Sharpe D-5-55 User manual

SHARPE MANUFACTURING COMPANY • P.O. BOX 1441, MINNEAPOLIS, MN 55440-1441

1-800-742-7731, www.sharpe1.com

309991C, 4/2006

THE SPRAY GUN PEOPLE

FOR PRODUCT INFORMATION CALL:

1-800-742-7731

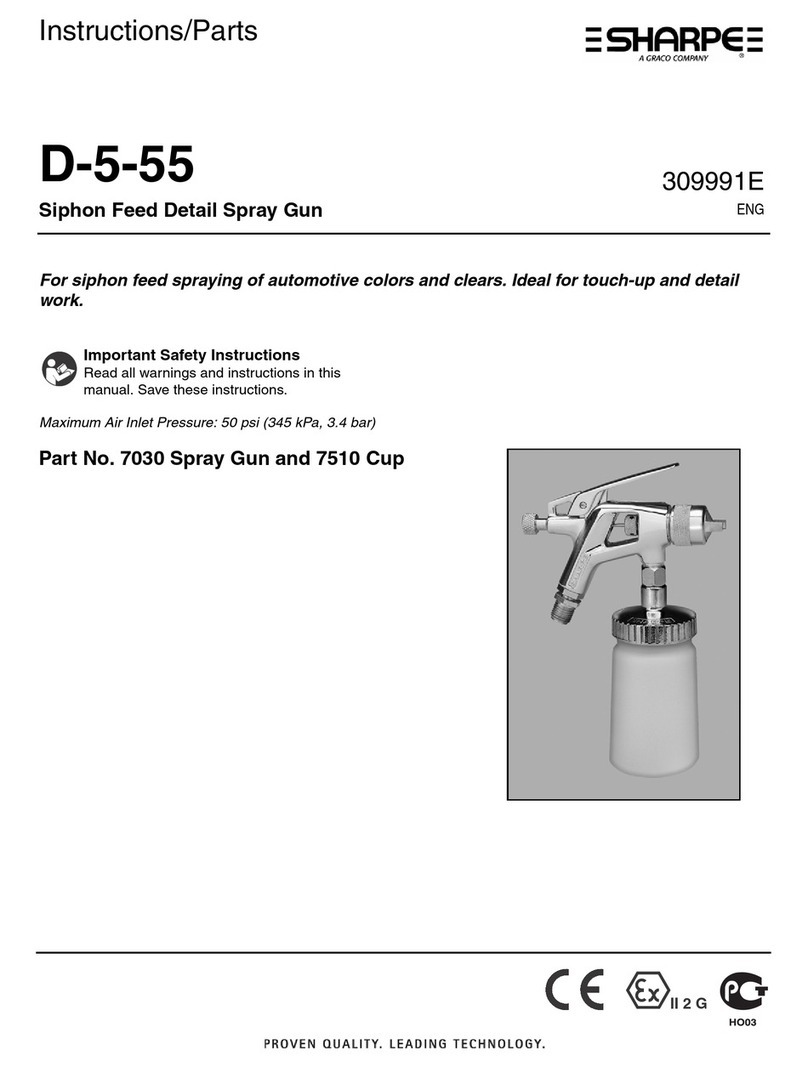

D-5-55

Siphon Feed Detail Spray Gun

Maximum Air Inlet Pressure: 50 psi (345 kPa, 3.4 bar)

Part No. 7030 Spray Gun and 7510 Cup

For siphon feed spraying of automotive colors and clears. Ideal for

touch-up and detail work.

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

II 2 G

2 309991C

2 Year Limited Warranty

Sharpe warrants this product to the original user against defective material or workmanship for a period of 1 year from the date of

purchase.

Sharpe reserves the right to determine whether the part or parts failed because of defective material, workmanship, or other causes.

Failures caused by accident, alteration, or misuse are not covered by this warranty.

Sharpe, at its discretion, will repair or replace products covered under this warranty free of charge. Repairs or replacements of products

covered under this warranty are warranted for the remainder of the original warranty period.

