8

R-312AW

R-312AK

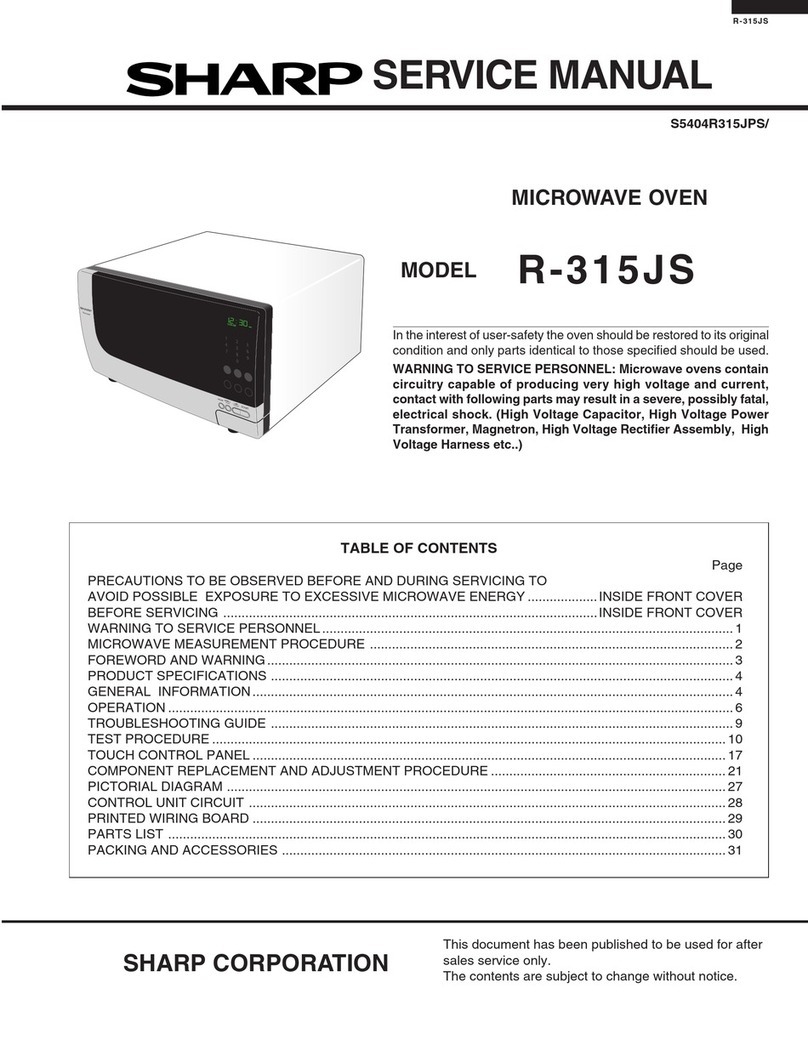

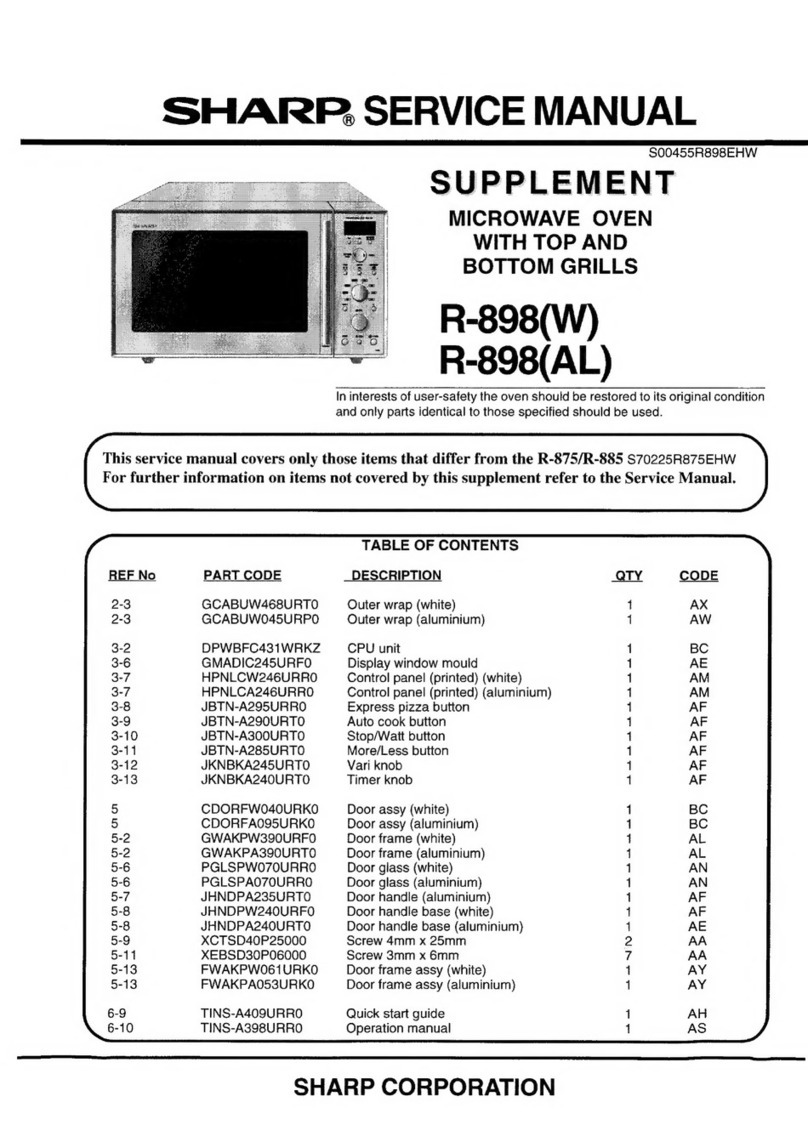

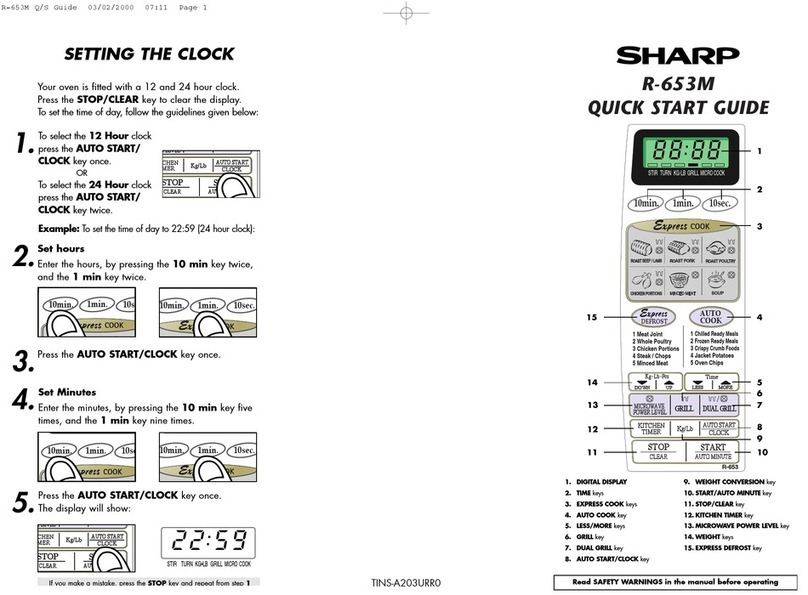

DOOR OPEN MECHANISM

The door is opened by pushing the open button on the

control panel, refer to the Figure D-1.

Whentheopenbuttonispushed,theopenbuttonpushesup

theswitchlever,andthentheswitchleverpushesupthethe

latch head. The latch heads are moved upward and re-

leased from latch hook. Now the door will open.

