8

14GT15

14GT20

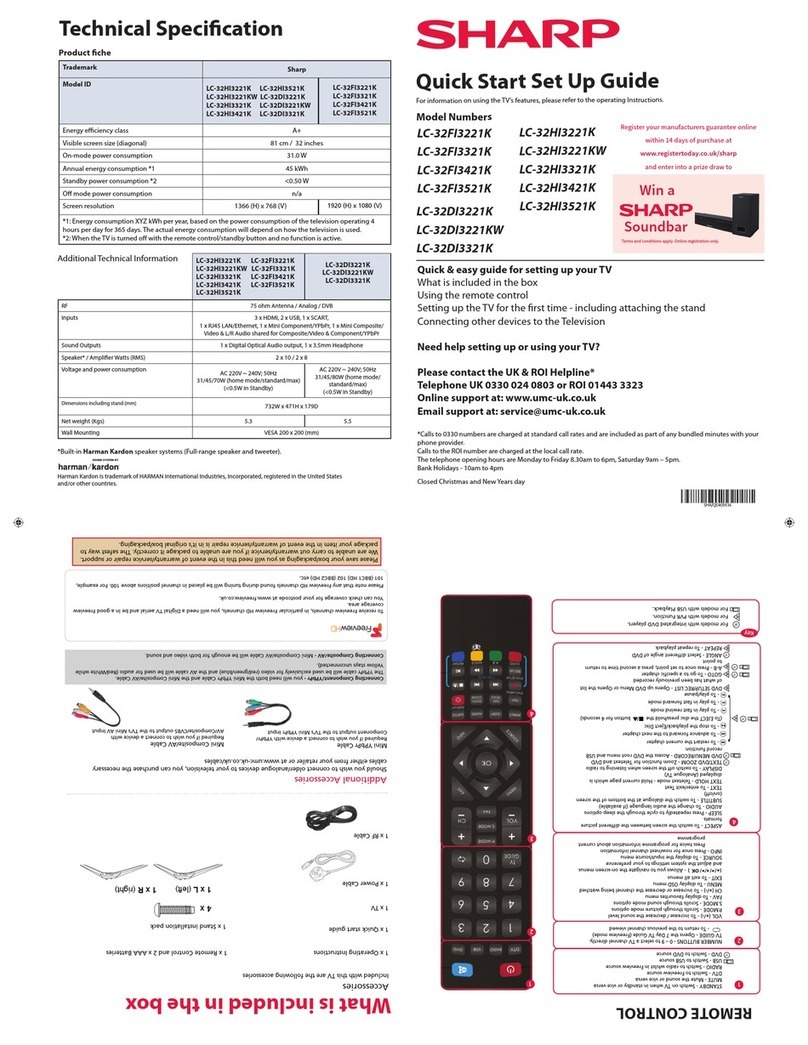

EEPROM ITEMS OSD DATA LENGTH

INITIAL DATA

FIX/ADJ REMARK

AGC TAKE OVER POINT AGC 0~63 14 ADJ

VERTICAL SLOPE V-LIN 0~63 32 ADJ

VERTICAL AMPLITUDE V-AMP 0~63 32 ADJ

VERTICAL SHIFT V-CENT 0~63 32 ADJ

HORIZONTAL SHIFT H-CENT 0~63 32 ADJ

S-CORRECTION S-COR 0~63 0 FIX

WHITE POINT RED STD WHITE TEMP DRI-RS 0~63 32 FIX

WHITE POINT GREEN STD WHITE TEMP DRI-GS 0~63 32 ADJ

WHITE POINT BLUE STD WHITE TEMP DRI-BS 0~63 32 ADJ

WHITE POINT RED WARM WHITE TEMP DRI-RW 0~63 32 FIX

WHITE POINT GREEN WARM WHITE TEMP DRI-GW 0~63 32 FIX (DRI-GS)-7 DATA

WHITE POINT BLUE WARM WHITE TEMP DRI-BW 0~63 32 FIX (DRI-BS)-7 DATA

WHITE POINT RED COOL WHITE TEMP DRI-RC 0~63 25 FIX

WHITE POINT GREEN COOL WHITE TEMP DRI-GC 0~63 32 FIX (DRI-GS)-7 DATA

WHITE POINT BLUE COOL WHITE TEMP DRI-BC 0~63 32 FIX

(DRI-BS)SAME DATA

MAX VOLUME SUB-VOL 0~63 63 FIX

SUB CONTRAST SUB-CON 0~63 63 FIX

SUB COLOUR SUB-COL 0~63 32 ADJ

SUB BRIGHTNESS SUB-BRI 0~63 32 ADJ

SUB TINT SUB-TINT 0~63 32 ADJ

SUB SHARPNESS SUB-SHP 0~63 32 ADJ

MAX HOTEL VOLUME HTL-VOL 0~63 32 ADJ

HOTEL PROGRAM NUMBER HTL-PRG

0~99 OR>99FOR NONE

255 FIX

OSD GRB REFERENCE RGB 0~15 15 FIX

BLACK LEVEL OFF-SET R CUT-R 0~15 8 FIX

BLACK LEVEL OFF-SET G CUT-G 0~15 8 FIX

CATHODE DRIVE LEVEL CDL 0~15 0 FIX

Y-DELAY TIME FOR PAL(TV) [YD] DL-PT 0~15 12 FIX

Y-DELAY TIME FOR SECAM(TV) [YD] DL-ST 0~15 15 FIX

Y-DELAY TIME FOR N358 (TV) [YD] DL-3T 0~15 12 FIX

Y-DELAY TIME FOR N443 (TV) [YD] DL-4T 0~15 12 FIX

Y-DELAY TIME FOR B/W (TV) [YD] DL-TV 0~15 12 FIX

Y-DELAY TIME FOR PAL (AV) [YD] DL-PA 0~15 12 FIX

Y-DELAY TIME FOR SECAM (AV) [YD] DL-SA 0~15 15 FIX

Y-DELAY TIME FOR N358 (AV) [YD] DL-3A 0~15 12 FIX

Y-DELAY TIME FOR N443 (AV) [YD] DL-4A 0~15 12 FIX

Y-DELAY TIME FOR B/W (AV) [YD] DL-AV 0~15 12 FIX

COLOUR OFFSET (PAL) COL-OP 0~15 8 FIX

COLOUR OFFSET (SECAM) COL-OS 0~15 8 FIX

COLOUR OFFSET (NTSC358) COL-03 0~15 4 FIX

COLOUR OFFSET (NTSC443) COL-O4 0~15 4 FIX

SHARPNESS OFFSET (PAL) SHP-OP 0~15 8 FIX

SHARPNESS OFFSET (SECAM) SHP-OS 0~15 4 FIX

SHARPNESS OFFSET (NTSC358) SHP-O3 0~15 12 FIX

SHARPNESS OFFSET (NTSC443) SHP-O4 0~15 8 FIX

AFTER SHORT JA 122 & JA 124 ,AND TURN ON THE MAIN POWER SWITCH,READ DATA FROM EEPROM

ADDRESS 00H ~ 03H,AND COMPARE TO THE LIST BELOW, IF DIFFERENT, INITIALIZE THE EEPROM.

Address : Data Address : Data

00H : 55H 02H : 43H

01H : 4FH 03H : A1H