13

VC-MH75HM

Notes:

1. Hold the torque gauge by hand so that it is not moved.

2. Donotkeepthereeldiskinlockstate.Donotallowlong-

time measurement.

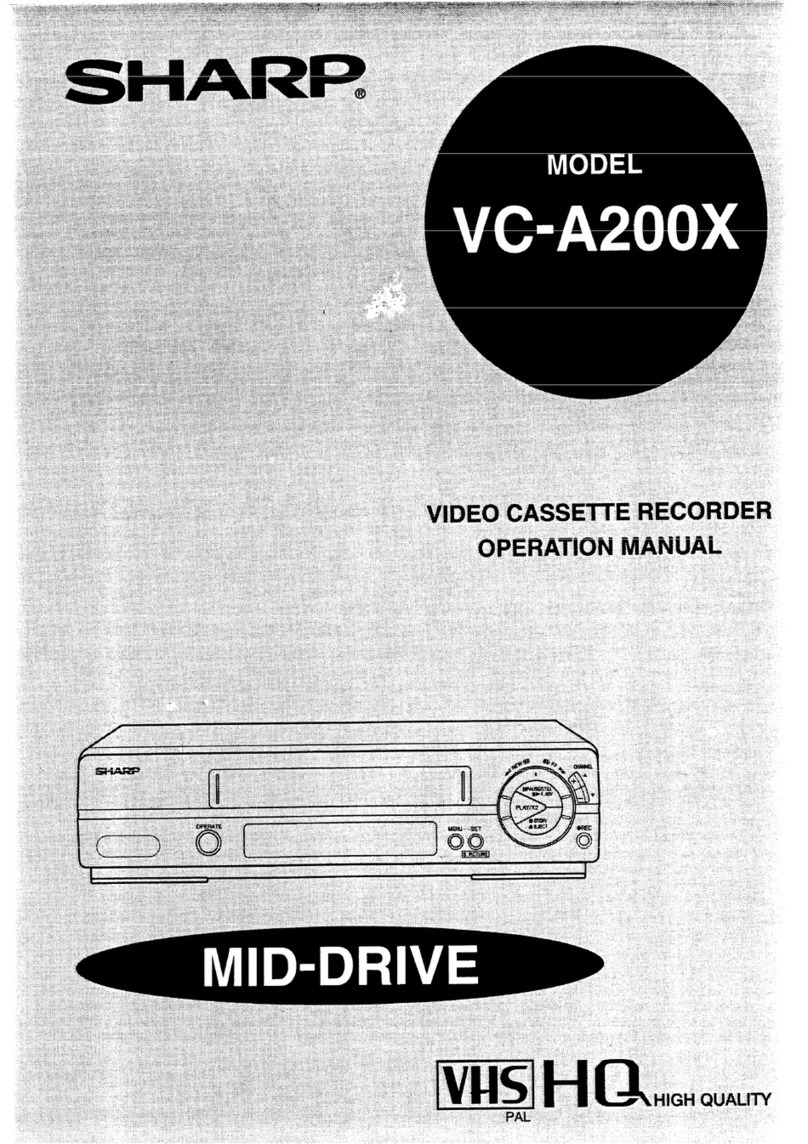

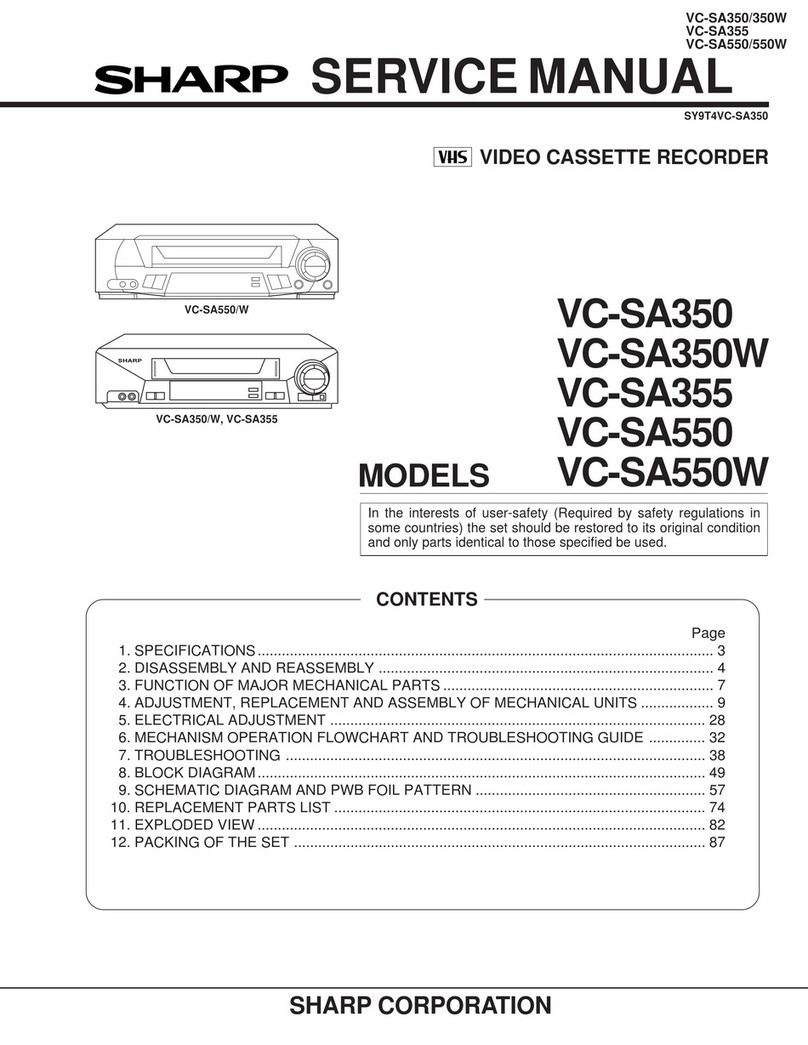

4-8 CHECKINGANDADJUSTMENTOFTAKE-

UP TORQUE IN RECORD/PLAYBACK

MODE

• Remove the cassette housing control assembly.

• After short-circuiting between TP803 and TP802

provided at main PWB, plug in the power cord.

• Turn off the power switch.

• Open the cassette torque meter lid, and fix it with

tape.

• Load the cassette torque meter into the unit.

• Put the weight (500g) on the cassette torque meter.

• Turn on the power switch.

• Press the picture record button, and set LP picture

record mode (x2).

4-9 CHECKINGANDADJUSTMENTOFTAKE-

UP TORQUE IN VIDEO SEARCH REWIND

MODE

• Remove the cassette housing control assembly.

• After short-circuiting between TP803 and TP802

provided at main PWB, plug in the power cord.

• Setting

Press the playback button and rewind button to set the

video search rewinding mode.

• Checking

Place the torque gauge on the supply reel disk, and turn it

counterclockwise very slowly (one rotation every 1 to 2