LATCH HOOK

DOOR SENSING

SWITCH

MONITOR

SWITCH

THIRD DOOR

SWITCH

SWITCH

LEVER

PRIMARY INTERLOCK

SWITCH

LATCH

HEADS

Figure D-1. Door Open Mechanism

DOOR SENSING, THIRD DOOR AND PRIMARY

INTERLOCK SWITCHES

Theprimaryinterlockswitchismountedinthelowerposition

of the latch hook and the door sensing switch in the

secondaryinterlocksystemismountedintheupperposition

of the latch hook. The third door switch is mounted in the

lower position at the back of the latch hook. They are

activated by the latch heads on the door. When the door is

opened, the switches interrupt the circuit to all components

except the oven lamp and the noise filter. A cook cycle

cannot take place until the door is firmly closed thereby

activating both interlock switches. The secondary interlock

system consists of the door sensing switch and secondary

interlock relay located on the control circuit board.

MONITOR SWITCH

Themonitorswitchisactivated(thecontactsopened)bythe

latch head on the door while the door is closed. The switch

is intended to render the oven inoperative by means of

blowning the monitor fuse when the contacts of the primary

interlock switch fail to open when the door is opened.

Functions:

1. When the door is opened, the monitor switch contact

close (to the ON condition) due to their being normally

closed. At this time the primary interlock switch is in the

OFF condition (contacts open) due to its being normally

open contact switches.

2. Asthedoorgoestoaclosedposition,themonitorswitch

contacts are first opened and then the door sensing

DESCRIPTION AND FUNCTION OF COMPONENTS

switch,theprimaryinterlockswitchandthirddoorswitch

contacts close. (On opening the door, each of these

switches operate inversely.)

3. If the door is opened, and primary interlock switch

contacts fail to open, the monitor fuse blows

simultaneouslywithclosingofthemonitorswitchcontacts.

CAUTION: BEFORE REPLACING A BLOWN MONITOR

FUSE TEST THE PRIMARY INTERLOCK

SWITCH AND MONITOR SWITCH FOR

PROPER OPERATION. (REFER TO CHAP-

TER “TEST PROCEDURE”).

NOTE: MONITOR FUSE AND SWITCH ARE REPLACED

AS AN ASSEMBLY

TURNTABLE MOTOR

The turntable motor rotates the turntable located on the

bottomof theoven cavity,so thatthe foodson theturntable

cookevenlyduringcooking.Theturntablemayturnineither

direction.

COOLING FAN MOTOR

The cooling fan motor drives a blade which draws external

cool air. This cool air is directed through the air vanes

surrounding the magnetron and cools the magnetron. This

air is channelled through the oven cavity to remove steam

and vapours given off from the heating foods. It is then

exhausted through the exhausting air vents at the oven

cavity.

OVEN THERMAL CUT-OUT

Thethermalcut-out,locatedonthetopoftheovencavity,is

designedtopreventdamage totheovenby fire.Ifthe foods

load is overcooked, by either error in cook time or defect in

the control unit, the thermal cut-out will open.

Under normal operation, the oven thermal cut-out remains

closed. However, when abnormally high temperatures are

reachedwithintheovencavity,theoventhermalcut-outwill

open at 257˚F(125˚C), causing the oven to shut down.

MAGNETRON THERMAL CUT-OUT

Thethermalcut-outlocatednearthemagnetronisdesigned

to prevent damage to the magnetron if an over heated

condition develops in the tube due to cooling fan failure,

obstructed air guide, dirty or blocked air intake, etc.

Undernormaloperation,thethermalcut-outremainsclosed.

However,whenabnormally hightemperaturesarereached

within the magnetron, the thermal cut-out will open at

203˚F(95˚C) causing the oven to shut down, when the

magnetron has cooled to 167˚F (75˚C), the thermal cut-out

closes and cook cycle will resume.

NOISE FILTER

The noise filter prevents the redio frequency interference

that might flow back in the power circuit.