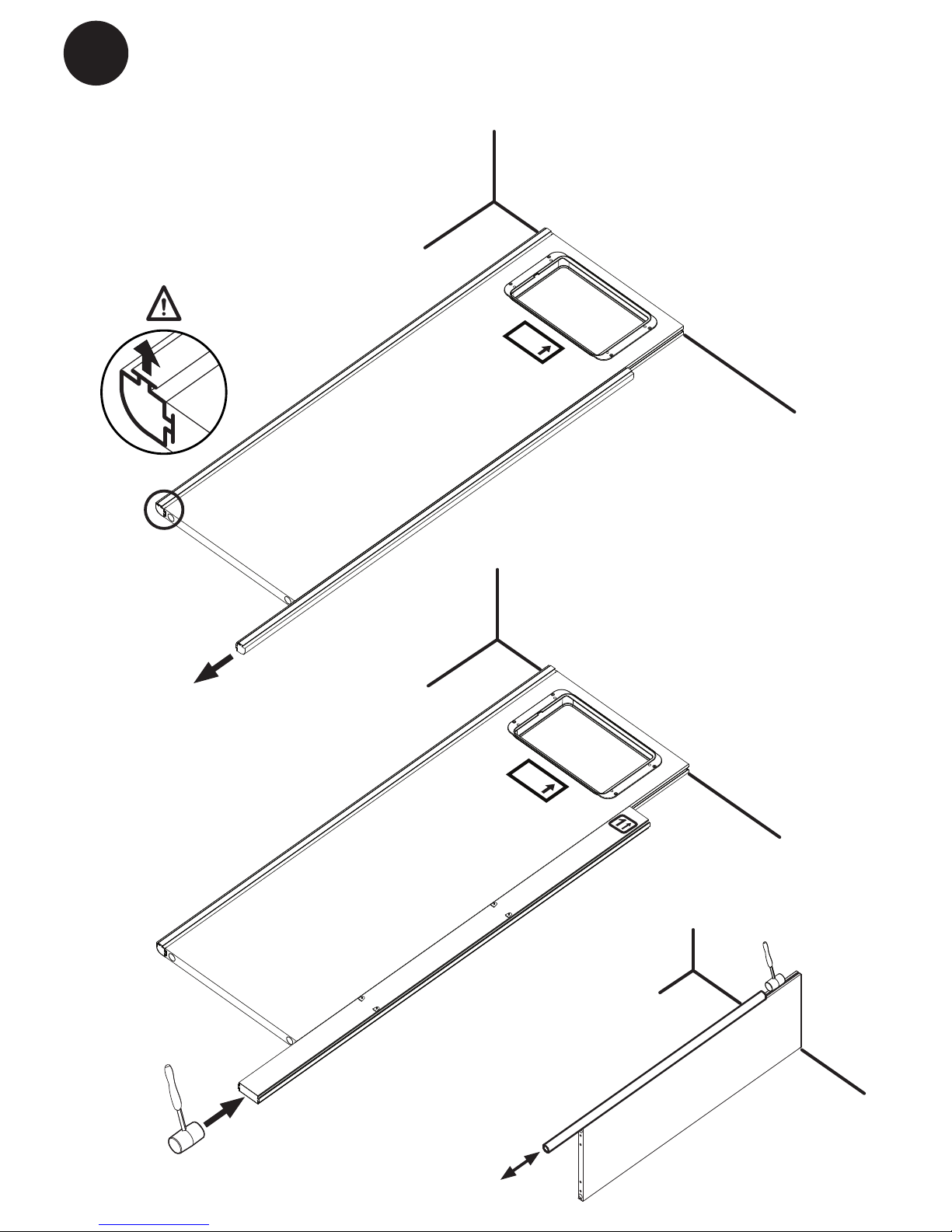

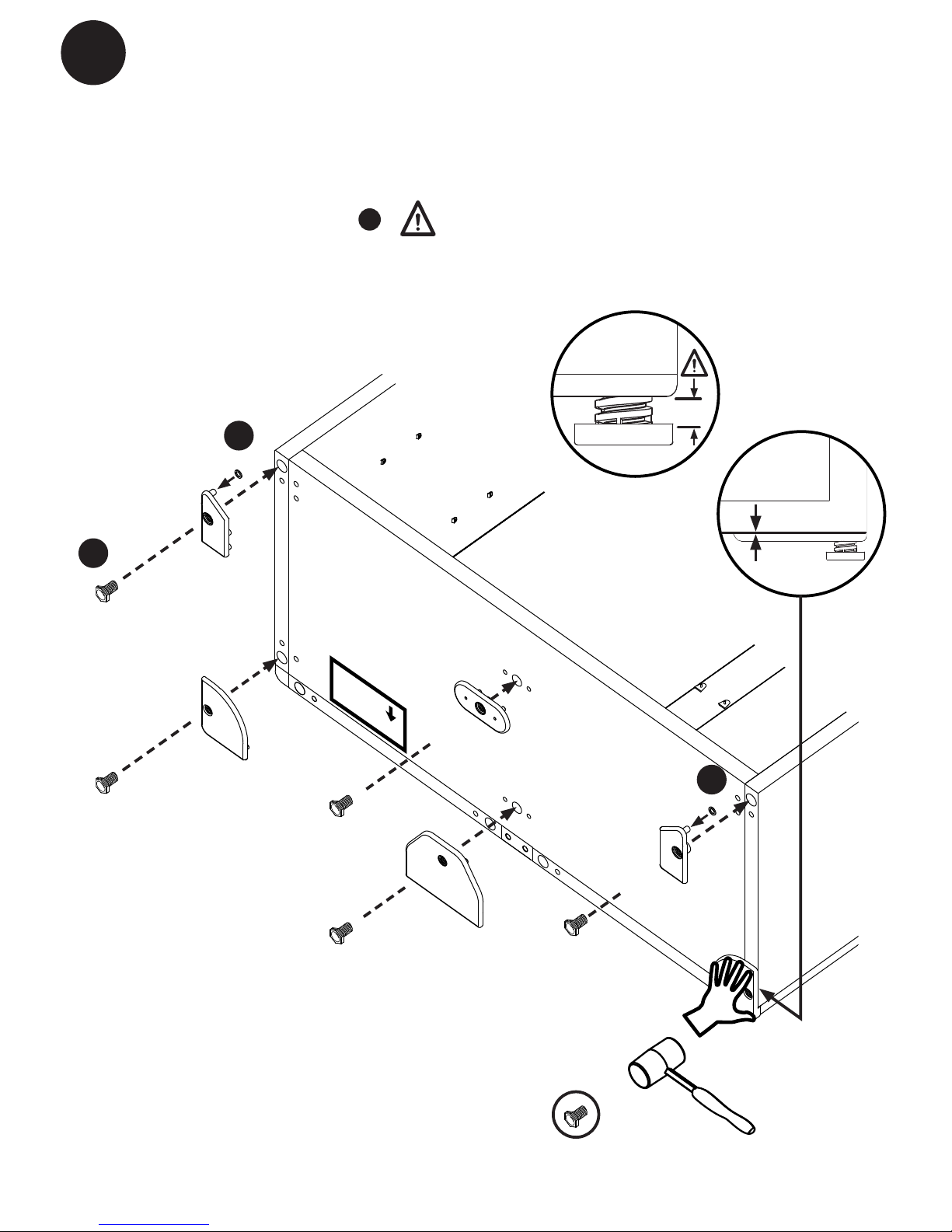

REMOVE RIGHT CORNER

1

BACK

PLACE AGAINST WALL

FLOOR

WALL

BACK

POST 1

BACK

PLACE AGAINST WALL

FLOOR

WALL

BACK

RIGHT CORNER

FLOOR

WALL

TIP

REMOVE

~ 5 ~

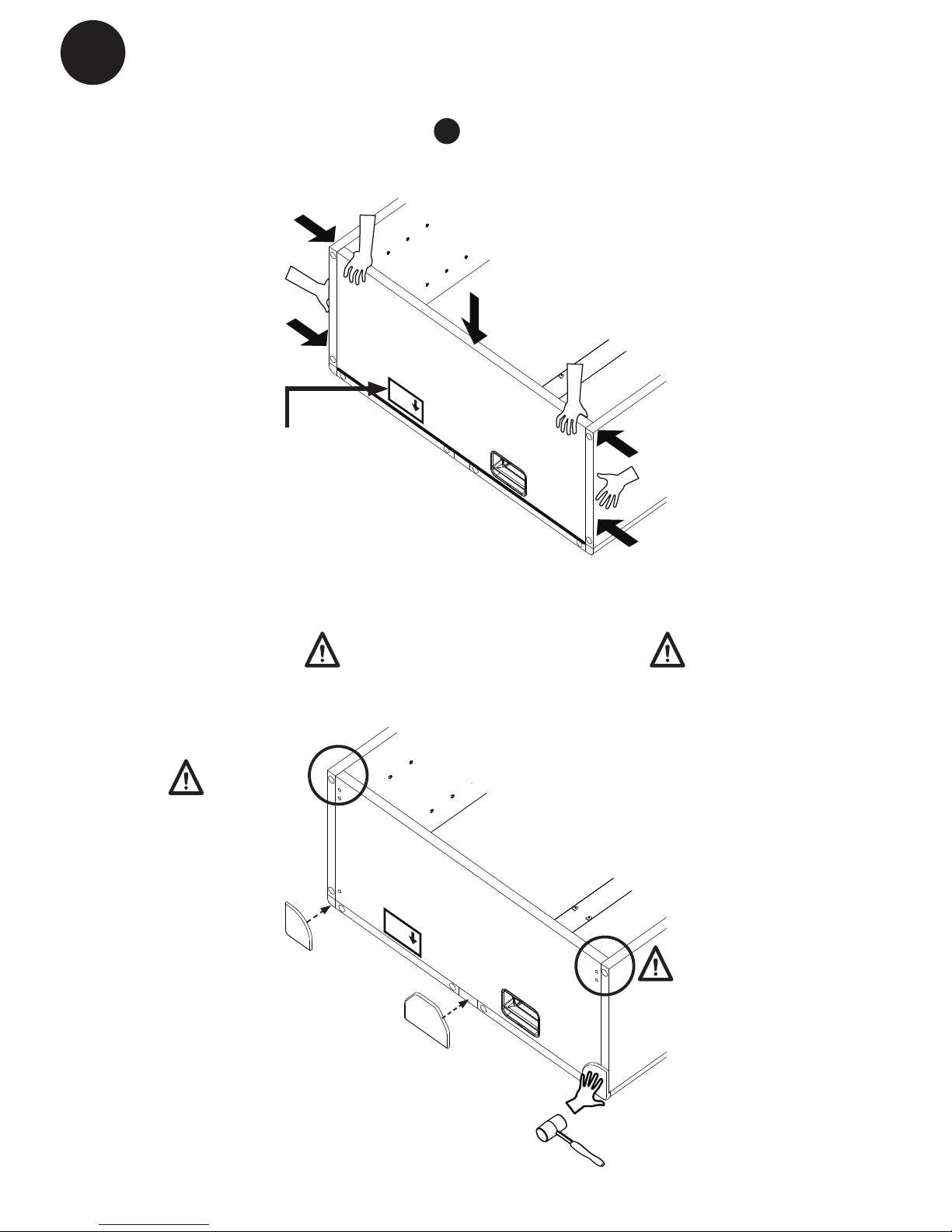

2