Sharpe or its authorized service representatives must perform all warranty repairs. Any repair to the product by unauthorized service

representatives voids this warranty. The rights under this warranty are limited to the original user and may not be transferred to

subsequent owners.

This warranty is in lieu of all other warranties, expressed or implied, including warranties of merchantability and fitness for a particular

purpose. Some states do not allow the exclusion or limitations of incidental or consequential damages, so the above limitations may not

apply to you.

WARNING

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent fire and explosion:

•Use equipment only in well ventilated area.

•Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic drop cloths (potential

static arc).

•Keep work area free of debris, including solvent, rags and gasoline.

•Do not plug or unplug power cords or turn lights on or off when flammable fumes are present.

•Ground equipment and conductive objects in work area.

•If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment until you identify and

correct the problem.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

•Do not exceed the maximum working pressure or temperature rating of the lowest rated system component. See Tech-

nical Data in all equipment manuals.

•Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all equipment manuals.

Read fluid and solvent manufacturer’s warnings.

•Check equipment daily. Repair or replace worn or damaged parts immediately.

•Do not alter or modify equipment.

•Use equipment only for its intended purpose. Call your Graco distributor for information.

•Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

•Do not use hoses to pull equipment.

•Keep children and animals away from work area.

•Comply with all applicable safety regulations.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or swallowed.

•Read MSDS’s to know the specific hazards of the fluids you are using.

•Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating area of the equipment

to help protect you from serious injury, including eye injury, inhalation of toxic fumes, burns, and hearing loss. This equip-

ment includes but is not limited to:

•Protective eyewear

•Clothing and respirator as recommended by the fluid and solvent manufacturer

•Gloves

•Hearing protection

PRESSURIZED EQUIPMENT HAZARD

Fluid from the gun/dispense valve, leaks, or ruptured components can splash in the eyes or on skin and cause serious

injury.

•Follow Pressure Relief Procedure in this manual, when you stop spraying and before cleaning, checking, or servicing

equipment.

•Tighten all fluid connections before operating the equipment.

•Check hoses, tubes, and couplings daily. Replace worn or damaged parts immediately.

3 309991C

D-5-55 DETAIL SPRAY GUN

Setup

•Set shop air pressure regulator (not supplied) according to

paint manufacturer’s recommendation. Do not exceed 50

psi (345 kPa, 3.4 bar).

•Make sure no air restrictions, such as low-volume cheater-

valves, obstruct the air flow. If an air adjusting valve is

desired, use a SHARPE Air Adjusting Valve 24AAV (part

no. 2210), 36AAV-HOV (part no. 3310) or HOV (part no.

U04410).

•Install a shutoff valve (not supplied) downstream of the air

regulator to shut off gun air.

•Install an inline air filter (not supplied) to clean and dry the

air supply to the gun.

1. Turn off air supply.

2. Connect a clean, dry, filtered air supply to gun air inlet (2).

3. If this is first time using the equipment, flush the spray gun.

Operation

Pressure Relief Procedure

1. Turn off gun air supply.

2. Trigger the gun to relieve pressure.

Flushing

Flush before using the equipment, before changing colors, and

when you are done spraying. Use solvent that is compatible with

gun wetted parts and fluid that will be sprayed. Flush at lowest

possible pressure.

1. Follow Pressure Relief Procedure.

2. Dispose of any paint in cup.

3. Fill cup with small amount of solvent.

4. Spray into grounded metal waste container until equipment

is clean.

5. Follow Pressure Relief Procedure.

Spraying

1. Fill cup (101) with material. Do not fill past cup “shoulder”

(A). See FIG. 1.

2. Screw cup (101) onto lid securely.

3. Slowly adjust gun air pressure while fully triggering the gun

until you have the desired atomization.

4. Adjust the pattern size and shape with the spray width

adjustment knob (10). See FIG. 2. Turn knob clockwise to

reduce pattern size and counterclockwise to increase it.

