16

-’

b

Before setting the

timer

clock, make sure

that

the current time

bs

correct.

n

Timer

operation

To listen to the radio

You can

listen

to a broadcasting station wth the timer-on

function

different from that to

which

you are

lkstening

wth timer-off function.

However, the band should be the same

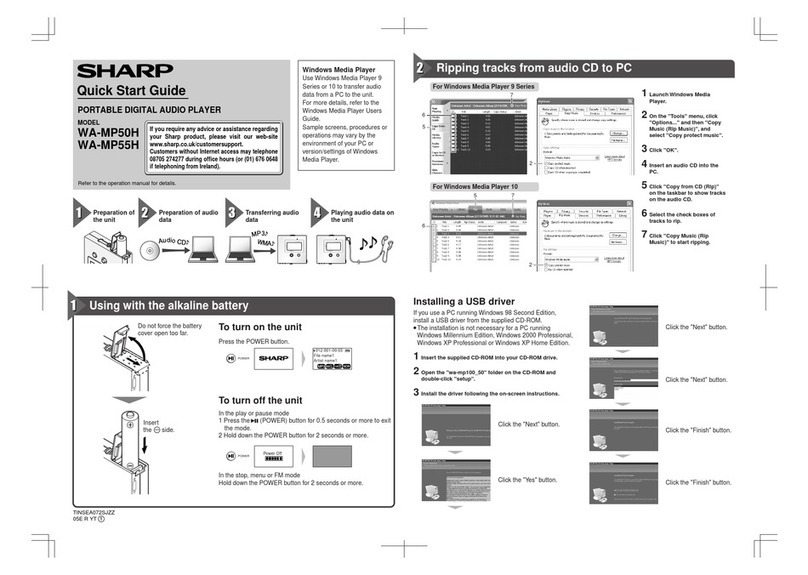

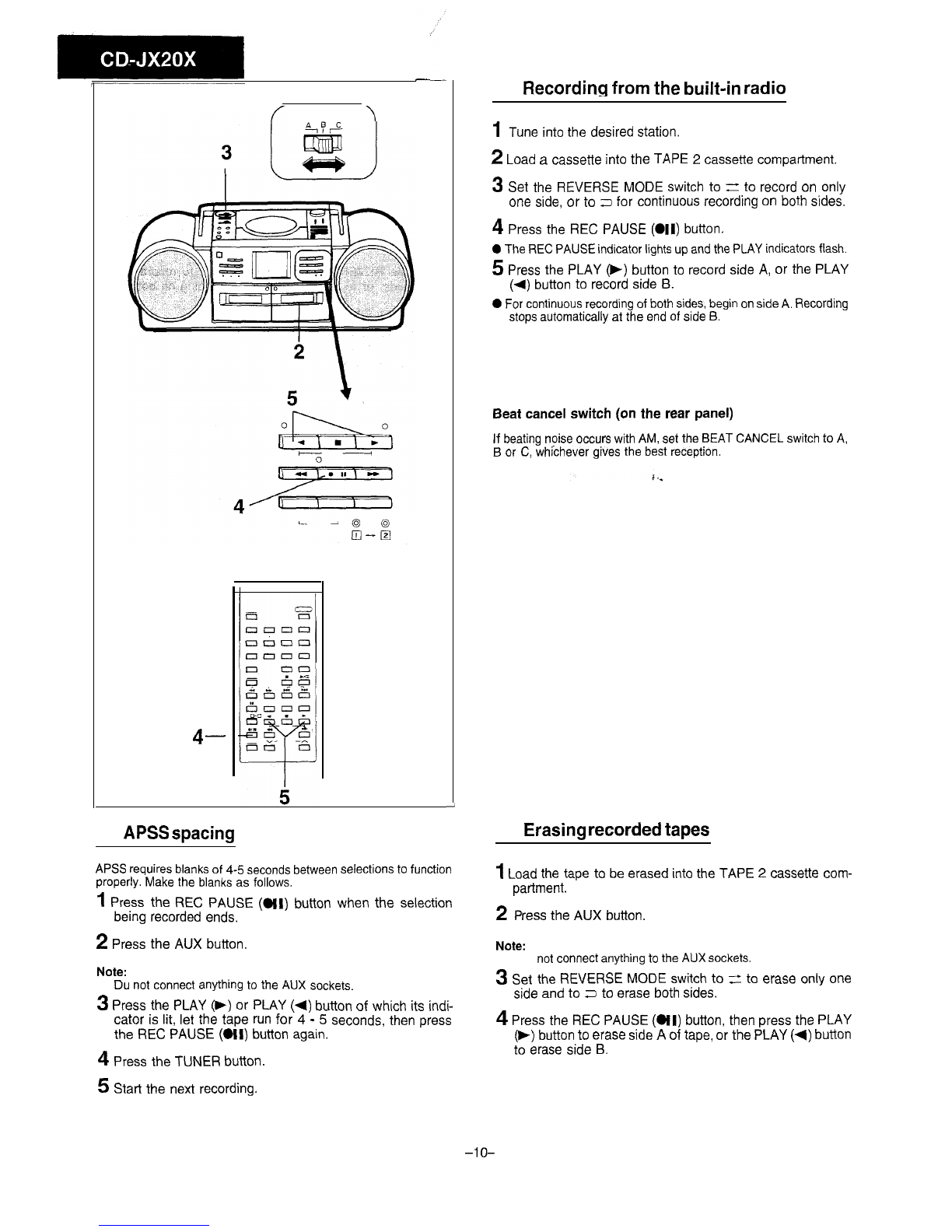

1Set the MAIN POWER switch to ON

2T

une into the desired station.

3

Press the DISPLAY button.

. The “ON TIME” Indicator goes on for 5 seconds.

4

Whilst the “ON TIME” mdicator is lit, and whilst pressing

the TIME ADJ button, press the HOUR and MINUTE but-

tons to set the desired time.

5

Whilst the “ON TIME” indicator is lit, select the desired

preset station on the remote control.

6

Set the TIMER REC

s&oh

to OFF.

7P

ress the TIMER button.

. The “TIMER SET” appears on the display.

This sets the

tmw

to the stand-by

conditlan

b

The radio turns on automatically at the preset

time.

.

When you listen to the

?.ame

broadcasting

slatron

with the timer-on

and timer-off

functions

to

which

you are listening, step 5 is

un-

To listen to the compact disc

1

Set the MAIN POWER switch to ON

2

Press the CD button

3

Load the disc.

4

Perform steps 3,4 and 6,7 of the “To listen to the radio”

sectloll.

. The

CD

playback statis automatically at the preset

time.

To playback a cassette

1Set the MAIN POWER switch to ON.

2

Press the TAPE button.

3

Load the recorded cassette tape into the TAPE 2 cassette

compartment,

4

Perform steps 3,4 and 6,7 of the “To listen to the radio”

section.

. Cassette playback starts

automatlcally

at the preset time.