REINSERT

FLOOR

BACK

PLACE AGAINST WALL

BACK

RIGHT

BACK

RIGHT

WALL

BACK

POST 1

RIGHT CORNER

FLOOR

BACK

RIGHT

WALL

BACK

RIGHT

RIGHT CORNER

~ 6 ~

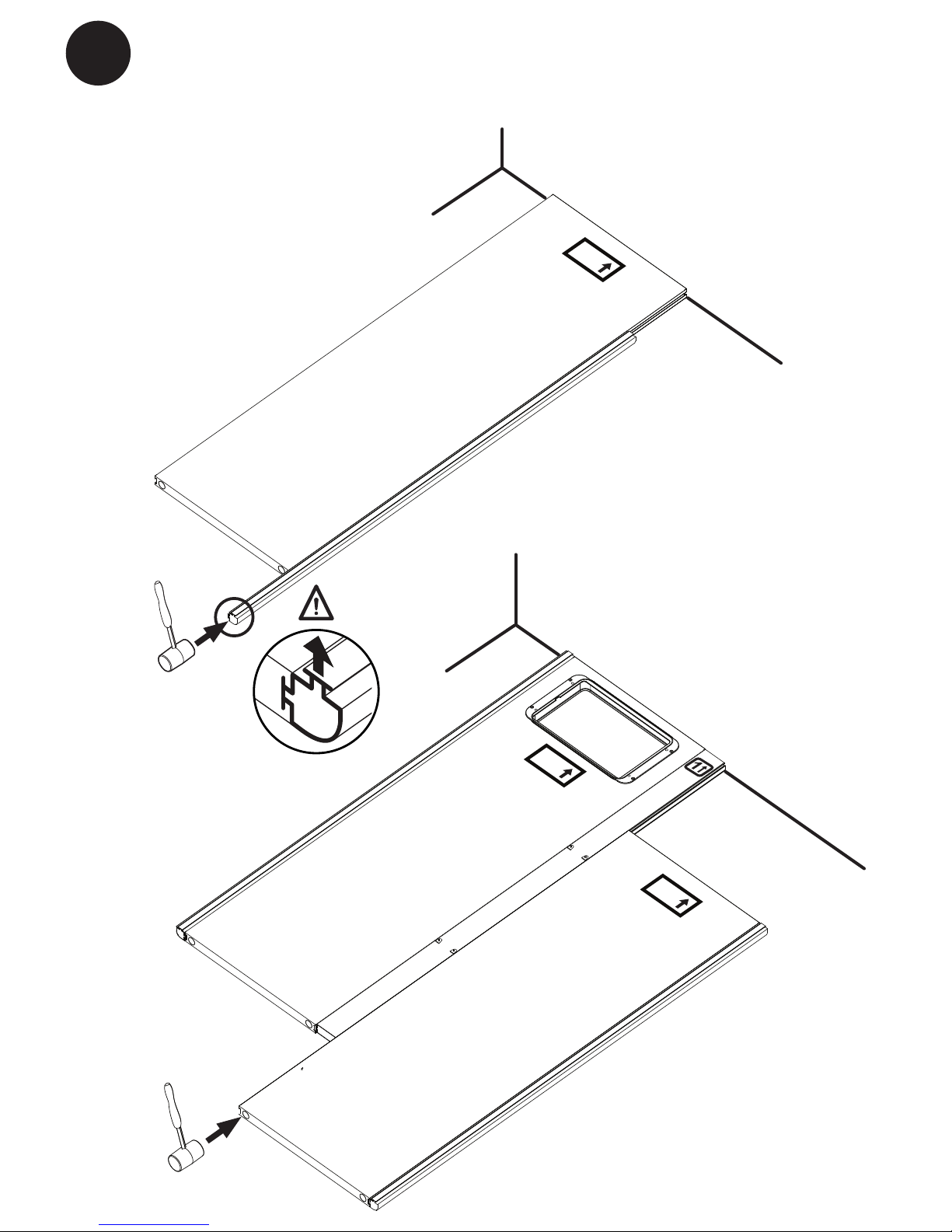

BACK

PLACE AGAINST WALL

LEFT

BACK

RIGHT

LEFT

RIGHT

WALL

BACK

RIGHT

SPACER SPACER