5. Fluid control knob (7) is factory set for maximum needle trig-

ger travel and material flow. To decrease needle/trigger

travel and decrease fluid flow, turn knob clockwise.

FIG. 1

WARNING

Follow Pressure Relief Procedure when you stop spraying

and before cleaning, checking, or servicing equipment. Read

warnings, page 2.

2

A

101

WARNING

Read warnings, page 2.

Refer to Compliant Cleaning Methods, page 4, to com-

ply with air quality laws if applicable.

CAUTION

Excessive atomizing air pressure can increase over-spray,

reduce transfer efficiency, result in a poor quality finish

from dry spray.

See Troubleshooting guide if you experience an irregular

pattern.

FIG. 2

7

10

4 309991C

D-5-55 DETAIL SPRAY GUN

Cleaning and Maintenance

Volatile Organic Compounds (VOC)

Regulation

In certain states, spraying solvents that release VOC’s into the

atmosphere when cleaning a spray gun is prohibited. To comply

with these air quality laws you must use a cleaning method that

prevents the escape of VOC vapors into the atmosphere. See

Compliant Cleaning Methods below.

Compliant Cleaning Methods

•Place spray gun in a gun washer that completely encloses

the gun and components during cleaning, rinsing, and

draining.

•Spray solvent through the spray gun into a closed gun

cleaning station.

Cleaning Gun and Cup

1. Follow Flushing procedure, page 3.

2. Use a rag moistened in solvent to wipe cup lid (109), fluid

tube (103), inside of cup (101), and outside of gun.

3. Blow dry gun inside and out. Lubricate gun as described in

Spray Gun Maintenance.

Cleaning Nozzle and Air Cap

To clean the air cap and nozzle, remove and soak

them in a compatible cleaning solution. Clean them

and front of gun with a soft-bristle brush dipped

into compatible solvent. Do not use a wire brush or

metal tools. To clean out air cap holes, use a soft

implement, such as a toothpick.

Spray Gun Maintenance

•Frequently lubricate the gun moving parts with a drop of

non-silicone oil (part no. 8255).

•Do not disassemble the spray gun if you are having a spray

pattern problem. Check Troubleshooting, page 5, for infor-

mation on how to correct the problem.

•Check for fluid leakage. Tighten fittings or replace equip-

ment as needed.

Technical Data

Maximum Air Inlet Pressure: 50 psi (345 kPa, 3.4 bar)

Wetted Parts: stainless steel, aluminum, brass,

LD polyethylene

Air Consumption: 4.1 scfm at 50 psi (345 kPa, 3.4 bar)

Spray Gun

•1/4 npsm (R1/4-19) air inlet

•1/4 npsm fluid inlet

•Weight - 8 oz. (227 grams)

Pressure cup: 6 oz. (177 cc)

WARNING

Follow Pressure Relief Procedure when you stop spraying

and before cleaning, checking, or servicing equipment. Read

warnings, page 2.

CAUTION

•Do not submerge gun in solvent. Solvent dissolves lubri-

cant, dries out packings, and may clog air passages.

•Do not use metal tools to clean air cap holes as this may

scratch them and distort the spray pattern.

•Use a compatible solvent.

•Gun and cup can be cleaned in a gun washer.

Clean air line filters as directed by the manufacturer.

Refer to Compliant Cleaning Methods to comply with air

quality laws if applicable.

CAUTION

•Trigger gun whenever you tighten or remove nozzle to

avoid damaging needle seat and nozzle.

•Do not use metal tools to clean air cap holes as this may

scratch them and distort the spray pattern.

5 309991C

D-5-55 DETAIL SPRAY GUN

Troubleshooting

WARNING

Follow Pressure Relief Procedure, page 3, before troubleshooting or servicing. Read warnings, page 2.

Problem Cause Solution

Normal pattern No action necessary

Dirty or damaged air cap or fluid nozzle. Rotate air cap 180°.

If pattern follows air cap, problem is in air cap. Clean and

inspect. If pattern is not corrected, replace air cap.

