1-3-1 E56A0IMP

1. IMPORTANT SERVICE NOTES

BEFORE RETURNING THE DVD VIDEO PLAYER

Before returning the DVD video player to the user,

perform the following safety checks.

1. Inspect all lead dress to make certain that leads are

not pinched or that hardware is not lodged between

the chassis and other metal parts in the DVD video

player.

2. Inspect all protective devices such as non-metallic

control knobs, insulation materials, cabinet backs,

adjustment and compartment covers or shields, isola-

tion resistor/capacitor networks, mechanical insula-

tors etc.

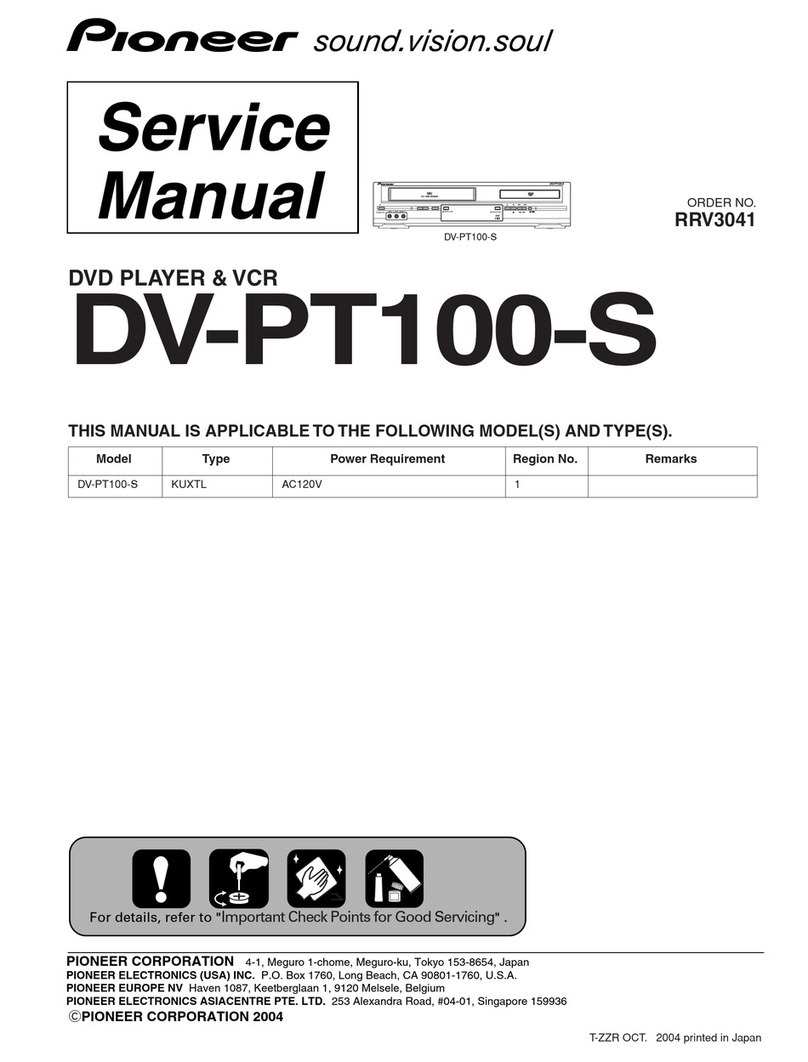

3. To be sure that no shock hazard exists, check for

current in the following manner.

Plug the AC line cord directly into a 120 volt AC outlet

(Do not use an isolation transformer for this test).

Using two clip leads, connect a 1.5k ohm, 10 watt

resistor paralleled by a 0.15µF capacitor in series with

all exposed metal cabinet parts and a known earth

ground, such as a water pipe or conduit.

Use an DVM or VOM with 1000 ohm per volt, or higher,

sensitivity or measure the AC voltage drop across the

resistor (See Diagram).

Move the resistor connection to earth exposed metal

part having a return path to the chassis (metal cabinet,

screw heads, knobs and control shafts, etc.) and

measure the AC voltage drop across the resistor.

Reverse the AC plug on the set and repeat AC voltage

measurements for each exposed part. Any reading of

0.45V rms (this corresponds to 0.3mA rms AC.) or

more is excessive and indicates a potential shock

hazard which must be corrected before returning the

DVD video player to the owner.

1. NOTES DE SERVICE IMPORTANTES

AVANT DE RENDRE LE REPRODUCTOR DE VíDEO

DVD

AvantderendrelereproductordevídeoDVDàl’utilisateur,

effectuer les vérifications de sécurité suivantes.

1. Vérifier toutes les gaines de fil pour être sûr que les fils

ne sont pas pincés ou que le matériel n’est pas coincé

entre le châssis et les autres pièces métalliques dans le

reproductor de vídeo DVD.

2. Vérifier tous les dispositifs de protection tels que les

boutons de commande non métalliques, les matériaux

d’isolement, le dos du coffret, les couvercles de

compartiment et ajustement ou les boucliers, les

réseaux de résistance / condensateur d’isolement, Ies

isolateurs mécaniques, etc.

3. Pourêtre sûr qu’il n’y aaucunrisque de choc électrique,

vérifier le courant de fuite de la maniére suivante.

Brancherle cordon d’alimentationsecteur directement

dans une prise de courant de 120 volts. (Ne pas utiliser

de transformateur d’isolement pour cet essai).

Utiliser deux fils à pinces et connecter une résistance

de10watts1,5 kohm en parallèle avec un condensateur

de0,15µFensérieavec des piècesducoffretmétallique

exposées et une masse de terre connue telle qu’un

tuyau ou un conduit d’eau.

Utiliser un DVM ou VOM avec une sensibilité de 1000

ohms par volt ou plus ou mesurer la chute de tension

CA entre la résistance (voir diagramme).

Déposer la connexion de la résistance à toutes les

pièces métalliques exposées ayant un parcours de

retour au châssis (coffret métallique, tétes de vis, bou-

tons et arbres de commande, etc.) et mesurer la chute

de tension CA entre la résistance. Inverser la fiche CA

(une fiche intermédiaire non polarisée doit être utilisée

à seule fin de faire ces vérifications.) sur l’appareil et

répéter les mesures de tension CA pour chaque piéce

métallique exposée. Toute lecture de 0,45 V rms (ceci

correspond à 0,3 mA rms CA) ou plus est excessive et

signale un danger de choc qui doit être corrigé avant de

rendre le reproductor de vídeo DVD à son utilisateur.

IMPORTANT SAFEGUARDS AND PRECAUTIONS

SSVM

AC SCALE

1.5k ohms.

10W

0.15

TEST PROBE

TO EXPOSED

METAL PARTS

CONNECT TO

KNOWN EARTH

GROUNG

F

VTVM

AC SCALE

1.5k ohms

10W

CONNECT TO

KNOWN EARTH

GROUND

TO EXPOSED

METAL PARTS

TEST PROBE

0.15 F