BACK

PLACE AGAINST WALL

LEFT

LEVEL

PUSH OR TAP

AT BOTTOM

TO TAB

LEFT

SPACER

LIFT

3

~ 7 ~

BACK

PLACE AGAINST WALL

LEFT

BOTTOM

OUTSIDE BACK

4INSTALL BOTTOM

2. REST BOTTOM ON SPACERS

OK

NO

SPACER SPACER

BOTTOM

OUTSIDE BACK

BACK

PLACE AGAINST WALL

LEFT

4. PULL OUT

SPACERS

BOTTOM

BOTTOM

BACK

PLACE AGAINST WALL

LEFT

BOTTOM

OUTSIDE BACK

BOTTOM

PRESS

PRESS

PRESS

PRESS

~ 8 ~

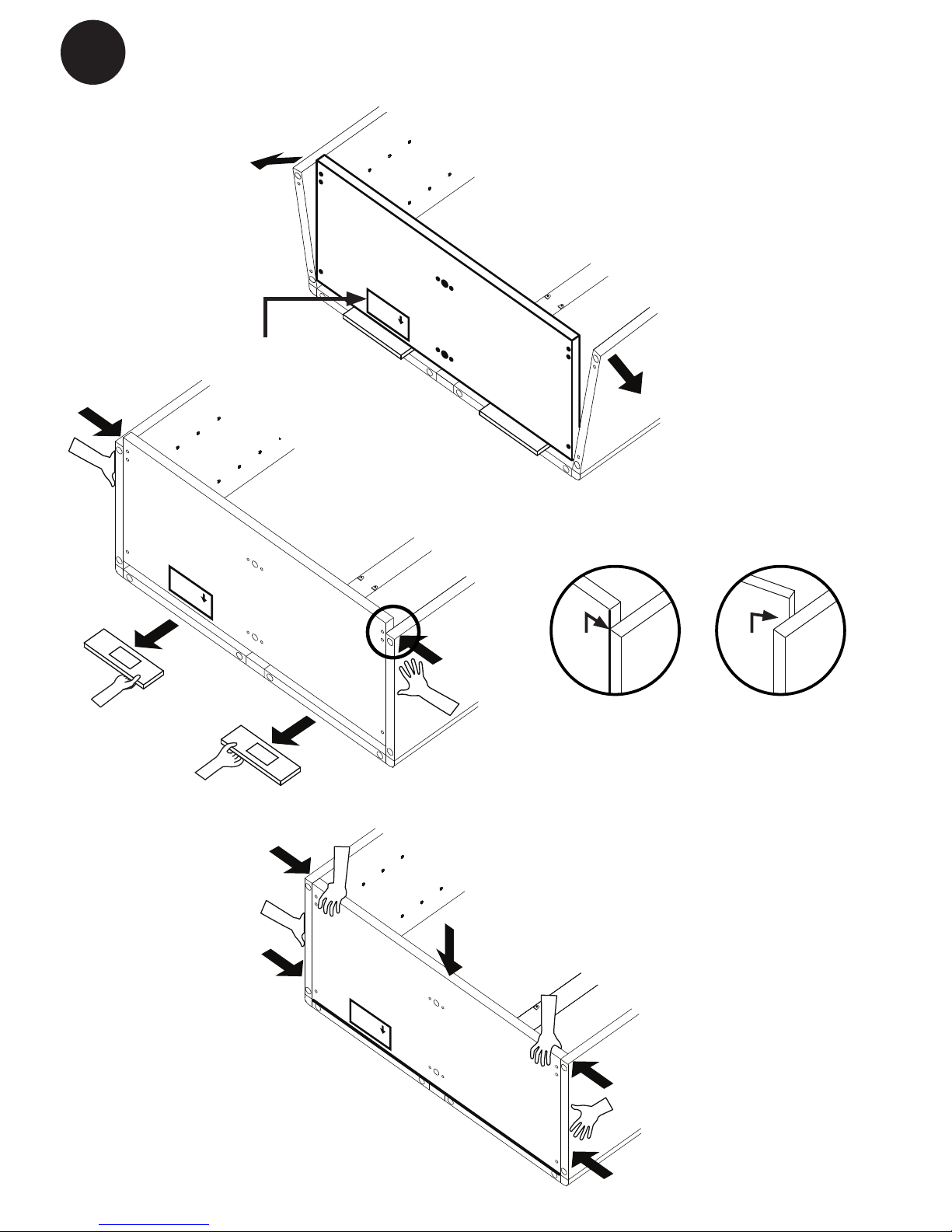

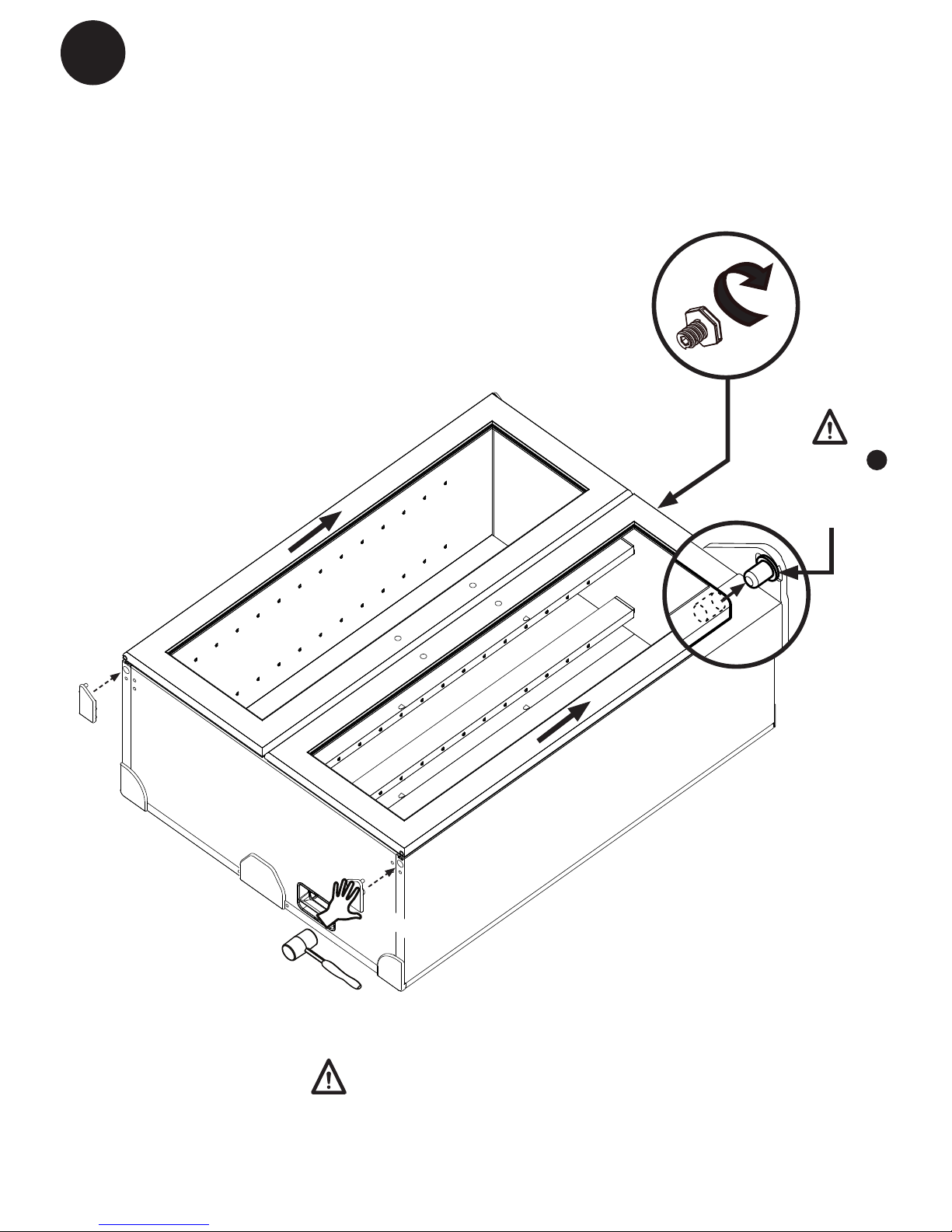

5

HAND PRESS IN ALL CONNECTOR PLATES IN BOTTOM

TAP IN CONNECTORS TIGHTLY (NO GAP) WITH CLOSED HAND OR RUBBER MALLET

SCREW IN ALL LEGS LEAVE 1/4” SPACING ON ALL LEGS

INSTALL BOTTOM CONNECTOR PLATES

1/4”MIN

BOTTOM

OUTSIDE BACK

BOTTOM

A

BOTTOM

LEFT

REAR

TAP

GENTLY

BOTTOM

RIGHT

REAR

HINGE 1

HINGE 2

CENTER

REAR

BOTTOM

CENTER

FRONT

B

LEGS

WASHER

A

WASHER

B

NO GAP!

