4

XA-905

XA-920

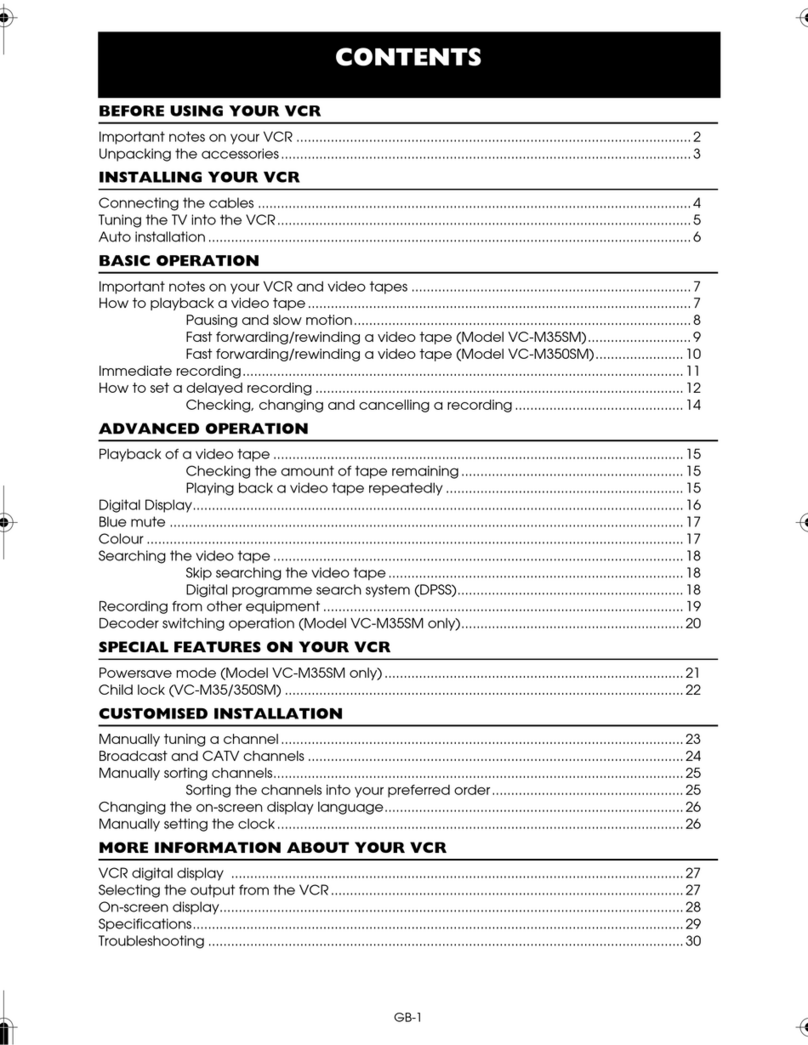

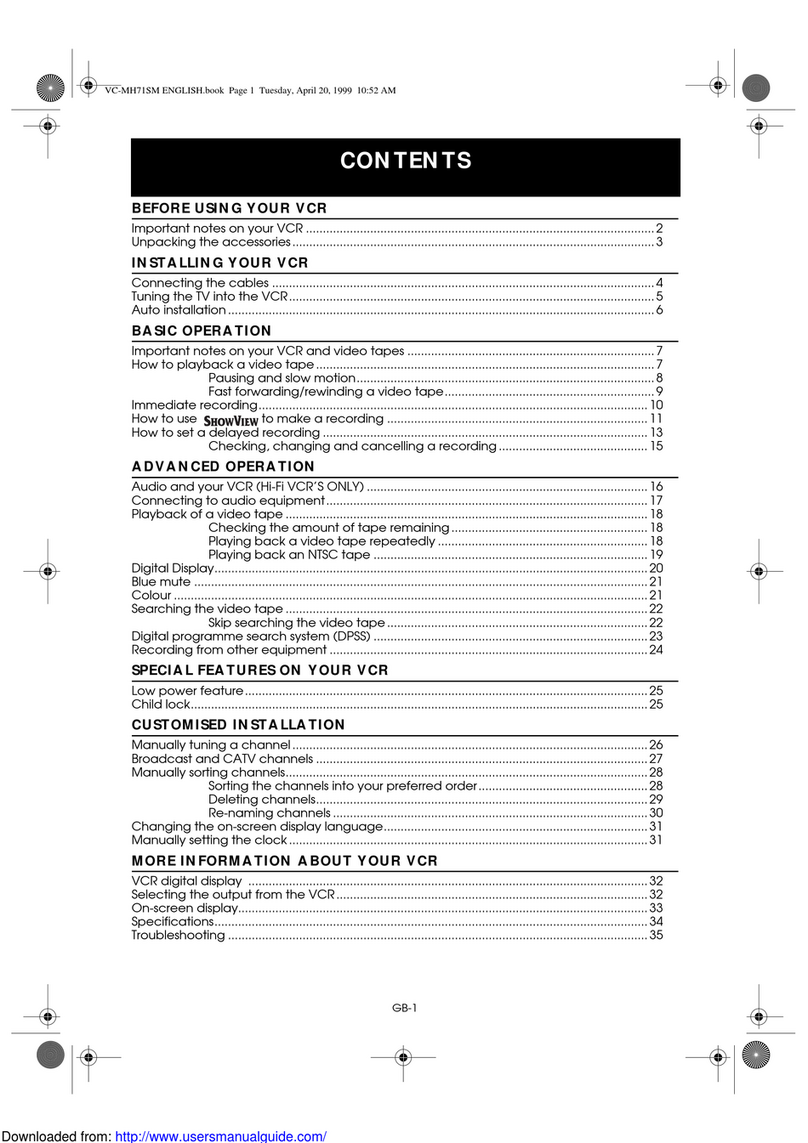

1. GENERAL INFORMATION

1-1. FEATURES

Only for XA-905

• Universal Remote Control

Only for XA-920

•Hi-Fi Stereo Sound

• Built-in MTS (Multi-channel TV Sound) Decoder

• * The VCR Plus+ Programming System

• Automatic Head Cleaning System

• Built in Front AV Jacks

• Universal Remote Control with light up buttons

Common Features

• 400 Times Rewind Speed to Fast Forward and Rewind.

• EZ Set Up

• S-VHS Quasi Playback

• Double-Azimuth 4-Heads

•19

µClear Picture System (in EP mode)

• HQ System for Better Resolution and Color Reproduction

• Multi-Language(English/Spanish/French)OSD(OnScreen

Display) with Menu Screen Guidance

• 181-channelPLLQuartzSynthesizedRandomAccessTuner

with Automatic Channel Setting

• Quick Start with Full Loading Mechanism

• 1-Year, 8-Event Programmable Timer

• Simple Recording Timer

• Sharp Super Picture

• Rec Tab Override

• Remote Pause IN/OUT Jacks

• BNC Video Connectors

• 3-Wire (Grounded) AC Power Cord

• 1 hour Timer Backup

• Field-Still/Variable Slow/Frame Advance

• Real-Time Counter

• Automatic Daylight Saving-Time (D.S.T.) Adjustment

• Blue Screen Noise Elimination

• Auto Tracking Control System

• Digital Program Search System (DPSS)

• Skip Search

• Instant Replay

• Exact Rec

• Tape Remaining

• One-Step Rewind

• Auto Zero Back

• Recorded Section Auto Repeat

• Full Automatic Playback

• Tamper Proof

• Up to 8 Hours of Recording and Playback (with T-160

cassette)