seconds) and check that the torque is within the set value

14.1 ± 3.5mN⋅m. (144 ± 35gf⋅cm)

Set value LP 6.9 mN⋅m (70 gf⋅cm)

Figure 4-8.

• Checking

1. Make sure that value is within the setting 6.9 mN·m

(70 gf·cm).

2. The winding-up torque fluctuates due to variation of

rotation torque of limiter pulley ass'y. Read the center

value of fluctuation as setting.

3. Set the LP record mode (x2) and make sure that the

winding-up torque is within setting.

• Adjustment

If the playback winding-up torque is not within the setting,

replace the limiter pulley assembly.

Note:

When the torque cassette is set, put a weight (500g) to

prevent rise.

When the cassette torque meter is taken out.

Turn off the power switch.

Figure 4-9.

Note:

Surely put the torque gauge on the reel disk to measure. If

the torque gauge is raised, accurate measurement is

impossible.

• Adjustment

Iftherewindingplaybackwinding-uptorqueisnotwithinthe

setting, replace the limiter pulley assembly.

Note:

The winding-up torque fluctuates due to variation of rota-

tion torque of supply reel disk. Read the center value of

fluctuation as setting.

Torque gauge

Supply reel disk

CCW

+20

–25

+2.0

–2.5

+2.0

–2.5 +20

–25

500g

Cassette torque meter