~ 9 ~

BACK

PLACE AGAINST WALL

LEFT

TOP

OUTSIDE

BACK

TOP

REPEAT STEP ON PAGE 7 FOR TOP

4

6

DO NOT INSTALL HINGES YET!

INSTALL TOP CONNECTOR PLATES

BACK

PLACE AGAINST WALL

LEFT

TOP

OUTSIDE

BACK

TOP

RIGHT

REAR

TAP

GENTLY

TOP

LEFT

REAR

CENTER

REAR

TOP

PRESS

PRESS

NO HINGE

NO HINGE

PRESS

PRESS

~ 10 ~

7

INSTALL CENTER POSTS

2

4

3

TOP

SLOTS

~ 11 ~

2

4

3

8

HINGE 2

PLACE WASHERS FIRST

INSTALL TOP HINGES

TURN BOTH CENTER LEGS

TO RAISE LEGS SLIGHTLY

TOP

ON BOTTOM

HINGES ONLY

HINGE 1

TAP

GENTLY

WASHER A

~ 12 ~

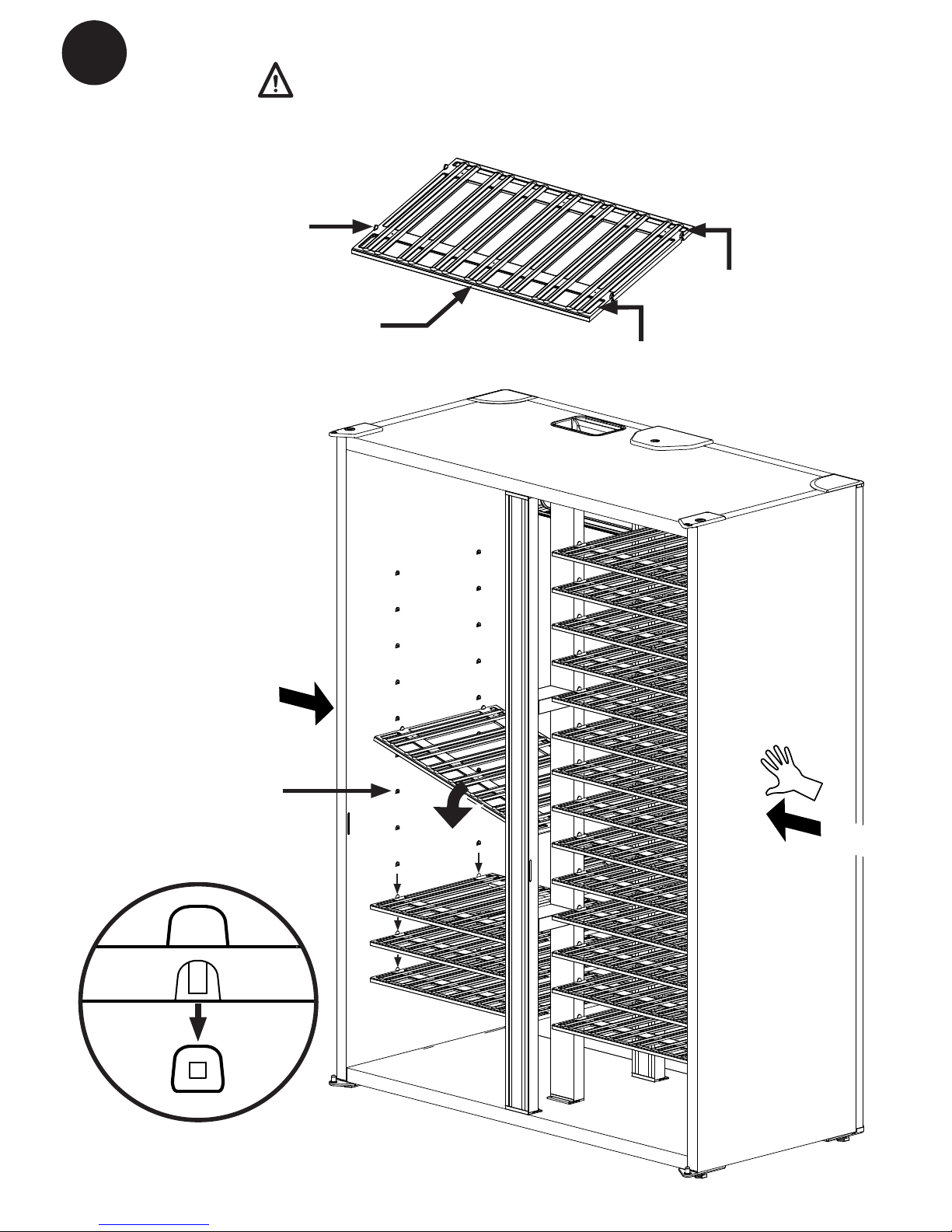

9

5

5

6

6

CELLAR BOTTOM

INSTALL BRACES 5 AND 6

( HELPER NEEDED TO HOLD CABINET STEADY )

6

TABS

ALIGN TO TABS, PUSH DOWN BRACES 5 (X 2)

AND 6 (X 2)

~ 13 ~

PRESS

CELLAR BOTTOM

10 INSTALL SHELVES

TAB REFERENCE

START AT MIDDLE

PRESS IN SIDES

CLICK SHELF

OVER TABS

LONGER

SHORTER

FRONT

SHELF

TAB

PRESS

~ 14 ~

11 PLACE COOLING UNIT IN CABINET

C

IN COOLING

UNIT BOX.

