2/6

GENERAL SAFETY PRECAUTIONS

Danger exists when loads are lifted, particularly when a winch is not being used properly or

is poorly maintained. Because an accident or serious injury could result, apply special

precautions to the winch during operation, assembly, maintenance and inspection.

WARNING

NEVER use this winch for lifting or moving persons.

NEVER lift or transport loads over or near people. Keep others away.

NEVER exceed lifting capacity stated on the winch.

ALWAYS make sure that winch anchoring structure provides adequate support and

withstands full load and all lifting operations.

ALWAYS let people around know when lifting is about to begin.

ALWAYS read the operation manual and safety instructions.

WARNING

Before use

ALWAYS ensure that operator is physically strong enough, qualified and instructed, older

than 18 years, familiar with this manual and trained in safety precautions and way

how to work and operate with the winch.

ALWAYS inspect winch and wire rope condition prior to operating the winch.

ALWAYS ensure wire rope is not corroded, frayed, is clean and undamaged.

NEVER use damaged or worn winch.

NEVER lengthen the wire rope with the help of clamps or by any other way.

WARNING

During operation

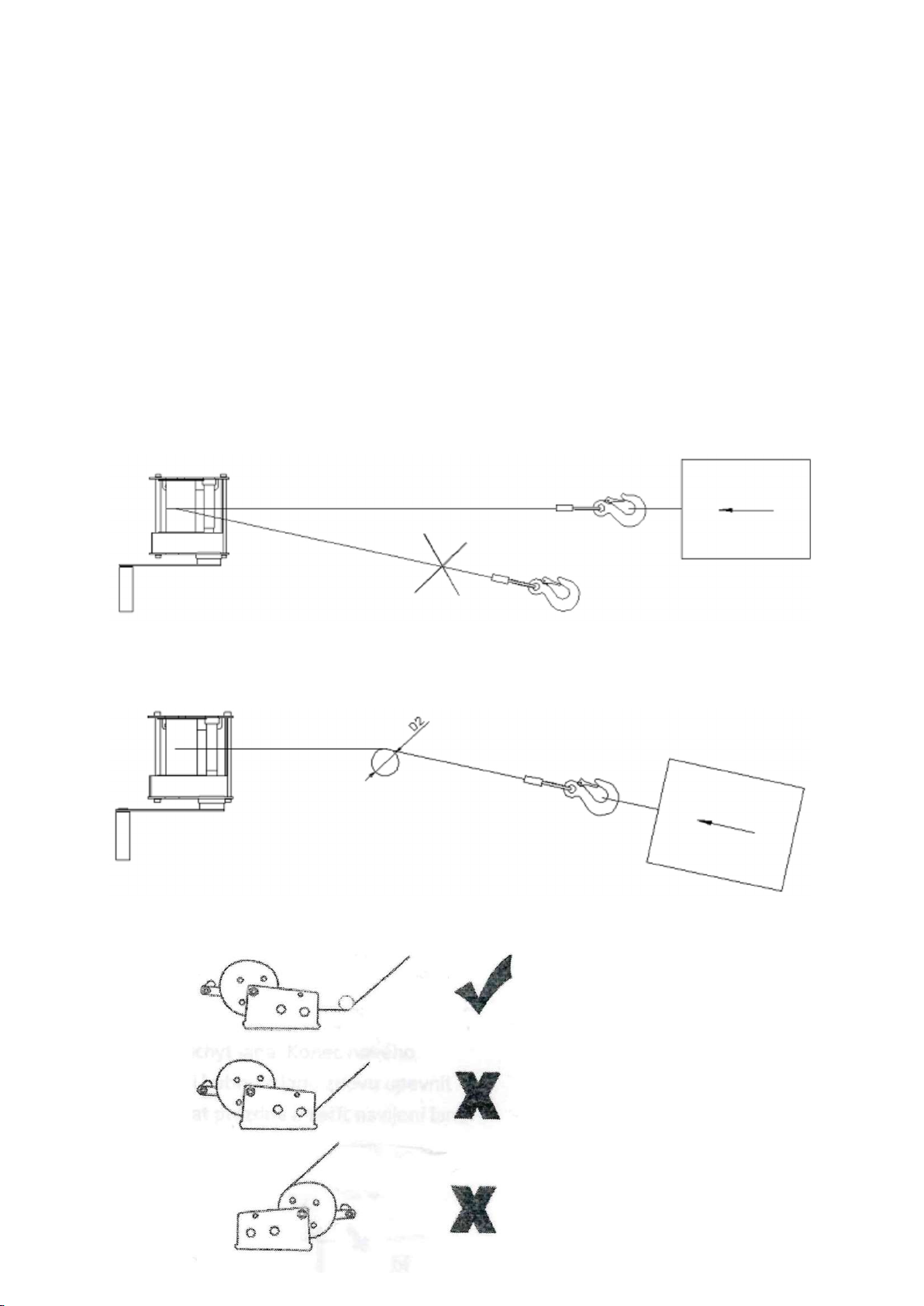

ALWAYS remove wire rope kinks and slings before start lifting or pulling.

ALWAYS wear heavy leather gloves when handling the wire rope.

ALWAYS make sure load is properly fixed in the hook´s safety latch.

Remember: proper rigging and lifting techniques are responsibility of the operator.

Check all applicable national directions, regulations and standards for further

information about safe use of your winch.