t

i

n

W

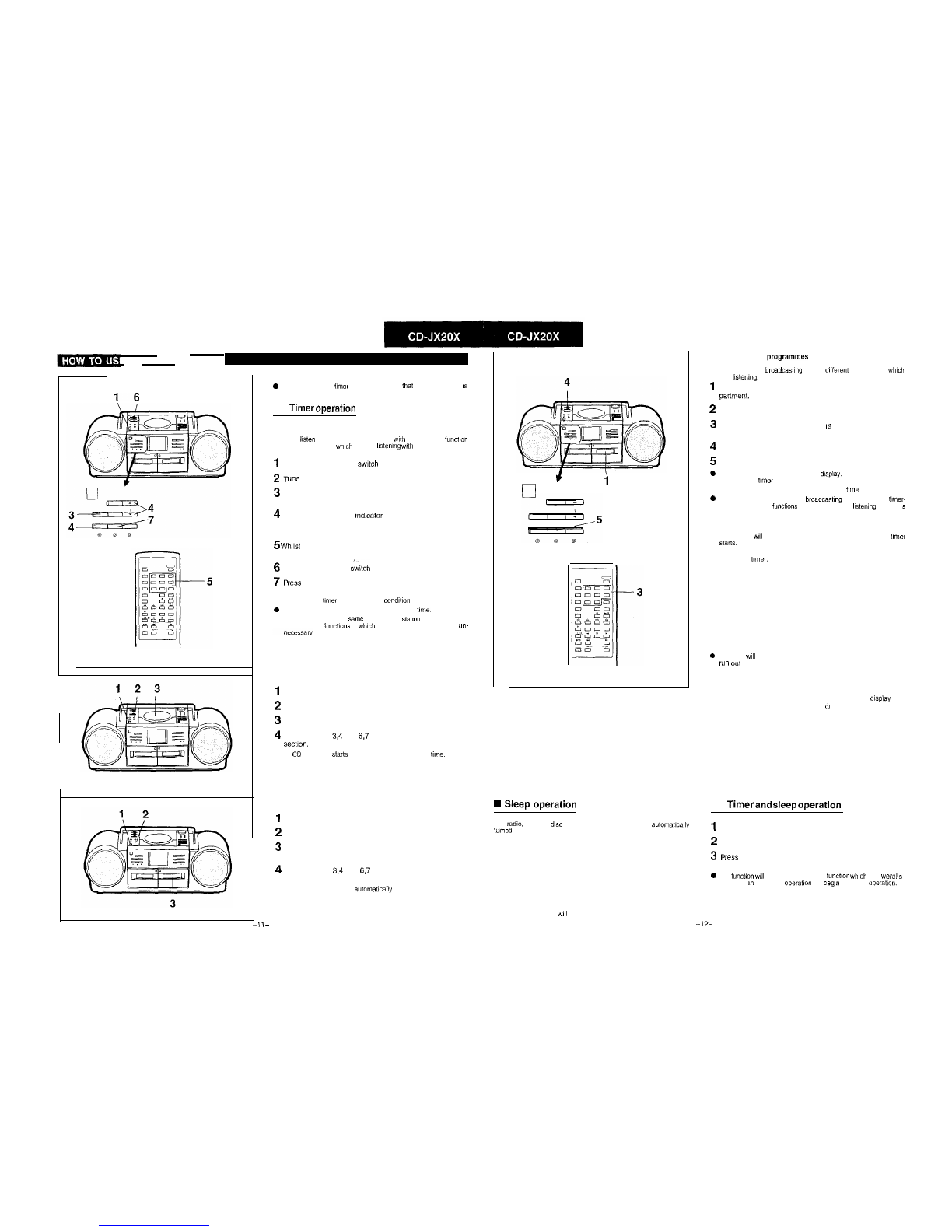

Sleep

operation

The

radio,

compact

disc

and cassette deck can all be

automatically

turned

off after 60 minutes.

Press the SLEEP button.

To stop the sleep operation:

Press the SLEEP button.

(The SLEEP indicator wll go out.)

