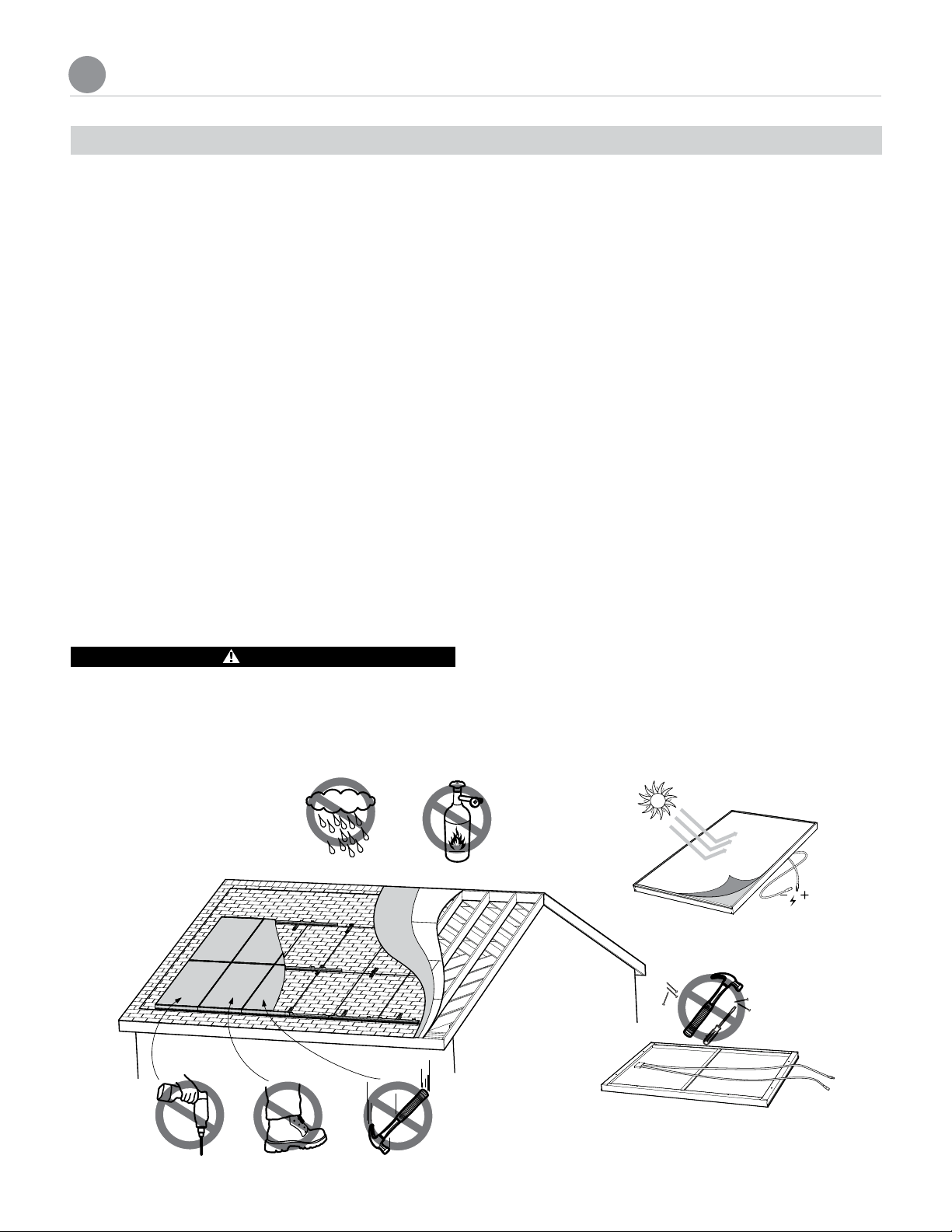

WARNING

Always follow OSHA guidelines.

Solar modules are installed on rooftops where there is

danger of personnel falling off of the roof. Scaffolding,

stepladders, and ladders may be dangerous and require

caution. The installation of solar modules involves work

in high places; take extreme precautions to avoid falling

from roof. To prevent accidents, safety regulations must

be observed. Always take the following precautions to

prevent accidents and injury.

1 Take the following precautions before starting work.

• Plan the job and visit the site before starting work.

• On site, do not work alone. Always work with at

least one other person.

• Inspect power tools before using them.

2 When conditions make it necessary, tell workers

to stop working.

• When it is raining, or there is a strong probability

that it will start raining.

• Immediately after rain, and when work areas are

slippery.

• When high wind conditions exist, or are expected,

or when a high wind warning has been issued.

• When it is snowing, or when there is snow

underfoot.

• When the condition of the scaffolding and ladders

is not satisfactory.

3 Wear appropriate work clothes and protective

equipment.

• Work clothes for both the upper and lower body

should fit well and allow you to move freely.

• Always wear protective equipment such as

harnesses and lifelines.

• Wear a helmet and secure it correctly.

• Wear non-slip shoes. Shoes get dirty when worn

on a roof, so keep the soles clean.

4 Observe safety regulations for ascending and

descending ladders and stepladders.

• Before use, always inspect ladders and stepladders

to makes sure they are in good condition.