CLEAR OPENING

PUSH THROUGH

GET HELPER TO

FASTENING

LEVEL TO

OPENING

UP

TIGHT!

~ 15 ~

12

13

Wine

List

Wine

List

CONNECT LIGHT AND HOOKS

LED LIGHT : WARM WHITE GLOW FOR NATURAL LIGHTING, NO HEAT, ENERGY EFFICIENT

E

USE HOOK TO

HANG WINE

LISTS OR

BOTTLE OPENER

INSTALL HANDLE

ROUNDED EDGE OF NUT

FACES WASHER

UP!

UP!

~ 16 ~

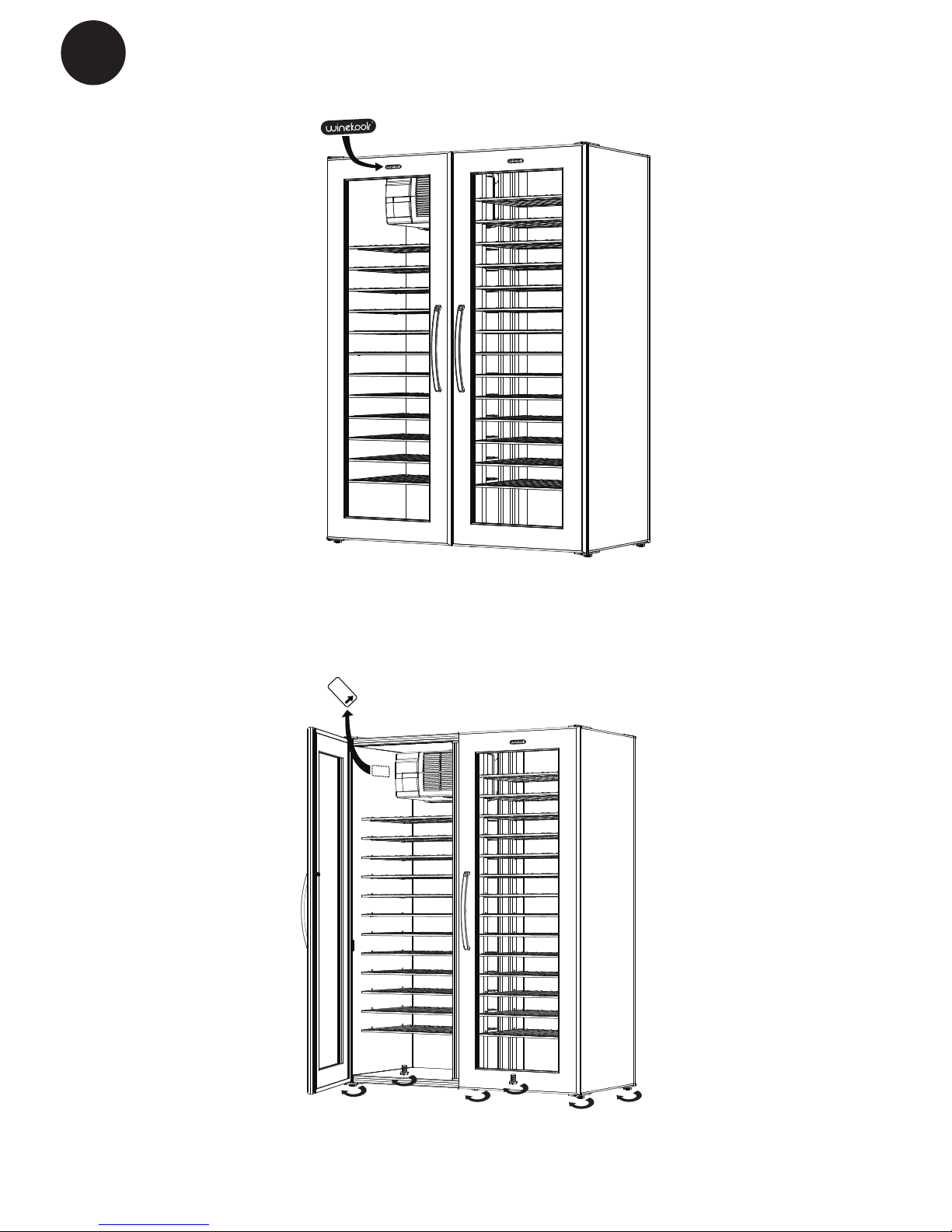

14 PLACE LOGO

LEVEL CELLAR

REMOVE VISIBLE STICKERS

LEFT

COMPENSATE FOR YOUR FLOOR

~ 17 ~

15

D

LEVEL DOOR

TIP: ADJUST LEGS TO HELP LEVEL DOOR

ADJUST HINGES IF REQUIRED

NEVER MOVE LOADED CABINET !

