Sharp CE-515P User manual

Other Sharp Printer manuals

Sharp

Sharp AR-M351N User manual

Sharp

Sharp MX-B468P User manual

Sharp

Sharp AJ-2100 User manual

Sharp

Sharp MX-M310 Setup guide

Sharp

Sharp AR-C260P User manual

Sharp

Sharp AR-M450N User manual

Sharp

Sharp AR-C200P - Color Laser Printer User manual

Sharp

Sharp JX-9400 User manual

Sharp

Sharp Laser Printer User manual

Sharp

Sharp MX-M350 User manual

Sharp

Sharp MX-C400P Installation and operating manual

Sharp

Sharp AR-C260P User manual

Sharp

Sharp AR-D29 User manual

Sharp

Sharp AR-M355N User manual

Sharp

Sharp MZ-80P4 User manual

Sharp

Sharp MX-C300P User manual

Sharp

Sharp MZ-80P6 User manual

Sharp

Sharp DX-B350P User manual

Sharp

Sharp AJ-2200 Setup guide

Sharp

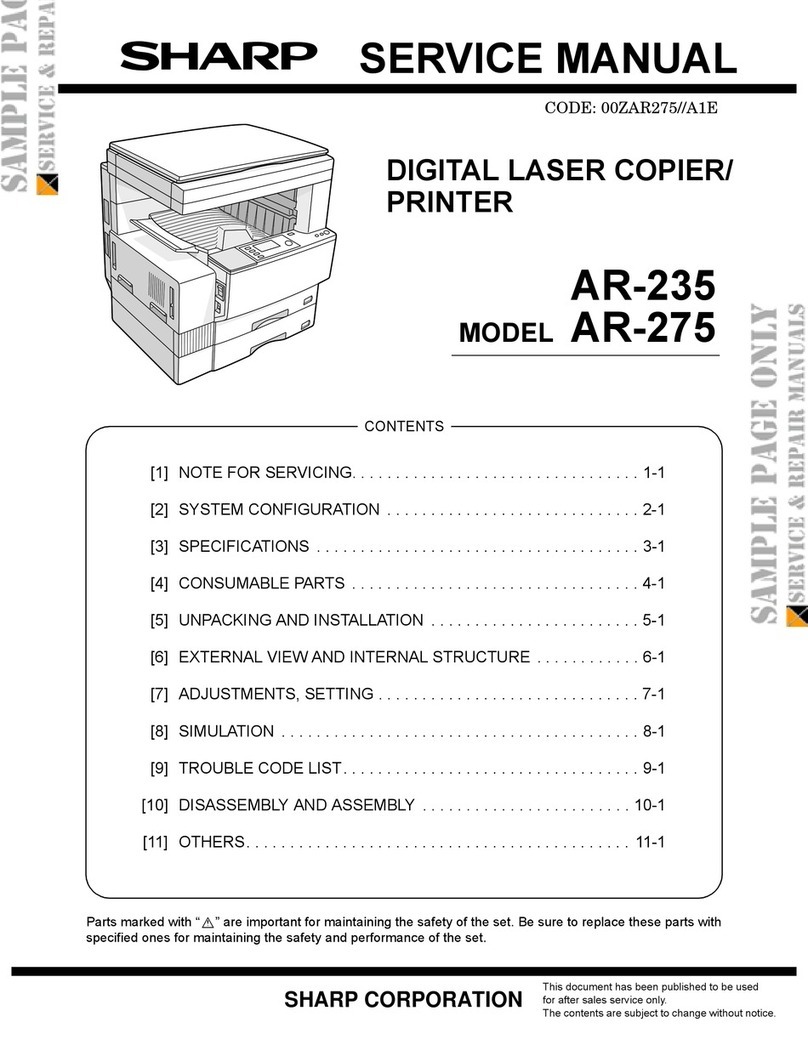

Sharp AR-235 User manual