Sharp SF-7200 User manual

Other Sharp Printer manuals

Sharp

Sharp AR-C265P User manual

Sharp

Sharp AJ-2000 Setup guide

Sharp

Sharp CE-126P User manual

Sharp

Sharp AR-M350 Imager User manual

Sharp

Sharp MX-B400P Installation and operating manual

Sharp

Sharp DX-C200 User manual

Sharp

Sharp MX-M310 Setup guide

Sharp

Sharp AR-M355 User manual

Sharp

Sharp CS-2635RH User manual

Sharp

Sharp Laser Printer User manual

Sharp

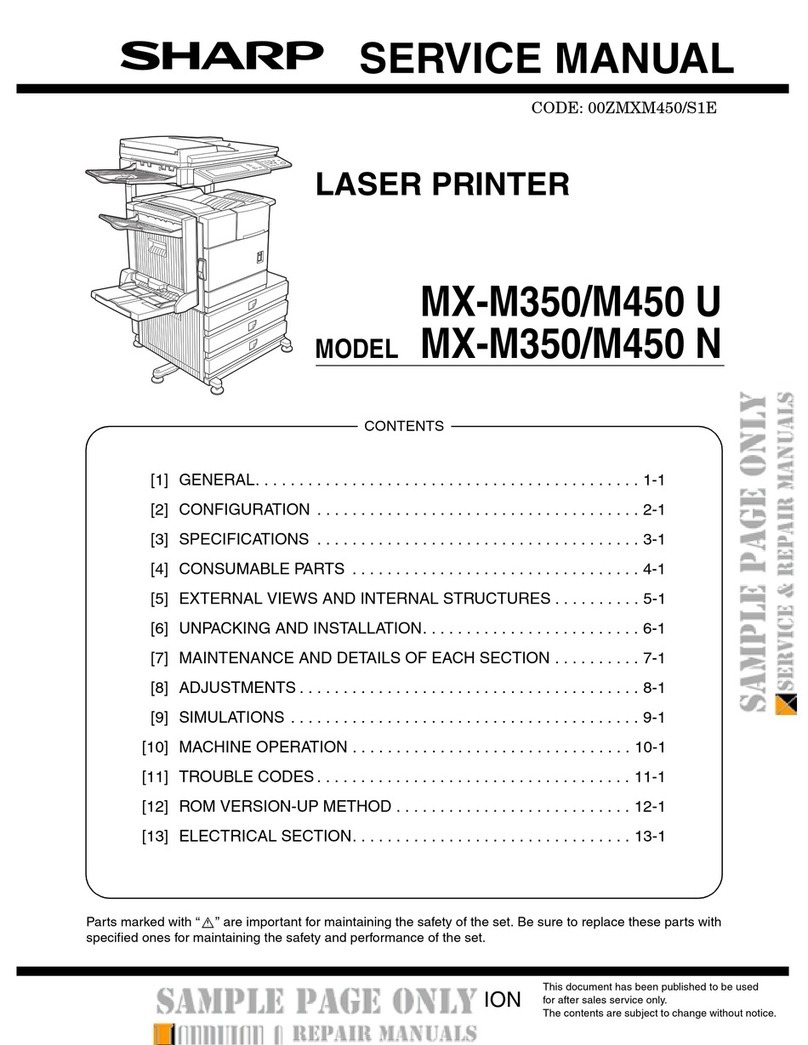

Sharp MX-M350/M450 U User manual

Sharp

Sharp AR-M355 User manual

Sharp

Sharp JX-8200 User manual

Sharp

Sharp AR-P13 User manual

Sharp

Sharp JX-8200 User manual

Sharp

Sharp AJ-1100 Setup guide

Sharp

Sharp MX-C607P User manual

Sharp

Sharp MX-B557P User manual

Sharp

Sharp AR-M351N User manual

Sharp

Sharp AJ-6010 Setup guide