EMPTY FIRST !

~ 18 ~

DISASSEMBLY

REMOVE COOLING UNIT AND SHELVES

LAY CELLAR DOWN

FULLY TIGHTEN LEGS

PRY OFF ALL CONNECTOR PLATES WITH FLAT SCREWDRIVER

BOTTOM

OUTSIDE

BACK

BOTTOM

TIGHTEN LEGS

FULLY

PRY OFF

CONNECTOR PLATE

REUSE LEG

FOR TOP HINGES

AND CENTER REAR

~ 19 ~

FEATURES:

Default SET temperature 57º F/14º C (ideal for wine storage).

Calibration option of the temperature sensor.

Display of actual temperature by request.

SET temperature range 52ºF-64ºF.

Digital temperature sensor.

Dual display Fº/Cº.

Settings are stored in memory for power failures.

OPERATION:

The display will show the detected temperature until the temperature falls within 3º of the SET POINT (normal cooling range).

If the temperature is above the default 57º F + 1º or other preset value, after a delay of 1 minute the fan will start, followed by the

compressor within the next minute.

The unit will cycle ON/OFF based on the temperature reading. Fan speeds are automatically set by the controller to achieve optimum

performance.

Minimum ON and OFF cycle times are imposed by software, to prevent "short cycling".

SAFETY FEATURES:

ALARM: - If the temperature exceeds 72º F the unit will shut down, a sound warning will start and the display will blink

alternating with the temperature reading.

- The unit will restart and continue the cooling and cycling if the temperature falls below 72º F.

TO RESET: - Unplug and re plug the unit after 10 minutes.

57º 56º

70º 57º

57º 57º

57º 58º

57º 56º

57º 14º

57º 57º

57º F0

F0 F1

F0 -1

Actual temperature: PRESS

SET temperature: PRESS

PRESS and RELEASE

To increase: PRESS once per degree

To decrease: PRESS once per degree

The new value will be memorized and the controller will reset automatically.

PRESS and HOLD until buzzer sounds in 5 seconds

The new value will be memorized and the controller will reset automatically.

PRESS and HOLD while holding PRESS and RELEASE BOTH QUICKLY

Wait 5 seconds

USE for each degree of positive offset

for each degree of negative offset

DISPLAY EXAMPLE

EROFEB

TO DISPLAY:

TO MODIFY SET

TEMPERATURE

(range is 52-64ºF):

TO CHANGE FROM

ºF to ºC: or ºC to ºF

TO CALIBRATE:

CONTROLLER

OPERATION ACTION

NOTE: A negative offset will result in a warmer cabinet and a positive offset will result in a cooler cabinet.

The new value will be memorized and the controller will reset automatically.

CONTROLS : PLUG IT IN (wait one minute) and ENJOY!

57

KEYS

DISPLAY:

+

-

AL

~ 20 ~

MAXIMUM CAPACITIES AND LOADING TIPS

Maximum capacities and sample loading arrangements for Winekoolr wine cellars are illustrated below. Standard Bur-

gundy and Bordeaux bottles are best arranged with necks facing out; some taller bottles may need to be arranged neck

to neck. Never stack bottles more than two rows high on a shelf; all shelves must be installed as directed. Avoid placing

bottles directly in front of the cooling unit’s circulating fan for more uniform temperature in cabinet.

Maximum capacity 500 bottles

Based on 10% (50 x 1/2 bottles)

MODEL 500

Specialized

Bottles

1/2 bottle

Ice wine

Magnum

Standard

Bordeaux 3”

Burgundy 3.25”

750 ml bottles

Champagne 3.5”

Standard bottles

Odd sized bottles

or Case storage

14

14

14

14

14

14

14

14

14

14

14

14

14

26

14

14

14

14

14

14

14

14

14

14

14

42

Standard

750 ml bottles

6

50

The top shelf of the cabinet should have the coldest temperature and may be used as your “chilling” section.

All Wine Cabinets have minor differences in temperature depending on where articles are stored. Top to Bottom

differences will be present in any Cellar due to layering and pressure differences. The coldest temperatures will

occur closest to the “Top” where the cold air originates.

The temperature readout represents samples of the air close to the position of the sensor. Other points in the cabinet

will vary according to many factors, including the type of bottle loading, proximity to the door, corners, exposure to

outside temperature, door usage etc. Just as in air conditioned rooms and refrigerators, not all locations measure the

same temperature.

For example if you measure the air temperature exiting the coil, it will always be substantially colder than the set

temperature. It is this basis that governs the ultimate tempera

air back into the cooling unit causing short cycles.

Remember, the important element for storing wine is constant temperature, not absolute temperature. We do guaran-

tee that if your cellar is working normally the liquid temperat 1/4 of a degree C.

IMPORTANT NOTE

Table of contents

Other shanghai koolspace Wine Cooler manuals