R-210D

4

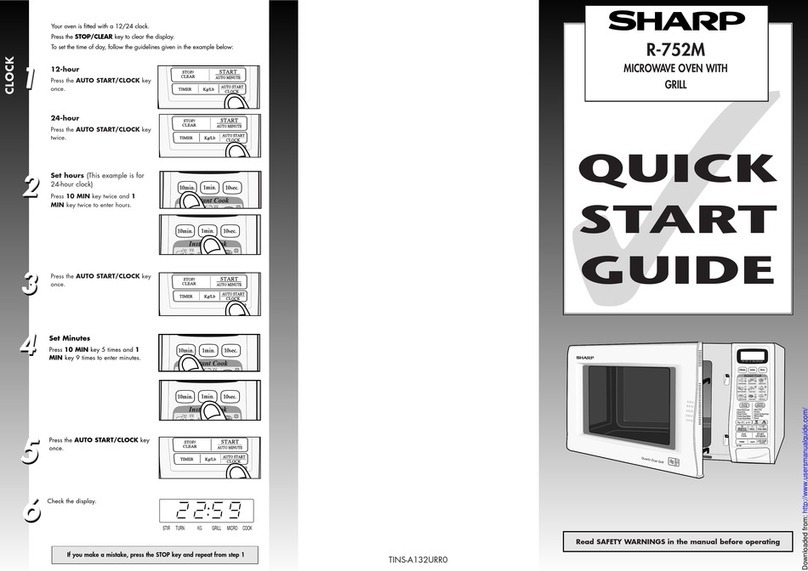

OPERATION SEQUENCE

OFF CONDITION

Closing the door activates all door interlock switches

(1st. latch switch, 2nd. latch switch and stop switch).

IMPORTANT

Whentheovendoorisclosed,themonitorswitchcontacts

(COM-NC) must be open.

Whenthemicrowaveovenispluggedinawalloutlet,rated

voltage is supplied to the noise filter and the control unit.

Figure O-1 on page 25

MICROWAVE COOKING CONDITION

HIGH COOKING

Select the power level HIGH by pressing the power level

button until the power level indicator indicates "HIGH".

And set the cooking time by rotating the Light Up Dial.

Function sequence

Figure O-2 on page 25

CONNECTED COMPONENTS RELAY

Oven lamp, Fan motor, Turntable motor RY1

Power transformer RY2

1. Ratedvoltage is suppliedtothe primary windingofthe

power transformer. The voltage is converted to about

3.3 volts A.C. output on the filament winding and high

voltage of approximately 2000 volts A.C. on the sec-

ondary winding.

2. The filament winding voltage (3.3 volts) heats the

magnetronfilamentandthehighvoltage(2000volts)is

sentto the voltage doublingcircuit, where it isdoubled

to negative voltage of approximately 4000 volts D.C..

3. The 2450 MHz microwave energy produced in the

magnetron generates a wave length of 12.24 cm. This

energyischannelledthroughthewaveguide(transport

channel)intotheovencavity,wherethe food is placed

to be cooked.

4. Whenthecookingtimeisup,asignaltoneisheardand

the relays RY1+RY2 go back to their home position.

The circuits to the oven lamp, power transformer, fan

motor and turntable motor are cut off.

5. When the door is opened during a cook cycle, the

switches come to the following condition.

CONDITION

DURING DOOR OPEN

SWITCH CONTACT COOKING

(NOCOOKING)

1st. latch switches COM-NO Closed Open

2nd. latch switch COM-NO Closed Open

Monitor switch COM-NC Open Closed

Stop switch COM-NO Closed Open

The circuits to the power transformer, fan motor, turn-

tablemotorandtheovenlamparecutoffwhenthe1st.

latch switch, 2nd. latch switch, and stop switch are

made open.

6. MONITOR SWITCH CIRCUIT

The monitor switch is mechanically controlled by oven

door, and monitors the operation of the 1st and 2nd.

latch switches.

6-1 When the oven door is opened during or after the

cycle of a cooking program, the 1st. latch and stop

switch must open their contacts first. After that the

contacts (COM-NC) of the monitor switch can be

closed and the contacts (COM-NO) of the 2nd. latch

switch can be opened.

6-2. When the oven door is closed, the contacts (COM-

NC) of the monitor switch must be opened and the

contacts (COM-NO) of the 2nd. latch switch must be

closed. After that the contacts of the 1st. latch switch

and stop switch are closed.

6-3. Whentheovendoorisopenedandthecontactsofthe

1st and 2nd latch switches remain closed. The fuse

M8A will blow, because the monitor switch is closed

and a short circuit is caused.

MEDIUM HIGH, MEDIUM, MEDIUM LOW, LOW

COOKING

When the microwave oven is preset for variable cooking

power, rated voltage is supplied to the power transformer

intermittently within a 27-second time base through the

relay contact which is coupled with the current-limiting

relay. The following levels of microwave power are given.

SETTING;

NOTE: The ON/OFF time ratio does not exactly corre-

spond to the percentage of microwave power,

because approx. 2 seconds are needed for heat-

ing up the magnetron filament.

HIGH 27 sec. ON

MEDIUM HIGH Approx. 70%

21 sec. ON 6 sec. OFF

12 sec. OFF

18 sec. OFF

22 sec. OFF

MEDIUM Approx. 50%

15 sec. ON

MEDIUM LOW Approx. 30%

9 sec. ON

LOW Approx. 10%

5 sec. ON