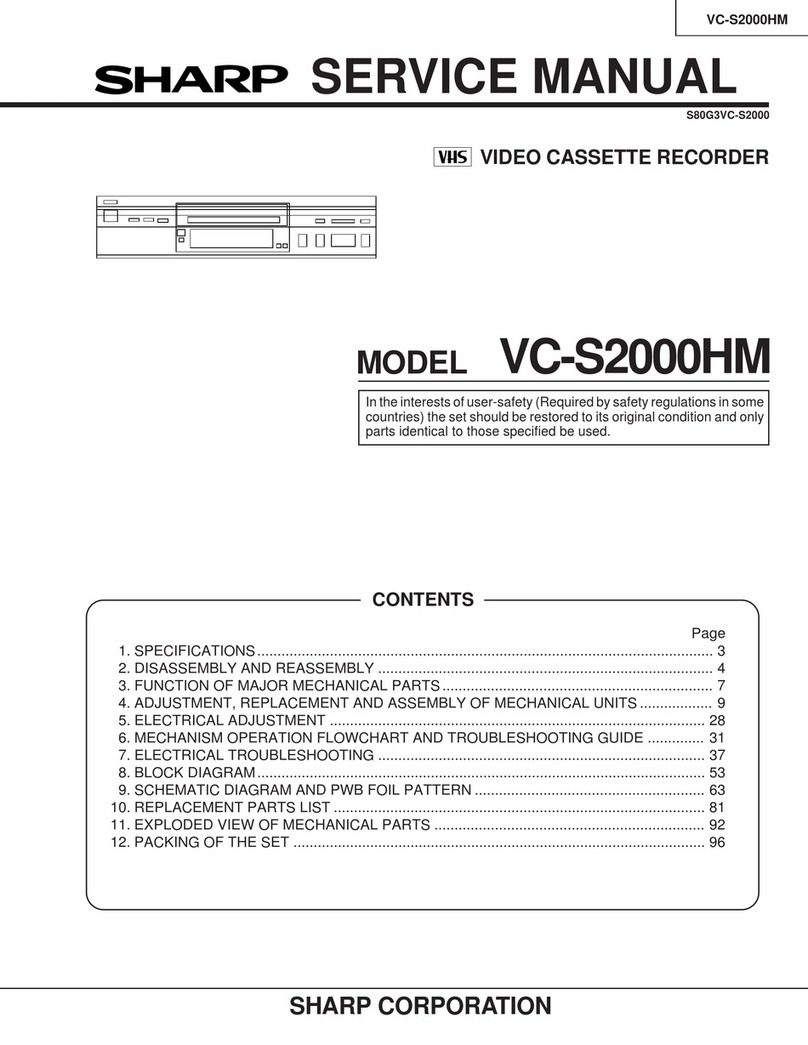

1-2. SPECIFICATIONS

Format: VHS NTSC Standard

Video Recording System: Rotary, Two-Head Helical Scanning

Number of Video Heads: 4

Video Signal Standard: NTSC Color System

Audio Recording System: 1 Stationary Head for Linear Audio

2 Rotary Heads for Hi-Fi stereo (Only Hi-Fi model)

Tape Width: 12.7 mm (1/2 inch)

Tape Speed: (SP) 33.35 mm/sec (1.31 i.p.s.)

(LP) 16.67 mm/sec (0.66 i.p.s.) (playback only)

(EP) 11.12 mm/sec (0.44 i.p.s.)

Maximum Recording Time: (SP) 160 min (T-160)

(EP) 480 min (T-160)

Channel Coverage: VHF 2-13

UHF 14-69

CATV 1-125

Antenna Input: 75 Ohm

Video Input: 0.5 to 2.0 Vp-p, 75 Ohm unbalanced

Video Output: 1.0 Vp-p, 75 Ohm unbalanced

Audio Input: –8 dBs, 47 kOhm unbalanced (0 dBs = 0.775 Vrms)

Audio Output: –8 dBs, 1 kOhm unbalanced (0 dBs = 0.775 Vrms)

Hi-Fi Audio (Only for Hi-Fi model):

Dynamic Range:

90 dB

Frequency Response:

20 Hz-20 kHz

Memory Backup: 1 hour

Operating Temperature: 5°C to 40°C (41°F to 104°F)

Storage Temperature: –20°C to 60°C (–4°F to 140°F)

Power Source: 120 V AC, 60 Hz

Power Consumption: 18 W

Dimensions (approx.): 360 (W) x 92.5 (H) x 262.5 (D) mm (14-3/16" x 3-41/64" x 10-21/64") (XA-905)

360 (W) x 92.5 (H) x 263.5 (D) mm (14-3/16" x 3-41/64" x 10-3/8") (XA-920)

Weight (approx.): 2.8 kg (6.2 lbs)

Accessories included: 75 ohm coaxial cable, Operation manual, Infrared remote control, Battery (2 pcs.),

Warranty Card

Note: Specifications are subject to change without notice.