If pattern does not follow the air cap, the problem is with the

fluid nozzle. Clean and inspect the nozzle. If the pattern is

not corrected, replace nozzle.

Pressure too high for viscosity of material

being sprayed.

a. Reduce air pressure.

b. Increase material viscosity

c. Correct pattern by narrowing fan size with spray width

adjustment knob.

Dirty or distorted air horn holes. Rotate air cap 180°.

If pattern follows air cap, problem is in air cap. Clean and

inspect. If pattern is not corrected, replace air cap.

Will not spray. a. Cup is not tight a. Tighten cup lid.

b. Cup empty. b. Fill cup.

c. Air cap not seated. c. Turn spray width adjustment knob fully counterclockwise.

Tighten air cap.

a. Air pressure too low. a. Increase air pressure.

b. Gun held too close to surface. b. Hold gun about 6-8 inches (150-200 mm) from surface.

Right

Wrong

Heavy top or

bottom pattern

Wrong

Split pattern

Wrong

Wrong

Heavy pattern or

orange peel

SHARPE MANUFACTURING COMPANY • P.O. BOX 1441, MINNEAPOLIS, MN 55440-1441

1-800-742-7731, www.sharpe1.com

309991C, 4/2006

D-5-55 DETAIL SPRAY GUN

Parts

Part No. 7030, D-5-55 Detail Spray Gun

Ref.

No. Part No. Description Qty.

1 29001 Gun Body 1

2 29054 Air Valve Assembly

Includes items 2a-2f

1

2a 34819 •Housing 1

2b* 29049 •Air Valve Stem 1

2c 29053 •Lock Nut 1

2d* 29050 •Ball

2e* 29036 •Needle Spring 1

2f* 29052 •Retainer 1

3 29033 Needle Packing Nut 1

4* 26022 Needle Packing 1

5* 29047 Plunger 1

6* 29036 Needle Spring 1

7 29046 Fluid Control Knob 1

8* 29056 Trigger Screw 1

9 29055 Trigger 1

10 29030 Width Control Assembly

Includes items 10a-10d

1

10a 118749 •Knob 1

10a

13

10b

10c*

10d*

10

12 1

6*

8*

9

5*

11 7

4*4* 3

2b*

2c

2a

2d*

2e*

2f*

2

105

104

103

101

102

Part No. U07510, D-500 Cup Assembly

10b 118741 •Packing Nut 1

10c* 29028 •Packing 1

10d* 29029 •Retaining Ring 1

11 29041 Fluid Needle 1

12 29021 Fluid Nozzle, 0.55 1

13 29006 Air Cap 1

* Parts included in Repair Kit 29086.

Ref.

No. Part No. Description Qty.

101 U07530 Cup with air-tight cover 1

102 29063 Gasket, pack of 5 1

103 29062 Lid with Fluid Tube 1

104 29057 Coupling Nut 1

105 29058 Nipple Fitting 1

Ref.

No. Part No. Description Qty.

This manual suits for next models

2

Table of contents

Other Sharpe Paint Sprayer manuals

Popular Paint Sprayer manuals by other brands

Titan

Titan IMPACT 410 owner's manual

DeVilbiss

DeVilbiss SRI PRO series Technical bulletin

Rockwood

Rockwood 8PC HVLP PAINT GUN SET instructions

Titan

Titan 805-000 Service manual

RainMaker

RainMaker 708910 Assembly and operating instructions manual

Parkside

Parkside PFS 100 B2 Operation and Safety Notes Translation of original operating instructions

Graco

Graco 220–856 D Series owner's manual

DeVilbiss

DeVilbiss FLG-CNS-115 Service manual

Central Pneumatic Professional

Central Pneumatic Professional 94572 Assembly and operating instructions

CET

CET CA Tech CPR-T3 manual

Fimco

Fimco ATVBK-500 Assembly / operation instructions / parts

DeVilbiss

DeVilbiss FLG-692 instructions