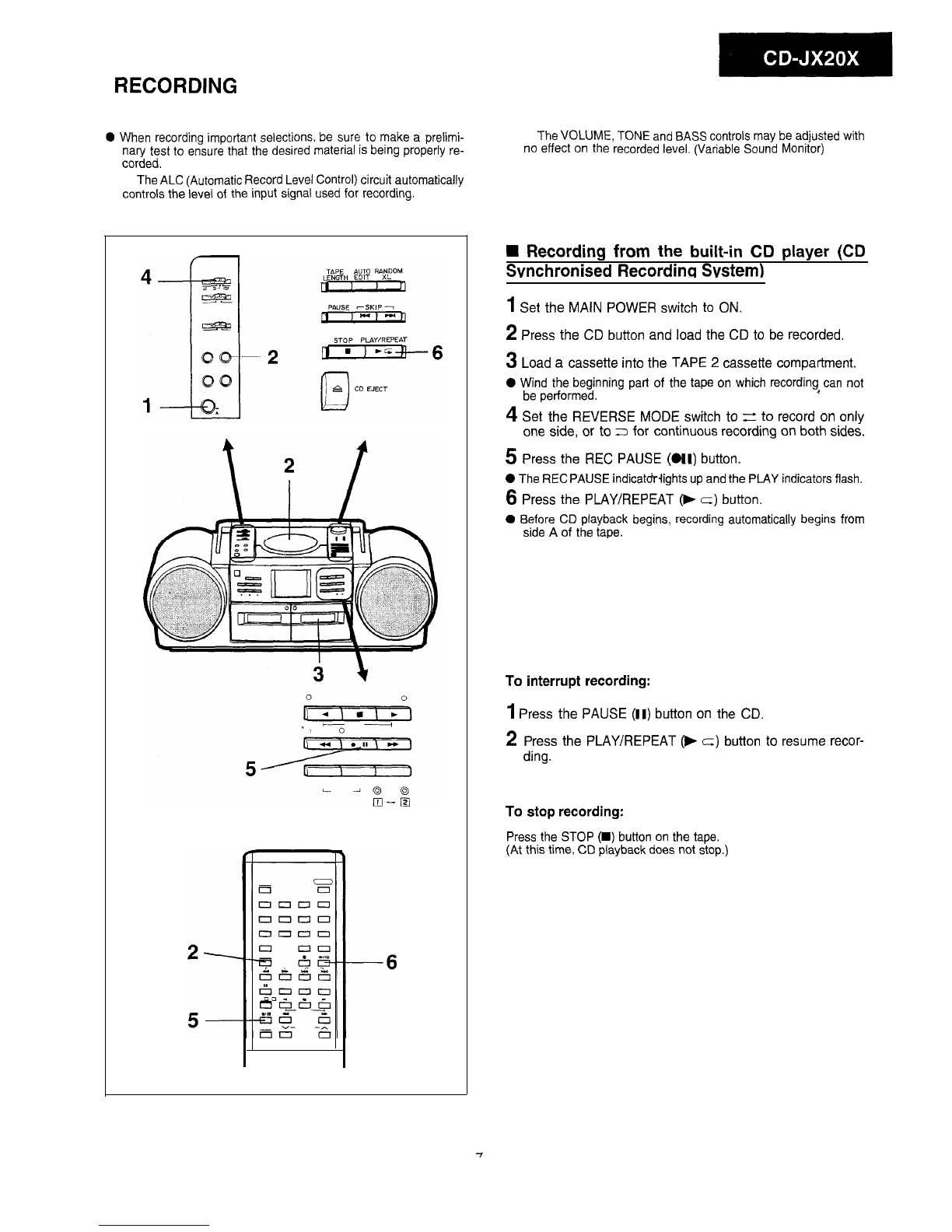

To record radio

programmes

You can record a

broadcasting

station

different

from that to

which

you are

listening.

However, the band should be the same.

1

Load a blank cassette tape into the TAPE 2 cassette corn-

partment.

2

Perform steps 1-4 of the “To listen to the radio” section.

3

Whilst the “ON TIME” Indicator

IS

lit, select the desired

preset station on the remote control.

4

Set the TIMER REC switch to ON.

5

Press the TIMER button.

0

The “TIMER SET” appears on the

display.

This sets the

timer

to the stand-by condition.

l

Recording starts automatically at the preset

tme.

b

When you record to the same

broadcastmg

station with the

timer-

on and timer-off

functions

to which you are

Ilstening.

step 3

is

unnecessary.

Notes:

l

The power wll be automatically turned off 2 hours after the

timer

starts.

l

To set the dewed volume level, use the VOLUME control before

setting the

timer.

To confirm the timer time setting:

Press the DISPLAY button

0

The tuner

will

keep accurate time until the clock/memory batteries

run

O”,

To cancel timer operation:

Press the TIMER button so that the “TIMER SET” in the

display

goes

out, or set the MAIN POWER switch to

(‘1

STAND-BY.

n

Timer

and

sleep

operation

1

Use the left procedure to confirm the sleep time

2

Set the timer time.

3P

ress the TIMER button. The “TIMER SET” appears on

the display.

b

The

function

wrll

not change, so the

function

which

you

were

IIS-

tening to

I”

the sleep

operatton

will

bqn

the timer

operabon.

Il-

-12-