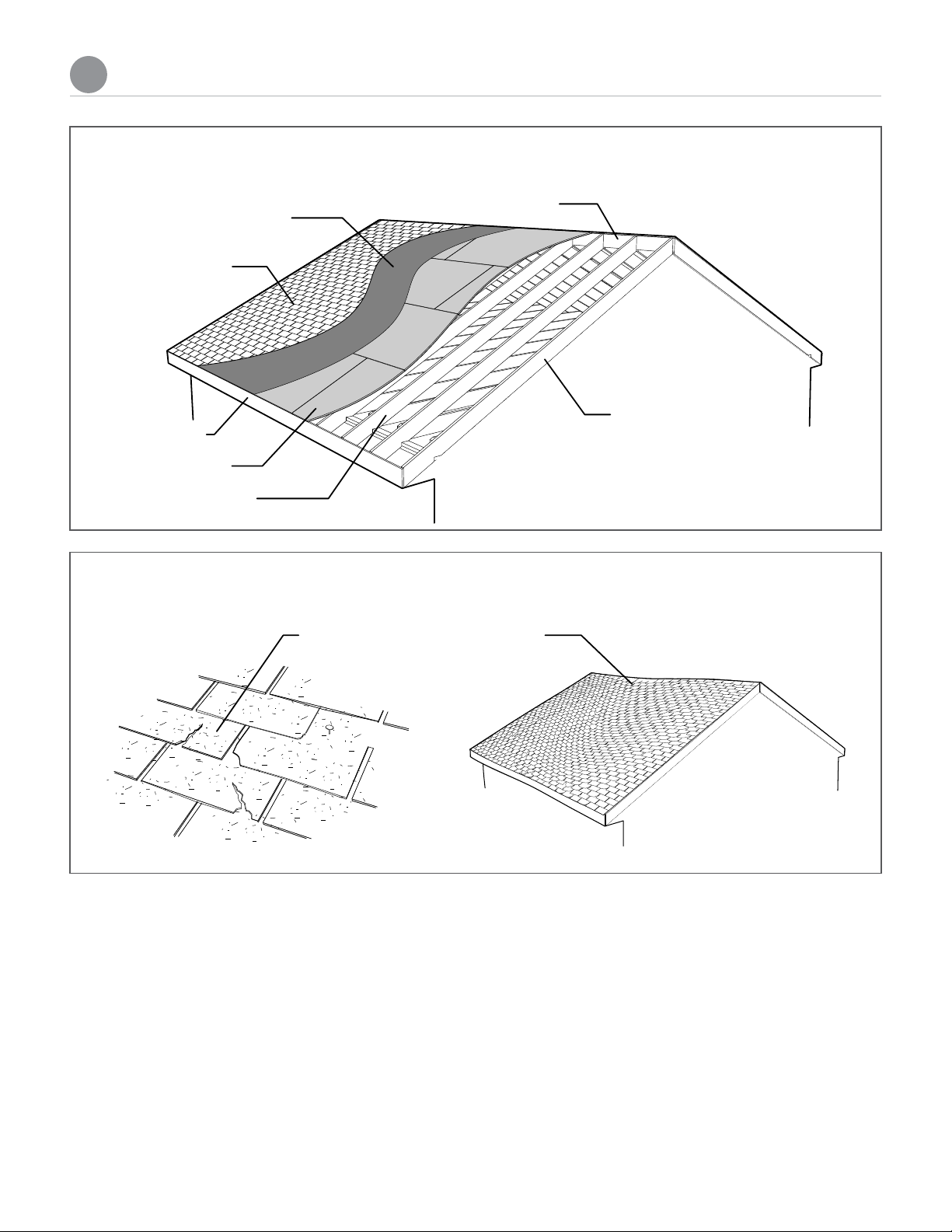

1.2 SRS MOUNTING SYSTEM

• Choose a safe spot to anchor ladders and

stepladders.

• Always work with a partner. One person should

hold the ladder steady.

• Ladders from a first-story roof to a second-story

roof are very dangerous. Do not set up a ladder

on a roof. When there is no other choice, straddle

the ridge and lay down a rubber anchor mat, and

secure the ladder to the mat. Always have one

person hold the ladder firmly.

• When you use a two-stage ladder, secure it with

ropes or stays to prevent it from sliding sideways,

and have two people hold the ladder steady.

• Use ladders with steps broad enough to permit

safe work.

5 When working in high places, wear harnesses and

use scaffolding.

• When working at heights of 6 feet or more, use

scaffolds or other equipment to ensure a stable

work platform.

• Scaffolds should be designed and erected by a

qualified person.

• When it is difficult to erect a stable work platform,

install safety nets, wear harnesses, and take other

measures to prevent falls.

• Regulations mandate the use of harnesses. Fasten

harnesses securely, and check that the length of

lifelines is 6 feet or less.

• Attach the primary support line securely to a

metal fixture installed for that purpose on a ridge

or beam.

6 Install enclosures and covers.

• Install enclosures, guardrails, or covers at the end of

work decks that are 10 feet or more above ground,

at openings, and at other dangerous locations.

• When it is extremely difficult to install enclosures,

guardrails, or covers, or when they must be

removed to work in that location, install a safety

net, wear harnesses, and take other measures to

prevent falls.

1FOR SAFE INSTALLATION WORK

7